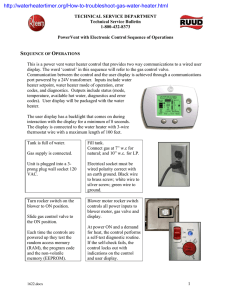

ULTRA HIGH EFFICIENCY POWER VENT

advertisement