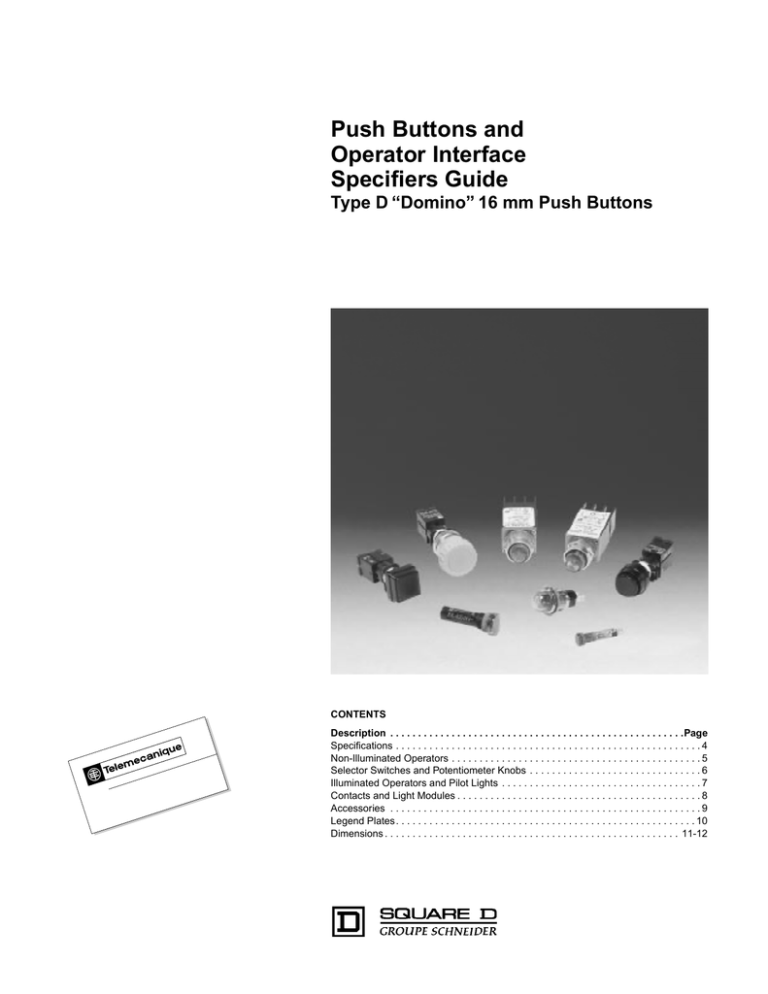

Push Buttons and

Operator Interface

Specifiers Guide

Type D “Domino” 16 mm Push Buttons

CONTENTS

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Non-Illuminated Operators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Selector Switches and Potentiometer Knobs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Illuminated Operators and Pilot Lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Contacts and Light Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Legend Plates. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-12

Push Buttons and Operator Interface Specifiers Guide

Type D – 16 mm

Specifications

Environment

Conforming to standards

IEC 947-5-1, IEC 337-1, NF C 63-140, ASE 0119, ASE 1003, BS 4794, VDE 0660 part 200, UL 508,

CSA C 22-2 n°14.

Approvals

In normal operation:

CSA, UL

ASE, DEMKO, NEMKO, SEMKO: pending.

Protective treatment

“TC” (All climates.)

Ambient air temperature

Storage: from -40 to +70 °C (-40 to +158 °F). Operation: from -25 to +60 °C (-13 to +140 °F).

Operating positions

All positions

Vibration resistance

Mushroom head push button: 8 gn; other push buttons: 15 gn(10 Hz < Frequency < 500 Hz)

conforming to IEC 68 2-6.

Shock resistance

Push button: 70 gn; mushroom head push button: 15 gn; selector switch: 200 g conforming to IEC 68 2-27.

Electric shock protection

Class II, conforming to IEC 536 and NF C 20-030

Degree of protection

conforming IEC 529 and NF C 20-010

NEMA Type 1, 4, 4X (indoor), 13

IP 65

Mechanical life

Push button: 1 million operations. Mushroom head push button: 0.1 million operations

Selector switch: 0.3 million operations.

Contact block characteristics

Rated insulation voltage

Ui = 380 V - degree of pollution: 3 conforming to IEC 947-1.

Rated shock resistance voltage

Uimp = 6 kV conforming to IEC 947-1.

Rated operating characteristics

AC-15: B150, 5 A Continuous; DC-13: Q150, 2.5 A continuous

Contact operation

Slow-make, N.O., slow-break, N.C., N.C. with direct opening operation conforming to EN60947-5-1 section 3.

Terminal referencing

Conforming to CENELEC EN 50013.

Short circuit protection

Fused 6 A gF conforming to IEC 269-1 and VDE 0660-200

For 1 million operations

Rated power

conforming to IEC 947-5-1

(electrical durability)

Connection by pin

or connector

Connection

Voltage V

24

48

60

120

230

380

AC-15

72 VA

144 VA

180 VA

360 VA

460 VA

380 VA

DC-13 (L/R - 15 ms)

144 W

144 W

180 W

120 W

46 W

- Pin 2.8 X 0.8 mm (0.110 x 0.32 in)

- Printed circuit connector

- Female connector (conforming to DIN 41651) + ribbon cable

Marking

File

E164353

CCN NKCR

File

Class

LR 44087

3211 03

For Declaration of Conformity, see page 226.

4

© 1997 Square D All Rights Reserved

11/97

Push Buttons and Operator Interface Specifiers Guide

Type D – 16 mm

Operators

Bezel Style 8

Round Black

Bezel Style 6

Square Chrome

Bezel Style 5

Square Black

Bezel Style 9

Round Chrome

Non-Illuminated Operators

Legends are not included with operators.

Type

Color

D5A2R

Momentary Flush Push Button, Square

D8A1G

D5A7Y

Momentary Flush Push Button, Round

Momentary Extended Guard Push Button

DkA2R

Green

DkA2G

Black

DkA2S

White

DkA2W

Yellow

DkA2Y

Blue

DkA2B

Red

DfA1R

Green

DfA1G

Black

DfA1S

White

DfA1W

Yellow

DfA1Y

Blue

DfA1B

Red

D t A7R

Green

D t A7G

Black

D t A7S

White

D t A7W

Yellow

D t A7Y

Blue

D t A7B

Momentary Push Mushroom

Red

D t B1R

Push Maintain/ Rotate Release Mushroom

Red

D t C1R

White

D t E1W

Toggle Switch

D6B1R

Catalog Number

Red

k Add desired bezel style code (see top of page). Only bezels 5 and 6 are available in this style operator.

f Add desired bezel style code (see top of page). Only bezels 8 and 9 are available in this style operator.

t Add desired bezel style code (see top of page). All four bezel styles are available in this style operator.

D5C1R

D8E1W

Contact Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 8

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pages 11-12

Legends . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 10

Application Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 4

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 9

5

11/97

© 1997 Square D All Rights Reserved

Push Buttons and Operator Interface Specifiers Guide

Type D – 16 mm

Selector Switches and Potentiometer Knobs

Bezel Style 5

Square Black

Bezel Style 8

Round Black

Bezel Style 6

Square Chrome

Bezel Style 9

Round Chrome

Selector Switches – Two Position

Type

Color

Catalog Number

Black

D t G2S

Key d

D t L30

Black

DtG7S

Color

Catalog Number

Black

D t G3S

Key d

D t L80

Momentary Spring Return

Both Sides To Center

Black

D t G4S

Momentary Spring Return

Right To Center

Black

D t G5S

Momentary Spring Return

Left To Center

Black

D t G6S

Maintained

Momentary Spring Return

D5Gkk

Selector Switches – Three Position

Type

Maintained

D5L80

Potentiometer Control Knobs (potentiometer not supplied)

Type

D8Rkk

Catalog Number

Integrated Mounting

4 mm shaft diameter X 50 mm length

D t R1S

PCB Board Mounting

4 mm shaft diameter X 50 mm length

D t R3S

d Key is removable in all positions. Replacement key is 9001Z18, CP1 (key is marked 8D1).

t Add desired bezel style code (see top of page). All four bezel styles are available in this style operator.

Contact Blocks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 8

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Pages 11-12

Legends. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 10

Application Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 4

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 9

6

© 1997 Square D All Rights Reserved

11/97

Push Buttons and Operator Interface Specifiers Guide

Type D – 16 mm

Pilot Lights and Illuminated Operators

Bezel Style 5

Square Black

Bezel Style 8

Round Black

Bezel Style 6

Square Chrome

Bezel Style 9

Round Chrome

Illuminated Operators

Legends are not included with operators. See page 10 for legends.

Type

D5A2R

Square Momentary Illuminated Push Button

Round Momentary Illuminated Push Button

D8A1G

Momentary Illuminated Extended Guard Button

D5A7Y

Square Push On - Push Off Illuminated Push Button

Round Push On - Push Off Illuminated Push Button

D9A1R

Color

Catalog Number

Red

D k A2R

Green

D k A2G

White

D k A2W

Yellow

D k A2Y

Blue

D k A2B

Red

D f A1R

Green

D f A1G

White

D f A1W

Yellow

D f A1Y

Blue

D f A1B

Red

D t A7R

Green

D t A7G

White

D t A7W

Yellow

D t A7Y

Blue

D t A7B

Red

D k A2R

Green

D k A2G

White

D k A2W

Yellow

D k A2Y

Blue

D k A2B

Red

D f A1R

Green

D f A1G

White

D f A1W

Yellow

D f A1Y

Blue

D f A1B

Color

Catalog Number

Pilot Lights

Legends are not included with operators. See page 10 for legends.

Type

D5V2Y

Square Pilot Light

Round Pilot Light

D8V1G

Red

D k V2R

Green

D k V2G

White

D k V2W

Yellow

D k V2Y

Blue

D k V2B

Red

D f V1R

Green

D f V1G

White

D f V1W

Yellow

D f V1Y

Blue

D f V1B

t Add desired bezel style code (see page 5). All four bezel styles are available in this style operator.

k Add desired bezel style code (see page 5). Only style 5 and 6 are available in this style operator.

f Add desired bezel style code (see page 5). Only style 8 and 9 are available in this style operator.

Contact Blocks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 8

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pages 11-12

Legends. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 10

Application Information . . . . . . . . . . . . . . . . . . . . . . . . . . Page 4

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 9

7

11/97

© 1997 Square D All Rights Reserved

Push Buttons and Operator Interface Specifiers Guide

Type D – 16 mm

Contacts and Light Modules

Contact Blocks Only

Type

Contact Arrangement

Catalog Number

N.O.

N.C.

N.O. – N.C.

N.O. – N.O.

N.C. – N.C.

N.O.

N.C.

N.O. – N.C.

N.O. – N.O.

N.C. – N.C.

N.O.

N.C.

N.O. – N.C.

N.O. – N.O.

N.C. – N.C.

N.O.

N.C.

N.O. – N.C.

N.O. – N.O.

N.C. – N.C.

N.O.

N.C.

N.O. – N.C.

N.O. – N.O.

N.C. – N.C.

DU10

DU01

DU11

DU20

DU02

DUB10

DUB01

DUB11

DUB20

DUB02

DV10

DV01

DV11

DV20

DV02

DVB10

DVB01

DVB11

DVB20

DVB02

DR10

DR01

DR11

DR20

DR02

For snap mounting to operator, 2.8 mm x 0.8 mm (0.110 x 0.032

inch) slip on termination.

DUkk

DUBkk

Printed circuit board mounting with 2.8 mm x 0.8 mm (0.110 x

0.032 inch) slip on termination

For use with Z203 PCB mounting base. See page 9.

DVkk

DVBkk

For snap mounting to operator. Has printed circuit board stabs.

For soldering to printed circuit board. Does not snap onto operator.

DRkk

DUF

Ribbon cable connector. Snaps onto operator.

Module With Lamp Holder Only

Type

DUFB

DVF

Catalog Number

For snap mounting to operator, 2.8 mm x 0.8 mm (0.110 x 0.032 inch) slip on termination.

Printed circuit board mounting with 2.8 mm x 0.8 mm (0.110 x 0.032 inch) slip on termination.

For use with Z203 PCB mounting base. See page 9.

For snap mounting to operator. Has printed circuit board stabs.

For soldering to printed circuit board. Does not snap onto operator.

Ribbon cable connector. Snaps onto operator.

DUF

DUFB

DVF

DVFB

DRF

Module With Lamp Holder And Contacts

Contact

Arrangement

Type

DVFB

DRF

For snap mounting to operator, 2.8 mm x 0.8 mm

(0.110 x 0.032 inch) slip on termination.

Printed circuit board mounting with 2.8 mm x 0.8

mm (0.110 x 0.032 inch) slip on termination. For use

with Z203 PCB mounting base. See page 9.

DUFBkk

DUFkkk

For snap mounting to operator. Has printed circuit

board stabs.

DVFkkk

DVFBkk

For soldering to printed circuit board. Does not snap

onto operator.

Ribbon cable connector. Snaps onto operator.

DRFkkk

N.O.

N.C.

N.O. – N.C.

N.O. – N.O.

N.C. – N.C.

N.O.

N.C.

N.O. – N.C.

N.O. – N.O.

N.C. – N.C.

N.O.

N.C.

N.O. – N.C.

N.O. – N.O.

N.C. – N.C.

N.O.

N.C.

N.O. – N.C.

N.O. – N.O.

N.C. – N.C.

N.O.

N.C.

N.O. – N.C.

N.O. – N.O.

N.C. – N.C.

6 to 120 V, 1.2 Watt Max. d

Momentary

Maintained k

DUF10

DUF01

DUF11

DUF20

DUF02

DUFB10

DUFB01

DUFB11

DUFB20

DUFB02

DVF10

DVF01

DVF11

DVF20

DVF02

DVFB10

DVFB01

DVFB11

DVFB20

DVFB02

DRF10

DRF01

DRF11

DRF20

DRF02

DUFR10

DUFR01

DUFR11

DUFR20

DUFR02

N/A

DVFR10

DVFR01

DVFR11

DVFR20

DVFR02

N/A

DRFR10

DRFR01

DRFR11

DRFR20

DRFR02

k Maintained operation is Push on - Push off.

d Contact ratings and lamp voltage can be limited by the type of mounting. i.e. printed circuit termination might not

carry full current because of the printed circuit board tracing.

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pages 11-12

Legends . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 10

Application Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 4

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 9

8

© 1997 Square D All Rights Reserved

11/97

Push Buttons and Operator Interface Specifiers Guide

Type D – 16 mm

Accessories

Type

Z201

Std. Pkg. Qty.t

Catalog Number

Ring Nut Wrench

1

Z201

Lamp Remover Tool

1

Z02

Closing Plate Black-Square

1

Z205

Closing Plate Black-Round

1

Z223

Replacement Mounting Ring Nut

1

Z216

Type

Voltage

Assembly Code

Std. Pkg. Qty. t

Catalog Number

6 Vac

06

10

Z206

12 Vac

12

10

Z207

24 Vac

24

10

Z208

48 Vac

48

10

Z209

60 Vac

60

10

Z210

24 V - Red

R4

5

Z219R

24 V - Green

G4

5

Z219G

24 V - Yellow

Y4

5

Z219Y

120 V - Red

R2

1

Z220R

Z02

Incandescent

(T 13⁄4)

LEDk 24 Vac/dc

Z205

LEDk 120 Vac

Std. Pkg. Qty.t

Catalog Number

Printed Circuit Board Adapter

For Type DU Contacts Only.

Type

1

Z203

Wire Harness.

For Type DU Contacts Only.

10

Z204

Z223

Z216

Type

Z2kk

Z204

Z203

Std. Pkg. Qty.t

Catalog Number

Replacement Key

(No 8D1)

1

Z18

Adjustable Spacer

(for rear fixing blocks)

4

Z220

Wire clip

2.8 mm x 0.8 mm (0.110 x 0.32 in.)

100

Z231

Ribbon Cable Connector

(for 4 wire DR Blocks)

25

Z228

Ribbon Cable Connector

(for 6 wire DR Blocks)

25

Z229

k

t

For use with illuminated operators of the same color as the LED.

Order must specify standard package quantity or multiples of that quantity.

Z18

Z220

Z231

Z22k

9

11/97

© 1997 Square D All Rights Reserved

Push Buttons and Operator Interface Specifiers Guide

Type D – 16 mm

Legend Plates

Type

Z213

Z215

Legend Plate with Holder

Anodized Aluminum

Z221

Z222

Marking

Z214

Z211

Z212

Std. Pkg. Qty.❋

Catalog Number

25

Z215

25

Z213

25

Z222

25

Z221

25

1

1

Z214

Z211

Z212

Legend Plate Holder with Blank Plate

Use with D5, D6 bezel

Legend Plate Holder Only, Use with D5

D6 bezel

Legend Plate Holder with Blank Legend

Use with D5, D6 bezel

Legend Plate Holder Only, Use with D5

D6 bezel

Blank Plate● without Holder (For use with all holders)

Yellow Contrast Plate-Round, 50 mm

Yellow Contrast Plate-Rectangular, 25 mm x 50 mm

Blank Legend

Special

Engraved

O

I

II

O I

II O I

Close

Down

Emerg. Stop

Fast

Forward

Hand Auto

Hand O Auto

High

In

Inch

Jog

Low

Lower

Off

Off On

On

Open

Out

Raise

Reverse

Run

Slow

Start

Stop

Stop Start

Test

Up

Legends Only

For D5, D6

Operators

Only

For D8, D9

Operators

Only

Legend

Plate

without

Holder

Catalog

Number

Catalog

Number

Catalog

Number

Mylar Inserts

White with

White with

Black Letters Black Letters

Legend Plate

for Round

for Square

without

Button

Button

Holder

Illuminated Illuminated

Devices

Devices

Catalog

Catalog

Catalog

Number

Number

Number

Z215

Z222

Z214

Z214

01D

01A

99Q2●

99R2●

99W2●

99S2●

N/A

N/A

02Q2

03Q2

04Q2

05Q2

34Q2

65Q2

77Q2

82Q2

78Q2

66Q2

21Q2

24Q2

80Q2

72Q2

74Q2

69Q2

81Q2

71Q2

63Q2

85Q2

62Q2

64Q2

73Q2

70Q2

67Q2

75Q2

79Q2

17Q2

18Q2

90Q2

84Q2

76Q2

02R2

03R2

04R2

05R2

34R2

65R2

75R2

82R2

78R2

66R2

21R2

24R2

80R2

72R2

74R2

69R2

81R2

71R2

63R2

85R2

62R2

64R2

73R2

70R2

67R2

75R2

79R2

17R2

18R2

90R2

84R2

76R2

02W2

03W2

04W2

05W2

34W2

65W2

77W2

82W2

78W2

66W2

21W2

24W2

80W2

72W2

74W2

69W2

81W2

71W2

63W2

85W2

62W2

64W2

73W2

70W2

67W2

75W2

79W2

17W2

18W2

90W2

84W2

76W2

03S2

04S2

05S2

34S2

65S2

77S2

82S2

78S2

66S2

21S2

24S2

80S2

72S2

74S2

69S2

81S2

71S2

63S2

85S2

62S2

64S2

73S2

70S2

67S2

75S2

79S2

17S2

18S2

90S2

84S2

76S2

65DE

77DE

82DE

78DE

66DE

65A

77A

82A

78A

66A

80DE

72DE

74DE

69DE

81DE

71DE

63DE

80A

72A

74A

69A

81A

71A

63A

62DE

64DE

73DE

70DE

67DE

75DE

79DE

62A

64A

73A

70A

67A

75A

79A

76DE

76A

● Engraving field is 16 mm x 22 mm. Factory engraving limited to 3 lines of 12 characters (including spaces). Black

letters on silver field.

❋ Order must specify standard package quantity or multiples of that quantity.

Legend Plate Dimensions

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 12

10

© 1997 Square D All Rights Reserved

11/97

Push Buttons and Operator Interface Specifiers Guide

Type D – 16 mm

Dimensions

Mounting conforming to DIN EN 50 007 and IEC 947 for

fixing holes with or without anti-rotation pip

13

25

25

9.8

15

9.8

A

A

25

1.5 - 6

16.2 +0.2

-0.0

29

18

18

29

A: d25

D5Gkk

D6Gkk

Ø25

D8Gkk

D9Gkk

A

1.5 - 6

A: d25

D5LkO

D6LkO

6

A

1.5 - 6

Ø25

A: d25

D8LkO

D5B1k

D9LkO

D6B1k

Potentiometer heads Integrated fixing

27

1.5 - 6

Ø25

D8B1k

D9B1k

Ø25

D5C1R

D9C1R

18

8

A

M7 x 0.75

6

A: d25

D5C1R

D6C1R

Board fixing

27

A

4

A

6

34

M16x1

18

18

M16x1

6

Ø25

D8A7k

D9A7k

È 31

È 31

M16x1

A

A

1.5 - 6

6

A: d25

D5A7k

D6A7k

M16x1

55

1.5 - 6

Ø25

D5A1k

D9A1k

M16x1

18

8

A: d25

D5A2k

D6A2k

M16x1

26

20

18

25

25

25

16.2 +0.2

-0.0

18

M16x1

25

1.7

1.7

Heads

without legend plate

25

M16x1

with legend plate

Push-buttons and pilot lights

50

1.5 - 6

A: d25

D5E1W

D6E1W

1.5 - 6

1.5 - 6

6

42 - 65

Ø25

D8E1W

D9E1W

A: d25

D5R1S

D6R1S

Ø25

D8R1S

D9R1S

A: d25

D5R3S

D6R3S

Ø25

D8R3S

D9R3S

Body

DVBkk

DRkk

41.5

9.5 13.5

40.5

17

9.5 13.5

42.5

DVkk

40.5

9.5 13.5

DUBkk

17

DUkk

42.5

Wiring Accessories

2.5

12.5

18

5.08

2.5

1

2.1

5

ø1.2

17

15

17

9.5 13.5

Z203

10.16

52

52

All dimensions are in

mm's. To convert to

approximate inches,

divide mm by 25.4.

Z204

7

DUBkk + Z203

16.5

DUkk + Z204

15.24

22

11

11/97

© 1997 Square D All Rights Reserved

Push Buttons and Operator Interface Specifiers Guide

Type D – 16 mm

Dimensions

Body

DUF

DUFkk

Pilot lights + contact

18

13

48

18

48

9.5 13.5

A

A

M16x1

M16x1

16

DUFB

DUFBkk

17

Pilot lights

Head

DVF

DVFkk

DVFB

DVFBkk

46

46

8

Ø25

D5V2k D8V1k

D5A2k

D8A1k

D6V2k D9V1k

D6A2k

D9A1k

17

A: d 25

DUF

DUFkk+Z204

DRF

DRFkkk

47

DUFB

DUFBkk + Z203

58

58

17

9.5 13.5

9.5 13.5

Head + DVkk

DVF

DVFkk

Head + DUkk

DUF

DUFkk + Z204

Head + DUkk

DUF

DUFkk + Z203

4

48.5

53.5

Adjustable spacer

Z220

9.5 13.5

9.5 13.5

9.5 13.5

48.5

Legend plate carrier

for square head

Z213

for round head

Z221

A:

d 25

Z205

44

44

15.5

39 - 58

M16 x 1

A

Blanking Plug

Head +DRkk

DRF

DRFkkk

58.5

64

48.5

9.5 13.5

1.5 - 6

Ø25

9.5 13.5

1.5 - 6

A: d25

Ø25

Z223

16.2

18.5

25

24.5

25

37

Legend plates

Z212

Z211

1.7

17.9

50

50

17.9

1.7

All dimensions are in mms. To convert to approximate inches, divide mm by 25.4.

16.2

16.2

25

12

© 1997 Square D All Rights Reserved

11/97

Push Buttons and Operator Interface Specifiers Guide

Push Buttons and

Operator Interface

Specifiers Guide

Type D – 16 mm

Dimensions

Type J, O, and XVL – Pilot Lights

Class 9001

CONTENTS

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page

Type J, Description and Selection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Type J, Dimensions and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Type O, Description and Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Type XVL, Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Type XVL, Selection and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

13

11/97

© 1997 Square D All Rights Reserved

Push Buttons and Operator Interface Specifiers Guide

Type J – Pilot Lights

Description and Selection

Pilot Lights, Push-To-Test and Remote Test Pilot Lights

JP1R29

Class 9001 Type J compact pilot lights are designed to be mounted in a .69" (11/16") diameter mounting

hole. Each terminal will accept up to two #14 AWG wires (CU only). Type J compact pilot lights meet

NEMA Type 4 (watertight) and NEMA Type 13 (oiltight) requirements. Type JT push-to-test pilot lights

have contacts built into the encapsulated body. Type JTR remote test pilot lights have dual inputs for one

push remote testing – all you need is a push button with a current rating equal to or greater than the total

lamp draw. Type JTR remote test pilot lights can also be energized from two separate input signals of

the same voltage and polarity. This is done by wiring the “test” terminal to the second input signal.

Standard Pilot Light

Style/Voltage

JTR1R29

File 25490

Class 3211 03

None

Trans/110-120Vac, 50-60 Hz

Incandescent/120 Vac or dc

Incandescent/24-28 Vac or dc

Other Voltagest

LED – 24-28 Vac

LED – 24-28 Vdc

LED – 120Vac

JP1R29

JP38R29

JP35R29

JPtR29

JP35LRR29

JP35DRR29

JP38LRR29

JP1G29

JP38G29

JP35G29

JPtG29

JP35LGG29

JP35DGG29

JP38LGG29

Yellow k

JP1Y29

JP38Y29

JP35Y29

JP tY29

JP35LYY29

JP35DYY29

JP38LYY29

Lamp

Volt/Amp

Replacement

Lamp

6.3 V, 0.15A

120 V, 0.015A

28 V, 0.040A

2550101020

2550101040

2550101024

28 V, 0.03A

28 V, 0.03A

28 V, 0.03A

(1)

(1)

(1)

Lamp

Volt/Amp

Replacement

Lamp

6.3 V, 0.15A

120 V, 0.15A

28 V, 0.040A

2550101020

2550101040

2550101024

28 V, 0.03A

28 V, 0.03A

28 V, 0.03A

(1)

(1)

(1)

Lamp

Volt/Amp

Replacement

Lamp

6.3 V, 0.15A

120 V, 0.015A

28 V, 0.040A

2550101020

2550101040

2550101024

28 V, 0.03A

(1)

Push-To-Test Pilot Light

Style/Voltage

File E42259

CCN NKCR

JP1

JP38

JP35

JPt

–

–

–

Color Cap

Redk

Greenk

None

Trans/110-120Vac, 50-60 Hz

Incandescent/120 Vac or dc

Incandescent/24-28 Vac or dc

Other Voltagest

LED – 24-28 Vac

LED – 24-28 Vdc

LED – 120 Vac

JT1

JT38

JT35

JTt

–

–

–

Color Cap

Red k

Green k

JT1R29

JT38R29

JT35R29

JTtR29

JT35LRR29

JT35DRR29

JT38LRR29

JT1G29

JT38G29

JT35G29

JTtG29

JT35LGG29

JT35DGG29

JT38LGG29

Yellow k

JT1Y29

JT38Y29

JT35Y29

JTtY29

JT35LYY29

JT35DYY29

JT38LYY29

Remote Test Pilot Light

Style/Voltage

None

Trans/110-120 Vac, 50-60 Hz

Incandescent/120 Vac

Incandescent/24-28 Vac

Other Voltages (ac Only)t

LED – 24-28 Vac

JTR1

JTR38

JTR35

JTRt

–

Color Cap

Red k

Green k

JTR1R29

JTR38R29

JTR35R29

JTRtR29

JTR35LRR29

JTR1G29

JTR38G29

JTR35G29

JTRtG29

JTR35LGG29

Yellow k

JTR1Y29

JTR38Y29

JTR35Y29

JTRtY29

JTR35LYY29

(1) See Page 18 for replacement LED lamps. For other voltage LED lamps contact local field office.

k Supplied with “plastic” color caps. If “glass” color caps are desired, substitute G26, R26, etc., for G29, R29, etc. Example:

JP1G26, JP1R26, etc. To order a pilot light with color cap not listed above, add the color cap type number from the table below

to the basic pilot light number. Example: For a standard 120 volt transformer style pilot light with a plastic amber color cap, order

a 9001JP1A29. LED lamps are only for use with plastic red, green or yellow color caps.

t Remote test (Type JTR) only is available in AC.

Voltage

JP/JT

Code

Incandescent/6 Vac or dc

Incandescent/12 Vac or dc

Incandescent/48 Vac or dc

Incandescent/60 Vac or dc

31

32

36

37

Other Voltagest

Replacement

Volt/Amp

Lamp

2550101020

2550101022

2550101025

2550101026

6.3 V, 0.15A

12 V, 0.17A

48 V, 0.053A

60 V, 0.05A

JTR

Code

Replacement

Lamp

Volt/Amp

31t

32t

36t

37t

2550101003

2550101022

2550101025

2550101026

3 V, 0.16A

12 V, 0.17A

48 V, 0.053A

60 V, 0.05A

14

© 1997 Square D All Rights Reserved

11/97

Push Buttons and Operator Interface Specifiers Guide

Type J – Pilot Lights

Dimensions and Accessories

Legend Plates

Max. No. of

Lines

Max. No. of

Characters

Catalog Number

Black Field

Red Field

Black Field

Red Field

Aluminum Field

2

2

2

2

2

8

8

8

8

16

JN100

JN100R

JN199

JN199R

JN700

Aluminum Field

2

16

JN799

Type

Blank

Special Marking (Specify

Marking)

Blank

Special Marking (Specify

Marking)

Replacement Color Caps - Class 9001, Type J

Catalog Number

Plastic

Glass

Color

Red

Green

Amber

Blue

Clear

White

Yellow

R29

G29

A29

L29

C29

W29

Y29

R26

G26

A26

L26

C26

W26

Y26

Replacement Parts - Class 9001, Type J

Type

Catalog Number

Ring Nut

6512909601

Locking Thrust Washer

6512909201

Trim Washer

6512909301

Rubber Sealing Washer

6512901801

Note:Octagonal ringnuts can be tightened with standard tools, or use the reverse end of Square D wrench

Class 9001 Type K95.

Type J Dimensions

Type

JTR1

JP, JT,

JTR31

through

JTR38

A

B

2.83" 1.20"

C

.93"

2.34" 1.11"

.84"

15

11/97

© 1997 Square D All Rights Reserved

Push Buttons and Operator Interface Specifiers Guide

Type O - Pilot Lights

Description and Selection

Instrument Type Incandescent Pilot Lights – Class 9001, Type O NEMA 13

Voltage AC/DC

Average Current (Amps)

12 V

Color

0.170

Type O

24 V

Red

OR12

Green

OG12

Amber

OA12

Clear

OC12

Yellow

OY12

White

OW12

Blue (Fluted)

FB12

Red

OR24

Green

OG24

0.073

120 Vt

Catalog Number

Amber

OA24

Clear

OC24

Yellow

OY24

White

OW24

Blue (Fluted)

FB24

Red

OR120

Green

OG120

0.025

Amber

OA120

Clear

OC120

Yellow

OY120

White

OW120

Blue (Fluted)

FB120

t This product is not recommended for continuous use at 120 V.

Replacement Lamps - Class 9001, Type O

Voltage

Sylvania Lamp Number

Square D Catalog

Number

12 V

24 V

120 V

12PSB

24PSB

120PSB

2550105003

2550105004

2550105005

Color

Catalog Number

Red

2550420020

Replacement Lenses* - Class 9001, Type O

Green

2550420040

Amber

2550420060

Clear

2550420010

Yellow

2550420030

White

2550430040

Blue

2550470010

Minimum Order Quantity 10

Approximate Dimensions

1.84

47

0.41

10

max panel

thickness

0.81

21

0.68

mtg hole

17.5 required

A30064-963

0.20

5

0.02

thickness

.5

width

Dual Dimensions inches

mm

16

© 1997 Square D All Rights Reserved

11/97

Push Buttons and Operator Interface Specifiers Guide

XVL Miniature LED Pilot Lights

Specifications

General

This new Telemecanique range of LED pilot lights meets the very latest requirements in signalling

techniques.

Because of their small size, Ø8 and Ø12 mm fixing pilot lights are particularly suitable for the following

applications:

• mounting on small control stations.

• shallow depth mounting.

• large number of signalling units on a control station (low power dissipation).

Small diameter LED pilot lights also have sealed front faces (IP 65 option available). An unsealed Ø8

mm fixing model with protruding LED and black bezel (aesthetic appearance) is also offered.

Advantages:

LED pilot lights have many advantages:

• very long life and so low maintenance costs (bulb test no longer required).

• highly resistant to shocks, vibrations and over-voltage.

• low power consumption which, for example, allows compatibility with programmable controller outputs

by parallel connection with the load, to give a direct indication of output state.

• very high reliability.

Quick fixing by means of tags for soldered clips for Ø8 mm type, or threaded connectors Ø12 mm type.

Safe connection due to integral ballast resistor and reverse polarity protection device.

Conforming to standards

IEC 947-5-1, NF C 63-140, VDE 0660-200.

Protective treatment

Standard version: “TC” treatment.

Ambient temperature

Operation: -25 °C to + 70 °C (-13 °F to +158 °F). Storage: -40 °C to + 70 °C (-40 °F to

+158 °F).

Electric shock protection

Class III conforming to IEC 536 and NF C 20-030.

Degree of protection

IP 40 (IP 65 with seal) conforming to IEC 529 and NF C 20-010.

Current consumption

25 mA.

Rated Insulation voltage

50 V conforming to NF C 20-040, VDE 0110.

Life

Can exceed 100,000 hours.

—)

Voltage limits including ripple (---

0.8 UN ≤ U ≤1.2 Un.

Terminal referencing

Polarity marked + – conforming to CENELEC EN 50013.

Cabling

XVLA1kk, XVLA2kk: tags for 2.8 x 0.5 mm quick connectors, also for soldered

connections.

XVLA3kk: threaded connectors, clamping, capacity: min. 1 - 26 AWG solid or stranded,

max. 1 - 16 AWG solid or stranded.

Dimensions

LED pilot lights

O8, with black bezel,

visible LED XVL-A1..

O 8, with lens incorporated,

protected LED XVL-A2

E

E

E

M8 x 0,5

O 16

M12 x 1

O10

O12

M8 x 0.5

12

1.5

O 12, with lens incorporated,

protected LED XVL-A3

10

12

32

1.5

E - mounting plate thickness 1 to 8 mm

6

34

E - mounting plate thickness 1 to 8 mm

45

E - mounting plate thickness 1 to 6 mm

All dimensions are in mms. To convert to approximate inches, divide mm by 25.4.

Marking

File LR 44087

Class 3211 03

File E164353

CCN NKCR2

For Declaration of Conformity, see page 230.

17

11/97

© 1997 Square D All Rights Reserved

Push Buttons and Operator Interface Specifiers Guide

XVL Miniature LED Pilot Lights

Selection and Accessories

With Black Bezel, Raised LED

Description

Supply Voltage DC

Color

XVLA113

Red

XVLA114

5V

XVLA1kk

Ø8 mm

with integral ballast resistor

and reverse polarity protection diode

12 V

Degree of protection IP 40

24 V

Catalog Number

Green

Orange-yellow

XVLA115

Green

XVLA123

Red

XVLA124

Orange-yellow

XVLA125

Green

XVLA133

Red

XVLA134

Orange-yellow

XVLA135

Green

XVLA143

Red

XVLA144

Orange-yellow

XVLA145

48 V

With Integral Lens Cap, Covered LED

Description

Supply Voltage DC

Color

XVLA213

Red

XVLA214

5V

XVLA2kk

(1)

Ø8 mm

with integral ballast resistor

and reverse polarity protection diode

12 V

Degree of protection IP 40

24 V

Orange-yellow

XVLA215

Green

XVLA223

Red

XVLA224

Orange-yellow

XVLA225

Green

XVLA233

Red

XVLA234

Orange-yellow

XVLA235

Green

XVLA243

Red

XVLA244

48 V

Orange-yellow

XVLA245

Green

XVLA313

Red

XVLA314

5V

XVLA3kk

(2)

Ø12 mm

with integral ballast resistor

and reverse polarity protection diode

12 V

Degree of protection IP 40

24 V

XVL-X..

Orange-yellow

XVLA315

Green

XVLA323

Red

XVLA324

Orange-yellow

XVLA325

Green

XVLA333

Red

XVLA334

Orange-yellow

XVLA335

Green

XVLA343

Red

XVLA344

Orange-yellow

XVLA345

48 V

XVLXkk

Catalog Number

Green

Accessories

Description

XVLZ91k

XVL-Z91.

Catalog Number

Tightening tools

(Sold singly)

For Ø8 mm pilot lights

XVLX08

For Ø12 mm pilot lights

XVLX12

Seals (IP 65)

(Sold in lots of 10)

For Ø8 mm pilot lights

XVLZ911

For Ø12 mm pilot lights

XVLZ912

1 Quick Connects (2.8 mm x 0.5 mm)

2 Screw Termination

18

© 1997 Square D All Rights Reserved

11/97

Push Buttons and

Operator Interface

Specifiers Guide

XA2B 22 mm, Double Insulated

CONTENTS

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page

General Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Non-Illuminated Operators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Mushroom Operators and Yellow Contrast Plates. . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Selector, Toggle, and Reset Switches. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Pilot Lights and Light Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Illuminated Operators and Selector Switches. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Square Illuminated Push Buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Contact Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Legend Plate Carriers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Accessories and Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

XALB General Purpose Control Stations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

XALB Enclosures and Base Mounted Components . . . . . . . . . . . . . . . . . . . . . . . . . 33

XALB Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

XA2B 22 mm Mounting Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Push Buttons and Operator Interface Specifiers Guide

XA2B 22 mm

Double Insulated

Environment

XB2B, XD2P: IEC-947-5-1, EN60947-5-1, NF C 63-140, ASE 0119, ASE 1003, BS 4794, VDE 0660-200, UL 508,

CSA C 22-2 No. 14.

CSA and UL: push buttons and selector switches NEMA Type A600 - Q600, pilot lights and illuminated push buttons

direct supply (120 V max); pilot lights and illuminated push buttons with transformer (600 V)

Approvals

ASE, DEMKO, NEMKO, SEMKO, BUREAU, VERITAS, SAHKOTARKASTUSKESKUS, GL, DNV, LROS

XD2P, standard version: CSA A600-Q600, LROS.

Protective treatment

Standard Version: “TC” (all climates).

Ambient temperature

Storage: -40 °C to +70 °C (-40 °F to +158 °F.). Operating: -25 °C to +70 °C (-13 °F to +158 °F.).

60 mm diameter mushroom head: 8 g. Other push buttons: 15 g. Small joystick controllers: 5g (from 40 to 50 Hz)

Resistance to vibration

conforming to IEC 68-2-6.

Push buttons: 70 g. Mushroom head push buttons: 15 g.

Resistance to shock

Selector switches: 120 g. Conforming to IEC 68-2-27.

Electric shock protection

XB2B, XD2P: Class 1, conforming to IEC 536 and NF 20-030.

NEMA ratings XB2B: 1, 2, 4, 4x, 12K, 13, XB2B, XD2P.

Degree of protection conforming to IEC 529

IP 65: flush and protecting, illuminated and non-illuminated push buttons (mounted).

and NEC 20-010.

IP 40: double-headed push buttons (IP 65 on request).

Push buttons -- 3 million operations. Latching mushroom head push buttons: 300,000 operations. Illuminated selector

switches: 100,000 operations. (The product life expressed is based on average usage and normal operating conditions.

Mechanical life

Actual operating life will vary with conditions. The above statements are not intended to nor shall they create any express

or implied warranties as to product operation or life. For information on the warranty offered on this product, please refer

to the Square D terms and conditions of sale found in the Square D Digest.)

Conformity to standards

Contact block characteristics

Nominal thermal current

Nominal insulation voltage

Insulation catagory

Contact operation

Contact resistance

Operating force

Terminal referencing

Short circuit protection

Rated power

conforming to IEC 947-5-1 Appendix C

duty categories AC15-DC13

Operating frequency: 3,600 ops/hour

Load factor: 0.5

AC supply (50-60 Hz)

10 A conforming to IEC 947-5-1, NF C 63-140, UL 508, CSA 22-2 No. 14, VDE 0660 part 2, NEMA Type A600-Q600.

500V conforming to NF C 20-040, VDE 0110, IEC 158-1, 600V conforming to UL 508, 600v conforming to

CSA 22-2 No. 14.

Group C conforming to NF C 20-040 and VDE 0110.

Slow-make N.O. or slow-break N.C. N.C. with direct opening operation conforming to EN 60 947-5-1 Section 3.

≤25 mΩ conforming to: NF C 93-050 method A or IEC 225-7 category 3.

Flush or projecting push buttons - with 1 NO contact: 2.25 lb - with 1 NC contact: 1.8 lb

Additional contacts - N.O.: add 1 lb - N.C.: add 0.7 lb.

Conforming to CENELEC EN 50013.

10 A cartridge fuses, g1 or N conforming to IEC 269-1 and VDE 0660-200.

DC supply

Power broken in watts

for 1 million operations

Voltage

24 V 48 V 120 V

Inductive

65 W 48 W 40 W

load

File E164353

CCN NKCR

File LR 44087

Class 3211 03

millions of operations

AC Ratings, Inductive - NEMA A600

127 V

220 V 24/48 V

1

35% Power factor

06

04

Volts

Make

Amperes

VA

Break

Amperes

02

120

240

480

600

60

30

15

12

7200

7200

7200

7200

6

3

1.5

1.2

ith = 10 A

01

.06

.04

VA

Continuous

carrying

Amperes

720

720

720

720

10

10

10

10

Resistive 75%

Power factor

Make, Break and

continuous

Amperes

10

10

10

10

For Declaration of Conformity,

see page 226.

DC Ratings, NEMA Type Q600

Inductive and resistive

.02

Volts

Make and break

Continuous

.01

125

0.55

2.5

250

0.27

2.5

600

0.10

2.5

1

Cabling

Marking

2

4 6 10 20 40 60

current in amperes

XB2B, XD2P: Screw and captive clamp terminals. Recommended torque 15.62 lb-in. Capacity: minimum 1 x .5mm2

(20 AWG), solid or stranded, maximum with or without cable end: 2 x 1.5 mm2(16 AWG) or 1 x 2.5 mm2 (14 AWG) or by

cable clips conforming to NF C 20-120 (on request).

XA2B Non-Illuminated Operators . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 21-23

XA2B Illuminated Operators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 25-27

XA2B Pilot Lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 24

Contact Blocks & Light Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 28

Legend Plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 29

Enclosures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 32-34

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 31

Mounting Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 35

20

© 1997 Square D All Rights Reserved

11/97

Push Buttons and Operator Interface Specifiers Guide

XA2B 22 mm

Non-Illuminated Operators

Operator

Type

Size

Flush head

Flush head

ZA2BA•

Flush head

premarked

Transparent flush head

ZA2BA•8

Transparent flush head

(for use with ZB2BY1• stick on legends

see page 30)

Extended head

Extended head

ZA2BL•

Extended head

premarked

Silicone booted head

Booted head

ZA2BP•

Neoprene booted head

Flush plunger

(with full guard)

Flush plunger

(with half guard)

Two flush

Two flush

premarked

Two button operators

One flush,

one extended

One flush, one extended

premarked

Color

White

Black

Green

Red

Yellow

Blue

Grey

Green “START”

Green “ON”

White “I”

Black “O”

Green “I”

Red “O”

Red “STOP”

Red “OFF”

Green

Red

Yellow

Blue

Clear

White

Black

Green

Red

Yellow

Blue

Red “STOP”

Red “O”

Red “OFF”

Black

Green

Red

Yellow

Blue

Black

Green

Red

Yellow

Blue

Black

Green

Red

Yellow

Blue

Black

Green

Red

Yellow

Blue

Black/Red

Green/Red

Black/Red “I/O”

Green/Red “I/O”

Black/Red “START/STOP”

Green/Red “START/STOP”

Black/Red

Green/Red

Black/Red “I/O”

Green/Red “I/O”

Black/Red “START/STOP”

Green/Red “START/STOP”

Catalog

Number

ZA2BA1

ZA2BA2

ZA2BA3

ZA2BA4

ZA2BA5

ZA2BA6

ZA2BA8

ZA2BA333

ZA2BA341

ZA2BA131

ZA2BA232

ZA2BA331

ZA2BA432

ZA2BA434

ZA2BA435

ZA2BA38

ZA2BA48

ZA2BA58

ZA2BA68

ZA2BA78

ZA2BL1

ZA2BL2

ZA2BL3

ZA2BL4

ZA2BL5

ZA2BL6

ZA2BL434

ZA2BL432

ZA2BL435

ZA2BP2

ZA2BP3

ZA2BP4

ZA2BP5

ZA2BP6

ZA2BP02

ZA2BP03

ZA2BP04

ZA2BP05

ZA2BP06

ZA2BA24

ZA2BA34

ZA2BA44

ZA2BA54

ZA2BA64

ZA2BA22

ZA2BA32

ZA2BA42

ZA2BA52

ZA2BA62

ZA2BA9124

ZA2BA9134

ZA2BA9224

ZA2BA9234

ZA2BA9724

ZA2BA9734

ZA2BL9324

ZA2BL9334

ZA2BL9424

ZA2BL9434

ZA2BL9824

ZA2BL9834

Application Information. . . . . . . . . . . . . . . . . . . . . . . . . . Page 20 Enclosures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 32-34

Contact Block Assemblies . . . . . . . . . . . . . . . . . . . . . . . Page 28 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 31

Legend Plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 29

21

11/97

© 1997 Square D All Rights Reserved

Push Buttons and Operator Interface Specifiers Guide

XA2B 22 mm

Mushroom Operators and Yellow Contrast Plates

Operator

Type

Size

30 mm

Mushroom Head

Momentary 30 mm

ZA2BC•4

Mushroom head

momentary

40 mm

60 mm

30 mm

Mushroom Head

Momentary 40 mm

ZA2BC•

Mushroom head

Latching

Push-Pull

40 mm

60 mm

Mushroom head

Latching

Turn to Release

Mushroom head

Latching, Turn to Release Trigger Actionf

Mushroom Head Turn to

Release 40 mm

ZA2BS54

Mushroom head

Latching

Key to Releasej

Mushroom head

Latching, Key to Release Trigger Actionfj

30 mm

40 mm

60 mm

30 mm

40 mm

30 mm

40 mm

60 mm

30 mm

40 mm

Color

Catalog Number

Black

Green

Red

Yellow

Blue

Black

Green

Red

Yellow

Blue

Black

Red

Black

Red

Black

Red

Black

Red

Red

Red

Red

Red

Red

Red

Red

Red

Red

Red

ZA2BC24

ZA2BC34

ZA2BC44

ZA2BC54

ZA2BC64

ZA2BC2

ZA2BC3

ZA2BC4

ZA2BC5

ZA2BC6

ZA2BR2

ZA2BR4

ZABT24

ZABT44

ZA2T2

ZA2BT4

ZA2BX2

ZA2BX4

ZA2BS44

ZA2BS54

ZA2BS64

ZA2BS834

ZA2BS844

ZA2BS74

ZA2BS14

ZA2BS24

ZA2BS934

ZA2BS944

f Key release operators come with Ronis #455 keys (quantity 2) as standard. For replacement keys see page 30. For

switches keyed with different keys, add the suffixes shown in the table below (no change in price). For other key numbers,

contact local field office.

Mushroom Head Key to

Release 40 mm

ZA2BS14

Key Number

Suffix

421

12

458A

10

520

14

3131A

20

j Trigger action mushroom heads are "tamper proof" whereby a change of contact state is not possible by “teasing” or

floating the operator.

ERGEN

M

Y

C

E

Yellow Contrast Plates▼

ST

OP

ZB2BY8330

PVC Yellow Legend Plates 60 mm diameter

Text

Language

Catalog

Number

Blank

Emergency Stop

Arret d’Urgence

Not Aus

Parada de Emergencia

Arresto Emergenza

N/A

English

French

German

Spanish

Italian

ZB2BY9101

ZB2BY9330

ZB2BY9130

ZB2BY9230

ZB2BY9430

ZB2BY9630

PVC Yellow Legend Plates 90 mm diameter

Text

Language

Catalog

Number

Blank

Emergency Stop

Arret d’Urgence

Not Aus

Parada de Emergencia

Arresto Emergenza

N/A

English

French

German

Spanish

Italian

ZB2BY8101

ZB2BY8330

ZB2BY8130

ZB2BY8230

ZB2BY8430

ZB2BY8630

▼ Yellow Contrast Plates comply with EN418 of the European Machinery Directive 89/392/EEC.

Application Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 20

Contact Block Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 28

Legend Plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 29

Enclosures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 32-34

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 31

22

© 1997 Square D All Rights Reserved

11/97

Push Buttons and Operator Interface Specifiers Guide

XA2B 22 mm

Selector, Toggle, and Reset Switches

Non-illuminated selector switches

Type

Catalog

Number

Positions, Action

Standard handle

or extended lever t

Standard

ZA2BD•

2-maintained

2-spring return from right to left

3-maintained

3-spring return to center from left and right

3-spring return from right to center

3-spring return from left to center

ZA2BD2

ZA2BD4

ZA2BD3

ZA2BD5

ZA2BD8

ZA2BD7

Key selectors

Type

Positions, Action

Extended

ZA2BJ•

Key switch f

Key Switch

ZA2BG•

2-maintained

2-maintained

2-spring return right to left

3-maintained

3-maintained

3-maintained

3-maintained

3-spring return to center

from left and right

3-spring return to center

from left

3-spring return to center

from right

Key

removal

Catalog

Number

Left

Left, Right

Left

All

Center

Left, Right

Left

ZA2BG2

ZA2BG4

ZA2BG6

ZA2BG0

ZA2BG3

ZA2BG5

ZA2BG9

Center

ZA2BG7

Right

ZA2BG1

Center

ZA2BG8

Selector Switch Sequences (using contact block assemblies, page 28)

2 Position selector switch

3 Position selector switch

Contact block guide

O

X

O

Contact block guide

X

O

X

1 N.O. (left or right)

1 N.C. (left or right)

1 N.O.

and

X

O

1 N.C.

Note: View from front of panel

X

O

O

X

O

X

O

X

O

X

X

O

O

O

X

O

X

X

1 N.O. (left)

2 NC wired in series (side-by-side)

1 N.O. (right)

1 N.C. (right)

1 N.C. (left)

2 NO wired in parallel (side-by-side)

Toggle switch

Description

Color

Catalog

Number

Two position toggle switch

Black

ZA2BD28

Reset buttons (Mechanical overload resets 10 mm travel)

Toggle Switch

ZA2BD28

NEMA Type 4X

(not suitable

for use with

ZA2BZ10•

body/contact

assemblies)

Blank

Flush

with legend

O

R

Extended

with legend

O

head

Plunger (may be trimmed to length desired)

The total operating distance may be set between 17 and 120 mm,

as measured from the front face of the panel.

Green

Red

Blue

Red

Blue

ZA2BA83

ZA2BA84

ZA2BA86

ZA2BA8401

ZA2BA8602

Red

ZA2BL8401

ZA2BZ13

When ordering extended lever, substitute “J” for “D” in part number (No additional cost).

Example: ZA2BD3 becomes ZA2BJ3

f Key selector switches come with Ronis #455 keys (quantity 2) as standard. For replacement keys see page 30.

For other key numbers contact local field office.

For switches keyed with different keys, add the following suffixes:

t

ZA2BA8602

Key Number

Suffix

421

458A

520

3131A

12

10

14

20

Application Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 20

Contact Block Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 28

Legend Plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 29

Enclosures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 32-34

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 31

23

11/97

© 1997 Square D All Rights Reserved

Push Buttons and Operator Interface Specifiers Guide

XA2B 22 mm

Pilot Lights and Light Modules

Pilot light head

Type

Color

Catalog Number

White

Standard

Standard

ZA2BV0•

Special lens for

neon and LED lamps

ZA2BV01

Green

ZA2BV03

Red

ZA2BV04

Amber

ZA2BV05

Blue

ZA2BV06

Clear

ZA2BV07

Green

ZA2BV033

Red

ZA2BV043

Amber

ZA2BV053

Blue

ZA2BV063

Clear

ZA2BV073

Pilot light modules

ZA2BV6

Type

Catalog Number

Direct supply (bulb included) a (AC/DC)

ZA2BV6a

Transformer type (AC only) 1.2 VA/6 V (bulb included)f

ZA2BV3

24 V

ZA2BV1

48 V

ZA2BV2

110/120 V

ZA2BV3

220/240 V

ZA2BV94

440/480 V

ZA2BV95

550/660 V

ZA2BV98

Resistor type 130 V (bulb included)

220/250 V

ZA2BV7

a Complete catalog number by adding one of the following voltages: 6, 12, 24, 48 or 120 V. If desired without bulb, omit voltage.

f Additional primary voltages are available. Contact local field office for details.

Lamps

Voltage

AC/DC

Type

Incandescent

Replacement bulbs

(Type BA9s)

DLICE • • •

(incandescent)

Neon

(use with direct supply light module)

Type

DLICJUS • • •

(LED)

LED, BA9s base for

Direct Supply blocks

LED, BA9s base for

retrofitting into transformer Light

Modules

Watts

Catalog Number

6

1.5

DL1CB006

12

2.0

DL1CE012

24

2.0

DL1CE024

48

2.4

DL1CE048

130

2.6

120

-

NE51HRT120V

220

-

NE51HRT220V

380

-

NE51HRT380V

Color

Voltage

Part Number

DL1CE130

Green

6 Vac/dc

DL1CJUS0063

Red

6 Vac/dc

DL1CJUS0064

Amber

6 Vac/dc

DL1CJUS0065

Green

12 Vac/dc

DL1CJUS0123

Red

12 Vac/dc

DL1CJUS0124

Amber

12 Vac/dc

DL1CJUS0125

Green

24 Vac/dc

DL1CJUS0243

Red

24 Vac/dc

DL1CJUS0244

Amber

24 Vac/dc

DL1CJUS0245

Green

120 Vac/dc

DL1CJUS1203

Red

120 Vac/dc

DL1CJUS1204

Amber

120 Vac/dc

DL1CJUS1205

Green

9 Vac only

DL1CJUS0093

Red

9 Vac only

DL1CJUS0094

Amber

9 Vac only

DL1CJUS0095

Application Information . . . . . . . . . . . . . . . . . . . . . Page 20

Replacement parts (bulbs & lenses). . . . . . . . . . . Page 30

Legend Plates. . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 29

Enclosures . . . . . . . . . . . . . . . . . . . . . . . . . . .Pages 32-34

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 31

24

© 1997 Square D All Rights Reserved

11/97

Push Buttons and Operator Interface Specifiers Guide

XA2B 22 mm

Illuminated Operators

Illuminated operators

Type

Color

Flush head

Flush head

ZA2BW3•

Flush head for neon and LED lamps

Extended head

Extended head

ZA2BW1•

Extended head for neon and LED lamps

With half guard

Half guard

ZA2BW3•2

Illuminated Turn-to-Release

mushroom head

Amber indicator

Two flush

Turn to release

ZA2BW7•

Two flush

premarked

Two button momentary

action operators

NEMA Type 1 only f

Amber indicator

One flush,

one extended

One flush

extended,

premarked

f

Catalog Number

White

Green

Red

Amber

Blue

Clear

Green

Red

Amber

Blue

Clear

White

Green

Red

Amber

Blue

Clear

Green

Red

Amber

Blue

Clear

White

Green

Red

Amber

Blue

Clear

Green

Red

Yellow

Blue

Clear

Black/Red

Green/Red

Black/Red “I/O”

Green/Red “I/O”

Black/Red “Start/Stop”

Green/Red “Start/Stop”

Black/Red

ZA2BW31

ZA2BW33

ZA2BW34

ZA2BW35

ZA2BW36

ZA2BW37

ZA2BW333

ZA2BW343

ZA2BW353

ZA2BW363

ZA2BW373

ZA2BW11

ZA2BW13

ZA2BW14

ZA2BW15

ZA2BW16

ZA2BW17

ZA2BW133

ZA2BW143

ZA2BW153

ZA2BW163

ZA2BW173

ZA2BW312

ZA2BW332

ZA2BW342

ZA2BW352

ZA2BW362

ZA2BW372

ZA2BW73

ZA2BW74

ZA2BW75

ZA2BW76

ZA2BW77

ZA2BW81254

ZA2BW81354

ZA2BW82254

ZA2BW82354

ZA2BW87254

ZA2BW87354

ZA2BW83254

Green/Red

ZA2BW83354

Black/Red “I/O”

Green/Red “I/O”

Black/Red “Start/Stop”

Green/Red “Start/Stop”

ZA2BW84254

ZA2BW84354

ZA2BW88254

ZA2BW88354

To upgrade to NEMA Type 3, 4 & 13 order silicon boot ZB2BW008.

Application Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 20

Light modules with Contact Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 28

Legend Plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 29

Replacement Parts (lenses) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 30

Enclosures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 32-34

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 31

25

11/97

© 1997 Square D All Rights Reserved

Push Buttons and Operator Interface Specifiers Guide

XA2B 22 mm

Illuminated Selector Switches

Selector Switches

Number of positions, action

2-maintained

Illuminated selector

ZA2BK1••

Catalog

Number

Color

Green

ZA2BK123

Red

ZA2BK124

Amber

ZA2BK125

Blue

ZA2BK126

Clear

ZA2BK127

2-spring return

Green

ZA2BK143

from right to left

Red

ZA2BK144

3-maintained

3-spring return to

center from right and left

3-spring return

from right to center

3-spring return

from left to center

Amber

ZA2BK145

Blue

ZA2BK146

Clear

ZA2BK147

Green

ZA2BK133

Red

ZA2BK134

Amber

ZA2BK135

Blue

ZA2BK136

Clear

ZA2BK137

Green

ZA2BK153

Red

ZA2BK154

Amber

ZA2BK155

Blue

ZA2BK156

Clear

ZA2BK157

Green

ZA2BK183

Red

ZA2BK184

Amber

ZA2BK185

Blue

ZA2BK186

Clear

ZA2BK187

Green

ZA2BK173

Red

ZA2BK174

Amber

ZA2BK175

Blue

ZA2BK176

Clear

ZA2BK177

Selector Switch Sequences (using light module/contact block assemblies, page 28)

2 Position selector switch

3 Position selector switch

Contact block guide

O

X

O

X

O

X

1 N.O. (left or right)

1 N.C. (left or right)

1 N.O.

and

X

O

1 N.C.

Note: View from front of panel

Contact block guide

X

O

O

X

O

X

O

X

O

X

X

O

O

O

X

O

X

X

1 N.O. (left)

2 NC wired in series (side-by-side)

1 N.O. (right)

1 N.C. (right)

1 N.C. (left)

2 NO wired in parallel (side-by-side)

Application Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 20

Light modules with Contact Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 28

Legend Plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 29

Replacement Parts (lenses) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 30

Enclosures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 32-34

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 31

26

© 1997 Square D All Rights Reserved

11/97

Push Buttons and Operator Interface Specifiers Guide

XA2B 22 mm

Square Push Buttons

Standard operators t

Description

Type

Flush

ZA2CAk

Push buttons

Extended head

Color

Catalog

Number

Black

ZA2CA2

Green

ZA2CA3

Red

ZA2CA4

Yellow

ZA2CA5

Blue

ZA2CA6

Black

ZA2CL2

Green

ZA2CL3

Red

ZA2CL4

Yellow

ZA2CL5

Blue

ZA2CL6

White

ZA2CV01

Standard pilot lightsf

ZA2CVO k

Green

ZA2CV03

Red

ZA2CV04

Yellow

ZA2CV05

Blue

ZA2CV06

Clear

ZA2CV07

White

ZA2CW31

Illuminated push buttonsj

Flush push button

heads

ZA2CW1k

Projecting

push button heads

Green

ZA2CW33

Red

ZA2CW34

Yellow

ZA2CW35

Blue

ZA2CW36

Clear

ZA2CW37

White

ZA2CW11

Green

ZA2CW13

Red

ZA2CW14

Yellow

ZA2CW15

Blue

ZA2CW16

Clear

ZA2CW17

Accessories for square push buttons

Mounting Tool

t

f

j

Ring Nut Wrench and Lens Extractor

ZA2CZ12

For use with contact block assemblies, page 28.

For use with pilot light modules, page 24.

For use with light module / contact block assemblies, page 28.

Application Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 20

Contact Block Assemblies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 28

Light modules with Contact Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 28

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 31

27

11/97

© 1997 Square D All Rights Reserved

Push Buttons and Operator Interface Specifiers Guide

XA2B 22 mm

Contact Block Assemblies

Contact block assemblies

contact blocks and mounting collar for XA2B pilot devices s

Contacts

N.O. N.C.

Description

1 Contact block

Contact block

with mounting collar

ZA2BZ101

2 Contact blocks

Catalog Number

1

-

ZA2BZ101

-

1

ZA2BZ102

2

-

ZA2BZ103

-

2

ZA2BZ104

1

1

ZA2BZ105

Additional contact blocks u

Description

For converting body/contact

assemblies to 3, 4, 5 or 6

contacts max or replacing

1st or 2nd contact blocks

Additional contact block

ZB2BE10k

Contact

N.O.

N.C.

■

Type

Catalog Number

Standard

ZB2BE101

Standard

ZB2BE102

Mounting collar only

for attaching contact block(s) to

operator heads

ZA2BZ009

Light module assemblies

mounting collar with light module and contact blocks for XA2B pilot devicess

Contacts

N.O. N.C.

Description

Catalog Number

Direct supply incandescent bulb included (AC/DC) j

Mounting collar

ZA2BZ009

Without contacts

1

-

ZA2BW061+

1 Contact block

-

1

ZA2BW062+

2

-

ZA2BW063+

-

2

ZA2BW064+

1

1

ZA2BW065+

2 Contact blocks

Transfomer type (1.2 VA/6 V incandescent bulb included) (AC only)fj

Without contacts◆

1

-

1 Contact block

-

1

ZA2BW0 t2

2

-

ZA2BW0 t3

-

2

ZA2BW0t4

1

1

ZA2BW0t5

2 Contact blocks

Transformer type

ZA2BWOt1

ZA2BW0 t1

Resistor type (130 V incandescent bulb included) 220-250 V supply

2 Contact blocks

1

1

ZA2BW075

■

N.C. contact is direct opening operation conforming to EN 60 947-5-1, Section 3.

+ Complete catalog number by adding one of the following voltages: 6, 12, 24, 48 or 120 V. If desired without bulb, omit

voltage.

t Select proper digit for desired primary voltage: 1 (24 V 50/60 Hz) 2 (48 V 50/60 Hz) 3 (110/120 V 50/60 Hz) 94

(220/240 V 60 Hz) 95 (440/480 V 60 Hz) 98 (550/600 V 60 Hz).

f Additional primary voltages are available. Contact local field for details.

u Non- illuminated devices can be configured with 6 contact blocks maximum (3 decks of 2).

j Illuminated devices can be configured with a light module and 4 contact blocks maximum (2 decks of 2).

s Contact blocks and light module assemblies are available with quick connectors. Add suffix “3” to end of part number.

Example: ZB2BE101 becomes ZB2BE1013.

Application Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 20

Replacement Parts (bulbs) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 30

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 31

28

© 1997 Square D All Rights Reserved

11/97

Push Buttons and Operator Interface Specifiers Guide

XA2B 22 mm

Legend Plate Carriers

Legend plate carriers (30 x 40 mm) for XA2B pilot devices

Complete with “snap-in” (27 x 8 mm) legend plates, with standard text.

“Start” functions: white characters on black. “Stop” functions: white characters on red.

Catalog

Number

Standard texts

Standard text

ZA2BZ32326

30 x 40 mm

Carrier only

ZA2BZ32

Standard texts

Catalog

Number

Auto-Hand

ZA2BZ32364

Off

Auto-O-Hand

ZA2BZ32385

On

ZA2BZ32312

ZA2BZ32311

Off-On

ZA2BZ32367

Open

ZA2BZ32313

Auto

ZA2BZ32115

Power On

ZA2BZ32326

Close

ZA2BZ32314

Reset

ZA2BZ32323

Down

ZA2BZ32308

Reverse

ZA2BZ32306

Emergency Stop

ZA2BZ32330

Run

ZA2BZ32334

Fast

ZA2BZ32328

Slow

ZA2BZ32327

Forward

ZA2BZ32305

Start

ZA2BZ32303

Hand

ZA2BZ32316

Stop

ZA2BZ32304

Inch

ZA2BZ32321

Up

ZA2BZ32307

Hand-O-Auto

ZA2BZ32387

Description

Complete with “snap-in”

(27 x 8 mm) legend plates, blank

Color

Catalog

Number

Black or red background

ZA2BZ32101

White or yellow background

Legend plate carriers only

ZA2BZ32102

ZA2BZ32

Snap in blank only (27 X 8 mm)

Black or red background

ZA2BY4101

White or yellow background

ZA2BY4102

Legend plate carriers (30 x 50 mm) for XA2Bf pilot devices

Description

30 x 50 mm

ZA2BZ33

Complete with “snap-in”

(27 x 18 mm) legend plates, blank

Color

Catalog

Number

Black or red background

ZA2BZ33101

White or yellow background

Legend plate carriers only

ZA2BZ33102

ZA2BZ33

Snap in blank only (27 x 18 mm)

Black or red background

ZA2BY5101

White or yellow background

ZA2BY5102

Legend carrier for square aspect head (30 x 40 mm) for XA2B pilot devices

With “snap-in” blank legend plate

Black or red background

White or yellow background

ZA2BZ34101

ZA2BZ34102

Legend plate carriers only

ZA2BZ34

No legend square aspect ring

ZA2BZ31

Legend carrier for square aspect head (30 x 50 mm) for XA2B pilot devices

30 x 40 mm

Square aspect

ZA2BZ34

With “snap-in” blank legend plate

Black or red background

White or yellow background

Legend plate carriers only

ZA2BZ35101

ZA2BZ35102

ZA2BZ35

30 x 50 mm

Square aspect

ZA2BZ35

29

11/97

© 1997 Square D All Rights Reserved

Push Buttons and Operator Interface Specifiers Guide

XA2B 22 mm

Accessories and Replacement Parts

Accessories

Type

Description

Guards/Locks

Closing plates

22 mm

Closing plate

ZB2SZ3

Miscellaneous Accessories

Tools

Push on/push off

mechanism

ZB2BZ21

Mylar circular

legends for use with

transparent flush

head operators

See page 21

Catalog Number

60 mm mushroom guard (black plastic)

no padlocking provision

ZB2BZ19

Black plastic

Gray plastic

Blue metallic

Add on push-on/push-off mechanism

Bulb extractor for use with BA9s

Ring nut wrench

Lense removal key

No text

O

I

Auto

Hand

Off

On

Start

Stop

Forward

Reverse

ZB2SZ3

ZB2SZ4

ZB2SZ2

ZB2BZ21

XBFX13

ZA2BZ905

ZB2BZ8

ZB2BY1101

ZBZBY1146

ZBZBY1147

ZB2BY1115

ZB2BY1316

ZB2BY1312

ZB2BY1311

ZB2BY1303

ZB2BY1304

ZB2BY1305

ZB2BY1306

Replacement Parts

Type

Mylar circular legend

ZB2BVkkk

Replacement lenses

ZB2-BV...

Replacement ring nut

ZB2BW93k

ZB2-BW93.

Replacement boots

Replacement keys

ZB2BP012

ZB2-BP012

+

j

Description

Lens – standard pilot light

Lens kit – standard pilot light (includes lens, diffuser and gasket)