Maintenance Schedule of Electrical Equipment

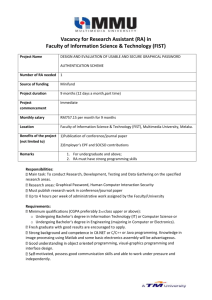

advertisement