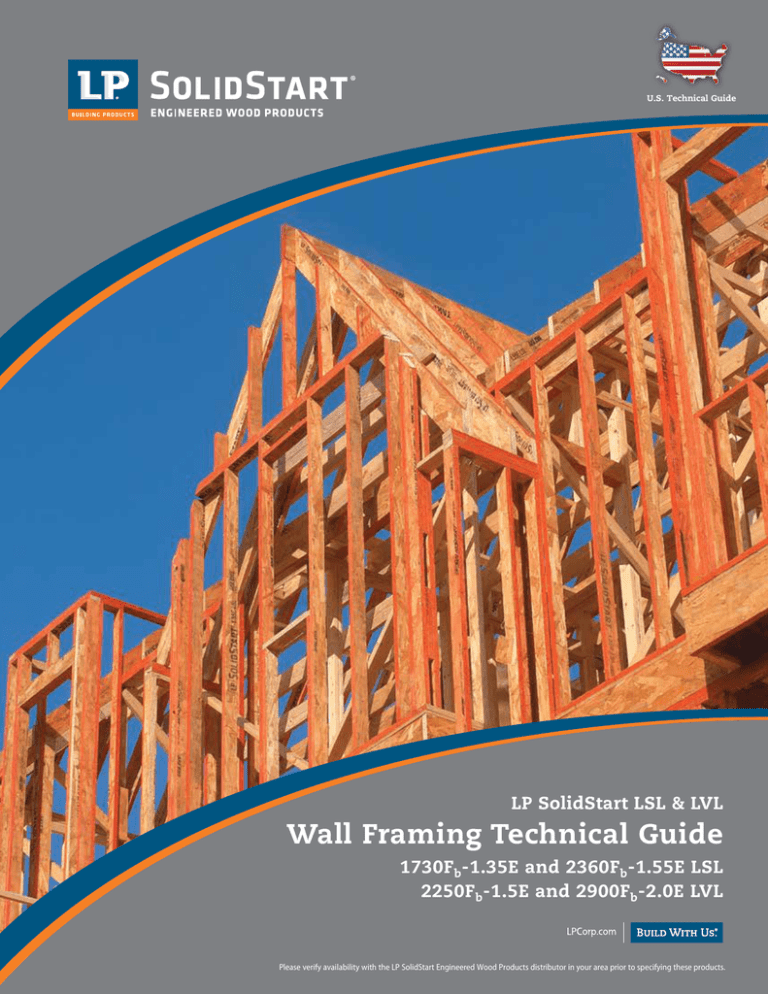

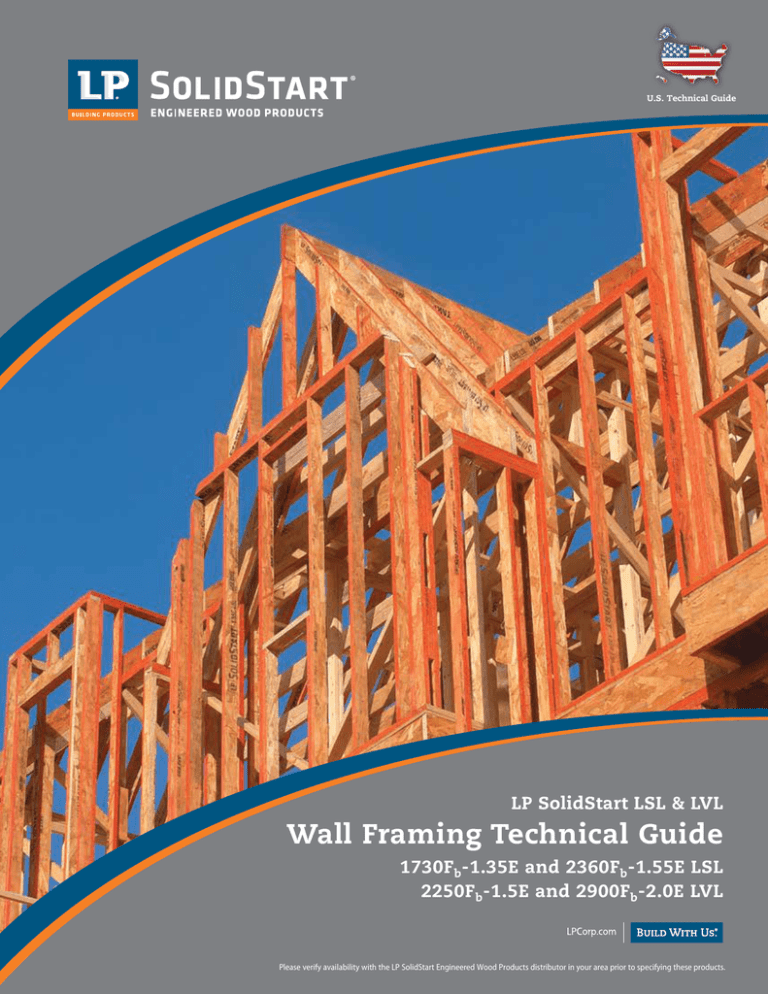

U.S. Technical Guide

LP SolidStart LSL & LVL

Wall Framing Technical Guide

1730Fb-1.35E and 2360Fb-1.55E LSL

2250Fb-1.5E and 2900Fb-2.0E LVL

Please verify availability with the LP SolidStart Engineered Wood Products distributor in your area prior to specifying these products.

Introduction

A Word About Wall Framing

Architects are raising the roof and stretching walls beyond

limitations are imposed on the load capacity of the studs. For

the reach of conventional lumber. LP® SolidStart® LSL and

both prescriptive and engineered wall systems, mineral wool

LVL studs redefine the standard for wall framing by providing

insulation is required in the wall cavity. Please refer to ICC-ES

structural walls that can be straighter, taller and stronger for

evaluation report ESR-2403 and APA product report PR-L280 for

both conventional and challenging engineered applications.

complete information on the use of LP SolidStart LSL and LVL in

Because LP manufactures its LSL and LVL to the highest

fire-resistance-rated walls, or use LP’s Wood-E Design software.

standards, builders know that they’ll get fewer callbacks and

save themselves time and money.

Where traditional lumber studs warp, bow and twist as they

ENGINEERED DESIGN CONSTRUCTION

In engineered design, calculations based on the expected

dry, LP SolidStart LSL and LVL won’t because they start dry from

in-service loads are performed to ensure that the allowable

the mill. Having straight walls gives home-owners the peace of

capacities of the wall members are not exceeded.

mind that their cabinets will stay flush to the wall, their tile and

Notches and holes in LP SolidStart LSL and LVL wall framing

drywall is less likely to crack and their windows and doors will

are permitted when designed in accordance with the provisions of

function properly. That’s performance you can count on.

the National Design Specification for Wood Construction (NDS),

Using this technical guide, LP SolidStart LSL and LVL can be

with additional adjustments as prescribed herein. The wall stud

specified for use in conventional (prescriptive) and engineered

and exterior wall column tables in this guide include the effects

wood-frame wall construction.

of notches and holes on their capacity. Refer to Drilling & Notching

on page 4 for the limitations of notch and hole size and location.

CONVENTIONAL CONSTRUCTION

Conventional construction provisions for wood-frame walls

are included in the International Building Code (IBC) and the

DEFLECTION LIMITS

Like floor and roof systems, walls are subject to code-

International Residential Code (IRC). In conventional construction,

prescribed deflection limits as well as industry recommendations.

wall members and their connections are selected from tables in

The IBC prescribes a deflection ratio limit of L/240 for walls

the Code rather than being calculated, as in engineered design.

with brittle finishes and L/120 for walls with flexible finishes.

LP’s compliance with the ICC Evaluation Service’s Acceptance

The IRC prescribes the additional ratio of L/360 for walls with

Criteria for Wood-Based Studs (AC202) permits LP SolidStart LSL

stucco or plaster. Additional deflection limits are recommended

and LVL to be a direct substitution to traditional lumber studs

for certain windows and wall finishes like brick. Always verify

prescribed in Section 2308.9 of the IBC and Section R602 of the IRC.

the requirements, but the following table summarizes common

Compliance with AC202 also demonstrates equivalence to

deflection limits.

the notching provisions prescribed in the Code for traditional

lumber studs in conventional construction.

LIFETIME LIMITED WARRANTY

LP SolidStart Engineered Wood Products are backed by a

FIRE-RESISTIVE WALL CONSTRUCTION

LP SolidStart LSL and LVL (1.5E and higher) are permitted

lifetime limited warranty. Visit LPCorp.com or call 1.888.820.0325

for a copy of the warranty.

to be used in the 1-hour fire-resistance-rated wall assemblies

listed in Table 720.1(2) of the IBC, with some additional design

and construction considerations as specified in LP’s evaluation

and product reports. When used in prescriptive wall framing,

LP SolidStart LSL and LVL can be directly substituted for the

equivalent size of No 2 or lower grade dimensional lumber.

When used in engineered wall construction, some additional

2

Condition

Deflection

Flexible Finish (IBC)

L/120

Windows & Doors

L/175

Brittle Finish (IBC)

L/240

Plaster & Stucco (IRC)

L/360

Brick

L/600

Table of Contents

Product Specifications, Design Values

and Drilling & Notching . . . . . . . . . . . . . . . . . . . . .

4

Wall Stud Capacity (plf) . . . . . . . . . . . . . . . . . . . . . 5

Exterior Wall Column Capacity (lbs):

2x4 & 2x6 Walls for 90 mph, Exposure B . . . . . . . . . . . . 6

Exterior Wall Column Capacity (lbs):

2 x 4 & 2 x 6 Walls for 100 mph, Exposure C . . . . . . . . . . . 7

Exterior Wall Column Capacity (lbs):

2x8 Walls for 90 mph, Exposure B . . . . . . . . . . . . . . . 8

Exterior Wall Column Capacity (lbs):

2 x 8 Walls for 100 mph, Exposure C . . . . . . . . . . . . . . . 9

Exterior Wall Column Capacity (lbs):

2 x 10 Walls for 90 mph, Exposure B . . . . . . . . . . . . . . 10

Exterior Wall Column Capacity (lbs):

2x10 Walls for 100 mph, Exposure C . . . . . . . . . . . . . . 11

Typical Wall Framing & Wall Stud Example . . . . . . . . . 12

Typical Wall Framing: Trimmer & King Stud Examples . . . . 13

Typical Wall Framing: Wall Column Examples . . . . . . . . 14

Free-Standing Interior Column Capacity (lbs) . . . . . . . . 15

Nailing and Connection Details . . . . . . . . . . . . . . . 16-17

Typical Connections . . . . . . . . . . . . . . . . . . . . . . . . 18

Handling and Storage Guidelines . . . . . . . . . . . . . . . . 19

3

Product Specifications, Design Values and Drilling & Notching

ALLOWABLE DESIGN STRESSES (PSI)

Beam (Edgewise) Orientation

Material

Bending Modulus of

Elasticity

Fb3, 4, 6

MOE9

Grade

1730Fb-1.35E

2360Fb-1.55E

2250Fb-1.5E

2900Fb-2.0E

LP® SolidStart® LSL

LP SolidStart LVL

1730

2360

2250

2900

Plank (Flatwise) Orientation

Axial

Shear

Fv

Compression

perpendicular-to-grain

Fc?

Bending

Fb5

Modulus of

Elasticity

MOE9

Shear

Fv

Compression

perpendicular-to-grain

Fc?

Tension

Ft7, 8

Compression

Fc

410

410

285

285

750

875

750

750

1910

2620

2200

2950

1.35 x 106

1.55 x 106

1.4 x 106

2.0 x 106

155

155

140

140

440

440

450

550

1300

1750

1350

1800

1650

2175

2350

3200

1.35 x 106

1.55 x 106

1.5 x 106

2.0 x 106

NOTES:

1. LP SolidStart LSL and LVL shall be designed for dry-use conditions only. Dry-use applies to products installed in dry, covered and well ventilated interior

conditions in which the equivalent moisture content in lumber will not exceed 16%. Adjustments for high temperature are beyond the scope of this guide.

2. The allowable strengths and stiffness are for normal load duration (10 year). Bending, Shear and Axial Tension and Compression shall be adjusted

according to code. Modulus of Elasticity and Compression perpendicular-to-grain shall not be adjusted for load duration.

3. The allowable Bending, Fb, for LP SolidStart LSL in the Beam orientation is tabulated for a standard 12" depth.

For depths other than 12," multiply Fb by (12/depth)0.143. For depths less than 3-1/2", adjust Fb by 1.193.

4. The allowable Bending, Fb, for LP SolidStart LVL in the Beam orientation is tabulated for a standard 12" depth.

For depths less than 12," multiply Fb by (12/depth)0.111. For depths less than 3-1/2," multiply Fb by 1.147.

For depths greater than 12," multiply Fb by (12/depth)0.143.

5. The allowable Bending, Fb, in the Plank orientation shall not be adjusted for depth (thickness).

6. The allowable edgewise Bending shall also be multiplied by the repetitive member factor, Cr = 1.04, when 3 or more pieces are properly connected

in direct contact or are used as wall studs spaced no more than 24" oc and properly connected together by an adequate wall sheathing.

7. The allowable Tension, Ft, for LP SolidStart LSL is assigned for a standard length of 3 feet. For lengths longer than 3 feet, multiply Ft by (3/length)0.092.

For lengths less than 3 feet, use the design tension stresses in the table above, unadjusted.

8. The allowable Tension, Ft, for LP SolidStart LVL is assigned for a standard length of 3 feet. For lengths longer than 3 feet, multiply Ft by (3/length)0.111.

For lengths less than 3 feet, use the design tension stresses in the table above, unadjusted.

9. Deflection calculations for LP SolidStart LSL and LVL shall include both bending and shear deformations.

PRODUCT ORIENTATION

270wL428.8wL2

Deflection for wall framing, uniform load: ∆ =

+

Where: ∆ = deflection (in)

E = modulus of elasticty (from table)

3

Ebd

Ebd

w = uniform load (plf) b = width (in)

L = design span (ft)

d = depth (in direction of bending) (in)

Equations for other conditions can be found in engineering references.

BEARING CAPACITY

Column Bearing (lbs)

Stud or

Column

Size

Hem-Fir

(405 psi)

1-1/2" x 3-1/2"

1-1/2" x 5-1/2"

1-1/2" x 7-1/4"

1-1/2" x 9-1/4"

3-1/2" x 3-1/2"

3-1/2" x 5-1/2"

3-1/2" x 7-1/4"

3-1/2" x 9-1/4"

5-1/4" x 5-1/2"

5-1/4" x 7-1/4"

5-1/4" x 9-1/4"

7" x 5-1/2"

7" x 7-1/4"

7" x 9-1/4"

2125

3340

4400

5615

4960

7795

10275

13110

11690

15415

19665

15590

20550

26220

SPF

LP LSL/LVL Concrete

(425 psi) (440 psi) (2500 psi)

2230

3505

4620

5895

5205

8180

10780

13755

12270

16175

20635

16360

21565

27515

2360

3710

4890

6240

5510

8660

11415

14565

12990

17125

21850

17325

22835

29135

4460

7010

9240

11790

10410

16360

21565

27515

24540

32350

41275

32725

43135

55035

Stud Bearing (plf)

Hem-Fir (405 psi)

SPF (425 psi)

12" oc

16" oc

12" oc

16" oc

2125

1590

2230

1670

3340

2505

3505

2625

4400

3300

4620

3465

5615

4210

5895

4420

n/a

b

d

Beam (Edgewise)

b

d

Plank (Flatwise)

NOTES:

1. The capacity for Wood Bearing is based on the compression strength,

perpendicular-to-grain, of the bearing plate and shall not be adjusted

for load duration. The allowable compression, perpendicular-to-grain,

for other species of lumber can be found in the 2012 edition of the

National Design Specification for Wood Construction (NDS).

2. The Bearing Capacity for concrete is based on a conversion to allowable

stress design for comparison to the column capacities in this guide.

3. To determine the Bearing Capacity of a multiple-ply member (such as

a double 2 x 4 stud), multiply the Bearing Capacity from the table by

the number of plies. The capacity is additive and may be increased

for bearing on wood plates per note 4.

4. When a stud or column is located at least 3" from the end of a wall

plate, the Bearing Capacities above are permitted to be increased by

the bearing area factor, Cb = (Lb + 0.375)/Lb, where Lb is the bearing

length measured parallel to the grain of the wall plate and is less than

6." For bearing lengths 6" or more, Cb = 1.00.

DRILLING & NOTCHING

2x Larger of Hole

or Notch Length

Maximum

Hole Diameter

1-3/8" for 2x4

2-3/16" for 2x6

and wider

h

2x Larger of Hole

or Notch Length

Holes/Notches

Permitted

Lessor of 3' and h/3

6"

5/8" min.

edge distance

3-1/2" max.

Holes/Notches

Permitted

6"

No Notches or Holes!

Lessor of 3' and h/3

NOTES:

Maximum

Notch Depth

7/8" for 2x4

1-3/8" for 2x6

and wider

1. Free-standing columns shall not be drilled or notched except as required for proper installation of column caps,

bases or other hold-downs without further analysis by a professional engineer. Bolts, lag screws and self-tapping

screws shall only be inserted through the face of the column, perpendicular to the face of the strands in LP LSL

and the veneers in LP LVL.

2. Cutting, notching and boring of nominal 2x4 (1-1/2" x 3-1/2") and 2x6 (1-1/2" x 5-1/2") LP LSL and LP LVL wall studs

used in prescriptive wall framing is permitted in accordance with sections 2308.9.10 and 2308.9.11 of the IBC and

section R602.6 of the International Residential Code (IRC).

3. For wall applications designed with the tables in this guide, notching and drilling shall be limited to the restrictions

of notes 4 through 6 (see details to left).

4. One hole up to 40% of the stud depth, maximum of 2-3/16," is allowed only in the upper or lower 3 feet or 1/3 of

the stud height, h (see Drilling and Notching detail for maximum hole sizes), except do not place a hole within 6"

of either end of the stud. Two small holes up to 1" diameter and vertically spaced no closer than 12" oc are permited

in studs with a depth of at least 5-1/2."

5. One notch up to 25% of the stud depth, maximum of 1-3/8," is allowed only in the upper or lower 3 feet or 1/3 of

the stud height, h (see Drilling and Notching detail for maximum notch sizes), except do not place a notch within 6"

of either end of the stud. The notch length shall not exceed 3-1/2."

6. Do NOT cut a hole and a notch at the same cross-section. Maintain a clear vertical separation of at least twice the

length of the notch or twice the diameter of the hole, whichever is greater.

7. For engineered wall applications beyond the scope of this guide, design for notching and drilling shall be based on a net

section analysis in accordance with the provisions of the 2012 NDS and with the restrictions listed in APA product report

PR-L280 and ICC-ES evaluation report ESR-2403. The allowable design stresses for bending, axial compression and

axial tension shall be reduced by the Strength Reduction Factors (tabulated below) to account for stress concentrations.

STRENGTH REDUCTION FACTORS

Material

LP SolidStart LSL

LP SolidStart LVL

4

Bending

0.95

0.80

Notch

Compression

0.90

0.90

Tension

0.75

0.60

Bending

1.00

0.95

Hole

Compression

1.00

0.95

Tension

1.00

0.95

Wall Stud Capacity (plf)

TO USE:

1.

2.

3.

4.

5.

Select the table for wind speed and exposure category.

Determine the height of the wall stud. If not listed, select the next tallest Height in the table.

Select the row for the desired Spacing.

Select the LP® SolidStart® LSL or LVL grade and size where the Vertical Load Capacity and Deflection Ratio meet or exceed the applied vertical load and required deflection limit.

Verify the plate bearing capacity for the selected stud. See Additional Note 9 below.

90 MPH BASIC WIND SPEED, EXPOSURE B

Height

8'

9'

10'

12'

14'

16'

18'

20'

22'

24'

26'

28'

30'

1.35E LP LSL

1.55E LP LSL or 1.5E LP LVL

Stud

Spacing 1-1/2" x 3-1/2" 1-1/2" x 5-1/2" 1-1/2" x 7-1/4" 1-1/2" x 9-1/4" 1-1/2" x 3-1/2" 1-1/2" x 5-1/2" 1-1/2" x 7-1/4"

12"

2880 L/699

4530 L/999

5980 L/999

7630 L/999

2880 L/776

4530 L/999

5980 L/999

16"

2160 L/524

3400 L/999

4480 L/999

5720 L/999

2160 L/582

3400 L/999

4480 L/999

12"

2480 L/500

4530 L/999

5980 L/999

7630 L/999

2850 L/556

4530 L/999

5980 L/999

16"

1720 L/375

3400 L/999

4480 L/999

5720 L/999

2090 L/417

3400 L/999

4480 L/999

12"

2030 L/371

4530 L/999

5980 L/999

7630 L/999

2430 L/412

4530 L/999

5980 L/999

16"

1370 L/278

3400 L/999

4480 L/999

5720 L/999

1680 L/309

3400 L/999

4480 L/999

12"

1360 L/220

4530 L/845

5980 L/999

7630 L/999

1650 L/245

4530 L/939

5980 L/999

16"

880 L/165

3400 L/634

4480 L/999

5720 L/999

1110 L/183

3400 L/704

4480 L/999

12"

950 L/142

3880 L/546

5980 L/999

7630 L/999

1170 L/158

4480 L/607

5980 L/999

16"

2910 L/410

4480 L/928

5720 L/999

3360 L/455

4480 L/999

12"

3210 L/374

5980 L/849

7630 L/999

3680 L/415

5980 L/944

16"

2240 L/280

4480 L/637

5720 L/999

2710 L/311

4480 L/708

12"

2570 L/267

5230 L/609

7630 L/999

3060 L/297

5980 L/677

16"

1750 L/200

3920 L/457

5720 L/939

2130 L/223

4480 L/507

12"

2040 L/198

4520 L/452

7630 L/931

2460 L/220

5210 L/502

16"

1360 L/148

3390 L/339

5720 L/698

1680 L/165

3910 L/376

12"

1610 L/151

3940 L/345

6980 L/712

1960 L/168

4510 L/383

16"

2790 L/258

5240 L/534

1310 L/126

3360 L/287

12"

3330 L/269

6220 L/557

1570 L/131

3940 L/299

16"

2270 L/202

4660 L/417

2770 L/224

12"

2770 L/215

5560 L/444

3330 L/238

16"

1850 L/161

4170 L/333

2290 L/179

12"

2310 L/174

5000 L/360

2800 L/193

16"

1510 L/130

3550 L/270

1900 L/145

12"

1930 L/143

4410 L/296

2370 L/159

16"

3020 L/222

-

2.0E LP LVL

1-1/2" x 9-1/4" 1-1/2" x 3-1/2" 1-1/2" x 5-1/2" 1-1/2" x 7-1/4"

7630 L/999

2880 L/999

4530 L/999

5980 L/999

5720 L/999

2160 L/776

3400 L/999

4480 L/999

7630 L/999

2880 L/741

4530 L/999

5980 L/999

5720 L/999

2160 L/556

3400 L/999

4480 L/999

7630 L/999

2880 L/549

4530 L/999

5980 L/999

5720 L/999

2160 L/412

3400 L/999

4480 L/999

7630 L/999

2360 L/327

4530 L/999

5980 L/999

5720 L/999

1630 L/245

3400 L/939

4480 L/999

7630 L/999

1700 L/210

4530 L/809

5980 L/999

5720 L/999

1150 L/158

3400 L/607

4480 L/999

7630 L/999

1270 L/144

4530 L/554

5980 L/999

5720 L/999

3400 L/415

4480 L/944

7630 L/999

4060 L/397

5980 L/902

5720 L/999

3030 L/297

4480 L/677

7630 L/999

3430 L/294

5980 L/670

5720 L/776

2430 L/220

4480 L/502

7630 L/791

2800 L/224

5980 L/511

5720 L/593

1940 L/168

4480 L/383

7210 L/618

2290 L/175

5230 L/399

5410 L/464

1550 L/131

3920 L/299

6420 L/493

1880 L/139

4600 L/318

4810 L/370

3290 L/238

5740 L/400

3990 L/258

4290 L/300

2770 L/193

5160 L/329

3410 L/212

3680 L/247

2340 L/159

1-1/2" x 9-1/4"

7630 L/999

5720 L/999

7630 L/999

5720 L/999

7630 L/999

5720 L/999

7630 L/999

5720 L/999

7630 L/999

5720 L/999

7630 L/999

5720 L/999

7630 L/999

5720 L/999

7630 L/999

5720 L/999

7630 L/999

5720 L/791

7630 L/825

5720 L/618

7630 L/658

5720 L/493

7600 L/533

5700 L/400

6840 L/439

5130 L/329

1.35E LP LSL

1.55E LP LSL or 1.5E LP LVL

2.0E LP LVL

Stud

Spacing 1-1/2" x 3-1/2" 1-1/2" x 5-1/2" 1-1/2" x 7-1/4" 1-1/2" x 9-1/4" 1-1/2" x 3-1/2" 1-1/2" x 5-1/2" 1-1/2" x 7-1/4" 1-1/2" x 9-1/4" 1-1/2" x 3-1/2" 1-1/2" x 5-1/2" 1-1/2" x 7-1/4"

12"

2730 L/404

4530 L/999

5980 L/999

7630 L/999

2880 L/448

4530 L/999

5980 L/999

7630 L/999

2880 L/598

4530 L/999

5980 L/999

16"

1790 L/303

3400 L/999

4480 L/999

5720 L/999

2160 L/336

3400 L/999

4480 L/999

5720 L/999

2160 L/448

3400 L/999

4480 L/999

12"

2050 L/289

4530 L/999

5980 L/999

7630 L/999

2560 L/321

4530 L/999

5980 L/999

7630 L/999

2880 L/428

4530 L/999

5980 L/999

16"

1270 L/216

3400 L/822

4480 L/999

5720 L/999

1670 L/241

3400 L/913

4480 L/999

5720 L/999

2160 L/321

3400 L/999

4480 L/999

12"

1580 L/214

4530 L/816

5980 L/999

7630 L/999

2010 L/238

4530 L/907

5980 L/999

7630 L/999

2880 L/317

4530 L/999

5980 L/999

16"

930 L/160

3400 L/612

4480 L/999

5720 L/999

1270 L/178

3400 L/680

4480 L/999

5720 L/999

1970 L/238

3400 L/907

4480 L/999

12"

960 L/127

4530 L/488

5980 L/999

7630 L/999

1280 L/141

4530 L/542

5980 L/999

7630 L/999

1960 L/188

4530 L/723

5980 L/999

16"

3260 L/366

4480 L/825

5720 L/999

3400 L/407

4480 L/917

5720 L/999

1250 L/141

3400 L/542

4480 L/999

12"

3580 L/315

5980 L/714

7630 L/999

4380 L/350

5980 L/794

7630 L/999

1350 L/121

4530 L/467

5980 L/999

16"

2340 L/236

4480 L/536

5720 L/999

2970 L/263

4480 L/595

5720 L/999

3400 L/350

4480 L/794

12"

2690 L/216

5980 L/490

7630 L/999

3340 L/240

5980 L/545

7630 L/999

4530 L/320

5980 L/727

16"

1700 L/162

4400 L/368

5720 L/754

2210 L/180

4480 L/409

5720 L/838

3290 L/240

4480 L/545

12"

2060 L/154

5170 L/352

7630 L/723

2590 L/172

5980 L/391

7630 L/803

3770 L/229

5980 L/521

16"

3490 L/264

5720 L/542

1670 L/129

4340 L/293

5720 L/602

2550 L/172

4480 L/391

12"

4210 L/261

7630 L/538

2000 L/127

5130 L/290

7630 L/597

2980 L/170

5980 L/387

16"

2790 L/195

5720 L/403

3510 L/217

5720 L/448

1970 L/127

4480 L/290

12"

3380 L/199

6980 L/411

4170 L/221

7630 L/457

2330 L/129

5950 L/295

16"

2170 L/149

5060 L/308

2790 L/166

5720 L/342

4110 L/221

12"

2680 L/155

6140 L/321

3370 L/173

7210 L/357

4900 L/230

16"

4150 L/241

2200 L/129

5160 L/268

3320 L/173

12"

2130 L/124

5140 L/256

2740 L/138

6270 L/285

4060 L/184

16"

3390 L/192

4290 L/213

2690 L/138

12"

4300 L/208

5310 L/231

3360 L/149

16"

2760 L/156

3560 L/173

12"

3590 L/171

4510 L/190

2800 L/122

16"

2230 L/128

2950 L/142

-

1-1/2" x 9-1/4"

7630 L/999

5720 L/999

7630 L/999

5720 L/999

7630 L/999

5720 L/999

7630 L/999

5720 L/999

7630 L/999

5720 L/999

7630 L/999

5720 L/999

7630 L/999

5720 L/803

7630 L/797

5720 L/597

7630 L/609

5720 L/457

7630 L/476

5720 L/357

7630 L/380

5720 L/285

7590 L/308

5250 L/231

6520 L/253

4440 L/190

100 MPH BASIC WIND SPEED, EXPOSURE C

Height

8'

9'

10'

12'

14'

16'

18'

20'

22'

24'

26'

28'

30'

DESIGN ASSUMPTIONS:

1. These tables are limited to structures with a mean roof height of 30'.

2. The vertical load capacity is valid for wall columns supporting roof and floor loads. The design dead load shall not exceed

design live load.

3. The vertical capacity has been reduced to allow for holes and notches. Refer to the Drilling & Notching guidelines on

page 4 for more information.

4. The vertical load capacity assumes an eccentricity of 1/6 of the wall thickness.

5. The design wind pressures are based on Method 2 (Analytical Procedure) from ASCE 7-05 for components and cladding,

(wall zone 4) for an enclosed, occupancy category II structure (importance factor, I = 1.00) with no wind speed-up associated with abrupt changes in local topography (topographic factor, Kzt = 1.00). The wind pressures for deflection have been

adjusted to approximate the main wind force resisting loads as specified in ASCE 7-05.

6. A load duration adjustment, CD = 1.60, has been applied for wind.

7. A repetitive member increase of 4% has been applied as allowed for 3 or more wall studs spaced no more than 24" oc,

properly connected by a suitable exterior sheathing. No increase in stiffness has been assumed for the wall sheathing.

8. A gypsum wall board is assumed attached to the interior side of the studs.

9. The tabulated capacities have been limited by the bearing capacity of LP SolidStart LSL or LVL as the wall plate (440 psi).

For plates with a bearing capacity less than 440 psi, the designer shall check the required vertical load against the bearing

capacity for the plate and adjust the stud size and/or spacing accordingly. Refer to the Bearing Capacity table on page 4 for the

common species of Hem-Fir and SPF. No increase is allowed without complete analysis of the vertical capacity of the wall stud.

ADDITIONAL NOTES:

1. Height is the clear height of the wall stud between the

bottom plate and the lower top plate.

2. The first value in each cell represents the allowable vertical

load capacity of a single stud, in pounds per lineal foot of wall

length (plf). These capacities are either the allowable capacity

for vertical loads acting alone (no horizontal wind pressure)

or the capacity of the stud after accounting for the bending

induced by the horizontal wind pressure.

3. The second value in each cell represents the deflection ratio

(L/x) based on the horizontal wind pressure. The designer

shall verify the correct deflection ratio limit for the intended

application.

4. Install full-width blocking per local code requirements,

normally no more than every 8' along the height of the stud.

5. Do not use a product where designated “-” without further

analysis by a professional engineer.

5

Exterior Wall Column Capacity (lbs): 2x4 & 2x6 Walls for 90 mph, Exposure B

TO USE:

1.

2.

3.

4.

5.

Select the table for 2x4 Walls or 2x6 Walls, as needed.

Determine the height of the column. If not listed, use the next tallest Height in the table.

Determine the Tributary Width of the wall associated with the horizontal wind pressure supported by the column. If not listed, use the next largest Tributary Width.

Select the LP® SolidStart® LSL or LVL grade and size where the Vertical Load Capacity and Deflection Ratio meet or exceed the applied vertical load and required deflection limit.

Verify the plate bearing capacity for the selected column. See Design Assumption 10 below.

2 X 4 WALLS

Height

8'

9'

10'

12'

14'

Tributary

Width

16"

24"

36"

48"

16"

24"

36"

48"

16"

24"

36"

48"

16"

24"

36"

48"

16"

24"

36"

48"

1.35E LP LSL

1.55E LP LSL or 1.5E LP LVL

Single9

Double

3-1/2" x 3-1/2" 5-1/2" x 3-1/2"

Single9

Double

3-1/2" x 3-1/2"

1-1/2" x 3-1/2" 1-1/2" x 3-1/2" Beam or Plank

Plank

1-1/2" x 3-1/2" 1-1/2" x 3-1/2" Beam or Plank

2870 L/524

2750 L/999

5280 L/999 9040 L/999 2880 L/582

2910 L/999

5650 L/999

2510 L/349

2750 L/699

5280 L/815

9040 L/999 2880 L/388

2910 L/776

5650 L/846

1910 L/234

2750 L/469 5280 L/547

9040 L/861

2580 L/260

2910 L/521

5650 L/568

1340 L/179

2560 L/358

5190 L/418

9040 L/657

2070 L/199

2870 L/398

5650 L/434

2250 L/375

2750 L/750

5280 L/876

8830 L/999

2740 L/417

2910 L/834

5650 L/908

1830 L/250

2750 L/500 5280 L/584 8830 L/917

2350 L/278

2910 L/556

5650 L/605

1190 L/166

2530 L/333

4970 L/389 8830 L/611

1770 L/185

2850 L/370

5650 L/403

570 L/127

2250 L/254 4380 L/297

8610 L/467

1240 L/141

2620 L/283 5090 L/308

1780 L/278

2750 L/556 4840 L/649

7620 L/999

2190 L/309

2910 L/618

5160 L/673

1370 L/185

2670 L/371

4730 L/432

7620 L/680

1820 L/206

2910 L/412

5160 L/448

750 L/123

2310 L/247

4060 L/288

7530 L/453

1260 L/137

2670 L/274

4540 L/299

1960 L/187

3440 L/219

6890 L/344

2380 L/208 3960 L/227

1140 L/165

2600 L/331

3640 L/386

5790 L/607

1450 L/183

2910 L/367

3900 L/400

2280 L/220

3210 L/257

5780 L/404

1110 L/122

2640 L/245

3530 L/267

1810 L/147

2600 L/171

5130 L/269

2230 L/163

2960 L/178

2000 L/128

4510 L/202

1830 L/122

2410 L/133

2170 L/213

2640 L/248 4530 L/391

2520 L/237

2860 L/258

1820 L/142

2250 L/165

4200 L/260

2190 L/158

2500 L/172

3620 L/173

3060 L/130

-

2.0E LP LVL

5-1/2" x 3-1/2"

Single9

Double

3-1/2" x 3-1/2" 5-1/2" x 3-1/2"

Plank

1-1/2" x 3-1/2" 1-1/2" x 3-1/2" Beam or Plank

Plank

9040 L/999 2880 L/776

4120 L/999

5960 L/999 9040 L/999

9040 L/999 2880 L/517

4120 L/999

5960 L/999 9040 L/999

9040 L/892 2880 L/347

4120 L/695

5960 L/811

9040 L/999

9040 L/682 2880 L/265

4120 L/531

5960 L/620 9040 L/974

9040 L/999 2880 L/556

4120 L/999

5960 L/999 9040 L/999

9040 L/951

2880 L/370

4120 L/741

5960 L/865 9040 L/999

9040 L/634

2870 L/247

4120 L/494 5960 L/576

9040 L/906

9040 L/484 2320 L/188

4010 L/377

5960 L/440 9040 L/692

8120 L/999 2880 L/412

4120 L/824 5960 L/961

9040 L/999

8120 L/705

2750 L/274

4120 L/549

5960 L/641

9040 L/999

8120 L/470

2170 L/183

4040 L/366

5960 L/427

9040 L/671

7610 L/356

1630 L/139

3720 L/278

5960 L/324 9040 L/509

6130 L/629

2140 L/245 4050 L/490 5500 L/572

8640 L/899

6130 L/419

1780 L/163

3940 L/327

5430 L/381

8640 L/599

5630 L/279

3490 L/218

4810 L/254

8630 L/399

5050 L/209

3050 L/163

4220 L/190

8000 L/299

4770 L/405

1510 L/158

3660 L/316

4290 L/368

6740 L/579

4550 L/270

3300 L/210

3940 L/245

6740 L/386

4000 L/180

2800 L/140

3370 L/163

6270 L/257

3490 L/135

2840 L/122

5700 L/193

2 X 6 WALLS

Height

8'

9'

10'

12'

14'

16'

18'

20'

22'

Tributary

Width

16"

24"

36"

48"

16"

24"

36"

48"

16"

24"

36"

48"

16"

24"

36"

48"

16"

24"

36"

48"

16"

24"

36"

48"

16"

24"

36"

48"

16"

24"

36"

48"

16"

24"

36"

48"

1.35E LP LSL

1.55E LP LSL or 1.5E LP LVL

2.0E LP LVL

Single9

Single9

Single9

Double

Double

Double

3-1/2" x 5-1/2"

3-1/2" x 5-1/2"

3-1/2" x 5-1/2"

1-1/2" x 5-1/2" 1-1/2" x 5-1/2"

1-1/2" x 5-1/2" 1-1/2" x 5-1/2"

1-1/2" x 5-1/2" 1-1/2" x 5-1/2"

4530 L/999

4330 L/999 8300 L/999

4530 L/999 4580 L/999

8870 L/999

4530 L/999 6480 L/999

9370 L/999

4530 L/999

4330 L/999 8300 L/999

4530 L/999 4580 L/999

8870 L/999

4530 L/999 6480 L/999

9370 L/999

4530 L/885 4330 L/999 8300 L/999

4530 L/983 4580 L/999

8870 L/999

4530 L/999 6480 L/999

9370 L/999

4530 L/676

4330 L/999 8300 L/999

4530 L/751

4580 L/999

8870 L/999

4530 L/999 6480 L/999

9370 L/999

4530 L/999

4330 L/999 8300 L/999

4530 L/999 4580 L/999

8870 L/999

4530 L/999 6480 L/999

9370 L/999

4530 L/949

4330 L/999 8300 L/999

4530 L/999 4580 L/999

8870 L/999

4530 L/999 6480 L/999

9370 L/999

4530 L/632

4330 L/999 8300 L/999

4530 L/703

4580 L/999

8870 L/999

4530 L/937

6480 L/999

9370 L/999

4530 L/483 4330 L/966 8300 L/999

4530 L/537

4580 L/999

8870 L/999

4530 L/716

6480 L/999

9370 L/999

4530 L/999

4330 L/999 8300 L/999

4530 L/999 4580 L/999

8870 L/999

4530 L/999 6480 L/999

9370 L/999

4530 L/706

4330 L/999 8300 L/999

4530 L/784 4580 L/999

8870 L/999

4530 L/999 6480 L/999

9370 L/999

4530 L/470

4330 L/941

8300 L/999

4530 L/523

4580 L/999

8870 L/999

4530 L/697

6480 L/999

9370 L/999

4530 L/357

4330 L/714

8300 L/834 4530 L/397 4580 L/794

8870 L/926

4530 L/529 6480 L/999

9370 L/999

4530 L/634

4330 L/999 8300 L/999

4530 L/704 4580 L/999

8870 L/999

4530 L/939 6480 L/999

9370 L/999

4500 L/422

4330 L/845 8300 L/986 4530 L/469 4580 L/939

8870 L/999

4530 L/626 6480 L/999

9370 L/999

3660 L/281

4330 L/563 8300 L/657

4530 L/313

4580 L/626

8870 L/730

4530 L/417

6480 L/835

9370 L/974

2810 L/211

4240 L/422 8300 L/493 4020 L/234 4580 L/469 8870 L/548 4530 L/313

6480 L/626

9370 L/730

3830 L/410

4330 L/820 8300 L/956 4430 L/455 4580 L/911

8870 L/999

4530 L/607 6480 L/999

9370 L/999

3280 L/273

4330 L/546 8300 L/637

4100 L/303 4580 L/607

8870 L/708

4530 L/404 6480 L/809

9370 L/944

2480 L/182

4250 L/364 8300 L/425

3380 L/202 4580 L/404 8870 L/472

4530 L/269 6480 L/539

9370 L/629

1670 L/136

3870 L/273

7730 L/318

2660 L/151

4400 L/303 8870 L/354

4390 L/202 6480 L/404 9370 L/472

2940 L/280 4330 L/561

7420 L/655

3560 L/311

4580 L/623 8500 L/727

4530 L/415

6480 L/831

9370 L/970

2420 L/187

4330 L/374

7420 L/436 3090 L/207

4580 L/415

8500 L/485 4520 L/277

6480 L/554

9370 L/647

1680 L/124

3920 L/249

6920 L/291

2410 L/138 4440 L/277

8360 L/323

3810 L/184 6480 L/369

9370 L/431

3450 L/187

6140 L/218

4050 L/207

7630 L/242

3120 L/138

6200 L/277

9370 L/323

2280 L/200

4270 L/401

6220 L/468 2800 L/223

4580 L/446 7090 L/521

3990 L/297

6440 L/595

9370 L/694

1810 L/133

4070 L/267

6150 L/312

2360 L/148

4570 L/297

7090 L/347

3530 L/198

6440 L/397

9370 L/463

3520 L/178

5400 L/208

4100 L/198

6580 L/231

2870 L/132

6200 L/264

9370 L/308

2980 L/133

4680 L/156

3640 L/148

5920 L/173

5690 L/198

8660 L/231

1770 L/148

4050 L/297

5280 L/347

2200 L/165

4440 L/331

6000 L/386

3190 L/220

6140 L/441

7950 L/515

3620 L/198

4920 L/231

4180 L/220 5860 L/257

2750 L/147

6140 L/294

7950 L/343

3000 L/132

4210 L/154

3640 L/147

5200 L/171

5540 L/196

7500 L/228

4570 L/128

4960 L/147

6840 L/171

3570 L/227

4410 L/265

1720 L/126

4100 L/252

5130 L/294

2540 L/168

5740 L/336

6810 L/392

3080 L/151

3910 L/176

3660 L/168

4710 L/196

5430 L/224

6690 L/261

4060 L/130

4750 L/149

5990 L/174

5330 L/130

ADDITIONAL NOTES:

5-1/4" x 5-1/2"

13610

13610

13610

13610

13610

13610

13610

13610

13610

13610

13610

13610

13610

13610

13610

13610

13610

13610

13610

13610

13610

13610

13610

13610

13610

13610

13610

13610

11950

11950

11950

11670

10230

10230

10080

9380

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/944

L/708

L/999

L/970

L/647

L/485

L/999

L/694

L/463

L/347

L/772

L/515

L/343

L/257

L/589

L/392

L/261

L/196

DESIGN ASSUMPTIONS:

1.

2.

3.

4.

5.

6

These tables are limited to structures with a mean roof height of 30'.

The vertical load capacity is valid for wall columns supporting roof and floor loads. The design dead load shall not exceed design live load.

The vertical capacity has been reduced to allow for holes and notches. Refer to the Drilling & Notching guidelines on page 4 for more information.

The vertical load capacity assumes an eccentricity of 1/6 of the wall thickness.

The design wind pressures are based on Method 2 (Analytical Procedure) from ASCE 7-05 for components and cladding (wall zone 4), for an enclosed, occupancy

category II structure (importance factor, I = 1.00) with no wind speed-up associated with abrupt changes in local topography (topographic factor, Kzt = 1.00).

The wind pressures for deflection have been adjusted to approximate the main wind force resisting loads as specified in ASCE 7-05.

6. A load duration adjustment, CD = 1.60, has been applied for wind.

7. No repetitive member increase has been applied.

8. Full-width blocking is assumed to be installed at 8' on-center or less.

9. Design for a Single 1-1/2" wall column also requires continuous, full-length lateral support through connection to the exterior wall sheathing and interior gypsum

wall board.

10. The tabulated capacities have been limited by the bearing capacity of LP SolidStart LSL or LVL as the wall plate (440 psi). For plates with a lower bearing capacity,

the designer shall check the required vertical load against the bearing capacity for the plate and increase the column size accordingly. Refer to the Bearing Capacity

table on page 4 for the common species of Hem-Fir and SPF. No increase is allowed without complete analysis of the vertical capacity of the column.

1. Height is the clear height of the

column between the bottom

plate and the lower top plate.

2. The first value in each cell

represents the allowable vertical

load capacity of the column, in

pounds (lbs). These capacities are

either the allowable

capacity for vertical

loads acting alone

(no horizontal wind

pressure) or the capacity of

the column after accounting

for the bending induced by the

horizontal wind pressure.

3. The second value in each cell

represents the deflection ratio

(L/x) based on the horizontal

wind pressure. The designer shall

verify the correct deflection ratio

limit for the intended application.

4. These tables are for members

in the Beam orientation except

for the 3-1/2" x 3-1/2" and

5-1/2" x 3-1/2" column sizes

for the 2x4 wall as noted in

the table. Refer to the Product

Orientation detail on page 4.

5. All members shall be solid, onepiece sections except for the

built-up Double (2-ply). For a

3-ply and 4-ply built-up column,

multiply the Double values by

1.5 and 2.0, respectively. See

page 17 for the connection of

built-up columns.

6. Columns supporting a Tributary

Width greater than 48" are

beyond the scope of this table.

7. Do not use a product where

designated “-” without further

analysis by a professional

engineer.

Exterior Wall Column Capacity (lbs): 2x4 & 2x6 Walls for 100 mph, Exposure C

TO USE:

1.

2.

3.

4.

5.

Select the table for 2x4 Walls or 2x6 Walls, as needed.

Determine the height of the column. If not listed, use the next tallest Height in the table.

Determine the Tributary Width of the wall associated with the horizontal wind pressure supported by the column. If not listed, use the next largest Tributary Width.

Select the LP® SolidStart® LSL or LVL grade and size where the Vertical Load Capacity and Deflection Ratio meet or exceed the applied vertical load and required deflection limit.

Verify the plate bearing capacity for the selected column. See Design Assumption 10 below.

2 X 4 WALLS

Height

8'

9'

10'

12'

14'

Tributary

Width

16"

24"

36"

48"

16"

24"

36"

48"

16"

24"

36"

48"

16"

24"

36"

48"

16"

24"

36"

48"

1.35E LP LSL

1.55E LP LSL or 1.5E LP LVL

Single9

Double

3-1/2" x 3-1/2" 5-1/2" x 3-1/2"

Single9

Double

3-1/2" x 3-1/2"

1-1/2" x 3-1/2" 1-1/2" x 3-1/2" Beam or Plank

Plank

1-1/2" x 3-1/2" 1-1/2" x 3-1/2" Beam or Plank

2320 L/303

2750 L/606 5280 L/707

9040 L/999 2880 L/336

2910 L/673

5650 L/733

1610 L/202

2660 L/404 5280 L/471

9040 L/740

2310 L/224

2910 L/448 5650 L/488

510 L/135

2260 L/271

4570 L/316

9040 L/497

1350 L/150

2630 L/301

5460 L/328

1850 L/207

3760 L/241

9040 L/380

2310 L/230

4670 L/250

1630 L/216

2740 L/433

5280 L/506 8830 L/795

2170 L/241

2910 L/482

5650 L/524

890 L/144

2390 L/289 4680 L/337

8830 L/530

1510 L/160

2740 L/321

5370 L/349

1840 L/192

3570 L/224

7750 L/353

2290 L/214

4310 L/233

1260 L/147

2520 L/171

6670 L/270

1850 L/163

3340 L/178

1180 L/160

2560 L/321

4520 L/375

7620 L/589

1640 L/178

2870 L/357

4970 L/389

2140 L/214

3760 L/250

7220 L/392

2530 L/238

4260 L/259

1480 L/142

2630 L/166

6070 L/261

1990 L/158

3230 L/172

1530 L/126

4990 L/198

1440 L/120

2240 L/131

2140 L/191

3010 L/223

5580 L/350

2510 L/212

3350 L/231

1600 L/127

2320 L/148

4840 L/233

2050 L/141

2700 L/154

3800 L/155

1660 L/123

2080 L/143

4020 L/226

2050 L/136

2340 L/149

3360 L/150

-

2.0E LP LVL

5-1/2" x 3-1/2"

Single9

Double

3-1/2" x 3-1/2" 5-1/2" x 3-1/2"

Plank

1-1/2" x 3-1/2" 1-1/2" x 3-1/2" Beam or Plank

Plank

9040 L/999 2880 L/448

4120 L/897

5960 L/999 9040 L/999

9040 L/768

2880 L/299

4120 L/598

5960 L/698 9040 L/999

9040 L/515

2670 L/200 4040 L/401

5960 L/468 9040 L/736

9040 L/394

1740 L/153

3700 L/307

5960 L/358 9040 L/562

9040 L/824 2880 L/321

4120 L/642

5960 L/749 9040 L/999

9040 L/549

2590 L/214

4120 L/428 5960 L/499 9040 L/785

8650 L/366

1570 L/142

3660 L/285

5960 L/333

9040 L/523

7660 L/280

3200 L/218

5960 L/254 9040 L/400

8120 L/611

2570 L/238

4120 L/476

5960 L/555 9040 L/873

7920 L/407

1910 L/158

3890 L/317

5960 L/370 9040 L/582

6840 L/271

3310 L/211

5680 L/246 9040 L/388

5850 L/206

2740 L/160

4650 L/187

9040 L/294

6050 L/363

1620 L/141

3800 L/283

5240 L/330 8640 L/519

5360 L/242

3290 L/188

4530 L/220 8340 L/346

4390 L/161

2530 L/125

3520 L/146

7270 L/230

3450 L/121

6250 L/173

4380 L/234

3140 L/182

3760 L/213

6690 L/334

3760 L/156

2580 L/121

3130 L/142

6010 L/223

5050 L/148

-

2 X 6 WALLS

Height

8'

9'

10'

12'

14'

16'

18'

20'

22'

Tributary

Width

16"

24"

36"

48"

16"

24"

36"

48"

16"

24"

36"

48"

16"

24"

36"

48"

16"

24"

36"

48"

16"

24"

36"

48"

16"

24"

36"

48"

16"

24"

36"

48"

16"

24"

36"

48"

1.35E LP LSL

1.55E LP LSL or 1.5E LP LVL

2.0E LP LVL

Single9

Single

Single9

Double

Double

Double

3-1/2" x 5-1/2"

3-1/2" x 5-1/2"

3-1/2" x 5-1/2"

1-1/2" x 5-1/2" 1-1/2" x 5-1/2"

1-1/2" x 5-1/2" 1-1/2" x 5-1/2"

1-1/2" x 5-1/2" 1-1/2" x 5-1/2"

4530 L/999

4330 L/999 8300 L/999

4530 L/999 4580 L/999

8870 L/999

4530 L/999 6480 L/999

9370 L/999

4530 L/761

4330 L/999 8300 L/999

4530 L/846 4580 L/999

8870 L/999

4530 L/999 6480 L/999

9370 L/999

4530 L/511

4330 L/999 8300 L/999

4530 L/568 4580 L/999

8870 L/999

4530 L/757

6480 L/999

9370 L/999

4530 L/390

4330 L/781

8300 L/911

4530 L/434 4580 L/868 8870 L/999

4530 L/578

6480 L/999

9370 L/999

4530 L/822

4330 L/999 8300 L/999

4530 L/913

4580 L/999

8870 L/999

4530 L/999 6480 L/999

9370 L/999

4530 L/548 4330 L/999 8300 L/999

4530 L/609 4580 L/999

8870 L/999

4530 L/812

6480 L/999

9370 L/999

4530 L/365

4330 L/731

8300 L/853

4530 L/406 4580 L/812

8870 L/947

4530 L/541

6480 L/999

9370 L/999

3280 L/279

4160 L/558 8300 L/651

4530 L/310

4580 L/620 8870 L/724

4530 L/413

6480 L/827

9370 L/965

4530 L/612

4330 L/999 8300 L/999

4530 L/680 4580 L/999

8870 L/999

4530 L/907 6480 L/999

9370 L/999

4530 L/408 4330 L/816

8300 L/952

4530 L/453 4580 L/907

8870 L/999

4530 L/604 6480 L/999

9370 L/999

3500 L/272

4280 L/544 8300 L/634

4530 L/302 4580 L/604 8870 L/705

4530 L/403 6480 L/806

9370 L/940

2000 L/206 3900 L/413

8280 L/481

3810 L/229 4430 L/458 8870 L/535

4530 L/305 6480 L/611

9370 L/713

4240 L/366

4330 L/732

8300 L/854 4530 L/407 4580 L/814

8870 L/949 4530 L/542 6480 L/999

9370 L/999

3270 L/244 4330 L/488 8300 L/569 4430 L/271

4580 L/542

8870 L/633

4530 L/361

6480 L/723

9370 L/844

1770 L/162

3870 L/325

8030 L/379

3100 L/180

4410 L/361

8870 L/422

4530 L/241

6480 L/482

9370 L/562

3320 L/244 7000 L/284

1710 L/135

3970 L/271

8390 L/316

3940 L/180

6180 L/361

9370 L/422

3040 L/236 4330 L/473

8300 L/552

3880 L/263 4580 L/526

8870 L/614

4530 L/350 6480 L/701

9370 L/818

2110 L/157

4080 L/315

8130 L/368 3040 L/175

4570 L/350

8870 L/409 4530 L/233 6480 L/467

9370 L/545

3400 L/210 6840 L/245

4020 L/233 8200 L/272

3510 L/155

6210 L/311

9370 L/363

2670 L/157

5550 L/184

3450 L/175

7120 L/204

5600 L/233

9370 L/272

2190 L/162

4250 L/324

7420 L/378

2880 L/180

4580 L/360 8500 L/420 4300 L/240 6480 L/480

9370 L/560

3700 L/216

6560 L/252

2100 L/120

4260 L/240 8030 L/280 3490 L/160

6430 L/320

9370 L/373

2880 L/144

5240 L/168

3580 L/160

6780 L/186

5680 L/213

9370 L/249

3940 L/126

2870 L/120

5580 L/140

4930 L/160

8910 L/186

3900 L/232

5910 L/270

2170 L/129

4430 L/258

7050 L/301

3320 L/172

6440 L/344

9370 L/401

3270 L/154

5070 L/180

3890 L/172

6270 L/200

5960 L/229 9040 L/267

3850 L/120

5160 L/133

5070 L/152

7860 L/178

6720 L/133

3430 L/172

4690 L/200

4010 L/191

5650 L/223

2560 L/127

5950 L/255

7950 L/297

3890 L/133

3400 L/127

4910 L/148

5270 L/170

7190 L/198

6070 L/132

2870 L/131

3690 L/153

3470 L/145

4510 L/170

5220 L/194

6470 L/226

4450 L/129

5680 L/151

-

ADDITIONAL NOTES:

5-1/4" x 5-1/2"

13610

13610

13610

13610

13610

13610

13610

13610

13610

13610

13610

13610

13610

13610

13610

13610

13610

13610

13610

13610

13610

13610

13610

13610

13610

13610

13610

12460

11950

11950

10860

9740

10230

9750

8580

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/844

L/633

L/999

L/818

L/545

L/409

L/841

L/560

L/373

L/280

L/602

L/401

L/267

L/200

L/446

L/297

L/198

L/148

L/340

L/226

L/151

-

DESIGN ASSUMPTIONS:

These tables are limited to structures with a mean roof height of 30'.

The vertical load capacity is valid for wall columns supporting roof and floor loads. The design dead load shall not exceed design live load.

The vertical capacity has been reduced to allow for holes and notches. Refer to the Drilling & Notching guidelines on page 4 for more information.

The vertical load capacity assumes an eccentricity of 1/6 of the wall thickness.

The design wind pressures are based on Method 2 (Analytical Procedure) from ASCE 7-05 for components and cladding (wall zone 4), for an enclosed, occupancy

category II structure (importance factor, I = 1.00) with no wind speed-up associated with abrupt changes in local topography (topographic factor, Kzt = 1.00).

The wind pressures for deflection have been adjusted to approximate the main wind force resisting loads as specified in ASCE 7-05.

6. A load duration adjustment, CD = 1.60, has been applied for wind.

7. No repetitive member increase has been applied.

8. Full-width blocking is assumed to be installed at 8' on-center or less.

9. Design for a Single 1-1/2" wall column also requires continuous, full-length lateral support through connection to the exterior wall sheathing and interior gypsum

wall board.

10. The tabulated capacities have been limited by the bearing capacity of LP SolidStart LSL or LVL as the wall plate (440 psi). For plates with a lower bearing capacity,

the designer shall check the required vertical load against the bearing capacity for the plate and increase the column size accordingly. Refer to the Bearing Capacity

table on page 4 for the common species of Hem-Fir and SPF. No increase is allowed without complete analysis of the vertical capacity of the column.

1. Height is the clear height of the

column between the bottom

plate and the lower top plate.

2. The first value in each cell

represents the allowable vertical

load capacity of the column, in

pounds (lbs). These capacities

are either the allowable capacity

for vertical loads acting alone

(no horizontal wind pressure)

or the capacity of the column

after accounting for the bending

induced by the horizontal wind

pressure.

3. The second value in each cell

represents the deflection ratio

(L/x) based on the horizontal

wind pressure. The designer shall

verify the correct deflection ratio

limit for the intended application.

4. These tables are for members

in the Beam orientation except

for the 3-1/2" x 3-1/2" and

5-1/2" x 3-1/2" column sizes

for the 2x4 wall as noted in

the table. Refer to the Product

Orientation detail on page 4.

5. All members shall be solid, onepiece sections except for the

built-up Double (2-ply). For a

3-ply and 4-ply built-up column,

multiply the Double values by

1.5 and 2.0, respectively. See

page 17 for the connection of

built-up columns.

6. Columns supporting a Tributary

Width greater than 48" are

beyond the scope of this table.

7. Do not use a product where

designated “-” without further

analysis by a professional

engineer.

1.

2.

3.

4.

5.

7

Exterior Wall Column Capacity (lbs): 2x8 Walls for 90 mph, Exposure B

TO USE:

1.

2.

3.

4.

Determine the height of the column. If not listed, use the next tallest Height in the table.

Determine the Tributary Width of the wall associated with the horizontal wind pressure supported by the column. If not listed, use the next largest Tributary Width.

Select the LP® SolidStart® LSL or LVL grade and size where the Vertical Load Capacity and Deflection Ratio meet or exceed the applied vertical load and required deflection limit.

Verify the plate bearing capacity for the selected column. See Design Assumption 10 below.

2 X 8 WALLS

Height

8'

9'

10'

12'

14'

16'

18'

20'

22'

24'

26'

28'

30'

8

Tributary

Width

16"

24"

36"

48"

16"

24"

36"

48"

16"

24"

36"

48"

16"

24"

36"

48"

16"

24"

36"

48"

16"

24"

36"

48"

16"

24"

36"

48"

16"

24"

36"

48"

16"

24"

36"

48"

16"

24"

36"

48"

16"

24"

36"

48"

16"

24"

36"

48"

16"

24"

36"

48"

Single9

1-1/2" x 7-1/4"

5980 L/999

5980 L/999

5980 L/999

5980 L/999

5980 L/999

5980 L/999

5980 L/999

5980 L/999

5980 L/999

5980 L/999

5980 L/999

5980 L/800

5980 L/999

5980 L/952

5980 L/635

5980 L/476

5980 L/928

5980 L/618

5980 L/412

5640 L/309

5980 L/637

5980 L/424

5080 L/283

4120 L/212

5170 L/457

4820 L/304

3910 L/203

3000 L/152

4480 L/339

3890 L/226

3030 L/150

3660 L/258

3070 L/172

2970 L/202

2380 L/134

2410 L/161

1960 L/130

-

1.35E LP LSL

Double

1-1/2" x 7-1/4"

5710 L/999

5710 L/999

5710 L/999

5710 L/999

5710 L/999

5710 L/999

5710 L/999

5710 L/999

5710 L/999

5710 L/999

5710 L/999

5710 L/999

5710 L/999

5710 L/999

5710 L/999

5710 L/952

5710 L/999

5710 L/999

5710 L/824

5710 L/618

5710 L/999

5710 L/849

5710 L/566

5710 L/424

5710 L/914

5710 L/609

5710 L/406

5430 L/304

5710 L/678

5710 L/452

5590 L/301

5090 L/226

5710 L/517

5710 L/345

5180 L/230

4570 L/172

5560 L/404

5320 L/269

4610 L/179

3920 L/134

5360 L/322

4820 L/215

4010 L/143

4900 L/261

4290 L/174

4360 L/214

3720 L/143

-

3-1/2" x 7-1/4"

10940

10940

10940

10940

10940

10940

10940

10940

10940

10940

10940

10940

10940

10940

10940

10940

10940

10940

10940

10940

10940

10940

10940

10940

10940

10940

10940

10930

10440

10440

10440

9620

9100

9100

8600

7700

7990

7940

7000

6100

7060

6640

5700

4810

6240

5580

4650

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/962

L/721

L/999

L/991

L/660

L/495

L/999

L/710

L/473

L/355

L/791

L/527

L/351

L/263

L/604

L/402

L/268

L/201

L/472

L/314

L/209

L/157

L/376

L/250

L/167

L/125

L/304

L/203

L/135

5360 L/250

4700 L/167

-

1.55E LP LSL or 1.5E LP LVL

Single9

Double

3-1/2" x 7-1/4"

1-1/2" x 7-1/4" 1-1/2" x 7-1/4"

5980 L/999

6040 L/999

11700 L/999

5980 L/999

6040 L/999

11700 L/999

5980 L/999

6040 L/999

11700 L/999

5980 L/999

6040 L/999

11700 L/999

5980 L/999

6040 L/999

11700 L/999

5980 L/999

6040 L/999

11700 L/999

5980 L/999

6040 L/999

11700 L/999

5980 L/999

6040 L/999

11700 L/999

5980 L/999

6040 L/999

11700 L/999

5980 L/999

6040 L/999

11700 L/999

5980 L/999

6040 L/999

11700 L/999

5980 L/889

6040 L/999

11700 L/999

5980 L/999

6040 L/999

11700 L/999

5980 L/999

6040 L/999

11700 L/999

5980 L/705

6040 L/999

11700 L/999

5980 L/529

6040 L/999

11700 L/999

5980 L/999

6040 L/999

11700 L/999

5980 L/687

6040 L/999

11700 L/999

5980 L/458

6040 L/916

11700 L/999

5980 L/343

6040 L/687

11700 L/802

5980 L/708

6040 L/999

11700 L/999

5980 L/472

6040 L/944

11700 L/999

5980 L/314

6040 L/629

11700 L/734

5640 L/236

6040 L/472

11700 L/550

5980 L/507

6040 L/999

11700 L/999

5940 L/338

6040 L/677

11700 L/789

5110 L/225

6040 L/451

11700 L/526

4290 L/169

6040 L/338

11700 L/394

5160 L/376

6040 L/753

11700 L/879

4830 L/251

6040 L/502

11700 L/586

4040 L/167

6040 L/335

11700 L/390

3270 L/125

5780 L/251

11510 L/293

4420 L/287

6040 L/575

10430 L/671

3880 L/191

6040 L/383

10430 L/447

3100 L/127

5840 L/255

10350 L/298

5340 L/191

9520 L/223

3630 L/224

6040 L/449

9120 L/524

3090 L/149

6020 L/299

9120 L/349

5390 L/199

8530 L/233

4780 L/149

7700 L/174

3000 L/179

5860 L/358

8030 L/418

5550 L/238

7920 L/278

4850 L/159

7050 L/185

6220 L/139

2480 L/145

5590 L/290

7120 L/338

5040 L/193

6710 L/225

4260 L/129

5850 L/150

5110 L/238

6320 L/278

4520 L/159

5710 L/185

4860 L/123

-

Single9

1-1/2" x 7-1/4"

5980 L/999

5980 L/999

5980 L/999

5980 L/999

5980 L/999

5980 L/999

5980 L/999

5980 L/999

5980 L/999

5980 L/999

5980 L/999

5980 L/999

5980 L/999

5980 L/999

5980 L/941

5980 L/705

5980 L/999

5980 L/916

5980 L/611

5980 L/458

5980 L/944

5980 L/629

5980 L/419

5980 L/314

5980 L/677

5980 L/451

5980 L/300

5980 L/225

5980 L/502

5980 L/335

5980 L/223

5270 L/167

5930 L/383

5640 L/255

4820 L/170

4030 L/127

5170 L/299

4600 L/199

3780 L/133

4330 L/238

3760 L/159

3640 L/193

3070 L/129

3070 L/159

-

2.0E LP LVL

Double

1-1/2" x 7-1/4"

8540 L/999

8540 L/999

8540 L/999

8540 L/999

8540 L/999

8540 L/999

8540 L/999

8540 L/999

8540 L/999

8540 L/999

8540 L/999

8540 L/999

8540 L/999

8540 L/999

8540 L/999

8540 L/999

8540 L/999

8540 L/999

8540 L/999

8540 L/916

8540 L/999

8540 L/999

8540 L/839

8540 L/629

8540 L/999

8540 L/902

8540 L/601

8540 L/451

8540 L/999

8540 L/670

8540 L/446

8540 L/335

8540 L/767

8540 L/511

8540 L/341

8170 L/255

8400 L/599

8400 L/399

8120 L/266

7460 L/199

8100 L/477

8100 L/318

7380 L/212

6630 L/159

7730 L/387

7460 L/258

6600 L/172

5780 L/129

7220 L/318

6650 L/212

5750 L/141

-

3-1/2" x 7-1/4"

5-1/4" x 7-1/4"

12360

12360

12360

12360

12360

12360

12360

12360

12360

12360

12360

12360

12360

12360

12360

12360

12360

12360

12360

12360

12360

12360

12360

12360

12360

12360

12360

12360

12360

12360

12360

12360

12360

12360

12360

12360

12090

12090

12090

11240

10650

10650

10160

9280

9450

9450

8560

7690

8440

8140

7230

6370

17940

17940

17940

17940

17940

17940

17940

17940

17940

17940

17940

17940

17940

17940

17940

17940

17940

17940

17940

17940

17940

17940

17940

17940

17940

17940

17940

17940

17940

17940

17940

17940

17940

17940

17940

17940

17940

17940

17940

17940

16010

16010

16010

15830

14210

14210

14210

13400

12680

12680

12310

11400

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/979

L/734

L/999

L/999

L/702

L/526

L/999

L/781

L/521

L/390

L/895

L/596

L/397

L/298

L/699

L/466

L/310

L/233

L/557

L/371

L/247

L/185

L/451

L/301

L/200

L/150

L/371

L/247

L/165

L/123

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/789

L/999

L/999

L/781

L/586

L/999

L/895

L/596

L/447

L/999

L/699

L/466

L/349

L/836

L/557

L/371

L/278

L/677

L/451

L/301

L/225

L/557

L/371

L/247

L/185

7" x 7-1/4"

22330

22330

22330

22330

22330

22330

22330

22330

22330

22330

22330

22330

22330

22330

22330

22330

22330

22330

22330

22330

22330

22330

22330

22330

22330

22330

22330

22330

22330

22330

22330

22330

22330

22330

22330

22330

22330

22330

22330

22330

21360

21360

21360

21360

18950

18950

18950

18950

16920

16920

16920

16440

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/781

L/999

L/999

L/795

L/596

L/999

L/932

L/621

L/466

L/999

L/743

L/495

L/371

L/903

L/602

L/401

L/301

L/743

L/495

L/330

L/247

DESIGN ASSUMPTIONS:

ADDITIONAL NOTES:

1. These tables are limited to structures with a mean roof height of 30'.

2. The vertical load capacity is valid for wall columns supporting roof and floor loads. The design

dead load shall not exceed design live load.

3. The vertical capacity has been reduced to allow for holes and notches. Refer to the Drilling &

Notching guidelines on page 4 for more information.

4. The vertical load capacity assumes an eccentricity of 1/6 of the wall thickness.

5. The design wind pressures are based on Method 2 (Analytical Procedure) from ASCE 7-05

for components and cladding (wall zone 4), for an enclosed, occupancy category II structure

(importance factor, I = 1.00) with no wind speed-up associated with abrupt changes in local

topography (topographic factor, Kzt = 1.00). The wind pressures for deflection have been

adjusted to approximate the main wind force resisting loads as specified in ASCE 7-05.

6. A load duration adjustment, CD = 1.60, has been applied for wind.

7. No repetitive member increase has been applied.

8. Full-width blocking is assumed to be installed at 8' on-center or less.

9. Design for a Single 1-1/2" wall column also requires continuous, full-length lateral support

through connection to the exterior wall sheathing and interior gypsum wall board.

10. The tabulated capacities have been limited by the bearing capacity of LP SolidStart LSL or LVL

as the wall plate (440 psi). For plates with a lower bearing capacity, the designer shall check

the required vertical load against the bearing capacity for the plate and increase the column

size accordingly. Refer to the Bearing Capacity table on page 4 for the common species of

Hem-Fir and SPF. No increase is allowed without complete analysis of the vertical capacity

of the column.

1. Height is the clear height of the column between the bottom plate and the lower top plate.

2. The first value in each cell represents the allowable vertical load capacity of the column,

in pounds (lbs). These capacities are either the allowable capacity for vertical loads acting

alone (no horizontal wind pressure) or the capacity of the column after accounting for the

bending induced by the horizontal wind pressure.

3. The second value in each cell represents the deflection ratio (L/x) based on the horizontal

wind pressure. The designer shall verify the correct deflection ratio limit for the intended

application.

4. This table is for members in Beam Orientation only.

5. All members shall be solid, one-piece sections except for the built-up Double (2-ply).

For a 3-ply and 4-ply built-up column, multiply the Double values by 1.5 and 2.0,

respectively. See page 17 for the connection of built-up columns.

6. Columns supporting a Tributary Width greater than 48" are beyond the scope of this table.

7. Do not use a product where designated “-” without further analysis by a professional

engineer.

Exterior Wall Column Capacity (lbs): 2x8 Walls for 100 mph, Exposure C

TO USE:

1.

2.

3.

4.

Determine the height of the column. If not listed, use the next tallest Height in the table.

Determine the Tributary Width of the wall associated with the horizontal wind pressure supported by the column. If not listed, use the next largest Tributary Width.

Select the LP® SolidStart® LSL or LVL grade and size where the Vertical Load Capacity and Deflection Ratio meet or exceed the applied vertical load and required deflection limit.

Verify the plate bearing capacity for the selected column. See Design Assumption 10 below.

2 X 8 WALLS

Height

8'

9'

10'

12'

14'

16'

18'

20'

22'

24'

26'

28'

30'

Tributary

Width

16"

24"

36"

48"

16"

24"

36"

48"

16"

24"

36"

48"

16"

24"

36"

48"

16"

24"

36"

48"

16"

24"

36"

48"

16"

24"

36"

48"

16"

24"

36"

48"

16"

24"

36"

48"

16"

24"

36"

48"

16"

24"

36"

48"

16"

24"

36"

48"

16"

24"

36"

48"

Single9

1-1/2" x 7-1/4"

5980 L/999

5980 L/999

5980 L/999

5980 L/864

5980 L/999

5980 L/999

5980 L/814

5980 L/622

5980 L/999

5980 L/913

5980 L/609

5980 L/462

5980 L/825

5980 L/550

5980 L/367

4700 L/275

5980 L/536

5980 L/357

4440 L/238

2640 L/178

5740 L/368

4640 L/245

2960 L/163

1150 L/122

4540 L/264

3490 L/176

3620 L/195

2630 L/130

2800 L/149

-

1.35E LP LSL

Double

1-1/2" x 7-1/4"

5710 L/999

5710 L/999

5710 L/999

5710 L/999

5710 L/999

5710 L/999

5710 L/999

5710 L/999

5710 L/999

5710 L/999

5710 L/999

5710 L/924

5710 L/999

5710 L/999

5710 L/734

5560 L/550

5710 L/999

5710 L/714

5660 L/476

5140 L/357

5710 L/736

5710 L/490

5310 L/327

4670 L/245

5710 L/528

5660 L/352

4920 L/234

4150 L/176

5710 L/391

5360 L/261

4490 L/174

3580 L/130

5590 L/299

4900 L/199

3850 L/133

5100 L/233

4290 L/155

4570 L/186

3650 L/124

4010 L/151

3430 L/124

-

3-1/2" x 7-1/4"

10940

10940

10940

10940

10940

10940

10940

10940

10940

10940

10940

10940

10940

10940

10940

10940

10940

10940

10940

10860

10940

10940

10940

9780

10940

10940

9950

8520

10440

10100

8570

7060

9100

8180

6650

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/999

L/856

L/642

L/999

L/834

L/556

L/417

L/859

L/572

L/381

L/286

L/616

L/410

L/273

L/205

L/457

L/304

L/203

L/152

L/349

L/232

L/155

7640 L/272

6580 L/181

5050 L/121

6350 L/217

5290 L/144

5290 L/176

4410 L/144

-

1.55E LP LSL or 1.5E LP LVL

Single9

Double

3-1/2" x 7-1/4"

1-1/2" x 7-1/4" 1-1/2" x 7-1/4"

5980 L/999

6040 L/999

11700 L/999

5980 L/999

6040 L/999

11700 L/999

5980 L/999

6040 L/999

11700 L/999

5980 L/960

6040 L/999

11700 L/999

5980 L/999

6040 L/999

11700 L/999

5980 L/999

6040 L/999

11700 L/999

5980 L/904

6040 L/999

11700 L/999

5980 L/691

6040 L/999

11700 L/999

5980 L/999

6040 L/999

11700 L/999

5980 L/999

6040 L/999

11700 L/999

5980 L/676

6040 L/999

11700 L/999

5980 L/513

6040 L/999

11700 L/999

5980 L/917

6040 L/999

11700 L/999

5980 L/611

6040 L/999

11700 L/999

5980 L/407

6040 L/815

11700 L/951

5980 L/305

6040 L/611

11700 L/713

5980 L/595

6040 L/999

11700 L/999

5980 L/397

6040 L/794

11700 L/926

5980 L/264

6040 L/529

11700 L/617

4820 L/198

5820 L/397

11700 L/463

5980 L/409

6040 L/818

11700 L/954

5980 L/272

6040 L/545

11700 L/636

4610 L/181

5960 L/363

11700 L/424

3080 L/136

5440 L/272

11480 L/318

5680 L/293

6040 L/586

11700 L/684

4730 L/195

6040 L/391

11700 L/456

3310 L/130

5650 L/260

11590 L/304

5020 L/195

10420 L/228

4580 L/217

6040 L/435

11700 L/508

3690 L/145

6000 L/290

11700 L/338

5290 L/193

10550 L/225

4550 L/145

9190 L/169

3640 L/166

6040 L/332

10430 L/387

5610 L/221

9960 L/258

4740 L/147

8570 L/172

7210 L/129

2850 L/129

5830 L/259

9120 L/303

5120 L/173

8140 L/202

6740 L/134

5330 L/207

7650 L/241

4530 L/138

6660 L/161

4800 L/167