Eye Protection

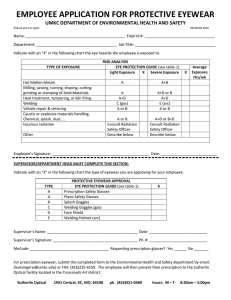

advertisement

• This training session discusses eye protection in the workplace. • Your vision is vitally important—think about what would happen if you lost it. That’s why it’s so important to understand eye hazards on the job, and to protect your eyes from these hazards whenever and wherever they are present. 1 The main objective of this session is to help protect your eyes, and your vision, while at work. Specifically, by the end of the session, you will be able to: • Identify potential eye hazards; • Prevent eye injuries by wearing protective eyewear; • Use, maintain, and inspect proper protective eyewear; and • Use appropriate first aid for emergencies involving eye injuries. 2 Eye injury statistics demonstrate how important it is to take eye protection seriously. • Each day, more than 2,000 workers suffer serious eye injuries. Each year, about 100,000 of these injuries result in temporary or permanent vision loss. These statistics are provided by Prevent Blindness America, a national nonprofit organization. • About 62,000 eye injuries each year result in at least one lost workday. • Finally, studies indicate that proper eye protection can reduce the number and severity of eye injuries in 90 percent of accidents. 3 Eye hazards depend on the type of work you do, but they are very common in the workplace. Examples include: • Flying objects; • Harmful dust particles; • Chemical splashing or spraying; • High-intensity heat or light; • Welding, brazing, and torch cutting; and • Direct or reflected sunlight. We’ll be discussing these hazards, and what you can do to protect yourself against them, on the next few slides. 4 Here are ways to protect yourself against the hazards of flying objects. • Flying objects present an impact hazard to the lens of your eye. According to the Bureau of Labor Statistics, 70 percent of serious eye injuries are caused by flying or falling objects, and 60 percent of these objects are smaller than the head of a pin. These types of objects include: – Fragments, chips, particles, sand, and dirt. Take a moment to think about the kinds of flying objects in your workplace that can be an eye hazard. • Work processes that can create a flying object hazard include: – Chipping, grinding, masonry work, woodworking, sawing, drilling, chiseling, riveting, and sanding. Can you think of the work processes in this workplace that can create flying objects? • Eye protection for flying object hazards include: – Safety glasses with side protection for many jobs; safety goggles are preferred for jobs with many flying objects; and a face shield might be required if there are flying objects that could injure your face as well as your eyes. 5 Dust hazards can be serious in certain situations. Dust particles don’t usually fly at you, but they can easily get into your eyes and cause problems. • The hazards include walking into a cloud of floating dust particles, resulting in eye irritation, redness, and abrasion. The cause of these particles could be: – Wood dust, foam dust, or soot. You can probably think of dust hazards like these in your workplace. • Work processes that create dust hazards include: – Woodworking, buffing, and cleaning with air wands and brooms. • Eye protection for dust hazards is: – Primarily goggles or some sort of eyewear that creates a seal around the eyes. The more hazardous the dust, the more the safety eyewear needs to fit tightly to your face. 6 Chemical hazards to your eyes are a significant concern if you work with chemicals. Virtually any kind of chemical can injure your eyes. • The hazard comes from the possibility of splashing, spraying, or mists that cause burning, pain, or blurred vision. – Acids and caustics, of course, can severely burn your eyes. Solvents can damage your eyes in many ways, depending on the type of solvent. • Work processes that can cause chemical hazards to your eyes include: – Virtually any job that requires you to work with chemicals or chemical processes. Think about the type of jobs you do that have chemical hazards. • Eye protection is very important to protect against chemical hazards: – Chemical-resistant goggles are a must if you are working with any liquid chemical that could splash or spray into your face and eyes. – A face shield worn over goggles is required if you are working with highly dangerous chemicals such as acids, or in situations with the potential for severe exposure. 7 Heat is an eye hazard that you might not have thought of immediately. • The hazard from heat comes from : – Steam, hot liquid, hot air, or flame that causes pain, eyelid burns, and blurred vision. • Work processes that could create a heat hazard include: – Furnace operations; pouring or casting molten metals; and any other kind of high-temperature operations. • To guard against heat hazards, wear eye protection. For operations that could cause splashing of hot material into your eyes and face, wear goggles under a face shield. For operations that do not present a splashing hazard, wear a protective screen or a reflective face shield that will keep extreme heat from your eyes. 8 Welding, brazing, and torch cutting create a number of potential eye hazards. • Welder’s flash or flying sparks cause pain, burns, and extreme sensitivity. Welder’s flash occurs when the eyes are overexposed to the intense light of welding operations. This can occur when welders strike the arc a split second before dropping their face shield or hood over their eyes. In addition, the skin or eyes can be burned from intense light and heat. Flying sparks, metal fragments, or slag can enter the eye. • The work process that creates these hazards is any kind of welding operation. – Even walking past a welding operation and observing it can cause an eye injury. • For eye protection when welding, use: – A welder’s face shield, which offers the best protection against intense light. – Sunglasses are totally inadequate for protection. 9 A final eye hazard to watch out for is sunlight. • Overexposure to direct or reflected sunlight can cause: – Retinal burns, blurred vision, pain, and even loss of eyesight. • Work processes that can create this hazard include: – Any job working outside in the sunlight, especially working near water where the sunlight can be reflected into your eyes, even when looking down. • Eye protection for sunlight hazards is pretty basic: – A pair of high-quality sunglasses and a hat. 10 • Do you have any questions about the types of eye hazards you might find in the workplace, and about eye protection for specific work processes? • It is important for your safety that you understand eye hazards and the eye protection you should use for specific processes. 11 Now we’ll discuss the selection, use, and care of protective eyewear that can protect you from eye injuries. Use proper protective eyewear whenever there is the possibility of eye hazards. • Ninety percent of occupational eye injuries could have been avoided with proper protective eyewear, according to OSHA. Note the word “proper” – many injuries have occurred when people thought they were wearing proper eyewear, but in fact were not. • OSHA found that many of the injured workers believed that protective eyewear was not necessary in their particular work situation. • Follow all company rules for wearing eye protection. We want to make sure that you know when it is necessary to wear eye protection, and know what kind of eyewear to use for each potentially hazardous situation. 12 Proper protective eyewear must meet certain standards. • It must comply with American National Standards Institute, or “ANSI,” standard Z87.1. This means the eye protection has met certain standards for resisting impacts, shattering, and chemicals. • Proper eye protection equipment will be marked with “Z87” to show that they meet the ANSI standard. Look for this marking on all protective eyewear. • Normal sunglasses or prescription glasses usually do not meet the ANSI standard. These could shatter or break if struck by a flying object, and cause additional eye injuries. 13 Choosing the right eye protection for the particular person and the particular job is very important. The first step is to determine what kind of protective eyewear should be used for the job. Then: • Fit the eyewear to the person who will be wearing it. Protective eyewear must fit well to protect properly and be comfortable. • Use high-quality eyewear; it will last longer and protect better. • Ensure good fit and comfort. If it doesn’t fit well, it won’t provide complete protection, and you will be inclined to remove it to make adjustments, or not wear it at all. • Lens options include antifog, antiglare, indoor/outdoor lenses, and different colors or tints. Your supervisor will let you know if there is a particular kind of lens you should use. 14 Always maintain your eyewear properly. • Cleaning stations include a squirt bottle of cleaning solution and some lint-free paper towels. Use them frequently. You can also use mild soap and water to clean protective eyewear. • Use holders or cases to protect the eyewear when not in use. Most highquality eyewear comes with cases. • Get new eyewear whenever necessary. When lenses are scratched or cracked, they are no longer safe. Note that some eyewear have removable lenses that can be replaced without having to replace the entire frame. 15 Routinely inspect your protective eyewear. • Eyewear should be inspected before each use. • Check for cracked lenses or face shields, and replace if necessary. • Replace scratched lenses or shields if they impair your vision. • Also check for loose frames and nose pieces. • Finally, fit test your eyewear before each use. Make sure there has been no damage that prevents a proper fit. 16 If you already wear prescription eyewear, there are some important safety points to know. • The National Institute for Occupational Safety and Health now recommends that contact lenses may be worn with appropriate PPE when handling hazardous chemicals provided that certain guidelines are followed and a hazard evaluation is performed. However, contact lenses may not be safe in radiation, high-dust or high-particulate environments. • Prescription safety glasses and goggles are available. These will meet the ANSI Z87 standard as well as your prescription requirements. • Overglasses or partial face shields are also options as barriers to eye hazards. These are designed to fit over your normal prescription glasses. 17 Eyewash stations are required by OSHA in areas that use large quantities of hazardous chemicals—especially corrosives—that could be splashed or sprayed into your eyes. • Chemical splashes require immediate first aid. This can make the difference between a temporary injury and permanent blindness. • Eyewash stations must be located within 10 feet, or 10 seconds travel time, of a work process that uses hazardous chemicals that could be splashed or sprayed into your eyes. • Always flush your eyes for at least 15 minutes after your eyes have been exposed to a hazardous chemical. 18 • Do you have any questions about selecting proper eyewear? • Do you feel you understand what you need to know about using protective eyewear and maintaining and inspecting it? • Do you understand about first aid for possible eye injuries? 19 • Assess the work you are doing for possible eye hazards. Whether at work or at home, ask yourself if there is the potential for eye injury from flying objects, dust, chemicals, heat, or other hazards. • Select the appropriate eye protection for the job. Remember, for example, that a face shield is for extra protection to wear over safety glasses or goggles, not a replacement for glasses or goggles. • Wear your eye protection at all times whenever there may be a hazard. It only takes a split second for an eye injury to occur. • Finally, don’t become an eye injury statistic. Using the right protective eyewear whenever you need it will protect you from eye injuries. This concludes this training session on Eye Protection. 20