Granite, Certified by DuPont TECHNICAL BULLETIN

advertisement

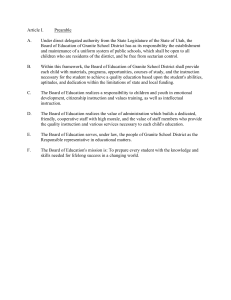

Granite, Certified by DuPont TECHNICAL BULLETIN December 1, 2005 G-1, Manufacturing and Installation Requirements for Granite, Certified by DuPont G-2005-002 This technical bulletin covers the quality standards that must be adhered to when manufacturing and/or installing Granite, Certified by DuPont. Adherence to the requirements contained in this bulletin are required under the terms of the applicable agreement entered into between DuPont and your firm and is the basis upon which DuPont offers a limited installed warranty to residential customers of Granite, Certified by DuPont. Definition of Terms & Measurements Manufacturer – Any company engaging in the fabrication or conversion of Granite, Certified by DuPont slabs into finished goods. Common Metric Measurement conversions to SAE Units 1.5 mm = 1/16 inch 12 mm = ½ inch 3 mm = 1/8 inch 2 cm = ¾ inch 6 mm = ¼ inch 3 cm = 1-1/8 inch Quality Requirements • The manufacturer must check the slab for non-conformities before manufacturing. • The manufacturer must check the color match of slabs to be used on the same job. Color shades should blend from one slab to another in a visually appealing manner. • Vein trends should run in only one direction unless otherwise approved by the customer. • Any repair performed during the manufacturing process should be of such quality as to be indistinguishable from the natural color and aesthetic of the original stone. Manufacturing Requirements • Cut to size, shape, and polish Granite Certified by DuPont using appropriate diamond tooling. • Join lamination (edge build up) seams with a two-part polyester, epoxy, or acrylic adhesive. • Note: Traditionally, lamination seams have been joined using a color matched two-part epoxy adhesive due to the strength and UV stability. • Inside Corner Radius Criteria: • On one piece shaped pieces (e.g., L, U, etc.) radius to minimum of ¼ inch (6 mm) to reduce corner stresses. • Multiple section (e.g., two piece L and 3 piece U) shaped pieces with seams in the corners (i.e., full 45˚miter or mason’s joint) do not need to have a radius in the corner. • Break all top and bottom edges of straight edge profiles to a minimum of 1/16-inch (1.5 mm) radius or chamfer. The information contained in this Technical Bulletin is given by the E. I. du Pont de Nemours and Company free of charge. It is based on technical data which DuPont believes to be reliable and is intended for use by persons having knowledge of this technical area at their own discretion and risk. Seller assumes no responsibility for results obtained or damage incurred from the use of this Technical Bulletin either in whole or in part by a buyer of Granite, Certified by DuPont. G-2005-002 December 1, 2005 Page 1 of 5 Granite, Certified by DuPont TECHNICAL BULLETIN December 1, 2005 G-1, Manufacturing and Installation Requirements for Granite, Certified by DuPont G-2005-002 • Radius all outside corners of straight edge profiles to a minimum of 1/8-inch (3 mm) radius. Cutout Requirements • Ensure proper cutout measurements have been obtained. Sinks, bowls, and cook-tops should be available for reference. • Rodding is required for reinforcement of cutouts (except back-splash cutouts). Rods should be placed on the backside of the stone. Rodding will consist of embedding a minimum ¼”x 1/8” rectangular stainless steel rod into a precut groove in the back of the stone. Rods should be located approximately 1” to 1.5” from the front and rear edges of the cutout, but care should be taken not to place rods in the area to be core drilled for faucet holes. Each rod should extend at least 12” past the cutout opening. The width of the groove cut for the rod should not be much larger than the rod width itself. A good flow grade epoxy should be used to set the rods in place. • Square corners are permitted on cooktop and sink cutouts so long as they are square and the cut does not extend beyond the cutout perimeter into the material (does not undercut). However, it is recommended to radius corners on all cutouts whenever possible. The larger the radius, the less likely the corner will fail. • Leave at least a 1/8-inch (3 mm) clearance space on all sides of the cutout to allow for cook-top/sink expansion. • Support cutouts on all sides within 3 inches of the edge of the cutout. • Support under-mount sinks with brackets. • Under-mount stainless steel and lavatory sinks must be mounted using clips for support. The clips should be attached to the underside of the countertop or to cradles attached to the outer perimeter cabinet support. • All others sink types must be mounted using cradles for support with the cradle attached to the outer perimeter cabinet support. • Under-mount sink cutouts should be finished to match the surface of the countertops and have a flat, square profile edge. • Cutouts in a back-splash (e.g., electrical outlets) that extend past the cutout perimeter must be filled with a two-part epoxy adhesive. A flexible adhesive must be used around the entire cutout perimeter when securing the back-splash to the wall. Installation General Requirements • The tops of the cabinets must be flat and in the same plane, within 1/8-inch of a flat surface, over a 118-inch (3 m) length. The cabinets must be capable of supporting the weight of the stone. The information contained in this Technical Bulletin is given by the E. I. du Pont de Nemours and Company free of charge. It is based on technical data which DuPont believes to be reliable and is intended for use by persons having knowledge of this technical area at their own discretion and risk. Seller assumes no responsibility for results obtained or damage incurred from the use of this Technical Bulletin either in whole or in part by a buyer of Granite, Certified by DuPont. G-2005-002 December 1, 2005 Page 2 of 5 Granite, Certified by DuPont TECHNICAL BULLETIN December 1, 2005 G-1, Manufacturing and Installation Requirements for Granite, Certified by DuPont G-2005-002 • A minimum 1/16-inch gap is recommended between the countertop and a wall. • Seal and secure the countertop to the cabinet frame by applying a 1/16 to 1/8-inch diameter bead of flexible adhesive between the underside of the countertop and the perimeter of the cabinet frames. • Stone to appliance joints should be per the appliance manufacturer’s recommendation. • Do not rigidly adhere Granite, Certified by DuPont to other products. Use only flexible adhesives to adhere to wood, steel, ceramic, tile, etc… • Adhere back-splash, up to six inches in height, to the countertop deck using a flexible adhesive. • Install Granite, Certified by DuPont tiles (≤12 inch x 12 inch) using only Marble Institute of America (MIA) approved tile adhesive. • A number of insert and fastener types may be used to secure hardware, however slip fit (i.e., plastic anchor) and glue inserts are recommended over pressure fit inserts. • Do not install Granite, Certified by DuPont over old countertops. • In wet wall installations, Granite, Certified by DuPont must be applied using traditional mud wall installation techniques and adhered to cement board that is attached to the wall. Granite, Certified by DuPont must be applied to the cement board with thin set structural adhesive as approved by the Marble Institute of America (www.marble-institute.com) (Note: The DuPont 10 year Limited Warranty for Granite Certified by DuPont does not cover wet wall applications). Installation Support Requirements • For all 2cm Granite, Certified by DuPont structures: • A full substrate underlayment must be utilized under the material for added strength. Use exterior glue plywood or cement backer board as the underlayment material. • For all 3cm Granite, Certified by DuPont structures: • Spans should not exceed 24” between support centers. Spans should always be kept to a minimum to prevent deflection of the stone. • Maximum length is 118" for sections without cutouts. • Maximum length is 100” for sections with cutouts. • For structures with support on 3 sides (e.g., dishwashers, desks, and frame-less cabinets) follow the 24” support criteria above, however, adding support to strengthen the unsupported side is recommended. Consideration should be given to the type of stone being used (fragility) and the intended use (load bearing) when assessing support needs. The information contained in this Technical Bulletin is given by the E. I. du Pont de Nemours and Company free of charge. It is based on technical data which DuPont believes to be reliable and is intended for use by persons having knowledge of this technical area at their own discretion and risk. Seller assumes no responsibility for results obtained or damage incurred from the use of this Technical Bulletin either in whole or in part by a buyer of Granite, Certified by DuPont. G-2005-002 December 1, 2005 Page 3 of 5 Granite, Certified by DuPont TECHNICAL BULLETIN December 1, 2005 G-1, Manufacturing and Installation Requirements for Granite, Certified by DuPont G-2005-002 • Overhangs for 2cm Granite, Certified by DuPont that exceed 6 inches will require additional support to be added. • For overhang >6” use a proper support system. Proper support systems include solid substrates, legs, brackets, corbels, or columns. • Overhangs for 3 cm Granite, Certified by DuPont that exceed 10 inches will require additional support to be added. • For overhang >10” use a proper support system. Proper support systems include solid substrates, legs, brackets, corbels, or columns. • Half wall (knee wall, pony wall) overhang support requirements for both 2cm and 3cm granite: • For overhangs <1/3 the depth of the top [i.e., support wall is 4 inches, countertop is 6 inches, overhang is 2 inches] no additional support required. (see Figure 1) • For all other half-wall overhangs, corbels are required to support the overhang where the bracket depth is 3/4 of the overhang depth. Spacing for corbels is a maximum of 24 inches throughout the span (see Figure 1). 6” countertop countertop 4” wall 2” 4” wall corbel ¾X X Figure 1 Half Wall Support Requirements • Acceptable support materials are MDF board, plywood, structural steel, and wood. Particleboard is not an acceptable support material. Installation Seam Requirements • All field seams must be filled through the entire seam thickness and filled with a DuPont designated adhesive. Follow manufacturer mixing ratio requirements to allow for optimal cure of adhesive. The information contained in this Technical Bulletin is given by the E. I. du Pont de Nemours and Company free of charge. It is based on technical data which DuPont believes to be reliable and is intended for use by persons having knowledge of this technical area at their own discretion and risk. Seller assumes no responsibility for results obtained or damage incurred from the use of this Technical Bulletin either in whole or in part by a buyer of Granite, Certified by DuPont. G-2005-002 December 1, 2005 Page 4 of 5 Granite, Certified by DuPont TECHNICAL BULLETIN December 1, 2005 G-1, Manufacturing and Installation Requirements for Granite, Certified by DuPont G-2005-002 • At a minimum, field seams must be supported on both sides of the seam in the front and back. Any seam that extends into an overhang must be supported. Whenever possible, seam support on both sides of the seam is recommended. • • Required maximum seam width is ≤ 1/16 inch. Required maximum seam height mismatch is ≤ 1/32 inch. • Do not place seams over a dishwasher. • A drop-in sink cutout can be seamed using rails or strips to bridge the material, provided the rails or strips and the sink are adequately supported. It is recommended that seams not be located through an under-mount sink cutout. Sealing Requirements Granite, Certified by DuPont must be sealed using only approved sealers or impregnators specified by DuPont. The sealer must be applied according to the manufacturer recommendations. DuPont recommends that sealer be reapplied by the homeowner or a professional installer every one to two years. If you have any questions regarding the information contained in this technical bulletin, contact DuPont Technical Service at (877) 229-3935 or www.granite.dupont.com The information contained in this Technical Bulletin is given by the E. I. du Pont de Nemours and Company free of charge. It is based on technical data which DuPont believes to be reliable and is intended for use by persons having knowledge of this technical area at their own discretion and risk. Seller assumes no responsibility for results obtained or damage incurred from the use of this Technical Bulletin either in whole or in part by a buyer of Granite, Certified by DuPont. G-2005-002 December 1, 2005 Page 5 of 5