Introduction to Lathe

advertisement

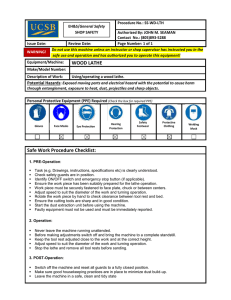

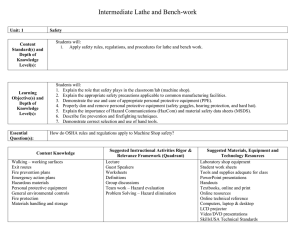

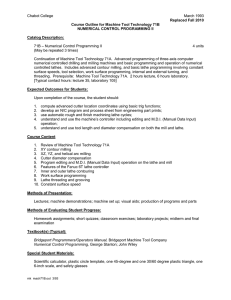

Introduction to Lathe Unit: 1 Safety Content Standard(s) and Depth of Knowledge Level(s): Learning Objective(s) and Depth of Knowledge Level(s): Essential Question(s): Students will: 1. Demonstrate care and safety for an engine lathe. Examples: maintenance—operating, cleaning, lubricating, setting up Students will: 1. Explain the role that safety plays in the classroom/Lab (machine shop). 2. Explain the appropriate safety precautions applicable to common manufacturing facilities. 3. Demonstrate the use and care of appropriate personal protective equipment (PPE). 4. Properly don and remove personal protective equipment (safety goggles, hearing protection, and hard hat). 5. Explain the importance of Hazard Communications (HazCom) and material safety data sheets (MSDS). 6. Describe fire prevention and firefighting techniques. 7. Demonstrate correct selection and use of hand tools. How do (OSHA) rules and regulations apply to Machine Shop safety? Content Knowledge 1. 2. 3. 4. 5. 6. 7. 8. 9. Walking – working surfaces Exit routes Fire prevention plans Emergency action plans Hazardous materials Personal protective equipment General environmental controls Fire protection Materials handling and storage Suggested Instructional Activities Rigor & Relevance Framework (Quadrant) Lecture Guest Speakers Worksheets Definitions Group discussions Team work – Hazard evaluation Problem Solving – Hazard elimination Suggested Materials, Equipment and Technology Resources Projector Worksheets Quizzes Tests Internet access Handouts Training material for OSHA 500 or 501 Appropriate texts Assorted safety equipment and PPE Unit Assessment: Unit/Course CTSO Activity: Unit/Course Culminating Product: Evaluation of student practices in the classroom and in the laboratory Written and performance assessments 1. Continue SkillsUSA Leadership Development Programs. 2. Establish documentation for students’ career portfolio. 3. Students review SkillsUSA Technical Standards and Contest Projects. Student portfolio items to include safety tests passed at 100% Injury free students at the end of the course Course/Program Credential(s): Other: Credential Certificate Postsecondary Degree University Degree Introduction to Lathe Unit: 2-3 Lathe Operations Content Standard(s) and Depth of Knowledge Level(s): Learning Objective(s) and Depth of Knowledge Level(s): Essential Question(s): Students will: 2. Demonstrate engine lathe operations, including mounting the chuck on the lathe, indicating the round stock in an independent jaw chuck, indicating the square stock in an independent jaw chuck, sharpening the lathe tool bit, centering or positioning cutting tools, face cutting a work piece, turning multiple diameters, center drilling a work piece, demonstrating angle cuts, knurling a work piece, threading a work piece, calculating speed and feed per material, and tooling. Examples: threading a work piece—chasing right and left hand external threads, manually tapping a hole, countersinking a hole, drilling a hole, picking up lead on existing threads 3. Demonstrate the ability to turn stock to specifications using a variety of methods and materials related to lathe operations. Students will: 1. Demonstrate safe operation and set up of an engine lathe. 2. Indicate round and irregular shaped work pieces in a independent 4 jaw chuck. 3. Perform multiple cutting operations. 4. Calculate surface speed and feed and determine RPM for turning operations. How does set up rigidity effect lathe operations? Content Knowledge Safety Machine Maintenance Basic lathe set up operations Machining calculations Suggested Instructional Activities Rigor & Relevance Framework (Quadrant) Laboratory demonstrations and experiments Guided practice Group investigation Listen, think, pair, share Demonstrations Discussion Individual and group practice Problem solving exercises Suggested Materials, Equipment and Technology Resources Laboratory shop equipment Student work sheets Tools and supplies adequate for class PowerPoint presentations Handouts Textbooks, online and print Online resources Online technical reference Math application exercises Math application worksheets Unit Assessment: Unit/Course CTSO Activity: Unit/Course Culminating Product: Computers, laptop and desktop LCD projector Video/DVD presentations SkillsUSA Technical Standards SkillsUSA Contest Projects SkillsUSA Professional Development Evaluation of student practices in the classroom and in the laboratory Written and performance assessments 1. Continue SkillsUSA Leadership Development Programs. 2. Establish documentation for students’ career portfolio. 3. Students review SkillsUSA Technical Standards and Contest Projects. Successful completion of industry-based written and performance testing Student portfolio submission Course/Program Credential(s): Credential*** Certificate Other: ***Aligns with NIMS Certification Standards Postsecondary Degree University Degree Introduction to Lathe Unit: 4-5 Project Students will: 4. Demonstrate the ability to produce a completed lathe project according to specifications. 5. Demonstrate use of measuring tools, including calipers, dial indicators, and micrometers to produce precision lathe projects. Content Standard(s) and Depth of Knowledge Level(s): Students will: 1. Complete NIMS Level I chucking part. 2. Interpret blueprints for project completion. 3. Utilize precision measuring instruments, to obtain dimensional accuracy. Learning Objective(s) and Depth of Knowledge Level(s): Essential Question(s): How does tool selection effect lathe productivity? Content Knowledge Safety Proper set up of lathe Inspection Blueprint reading Suggested Instructional Activities Rigor & Relevance Framework (Quadrant) Laboratory demonstrations and experiments Guided practice Group investigation Listen, think, pair, share Demonstrations Discussion Individual and group practice Problem solving exercises Math application exercises Math application worksheets Suggested Materials, Equipment and Technology Resources Laboratory shop equipment Student work sheets Tools and supplies adequate for class PowerPoint presentations Handouts Textbooks, online and print Online resources Online technical reference Computers, laptop and desktop LCD projector Video/DVD presentations SkillsUSA Technical Standards SkillsUSA Contest Projects SkillsUSA Professional Development Unit Assessment: Unit/Course CTSO Activity: Unit/Course Culminating Product: Evaluation of student practices in the classroom and in the laboratory Written and performance assessments 1. Continue SkillsUSA Leadership Development Programs. 2. Establish documentation for students’ career portfolio. 3. Students review SkillsUSA Technical Standards and Contest Projects. Successful completion of industry-based written and performance testing Student portfolio submission Course/Program Credential(s): Credential*** Certificate Other: ***Aligns with NIMS Certification Standards Postsecondary Degree University Degree