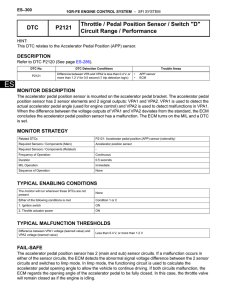

Toyota 1KD-FTV ECD System: Throttle Position Sensor Diagnostics

advertisement

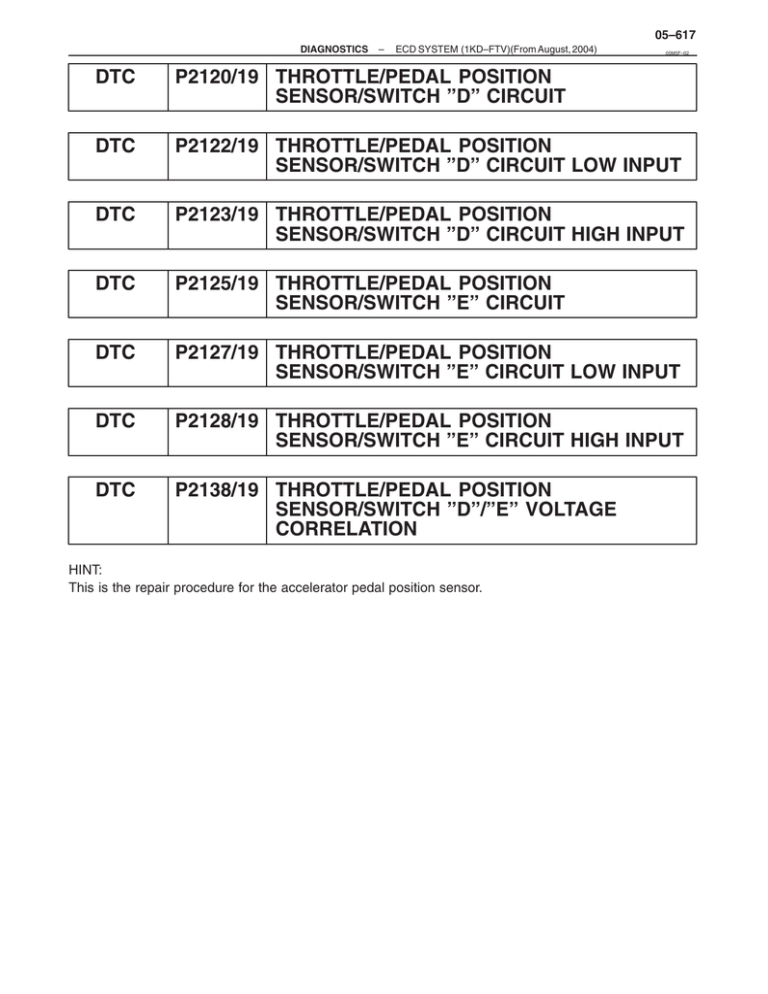

05–617 DIAGNOSTICS – ECD SYSTEM (1KD–FTV)(From August, 2004) 05M5F–02 DTC P2120/19 THROTTLE/PEDAL POSITION SENSOR/SWITCH ”D” CIRCUIT DTC P2122/19 THROTTLE/PEDAL POSITION SENSOR/SWITCH ”D” CIRCUIT LOW INPUT DTC P2123/19 THROTTLE/PEDAL POSITION SENSOR/SWITCH ”D” CIRCUIT HIGH INPUT DTC P2125/19 THROTTLE/PEDAL POSITION SENSOR/SWITCH ”E” CIRCUIT DTC P2127/19 THROTTLE/PEDAL POSITION SENSOR/SWITCH ”E” CIRCUIT LOW INPUT DTC P2128/19 THROTTLE/PEDAL POSITION SENSOR/SWITCH ”E” CIRCUIT HIGH INPUT DTC P2138/19 THROTTLE/PEDAL POSITION SENSOR/SWITCH ”D”/”E” VOLTAGE CORRELATION HINT: This is the repair procedure for the accelerator pedal position sensor. 05–618 DIAGNOSTICS – ECD SYSTEM (1KD–FTV)(From August, 2004) CIRCUIT DESCRIPTION HINT: S S Accelerator Pedal Position Sensor Magnet IC No. 1 VPA EPA VCPA VPA2 EPA2 IC No. 2 VCP2 ECM Accelerator Pedal Position Sensor Output Voltage (V) This electrical throttle system does not use a throttle cable. This accelerator pedal position sensor is non–contact type. The accelerator pedal position sensor is mounted on the accelerator pedal and detects the opening angle of the accelerator pedal. Since this sensor is electronically controlled with Hall–effect elements, accurate control and reliability can be obtained. It has 2 sensors to detect the accelerator position and a malfunction of the accelerator position sensor. In the accelerator pedal position sensor, the voltage applied to pedal terminals VPA and VPA2 of the ECM changes between 0 V and 5 V in proportion to the opening angle of the accelerator pedal. The VPA is a signal to indicate the actual accelerator pedal opening angle which is used for the engine control, and the VPA2 is a signal to indicate the information about the opening angle which is used for detecting malfunctions. The ECM judges the current opening angle of the accelerator pedal from these signals input from terminals VPA and VPA2 and, the ECM controls the throttle motor based on these signals. *1 *2 5 VPA2 3.7 to 5.0 2.9 to 4.2 VPA 1.4 to 1.8 0.6 to 1.0 0 Usable Range 20.67 Accelerator Pedal Turning Angle (deg.) Magnet *1: Accelerator Pedal Fully Released *2: Accelerator Pedal Fully Depressed A19694 G36462 05–619 DIAGNOSTICS – ECD SYSTEM (1KD–FTV)(From August, 2004) DTC Detection Condition (All of following are 1 trip detection logic) DTC No. Trouble Area Condition (a) continues for 0.5 sec. or more: (a) VPA is 0.2 V or less or VPA is 4.8 V or more S Accelerator pedal position sensor S Accelerator pedal S Accelerator pedal rod (arm) deformed S ECM VPA is 0.2 V or less for 0.5 sec. or more when VPA2 output indicate accelerator pedal is opened S Accelerator pedal position sensor S Open in VCPA circuit S VPA circuit open or ground short S Accelerator pedal S Accelerator pedal rod (arm) deformed S ECM P2123/19 Condition (a) continues for 2.0 sec. or more: (a) VPA is 4.8 V or more S Accelerator pedal position sensor S Open in EPA circuit S Accelerator pedal S Accelerator pedal rod (arm) deformed S ECM P2125/19 Condition (a) continues for 0.5 sec. or more: (a) (VPA2 is 0.5 V or less) or (VPA2 is 4.8 V or more) S Accelerator pedal position sensor S Accelerator pedal S Accelerator pedal rod (arm) deformed S ECM P2127/19 VPA2 is 0.5 V or less for 0.5 sec. or more when VPA output indicates accelerator pedal is opened S Accelerator pedal position sensor S Open in VCP2 circuit S VPA2 circuit open or ground short S Accelerator pedal S Accelerator pedal rod (arm) deformed S ECM P2128/19 Conditions (a) and (b) continue for 2.0 sec. or more: (a) VPA2 is 4.8 V or more (b) VPA is 0.2 V or more and VPA is 3.45 V or less S Accelerator pedal position sensor S Open in EPA2 circuit S Accelerator pedal S Accelerator pedal rod (arm) deformed S ECM P2138/19 Condition (a) or (b) continues for 2.0 sec. or more: (a) Difference between VPA and VPA2 is 0.02 V or less (b) VPA is 0.2 V or less and VPA2 is 0.5 V or less S VPA and VPA2 circuit are short circuited S Accelerator pedal position sensor S Accelerator pedal S Accelerator pedal rod (arm) deformed S ECM P2120/19 P2122/19 HINT: When DTC P2120/19, P2122/19, P2123/19, P2125/19, P2127/19, P2128/19 or P2138/19 is detected, check the output voltage of the accelerator pedal position sensor by entering the following menus on the intelligent tester II: Powertrain / Engine / Data List / Accelerator Position No. 1 and Accelerator Position No. 2. Accelerator pedal position expressed as voltage output Accelerator pedal position expressed as voltage output Accelerator pedal position expressed as voltage output Accelerator pedal position expressed as voltage output Accelerator pedal released Accelerator pedal released Accelerator pedal depressed Accelerator pedal depressed Trouble Area ACCEL POS No. 1 ACCEL POS No. 2 ACCEL POS No. 1 ACCEL POS No. 2 VCP circuit open 0 to 0.2 V 0 to 0.2 V 0 to 0.2 V 0 to 0.2 V 3.7 to 5.0 V VPA circuit open or ground short 0 to 0.2 V 1.4 to 1.8 V 0 to 0.2 V VPA2 circuit open or ground short 0.6 to 1.0 V 0 to 0.2 V 2.9 to 4.2 V 0 to 0.2 V EPA circuit open 4.5 to 5.0 V 4.5 to 5.0 V 4.5 to 5.0 V 4.5 to 5.0 V HINT: Accelerator pedal positions are expressed as voltages. 05–620 DIAGNOSTICS – ECD SYSTEM (1KD–FTV)(From August, 2004) WIRING DIAGRAM A28 Accelerator Pedal Position Sensor ECM EP2 BR–Y 8 IC3 BR–Y 29 E14 EPA2 GR–G 9 IC3 GR–G 23 E14 VPA2 BR–R 10 IC3 BR–R 27 E14 VCP2 BR–W 19 IC3 BR–W 28 E14 EPA 2 VPA2 3 VCP2 1 EP1 5 VPA1 W–L 6 VCP1 LG–R 4 20 IC3 21 IC3 W–L LG–R 22 E14 VPA 26 E14 VCPA G38692 INSPECTION PROCEDURE HINT: Read freeze frame data using the intelligent tester II. Freeze frame data records the engine conditions when a malfunction is detected. When troubleshooting, freeze frame data can help determine if the vehicle was running or stopped, if the engine was warmed up or not, and other data from the time the malfunction occurred. 05–621 DIAGNOSTICS – ECD SYSTEM (1KD–FTV)(From August, 2004) When using intelligent tester II: 1 READ DATA LIST (ACCELERATOR POSITION NO. 1, ACCELERATOR POSITION NO. 2) (a) (b) (c) (d) Released Depressed FI7052 Connect the intelligent tester II to the DLC3. Turn the ignition switch ON and turn the intelligent tester II ON. Enter the following menus: Powertrain / Engine / Data List / Accelerator Position No. 1 and Accelerator Position No. 2. Read the values. Standard: Accelerator Pedal Accelerator Position No. 1 Accelerator Position No. 2 Released 0.6 to 1.0 V 1.4 to 1.8 V Depressed 2.9 to 4.2 V 3.7 to 5.0 V OK Go to step 5 NG 2 CHECK WIRE HARNESS (ECM – ACCELERATOR PEDAL POSITION SENSOR) Wire Harness Side A28 Accelerator Pedal Position Sensor VCP2 VPA1 EP2 VPA2 VCP1 VCP2 VPA OK Disconnect the A28 sensor connector. Disconnect the E14 ECM connector. Measure the resistance of the wire harness side connectors. Standard: Tester Connection Specified Condition A28–1 (VCP2) – E14–27 (VCP2) A28–2 (EP2) – E14–29 (EPA2) A28–3 (VPA2) – E14–23 (VPA2) A28–4 (VCP1) – E14–26 (VCPA) A28–5 (EP1) – E14–28 (EPA) A28–6 (VPA1) – E14–22 (VPA) Below 1 Ω A28–1 (VCP2) or E14–27 (VCP2) – Body ground A28–2 (EP2) or E14–29 (EPA2) – Body ground A28–3 (VPA2) or E14–23 (VPA2) – Body ground A28–4 (VCP1) or E14–26 (VCPA) – Body ground A28–5 (EP1) or E14–28 (EPA) – Body ground A28–6 (VPA1) or E14–22 (VPA) – Body ground 10 kΩ or higher EP1 E14 VPA2 EPA2 EPA (a) (b) (c) VCPA A99833 NG REPAIR OR CONNECTOR REPLACE HARNESS OR 05–622 DIAGNOSTICS 3 – ECD SYSTEM (1KD–FTV)(From August, 2004) CHECK ECM (VCPA, VCP2 VOLTAGE) (a) (b) (c) A28 Accelerator Pedal Position Sensor Connector VCP2 Disconnect the A28 sensor connector. Turn the ignition switch ON. Measure the voltage of the ECM connector. Standard: Tester Connection Specified Condition E14–26 (VCPA) – E14–28 (EPA) E14–27 (VCP2) – E14–29 (EPA2) 4.5 to 5.0 V E14 NG VCPA EPA2 Y A49521 A66060 EPA A96639 REPLACE ECM (See Pub. No. RM990E, page 10–34) NOTICE: After replacing the ECM, allow for ECM learning start the engine and idle it until it is fully warmed up. OK 4 REPLACE ACCELERATOR PEDAL ROD ASSY (See Pub. No. RM990E, page 10–33) NEXT 5 (a) (b) (c) (d) READ OUTPUT DTC (ACCELERATOR PEDAL POSITION SENSOR DTC IS OUTPUT AGAIN) Clear the DTC (see page 05–466). Start the engine. Drive the engine at idle for 15 seconds or more. Read the DTC (see page 05–466). Result: Display (DTC output) Proceed to P2120/19, P2121/19, P2122/19, P2123/19, P2125/19, P2127/19, P2128/19 or P2138/19 is output again A P2120/19, P2121/19, P2122/19, P2123/19, P2125/19, P2127/19, P2128/19 or P2138/19 is not output B B SYSTEM OK A REPLACE ECM (See Pub. No. RM990E, page 10–34) NOTICE: After replacing the ECM, allow for ECM learning start the engine and idle it until it is fully warmed up. 05–623 DIAGNOSTICS – ECD SYSTEM (1KD–FTV)(From August, 2004) When not using intelligent tester II: 1 CHECK ECM (VPA, VPA2 VOLTAGE) VPA2 (+) VPA (+) (a) (b) E14 Turn the ignition switch ON. Measure the voltage of the ECM connector. Tester Connection Accelerator Pedal Condition Specified Condition E14–22 (VPA) – E14–28 (EPA) Released 0.6 to 1.0 V E14–22 (VPA) – E14–28 (EPA) Depressed 2.9 to 4.2 V E14–23 (VPA2) – E14–29 (EPA2) Released 1.4 to 1.8 V E14–23 (VPA2) – E14–29 (EPA2) Depressed 3.7 to 5.0 V EPA2 (–) EPA (–) A66060 OK REPLACE ECM (See Pub. No. RM990E, page 10–34) NOTICE: After replacing the ECM, allow for ECM learning start the engine and idle it until it is fully warmed up. NG 2 CHECK WIRE HARNESS (ECM – ACCELERATOR PEDAL POSITION SENSOR) Wire Harness Side A28 Accelerator Pedal Position Sensor VCP2 VPA1 EP2 VPA2 VCP1 VCP2 VPA OK Disconnect the A28 sensor connector. Disconnect the E14 ECM connector. Measure the resistance of the wire harness side connectors. Standard: Tester Connection Specified Condition A28–1 (VCP2) – E14–27 (VCP2) A28–2 (EP2) – E14–29 (EPA2) A28–3 (VPA2) – E14–23 (VPA2) A28–4 (VCP1) – E14–26 (VCPA) A28–5 (EP1) – E14–28 (EPA) A28–6 (VPA1) – E14–22 (VPA) Below 1 Ω A28–1 (VCP2) or E14–27 (VCP2) – Body ground A28–2 (EP2) or E14–29 (EPA2) – Body ground A28–3 (VPA2) or E14–23 (VPA2) – Body ground A28–4 (VCP1) or E14–26 (VCPA) – Body ground A28–5 (EP1) or E14–28 (EPA) – Body ground A28–6 (VPA1) or E14–22 (VPA) – Body ground 10 kΩ or higher EP1 E14 VPA2 EPA2 EPA (a) (b) (c) VCPA A99833 NG REPAIR OR CONNECTOR REPLACE HARNESS AND 05–624 DIAGNOSTICS 3 – ECD SYSTEM (1KD–FTV)(From August, 2004) CHECK ECM (VCPA, VCP2 VOLTAGE) (a) (b) (c) A28 Accelerator Pedal Position Sensor Connector VCP2 Disconnect the A28 sensor connector. Turn the ignition switch ON. Measure the voltage of the ECM connector. Standard: Tester Connection Specified Condition E14–26 (VCPA) – E14–28 (EPA) E14–27 (VCP2) – E14–29 (EPA2) 4.5 to 5.0 V E14 NG VCPA EPA2 Y A49521 A66060 EPA A96639 REPLACE ECM (See page RM990E, page 10–34)) (See Pub. No. NOTICE: After replacing the ECM, allow for ECM learning start the engine and idle it until it is fully warmed up. OK 4 REPLACE ACCELERATOR PEDAL ROD ASSY (See Pub. No. RM990E, page 10–33) NEXT 5 (a) (b) (c) (d) READ OUTPUT DTC (ACCELERATOR PEDAL POSITION SENSOR DTC IS OUTPUT AGAIN) Clear the DTC (see page 05–466). Start the engine. Drive the engine at idle for 15 seconds or more. Read the DTC (see page 05–466). Result: Display (DTC output) Proceed to P2120/19, P2121/19, P2122/19, P2123/19, P2125/19, P2127/19, P2128/19 or P2138/19 is output again A P2120/19, P2121/19, P2122/19, P2123/19, P2125/19, P2127/19, P2128/19 or P2138/19 is not DTC output B B SYSTEM OK A REPLACE ECM (See Pub. No. RM990E, page 10–34) NOTICE: After replacing the ECM, allow for ECM learning start the engine and idle it until it is fully warmed up.