Chapter 4

advertisement

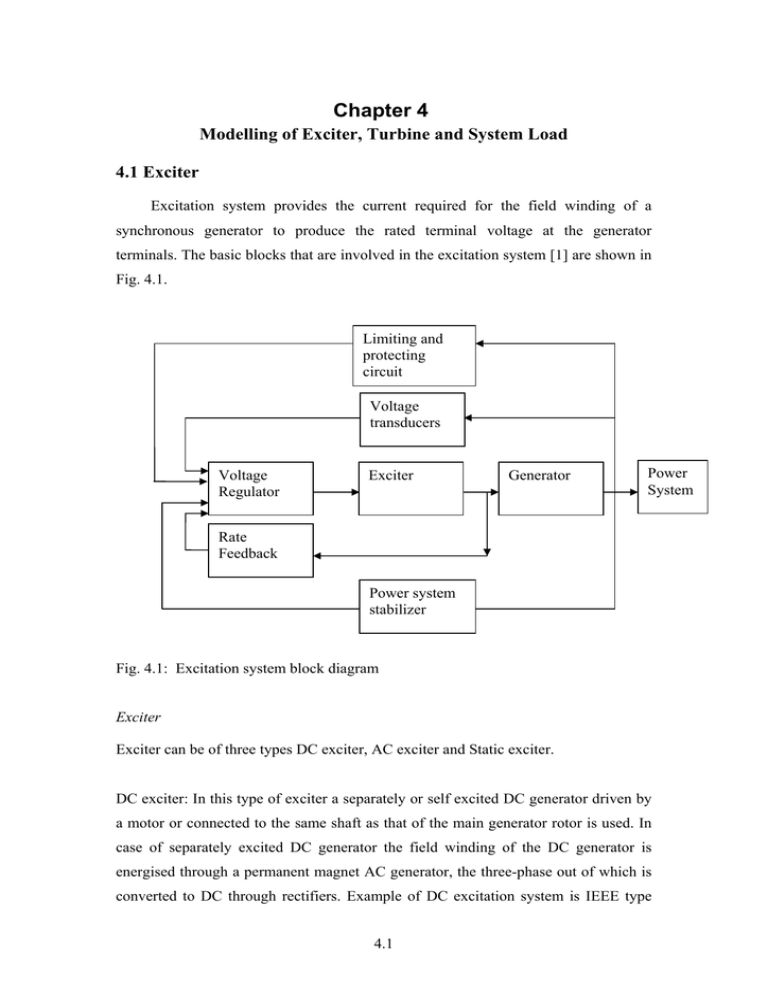

Chapter 4 Modelling of Exciter, Turbine and System Load 4.1 Exciter Excitation system provides the current required for the field winding of a synchronous generator to produce the rated terminal voltage at the generator terminals. The basic blocks that are involved in the excitation system [1] are shown in Fig. 4.1. Limiting and protecting circuit Voltage transducers Voltage Regulator Exciter Generator Power System Rate Feedback Power system stabilizer Fig. 4.1: Excitation system block diagram Exciter Exciter can be of three types DC exciter, AC exciter and Static exciter. DC exciter: In this type of exciter a separately or self excited DC generator driven by a motor or connected to the same shaft as that of the main generator rotor is used. In case of separately excited DC generator the field winding of the DC generator is energised through a permanent magnet AC generator, the three-phase out of which is converted to DC through rectifiers. Example of DC excitation system is IEEE type 4.1 DC1A [1], [2]. This type of excitation was widely used up to 1960 but now-a-days AC excitation or static excitation is being used. For older generating stations where DC excitation is still used the voltage regulator alone is replaced with electronic regulators. AC exciter: In this type of exciter the AC generator whose armature is mounted on the same shaft as that of the main generator, with its field stationary, is used for supplying field current to the main generator field winding. The output of AC exciter generator is converted to DC through rotating rectifiers, as the armature is now rotating at the main generator rotor speed, and the output is directly connected to the main field winding. The filed of the AC exciter generator itself is energised through a pilot permanent magnet AC generator whose three-phase output is converted to DC through rectification. Example IEEE type AC1A. Static exciter: In this exciter the output of the main synchronous generator is converted from AC to DC through static rectification and then the output is supplied to the main generator field winding through slip rings. Example IEEE type ST1A. Voltage transducers: Voltage transducers measure the three-phase terminal voltage through potential transformers and convert them and filter them to DC which is compared with the reference voltage and the error signal is used to control the main exciter field winding current through the exciter. Voltage Regulator: The voltage regulator can be of magnetic amplification type or digital amplification type. At present digital amplification is widely used. The voltage regulator amplifies the error signal generated by voltage transducers and the output of the voltage regulator is used to control the pilot excitation there by controlling the main generator field winding through the DC/AC excitation system. Limiting and protection circuit: Limiting and protection circuits are used to limit main generator field winding current, over excitation, under excitation, terminal voltage, Volts-per-Hertz etc. 4.2 Rate feedback: Rate feedback is used to stabilize the excitation system and will be explained shortly Power system stabilizer: It is used to damp the power system oscillations through the excitation system. Power system stabilizer will be explained in detail while discussing small-signal stability. 4.1.1 IEEE Type DC1A The modelling of IEEE Type DC1A [1], [2] will be discussed here. Though, only DC excitation modelling is dealt here, the same approach can be extended to IEEE Type AC1A and ST1A [1]. A separately excited DC generator excitation is shown in Fig. 4. 2. rf 1 La1 ra iin1 ein1 Lf 1 K a11a1 eout1 v fd Fig. 4.2: Separately excited DC machine circuit The output of the DC generator, eout1 , can be directly applied to the main generator field winding and hence eout1 v fd . DC generator field is excited through a pilot generator as explained earlier. If ein1 is the voltage applied to the DC generator field, with field current iin1 , then the following expression can be written ein1 iin1rf 1 N f 1 d f 1 (4.1) dt 4.3 Where, rf 1 , L f 1 are the resistance and inductance of the DC generator field winding. N f 1 is the number of turns of the DC generator field winding. If the flux produced due to field current iin1 is f 1 and a fraction of it 1/ links the armature of the DC generator then the armature flux a1 1/ f 1 . The induced emf in a DC generator armature is directly proportional to the speed of the armature and the flux linking it and can be written as ea1 ka1a1 (4.2) here, a1 is the speed of the armature and k is a proportionality constant corresponding to specific machine. The leakage inductance of the DC generator armature La1 and resistance ra1 are negligible. Hence, the following expression can be written ea1 eout1 v fd ka11a1 (4.3) From equation (4.3) we can express f 1 in terms of the DC generator output voltage, armature speed and proportionality constant as f 1 a1 v fd ka11 (4.4) The DC generator field winding flux linkage is given as f 1 l f 1iin1 N f 1 f 1 V fd iin1 N f1 v fd ka11 (4.5) ka11 l f 1 kg N f 1 1 (4.6) Hence, without considering the effect of saturation, 4.4 iin1 V fd (4.7) kg slope k g v fd iin1 v fd iin1 kg Fig. 4.3: Excitation saturation characteristics As can be observed from Fig. 4.3, field current iin1 v fd kg lead to a DC generator output voltage v fd without saturation. If saturation is considered then an additional current iin1 is required to produce the same output voltage v fd . Hence iin1 v fd kg iin1 v fd kg f sat (v fd )v fd (4.8) iin1 is the function representing the effect of saturation. v fd Substituting equations (4.4) and (4.8) in (4.1) lead to Where, ein1 rf 1 kg f sat (v fd ) v fd rf 1 f sat (v fd )v fd l f 1 dv fd (4.9) k g dt Since, the DC generator output is directly connected to the generator field winding the base used for the field circuits to express parameters in per units can be 4.5 used here as well. Hence, divide both sides of equation (4.9) by V fd _ base and multiply by X md X (note E fd md V fd ) and this lead to R fd R fd E S ( E fd ) fd K E VR E 1 r X R X X md 1 rf 1 f sat fd E fdVbase _ fd md V fd ein1 f 1 md V fd Vbase _ fd R fd Vbase _ fd k g R fd X md R fd (4.10) TE l d X .... f 1 md V fd k g dt R fd TE dE fd dt VR K E S E ( E fd ) E fd (4.11) In equation (4.11) K E , TE are the gain and time constant of the DC exciter. The saturation function S E ( E fd ) can be mathematically approximated as S E ( E fd ) Ae BE fd (4.12) Where, A, B are constants which can be computed. In the steady state a maximum scaled DC field winding input voltage VR max will lead to a maximum scaled DC generator output armature voltage E fd hence 0 VR max K E S E ( E fd max ) E fd max (4.13) Usually the value of saturation function S E ( E fd ) at two different values, S E _ max ( E fd max ) and S E _ 0.75max (0.75E fd max ) for two different E fd is specified S E _ max ( E fd ) Ae BE fd max S0.75 E _ max ( E fd ) Ae (4.14) B 0.75 E fd max 4.6 The constants A, B can be computed by solving equations (4.13) and (4.14). The voltage regulator can be simply represented by a first order system with a gain K A , by which it amplifies the error signal, and a time constant TA . If the input to the voltage regulator is an error signal Vin and the output of the voltage regulator is the input to the DC generator field winding VR then the dynamic equation of the voltage regulator can be expressed as TA dVR VR K AVin dt VR _ min VR VR _ max (4.15) So far a separately excited DC generator was considered. A self excited DC generator can also be modelled in the same way. In case of self excited DC generator since armatures it self supplies the field current as well assuming there is residual field voltage to build up the armature voltage gradually. The voltage regulator output comes in series with the field winding and hence v fd iin1rf 1 N f 1 d f 1 dt ein1 (4.16) with this modification the dynamic equation of the exciter in per units can be written as TE dE fd dt VR K E S E ( E fd ) E fd (4.17) where, K E K E 1 , and is a small negative number. From equation (4.17) it can be observed that since K E is small negative number and with small positive S E ( E fd ) the closed loop transfer function, with input VR and output E fd , has a positive eigen value making the system unstable. Even without this problem to make the entire open loop excitation system with the voltage regulator and exciter stable a feedback system is used to stabilize. A transformer as shown in Fig. 4.4 is used to feeds back the output 4.7 voltage E fd to the input. The transformer secondary side produces a voltage VF which is then subtracted from the input voltage VR . It 2 Rt 2 Lt1 Lt 2 N 2 : N1 VF rt1 I t1 Ltm E fd Fig. 4.4: Stabilizing transformer circuit From Fig. 4.4, the following voltage equation can be written E fd Rt1 I t1 Lt1 Ltm dI t1 dt (4.18) Where, Rt1 , Lt1 , Ltm are the resistance, leakage inductance and magnetising inductance of the primary side of the feedback transformer. I t1 is the primary side current. If the secondary side the leakage inductance Lt 2 is very large then the secondary side current cannot change from its initial conditions and in this case it is zero then with turns ratio N 2 : N1 VF dI N2 Ltm t1 N1 dt (4.19) or d 2 I t1 dVF N 2 Ltm dt N1 dt 2 (4.20) Differentiating equation (4.18) and rearranging we get 4.8 dE fd d 2 I t1 Rt1 N1 1 VF 2 dt dt Lt1 Ltm Ltm N 2 (4.21) Substituting equation (4.20) in (4.21) we get dE fd R N dVF N 2 1 Ltm t1 1 VF dt N1 dt Lt1 Ltm Ltm N 2 (4.22) let, TF Lt1 Ltm N L , K F 2 tm Rt1 N1 Rt1 (4.23) Then, equation (4.22) can be written as E fd 1 dVF K V VF F R K E S E ( E fd ) dt TF TF TE TE (4.24) Defining, RF KF E fd VF TF (4.25) RF is called as the rate feedback. Differentiating equation (4.25) and rearranging we get TF dRF K RF F E fd dt TF (4.26) Finally the IEEE type DC1A exciter dynamics can be expressed by the following three equations 4.9 TE TA dE fd dt VR K E S E ( E fd ) E fd (4.27) dVR K K VR K A RF A F E fd K A Vref Vt , VR _ min VR VR _ max dt TF (4.28) dRF K RF F E fd dt TF (4.29) The control block diagram corresponding to the dynamics equations (4.27) to (4.29) is given in Fig. 4.5. VR max Vt Vref Vin KA 1 sTA VR VR min 1 sTE E fd KE S E ( E fd ) VF Rf KA 1 sTA KF TF Fig. 4.5: Control block diagram of IEEE type DC1A exciter 4.2 Model of Turbine So far the modelling of synchronous machine along with the exciter was explained. Now, modelling of prime mover will be explained. Prime mover can be a diesel generator, gas turbine, hydro turbine or steam turbine. Prime mover provides the mechanical power required as input to the synchronous machine to rotate the rotor 4.10 of the synchronous machine at synchronous speed. Here, we will discuss about hydro and steam turbine. 4.2.1 Hydro Turbine Hydro generating stations consists of a reservoir, gate to release water to generating station, penstock (a conduit) to carry water from the reservoir up to the hydro turbine. The turbine can be impulse-type (Pelton wheel) or reaction turbine (Francis or propeller). The water which flows from the reservoir through the penstock is directed on to the turbine blades, which are spoon-shaped buckets, and this force makes the turbine rotate. The hydro turbine and the rotor of the synchronous machine are mounted on the same shaft. Hydro turbine modelling Let H be the height from the gate to the water level in the reservoir also called as head, U the water velocity and G the gate position (full open means full rated mechanical power input to the hydro turbine and full close means nil power to the hydro turbine). The velocity of the water and be expressed as U Ku G H (4.30) Where K u is a constant of proportionality. If there is a small change in the velocity of water it can be expressed as a sum of linear changes in the gate position and head as U U U H G H G (4.31) The partial derivatives in equations (4.31) should be evaluated at an initial operating condition from which speed of the water changed by a small amount. The initial speed of water, for a given initial gate position Go and head H o , is given as 4.11 U o K u Go H o (4.32) Hence, equation (4.31) can be written as U 1 K u Go H K u H o G 2 Ho (4.33) Equation (4.33) can be normalized by dividing it with equation (4.32) U H G U o 2 H o Go (4.34) Let U / U o be represented as a normalized value as U . Similarly, H and G represents the normalized values of small changes in head and gate positions. So, equation (4.34) can be written as U 1 H G 2 (4.35) The turbine mechanical power is proportional to the product of pressure and flow and hence, with proportionality constant K P Pm K P HU (4.36) Again a small change in Pm can be expressed in a normalized form with the initial condition Pmo K P H oU o , as Pm H U 1.5H G (4.37) From Newton’s second law ( Force=Mass×acceleration ), the acceleration in water column due to change in water head can be written as 4.12 LA d U A ag H dt (4.38) Where, L, A, are the length of the conduit, area of the pipe and the mass density of the water. ag is the acceleration due to gravity. LA represents the mass of the water in conduit and ag H represents the incremental force. To normalize equation (4.38) divide both sides by A ag H oU o . After rearranging the normalized equation (4.38) is written as TW LU o d U d U H H or TW dt ag H o dt (4.39) TW has seconds as its units which can be verified from equation (4.39). It is called as water starting time and it the time required for a head H o to accelerate the water to a velocity U o . If equation (4.39) is converted in to Laplace domain then TW sU ( s ) H ( s ) (4.40) Substituting, H 2 U G , from equation (4.35) in equation (4.39) and rearranging leads to U ( s ) 1 G ( s ) 1 1 TW s 2 (4.41) From equation (4.35) and (4.37) it can be observed that Pm 3U 2G (4.42) Substituting equation (4.42) in (4.41) and eliminating U lead to 4.13 Pm ( s ) 1 TW s G ( s ) 1 1 TW s 2 (4.43) Now this model is a linear model and hence is only valid for slow gradual small changes and not for sudden large changes. Equation (4.43) can be represented in time domain as TW d Pm d G 2 Pm G TW dt dt (4.44) The gate position G is the corresponding power output of the turbine that is a per unit change in gate position leads to per unit change in the mechanical power output Pm . Also, since the model is valid for perturbations around an operating point we can write the actual parameters as Pm Pmo Pm , (4.45) G Go G, With the assumption given in (4.45) we can write equation (4.44) as TW dPm dG 2 Pm G TW dt dt (4.46) Since the synchronous machine model is represented in per units the turbine model should also be presented in per units. To do this we can divide both sides of equation (4.46) by base MVA or the rating of the synchronous machine. Also it can be noted that in per units power and torque are same hence TW dG pu dTM 2 TM G pu TW dt dt (4.47) 4.14 It has to be noted that TM is the per unit mechanical torque output of the hydro turbine. Equation (4.47) represents the dynamic behaviour of hydro-turbine [3]. 4.2.2 Steam Turbine The steam generating system consists of a boiler to generate steam, steam chest with a valve to store the steam and release it in to the turbine as shown in Fig. 4.6 [3]. The steam from the steam chest initially enters a high pressure turbine through the steam valve nozzle at high temperature and pressure with a high velocity and this gets converted in to rotational kinetic energy through blades connected to the turbine shaft. Now as in the case of hydro turbine the position of the steam valve is proportional to the mechanical power output of the turbine. Only part of the input power gets converted into mechanical power at the high pressure turbine shaft and the steam then enters reheater were the temperature and pressure of the steam are increased and then again this reheated steam is forced in to a low pressure or a series of intermediate and low pressure turbines. Each of these turbines convert the steam into rotational energy through their blades connected on the shaft. The connection can be tandem connected that is all the high pressure, intermediate pressure, low pressure turbine and the generator are on the same shaft as is shown in Fig. 4.6 or cross connected that is there may be two shafts cross connected with same steam input valve and two generators connected to each shaft respectively. Fig. 4.6: Steam generation system schematic diagram The steam chest with a valve and the high pressure turbine can be modelled as a linear first order system. Let PSV be the change in the steam valve position and PCH is the change in the output power of the steam chest which gets converted in to 4.15 the mechanical power at the turbine shaft. If TCH is the time delay of the steam chest then we can represent the dynamics of the steam chest along with steam valve as TCH d PCH PCH PSV dt (4.48) A fraction of the power output of the steam chest, K HP PCH , gets converted in to mechanical power at the high pressure turbine shaft and the remaining power that is 1 K HP PCH enters the reheat chamber. The reheat chamber itself has a time delay TRH . After the time delay the steam output from the rehear chamber is forced into the low pressure turbine (or a series of intermediate turbines followed by a low pressure turbine. But here only low pressure turbine is taken and the explanation can extended to any number of turbines in tandem or cross connected) where it gets converted into incremental mechanical power PRH . The reheat chamber can also be represented as a linear first order system as TRH d PRH PRH 1 K HP PCH dt (4.49) The total shaft mechanical power or torque (as torque and power in per units on the generator MVA basis are same) is the summation of high pressure and low pressure turbine mechanical power and can be written as TM PRH K HP PCH (4.50) Substituting equation (4.50) in (4.49) by eliminating PRH we can represent the dynamics of steam turbine system as TRH K T d TM TM 1 HP RH dt TCH K HPTRH PSV PCH TCH 4.16 (4.51) TCH d PCH PCH PSV dt (4.52) In case reheater dynamics are not considered then TRH is zero and the dynamic equations can be written as TCH d TM TM PSV dt (4.53) Where, TM PCH . Equations (4.51) and (4.52) can be converted to equations (4.54) and (4.55); by defining actual variables as TM TM 0 TM , PCH PCH 0 PCH , PSV PSV 0 PSV , where TM 0 , PCH 0 , PSV 0 are the initial operating conditions, TRH TCH K T dTM TM 1 HP RH dt TCH dPCH PCH PSV dt K HPTRH PSV PCH T CH (4.54) (4.55) 4.2.3 Turbine governor The gate position G or the steam valve position PSV can be automatically controlled to change the power input according to the output power required through governor mechanism. The speed governor mechanism [4] is shown in Fig. 4.7. The speed governor mechanism consists of a fly ball mechanism which detects the change in the shaft speed above the reference speed. Levers with connecting rods and a main piston operated through high pressure oil to either open or close the value or gate. If the speed of the shaft increases above the reference speed the centrifugal force on the fly balls will increase and they move away from each other there by moving the point b downwards and this lead to lowering of point c and hence point d. As point d move down wards the high pressure oil enters the main piston chamber through the lower opening and hence pushes the point e and piston upwards and there by reducing the steam input. Increases in shaft speed above the reference speed indicates that the input power is more than the output power required and hence speed increasing and to bring back to the reference speed the input mechanical power should be reduced i.e. the gate 4.17 or valve should position should change to reduced the input power and this is what happen in the governor mechanism. Fig. 4.7: Speed governor mechanism Similarly if speed is decreasing then more input power is required and it can be observed that with decrease in speed the fly balls will move towards each other and the point c moves upwards and leads to movement of point d upwards now the high pressure oil will enter the main piston chamber through upper opening and there by forcing the piston downwards and opening the valve. The actual mechanical power input reference can also be changed at reference speed by changing the set point through speed changer i.e. moving point a downwards or upwards and thereby decreasing or increasing the power input. The governor can be mathematically modelled by assuming that the change in the positions of the points a, b, c, d and e can be related to each other linearly depending on the length of the rods separating them. If the point b moves a distance yb then it is related to the change in point a ( ya ) and c ( yc ), as it is directly connected to them, as yb K ba ya K bc yc (4.56) 4.18 where, K ba , K bc are constants. Similarly we can write yd K dc yc K de ye (4.57) The point a is related to the change in the reference power and if the reference power is Pref then Pref K a ya (4.58) The point b changes according to the change in the speed of the shaft and is proportional to it and hence base K b yb (4.59) Point d effects point e through the high pressure oil servo mechanism. The point e moves according to the rate of change of oil flow in the main piston chamber and the flow in turn is effected by point e. Also it can be noted that point d and e move in opposite directions and hence the following expression can be written d ye K e yd dt (4.60) Substituting, equation (4.57) in (4.60) lead to d ye K e yd K dc K e yc K e K de ye dt (4.61) From equation (4.56), yc can be expressed in terms of ya , yb and this can be substituted in equation (4.61) which lead to 4.19 y K ba ya d ye K dc K e b dt K bc K e K de ye (4.62) K K K KK dc e yb dc e ba ya K e K de ye K bc K bc ya , yb can be represented in terms of Pref , from equations (4.58) and (4.59) this when substituted in (4.62) lead to d ye K dc K e K KK dc e ba Pref K e K de ye base K b K bc dt K bc K a or PSV RD TSV 1/ K a K bc K a K de 1 K bc K a K de d ye Pref ye K e K de K dc K ba dt K b K ba base K dc K ba TSV d PSV 1 PSV Pref dt RD base (4.63) (4.64) If we define the variables as PSV PSV 0 PSV , Pref Pref 0 Pref , base then we can express equation (4.64) as, with limits on the valve position included, TSV dPSV 1 Max PSV Pref 1 , 0 PSV PSV dt RD s (4.65) RD is the speed regulation and it depends on the droop, the amount by which the frequency falls from no load to full load without change in the input power. RD can be defined in terms of droop as RD 2 droop (4.66) base 4.20 Where, droop has units of Hz/per megawatts. If droop is defined in terms of percentage i.e. the percentage by which the frequency falls from no load to full load then RD %droop 100 (4.67) So far we have discussed about the modelling of the synchronous generator along with exciter, hydro/steam turbine and turbine governor. Next we will discuss about modelling of loads. 4.3 Load Representation The loads can be represented as either static or dynamic loads. Lighting and heating loads can be represented by static models. Whereas, to represent motor loads like synchronous motors and induction motors the motor dynamics have to be taken into consideration. 4.3.1 Static load representation Static load representation is a simple way of representing the effect of load on the system stability. The effect of change in voltage and system frequency can be incorporated in the static load model. Usually instead of representing each static load separately an aggregate load is represented like all loads at particular distribution station can be clubbed together and represented as a single load. The typical way of representing static loads is either as a constant impedance load or constant current load or constant power load. If Po , Qo ,Vo are the initial real power, reactive power and voltage then the effect of change in the voltage on the static load can be represented as [5] V P Po Vo np (4.68) 4.21 V Q Qo Vo nq (4.69) Where, P, Q are the real and reactive powers at changed voltage V . In case equation (4.68) and (4.69) are representing single loads then np, nq when taken as 0 represents constant power load, taken as 1 represents constant current and taken as 2 represents constant impedance loads. For aggregate loads np, nq may be chosen to approximate the actual behaviour of the load and may be in the range of 0.5 to 1.8 for np and in the range of 1.5 to 6 for nq . A polynomial mode of load representation [5] can also be used which includes all the types i.e. constant impedance (Z), current (I) and power (P) called as ZIP load as shown in equation (4.70) and (4.71) V 2 V P Po PZ PI PP Vo Vo (4.70) V 2 V Q Qo QZ QI Vo Vo (4.71) Q P Where, PZ , I , P , QZ , I , P are constants representing the approximated fraction of the aggregated load taken as constant impedance, current and power loads. Though constant impedance are practical loads like lighting and heating, constant current and power loads are not real loads but are used to represent dynamic loads like motors as static loads assuming that after a disturbance the motor loads will reach their steady state rapidly. Hence it is necessary to take the effect of frequency variation also on the loads to improve the accuracy and can be represented as V 2 V P Po PZ PI Vo Vo P P 1 K Pf f V 2 V Q Qo QZ QI QP 1 K qf f Vo Vo 4.22 (4.72) (4.73) In equations (4.72) and (4.73), the effect of change in the bus frequency from the steady state frequency, f f f 0 , is included in the static load model with constant K pf taking a value between 0 to 3.0 and K qf a value between -2 to 0 [6]. The bus frequency information is not available but can be obtained by the rate of change of the bus angle which can be computed. For a very wide variation in voltage the aggregate static load is converted into constant impedance load for computational simplicity. In fact constant impedance load representation has several computational benefits which will be discussed later. Though IP part of ZIP load represents the static model of motor loads this representation is not accurate and can lead to erroneous conclusions. Hence, for large motor loads it is better to take the dynamics of the motors into consideration for stability studies. In this context we will discuss the modelling of synchronous motor and induction motor. 4.3.2 Model of synchronous motor The dynamic equations (3.149)-(3.157) and (3.162) given in Chapter 3 representing the synchronous generator can also be used for representing the synchronous motor as well with a modification in equation (3.162) given in Chapter 3 as shown in equation (4.74) 2 H d Te D base Tm base dt (4.74) This change is required because in a motor electrical energy is converted to mechanical energy and hence electrical torque is the input whereas mechanical torque is the output. The converse is true of a synchronous generator. It has to be also noted that in case of a synchronous motor current into the stator should be taken as positive unlike the case of synchronous generator. The IEEE type DC1A exciter model can also be used for the synchronous motor. 4.23 4.3.4 Model of induction motor The stator of the induction machine is similar to a synchronous machine with a three-phase winding distributed symmetrically with 120 separation. The rotor of an induction machine also has three phase windings distributed symmetrically with 120 separation with same number of poles as that of stator (a set of three phase windings distributed symmetrically with 120 separation produces a pair of poles in the air gap rotating at synchronous speed). The three-phase rotor windings terminals are brought out to be connected to external resistance in case of a wound rotor induction machine and short circuited in case of a squirrel cage induction machine. For modelling purpose both can be considered same with some assumptions. Some points to be noted which can help us in modelling induction machine are [7] The dq 0 transformation used for modelling synchronous machine can also be used for modelling induction machine as well. The rotor is cylindrical and hence has a uniform air-gap due to which there will be no difference between d -axis or q -axis inductances and time constants. In case of synchronous machine the d -axis was aligned with the rotor of the machine as it rotates at synchronous speed in steady state for varying loads. In case of induction machine the rotor speed is not synchronous speed and its speed depends on the load torque required. Even though the rotor of induction machine rotates at slip speed the rotor winding produces a synchronously rotating field with the same number of poles as that of the stator winding field. Hence, a synchronously rotating dq -axis can be taken which is neither fixed to rotor or fixed to stator and the three-phase rotor and stator quantities can be referred to this axis. The current in the rotor of an induction machine does not depend on the excitation system like in the case of synchronous machine but instead depends on the relative speed between the synchronously rotating stator field and the rotor speed that is the slip speed. 4.24 The same model can be used for induction motor and generator and the main difference lies in the slip. With these assumptions let us look in to the modelling of an induction machine. The basic diagram of induction machine with all the relevant windings represented is shown in Fig. 4.8. The stator three-phase voltages and currents are represented by va , vb , vc and ia , ib , ic . Similarly, rotor three-phase voltage and currents are represented by v A , vB , vC and iA , iB , iC . The rotor along with its windings will rotate at a speed r . Let the angle with which the field axis of rotor A-phase leads the field axis of stator aphase be then with continuous time we can write s d axis ib r iA r iB vB v A vb va ia vC vc ic iC Fig. 4.8: Induction machine with all the windings represented r t (4.75) The slip is defined as the ratio of the difference between the synchronous speed and the rotor speed to the synchronous speed. Hence, slip can be expressed as s s r s (4.76) 4.25 From equation (4.76), the angle in equation (4.75) can be represented in terms of slip and synchronous speed as r t 1 s s t (4.77) If now we consider dq -axis rotating in the air-gap at synchronous speed and is separated by an angle r with the field axis of rotor A-phase. Then the following expression can be written r s t ss t (4.78) d r ss dt (4.79) In the same way we have written voltage equations for synchronous machine stator windings we can also write voltage equations for the windings shown in Fig. 4.8 as va rs 0 0 ia a v 0 r 0 i d b s b dt b vc 0 0 rs ic c (4.80) v A rr 0 0 iA A v 0 r 0 i d A r B dt B vC 0 0 rr iC C (4.81) Where, rs , rr are the stator and rotor winding resistances. a ,b ,c , A, B ,C are the flux linkage of the three-phase stator and rotor windings, respectively. Let the self inductance of the stator a-phase winding be laa and this can be assumed to the same for all the three-phases. The mutual inductance between any two phases, let it be lab , of the stator will be same and independent of the rotor position as the air-gap is uniform. Let the maximum value of the mutual inductance between any rotor and 4.26 stator winding be laA then the flux linkage equation of stator and rotor can be written as laA cos 120 laA cos 120 iA a laa lab lab ia laA cos l l l i l cos 120 l cos l cos 120 b ab aa s ab b aA aA aA iB c lab lab laa ic l cos 120 l cos 120 laA cos cos iC aA aA (4.82) laA cos 120 laA cos 120 ia l AA l AB l Ab iA A laA cos l cos 120 l cos l cos 120 B aA aA aA ib l AB l AA l AB iB C l cos 120 l cos 120 laA cos cos ic l AB l AB l AA iC aA aA (4.83) The Park’s transformation used in synchronous machine modelling can also be used here but a separate transformation has to be used for stator and rotor windings. Let rotor Park’s transformation be Tdqr 0 and that of stator be Tdqs 0 and can be expressed as Tdqs 0 cos(s t ) cos(s t 120) cos(s t 120) 2 sin(s t ) sin(s t 120) sin(s t 120) 3 1 1 1 2 2 2 (4.84) Tdqr 0 cos s r t cos s r t 120 cos s r t 120 2 sin s r t sin s r t 120 sin s r t 120 3 1 1 1 2 2 2 (4.85) Applying transformation given in (4.84) and (4.85) to flux linkage equations (4.82) 3 and (4.83) and also assuming that lss laa lab , lrr l AA l AB and lm laA we get 2 flux linkage equations in dq0 reference frame as 4.27 ds lss 0 0 ids lm 0 0 idr qs 0 lss 0 iqs 0 lm 0 iqr 0 0 0 i 0 0 0 i 0s 0s 0r (4.86) dr lm 0 0 ids lrr 0 0 idr qr 0 lm 0 iqs 0 lrr 0 iqr 0 0 0 i 0 0 0 i 0r 0s 0r (4.87) Similarly, applying transformations to voltage equations given in (4.80) and (4.81) leads to vds rs 0 0 ids 0 s vqs 0 rs 0 iqs s 0 v 0 0 rs i 0 0 0s 0s ds 0 ds d 0 qs qs dt 0 0 s 0s s r 0 dr vdr rr 0 0 idr 0 dr d 0 qr qr vqr 0 rr 0 iqr s r 0 dt v 0 0 rr i 0 0 0 0 r 0r 0r 0r (4.88) (4.89) The rotor power input can be expressed in dq -axis by using equation (4.89) as S rotor vA vB vC T iA vdr i v B qr iC v0 r T T r dq 0 1 T idr Tdqr 0 iqr i 0r (4.90) d qr d 3 3 rr idr2 iqr2 dr iqr qr idr s r idr dr iqr 2 2 dt dt In the steady state d dr d qr , are zero, then from equation (4.90) it can dt dt observed that there are two parts of which the first part corresponds to the rotor copper losses and the second part corresponds to the product of torque produced and the difference of the rotor speed with respect to the synchronous speed. If the torque is defined at the relative speed of the rotor speed with respect to the speed of dq -axis, 4.28 r s , then from equation (4.90) the torque can be expressed for a P number of poles as te 3P qr idr dr iqr 22 (4.91) Per unit representation The same base quantities can be taken for both stator and rotor. Let, Vbase = peak value of rated phase voltage, V I base = peak value of rated current, A fbase = rated frequency, Hz Z base Vbase Z V , base s 2 fbase elec.rad/s , Lbase base H , base base , base base I base 3 3P sbase Vbase I base , Tbase base I base N.m 2 22 With the base voltage and current defined as above and given the transformations in (4.85) and (4.86) it can be observed that a per unit phase voltage and current in abcreference frame leads to per unit voltage and current in dq 0 -reference frame as well hence same base quantities can be used in both abc and dq 0 -reference frames. i i i i I ds ds , I qs qs , I dr dr , I qr qr , I base I base I base I base ds ds , qs qs , dr dr , qs qr , base base base base baselss baselrr baselm rs Xs , Rs , , Xr , Xm Z base Z base Z base Z base t r Rr r Te e , r _ pu r 1 s Z base Tbase base Vds v v vds v , Vqs qs , Vdr dr , Vqr qr Vbase Vbase I base I base 4.29 (4.92) Then equations (4.86) to (4.89) can be written in per units as Vds Rs I ds qs 1 d ds base dt (4.93) Vqs Rs I qs ds 1 d qs base dt (4.94) Vdr Rr I dr s qr 1 d dr base dt (4.95) Vqr Rr I qr s dr 1 d qr base dt (4.96) ds X s I ds X m I dr (4.97) qs X s I qs X m I qr (4.98) dr X m I ds X r I dr (4.99) qr X m I qs X r I qr (4.100) The stator transients of the induction machine can be neglected as was done for the synchronous machine stator transients. Hence, equations (4.93) and (4.94) are simplified to Vds Rs I ds qs (4.101) Vqs Rs I qs ds (4.102) Eliminating I dr , I qr from equations (4.99) and (4.100), substituting them in (4.97) and (4.98) and in turn substituting them in equations (4.95) and (4.96), noting that for a squirrel cage rotor Vdr Vqr 0 , leads to (4.103) (4.104) dVd' T Vd' X s X s' I qs base sT0'Vq' dt ' 0 ' 0 T dVq' dt Vq' X s X s' I ds base sT0'Vd' 4.30 Where, Vd' Xm X X2 Xr qr , Vq' m dr , X s' X s m , To' base Rr Xr Xr Xr The per unit torque is give as Te te Tbase 3P qr idr dr iqr 2 2 qr I dr dr I qr 3P base I sbase 22 (4.105) The equation of motion of the induction machine is given as J d m te t m dt (4.106) Where, m is the speed of the rotor in mechanical radians per second. Dividing both side by Sbase 2 Tbasebase we get P 2 J base t t d P m e m base Sbase dt base Tbase Tbase (4.107) 1 2 J base 2 let, H 2 and also noting that r m we get Sbase P 2H dr _ pu dt 2 H ds Te Tm dt (4.108) Algebraic equations relating the stator voltage Vds , Vqs to the dynamic state Vd' , Vq' can be obtained by eliminating I dr , I qr from equations (4.99) and (4.100), substituting 4.31 them in (4.97) and (4.98) and in turn substituting them in equations (4.101) and (4.102) leads to Vds Rs I ds X s' I qs Vd' (4.109) Vqs Rs I qs X s' I ds Vq' (4.110) If the three-phase stator voltage are given as va 2Vt cos s t vb 2Vt cos s t 120 (4.111) vc 2Vt cos s t 120 Where, Vt is the rms phase voltage. Applying parks transformation defined in equation (4.84) to equation (4.111) and dividing both sides by base voltage lead to Vds Vt _ pu cos Vt , where, Vt _ pu V Vsbase qs Vt _ pu sin (4.112) Hence, the dq components of the voltages can be used to represent a phasor with real and imaginary parts in per units as Vds jVqs Vt _ pu cos j sin Vt _ pu e j (4.113) With the same argument the stator currents in dq -axis can be represented in per units as I ds jI qs I t _ pu cos j sin I t _ pu e j 4.32 (4.114) Where, I t _ pu is the stator current in per units with a phase angle . Since stator voltage in dq -axis can be expressed as phasors we can add equations (4.109) and (4.110) by multiplying equation (4.110) with complex number j1 , then we get Vt _ pu e j Vds jVqs Rs jX s' I ds jI qs Vd' jVq' (4.115) Hence, a simple electrical equivalent circuit can be formed for the induction machine with an internal transient voltage behind the transient reactance X s' as shown in Fig. 4. 9. X d' V ds Rs I d jI q I t _ pu e j V jV jVqs Vt _ pu e j d q Fig. 4.9: Electrical equivalent circuit of an induction motor Hence, the complete induction machine dynamic model in per units is defined by 1 d r base r s base dt base (4.116) ds Te Tm dt (4.117) 2H T0' T0' (4.118) (4.119) dVd' Vd' X s X s' I qs base sT0'Vq' dt dVq' dt Vq' X s X s' I ds base sT0'Vd' Te qr I dr dr I qr Vd' I ds Vq' I qs (4.120) Vt _ pu e j Vds jVqs Rs jX s' I ds jI qs Vd' jVq' (4.121) 4.33 Initial Conditions To find the initial conditions of a induction motor, the dynamics given by equations (4.118) and (4.119) can be equated to zero, which lead to V X V X ' d s ' q s X I X s' I qs base sT0'Vq' 0 (4.122) sT0'Vd' 0 (4.123) ' s ds base Now multiply equation (4.123) by complex number j1 on both sides and add this to equation (4.122). Vd' jVq' j X s X s' I ds jI qs jbase sT0' Vd' jVq' 0 Now, V Vd' jVq' , I t _ pu e j I ds jI qs (4.124) and Vt _ pu e j Vd jVq , then equation (4.124) leads to Vd' jVq' j X s X s' V I t _ pu e j I ds jI qs 1 jbase sT0' (4.125) Substituting equation (4.125) in equation (4.115) lead to X s X s' I e j Vt _ pu e j Rs jX s' j 1 jbase sT0' t _ pu (4.126) Equation (4.126) can be further simplified and expressed as I t _ pu e j R s base 1 j sT sT X j sT R base ' 0 ' s ' 0 base ' 0 s Xs Vt _ pu e j The real power input to the induction machine is given as 4.34 (4.127) Pt Real Vt _ pu e j I t _ pu e j * ' ' ' ' Rs base sT0 X s base sT0 base sT0 Rs X s 2 Vt _ pu 2 ' ' 2 ' R sT X sT R X s base 0 s base 0 s s (4.128) If from load flow analysis the Pt , Qt ,Vt _ pu are defined then from equation (4.128) the slip can be found out. Equation (4.128) lead to a quadratic expression of slip and hence there will be two solutions of which the feasible solution should be considered if it exists for the given conditions. The other way is if we define a slip with terminal voltage given then real power can be computed from (4.128) and similarly reactive power can also be computed. References 1. IEEE Standards 421.4, IEEE Recommended Practice for excitation system models for power system stability studies, 1992. 2. IEEE Committee report, “Excitation system models for power system stability studies,” IEEE Trans. Power Appar. Syst., PAS-100, pp. 494-509, February 1981. 3. IEEE Committee Report, “Dynamic models for steam and hydro turbines in power system studies,” IEEE Trans., Vol. PAS-92, pp. 1904-1915, December 1973. 4. O. I. Elgerd, Electric Energy System Theory, an Introduction, McGraw-Hill Book Co., New York, 1982. 5. IEEE Task Force Report, “Load representation for dynamic performance analysis,” IEEE PES winter meeting, New York, January 26-30, 1992. 6. C. Concordia and S. Ihara, “Load representation in power system stability studies,” IEEE Trans., Vol. PAS-101, pp. 969-977, April 1982. 7. D. S. Brereton, D. G. Lewis and C. C. Young, “Representation of induction motor loads during power system stability studies,” AIEE Tans., Vol. 76, Part III, pp. 451-460, August 1957. 4.35