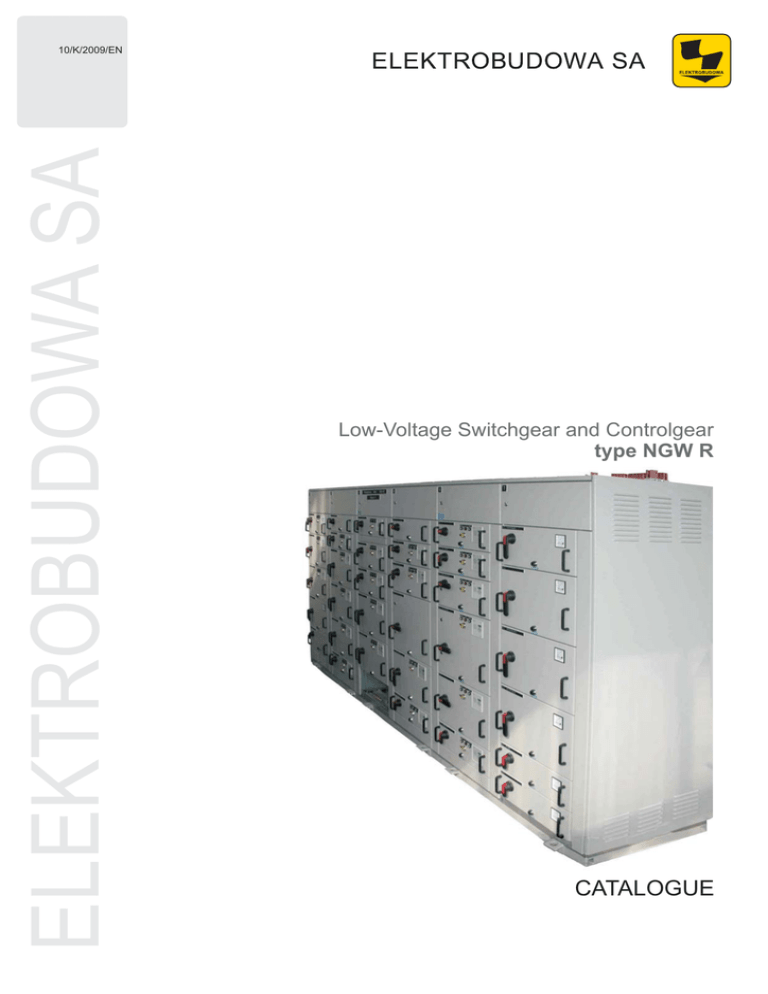

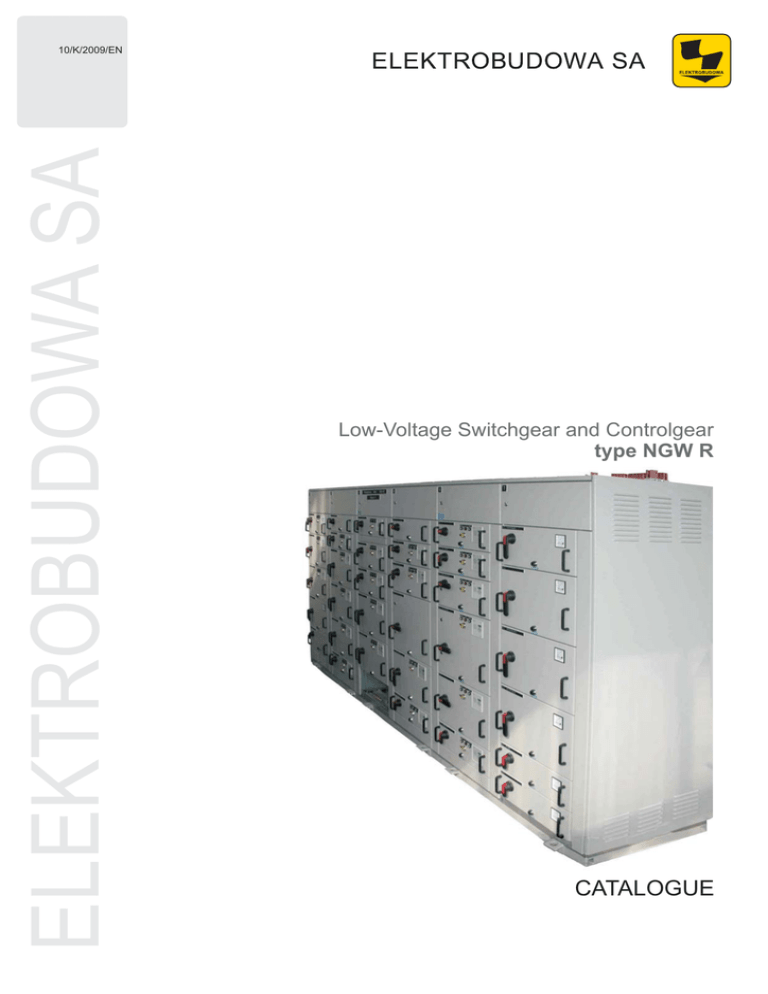

ELEKTROBUDOWA SA

10/K/2009/EN

Low-Voltage Switchgear and Controlgear

type NGW R

CATALOGUE

ELEKTROBUDOWA SA

INTRODUCTION

1. GENERAL CHARACTERISTICS

1.1. APPLICATION

1.2. FEATURES

1.3. OPERATION CONDITIONS

1.4. CONFORMITY TO STANDARDS

2. TECHNICAL DATA

3. SWITCHGEAR DESIGN

Functional units compartment

The busbars compartment

The distribution busbars compartment

The auxiliary/common circuits compartment

The connections compartment

3.1. Sections with an air circuit breaker

3.2. Sections with withdrawable and remowable part

3.3. Sections with a digital control and supervision system

3.4. Reactive power compensation sections

3.5. Lighting switchgears

3.6. Sections with blocks of disconnecting switches

4. MAIN CIRCUITS

5. OPERATION CHARACTERISTIC

5.1. Degree of protection

5.2. Interlocks

5.3. Protection against electic shock

5.4. Equipment supplied together with the switchgear

5.5. Operation equipment

5.6. Nameplates and labels

6. MOUNTING

7. TRANSFORMER CHAMBER

8. BUSDUCT

9. DESIGNING

9.1. Contents of the engineering design

9.2. Hints for designing

10. TRANSPORT

11. ORDERING

1

1

1

1

1

2

2

4

6

6

7

7

8

9

10

10

11

11

12

15

15

15

15

15

15

16

16

17

18

20

20

20

21

21

Switchgear 0,4kV in Rafinery ORLEN

P³ock Poland

Efficient, safe, economical, beneficial - such is the low voltage NGW distribution system offered by

ELEKTROBUDOWA SA. Versatile possibilities of application in low voltage electric network, universal permanent,

plug-in and withdrawable units in one section, safe supply by encapsulated busbar trunking system and variety of

cable, wire and busbar connections - distinguish our product in the international market. A lot of possibilities to choose

from mass-produced modules determinate the high quality of product.

¢

¢

¢

¢

¢

Mentioned below products are parts of the system NGW:

switchgears NGW R-1 up to 7500A; up to IP42,

control assemblies NGW R-18 up to 630A; up to IP42,

switchgears NGW R-2 up to 2500A; IP55,

busbar trunking systems NGW M-1,

transformer chambers NGW K.

The catalogue presents the switchgears in detail. General information about busbar trunking systems and

transformer chambers is included.

1. GENERAL CHARACTERISTICS

Indoor switchgears and controlgear systems NGW R are

assembled from elements manufactured serially in the

numerically controlled machining centres. Parts of the

construction are made from high quality material protected

with anticorrosive electrolytic or powder paint coats.

1.1. APPLICATION

Indoor low voltage switchgears NGW R are designed for

low voltage AC or DC electric energy distribution, and for the

control and protection of electric equipment against short

circuit and overload consequences. They can be used as main

switchgears, motor control centre and subdistribution boards.

They can work with busbar trunking system in TNC or TN-S

alternating current networks and in direct current networks.

The NGW assemblies meet the needs of numerous clients

in industrial plants, power industry, transportcommercial and

public buildings and environmental protection plants.

1.2. FEATURES

The most distinguishing features of the type NGW R

systems are:

Polish product conforming to international standards

in quality,

one manufacturer fulfils all energy distribution

requirements,

configuration of switchgear, busduct and transformer

chamber according to the needs,

convenient access to apparatus and comfortable

operation,

separation of compartments in any agreed form, from

1 to 4 according to PN-EN 60 439-1:2003/A1:2006,

adaptation for cooperation with digital equipment for

monitoring and control,

easy replacement of functional units or adding new

ones,

each assembly type tested (TTA),

safety for personnel and protection of equipment,

reliability and long life,

minimum maintenance and inspection requirements,

manufacturer's professional service,

quick assembly,

short response times for delivery.

1.3.

OPERATION CONDITIONS

NGW R-1, 2 switchgears and other elements of

NGW system are designed to operate in rooms

ensuring normal environment condition according to

standard PN-EN 60439-1:2003/A1:2006. Special

environment conditions must be agreed between

manufacturer and user.

NGW R-2, IP55 Assembly

1.3.

CONFORMITY TO STANDARDS

Elements of NGW system meet the requirements of

standards:

PN-EN 60439-1:2003/A1:2006 Low voltage switchgear

and controlgear assemblies. Requirements for typetested and partially type tested assemblies.

PN-EN 60439-2:2004/A1:2007 Low voltage switchgear

and controlgear. Requirements for busbar trunking

sytem.

PN-EN 60439-3:2004 Low voltage switchgear and

controlgear. Requirements for low voltage switchgear

and controlgear designed for installation in places

accessible for the unqualified personnel. switchboards.

PN-EN 60439-4:2008 Low voltage switchgear and

controlgear. Requirements for assemblies to

be

installed on site.

PN-E 05163:2002 Enclosed low-voltage switchgears

and controlgears. Arc-resistance commissioning and

testing.

PN-EN 60529: 2003 Degrees of protection provided by

enclosures (IP Code).

ELEKTROBUDOWA SA applies the management system

according to ISO 9001; ISO 1401 and AQAP-2110.

1

ELEKTROBUDOWA SA

2. TECHNICAL DATA

NGW R-1

Rated values

insulation Ui

Rated voltage

Rated current In

V

V AC

V DC

operation ue

continuous of horizontal busbars

continuous of supply cubicles

continuous of cubicle vertical buses

Short-circuit currents Icw, Ipk, fault duration time tcw

A

A

A

A

Hz

Rated frequency fr

NGW R-2

do 1000

500

up to 1000

250

up to 660

up to 630

up to 7500

125, 250

up to 6300

up to 1600

up to 231 according to table

-

up to 1000

up to 660

up to 2500

up to 2500

1600

page 6

50 ÷ 60

up to IP42

Protection degree of enclosures according to IEC 529

kg

Average mass of a section

NGW R-18

120

250

Resistance to consequences of internal arc

according to category B1*

IP55

230

65 kA during 0,1s

3. SWITCHGEAR DESIGN

Construction parts of a section

Mounting frame

Construction framework

Partitions between sections,

mounting plates, connection elements

External enclosures

Corrosion-proof coating

epoxy powder paint

protective coat Al-Zn

protective coat Al-Zn

epoxy powder paint

Switchgear's construction allows for the installation of 3- or 4- pole

apparatus. In segments there are separated compartments. The

compartmented design provides the protection against contact with

live parts belonging to the adjacent functional unit and the reduction

of spreading arc fault consequences outside the place it is initiated,

and thus considerably increase the degree of safety.

The basic module

is a cuboid

125x50x50 mm

Construction parts of a switchgear section

Dimensions of a section are a multiple of a 125x50x50 mm cuboid.

Preferred dimensions of sections

width w

height h

depth d

Type of a section

mm

mm

with withdrawable/removable parts up to IP42

with a side connections compartment

850, 1000

2150

with a rear connections compartment

700

with withdrawable/removable parts IP55

with a side connections compartment

950, 1100

2150

with a rear connections compartment

800

with a side connections compartment

with a rear connections compartment

with fixed parts up to IP42 or IP55

650, 850, 1000

2150

400, 600, 750, 1000

version with an additional door

preferred sections up to IP42

Other dimensions subject to agreement

2

400, 600, 750, 850, 1000

2150

mm

550, 750, 1000

750, 900, 1000

700, 900, 1150

900, 1050, 1150

250, 400, 450, 550

600, 650, 750

550, 700, 750,

900, 1000, 1150

2000 = 16 x M

h = 2150

50

Wall-mounted – access from the front

A

A

A

foundation frame

A

A

50

V

d

w

Double incoming feeder

rear connections compartment

Free-standing – access from the front and back

Functional compartments:

- functional units

- main busbars

- distribution busbars of the segment

- auxiliary/common circuits

A

A

A

A

V

A

- connections

Options: from the bottom, from the left side, from the right side or from the back

Optional configuration of sections

In the NGW R switchgear design enables all methods

of internal division of a section by means of partitions or

barriers are possible. According to PN-EN 604391:2003/A1:2006 the inside of a section can be divided in

one of the following ways:

Form 1

Form 3a

Form 3b

Form 2a

Form 2b

Form 4a

Form 4b

Different forms of compartments separation according to PN-EN 60439-1:2003/A1:2006

3

ELEKTROBUDOWA SA

FUNCTIONAL UNITS COMPARTMENT

2M

In the standard section 2150 mm high,

the height of a functional unit compartment

is conventionally divided into 14 or 16

modules M = 125 mm. In this compartment

units with withdrawable, removable or

fixed parts can be situated.

A

A

A

A

A

V

16M

h = 2150

14M

A

A

600

w

w

- with a busbar compartment

- without a busbar compartment

Typical sections - examples

Withdrawable units

Apparatus of main and auxiliary circuits are mounted on

a common base which can be completely removed from the

section even if the circuit to which it is connected is under

voltage. The withdrawable part can take one of the four basic

positions:

a connected position the part is fully connected for its

normally intended function,

a test position the switch in the main circuit is open, the

safe isolating distance in main circuits is provided, auxiliary

circuits are connected, the part remains mechanically

attached to the assembly,

a disconnected position

an isolating distance is

established in main and auxiliary circuits, the withdrawable

part is mechanically attached to the segment,

a removed position

the part is mechanically and

electrically separated from the section (outside the

switchgear).

In the connected position the withdrawable part is

mechanically interlocked and can be additionally blocked (item

5.2). For inspection or repair time the withdrawable part can be

replaced with an earthing part in order to earth the outgoing

cable (item 5.5).

There are seven sizes of withdrawable parts: W04, W02,

W1, W1,5, W2, W3 i W4.The size of a withdrawable part

depends on:

the rated continuous current and number of main busbars

The size of a withdrawable part

Rated current In

Number of main busbars

W04

32A

W02

63A

2; 3; 3 + N

Withdrawable unit 550mm wide

Withdrawable unit W02 and W04

The minimal size of a withdrawable part 550 mm wide

Number of main busbars

Rated current In

160A

250A

400A

630A

3

3+N

1,5M

2M

2M

4M

1,5M

3M

3M

4M

2

1,5M

2M

2M

3M

2M

4M

4M

—

¢ the type and quantity of mounted apparatus

Size of a

withdrawable

part

W04

W02

W1

W1,5

W2

W3

W4

4

Mounting space on a withdrawable part

Height of a

withdrawable part height h

depth d

width w

mm

187,5

187,5

125

187,5

250

375

500

145

145

54

117

180

306

432

110

220

330

529

400

h

d=

400

w=

The withdrawable part W1 ÷ W4

529

The main moving contact of the main circuits is

located in an insulating beam of the withdrawable part.

Its shape ensures the efficient decomposition of electrodynamic forces. Contacts can be joined in parallel.

The main moving contact of the auxiliary circuits is

located under the base. It is used as:

external connections block,

interconnections block,

limit switch.

Withdrawable

part

The main moving contact of the auxiliary circuits greatest amount of contacts

W04

W02

W1÷W4

36

36

45

The main contacts of the

withdrawable part W04 or W02

The main contact of the

withdrawable unit W1 ÷ W4

in the connected position

Removable (plug-in) parts

or

The removable (plug-in) part can be removed from

the switchgear even when the circuit to which it is

connected is live. It can take up following position:

the connected position,

the removed position.

The removable (plug-in) part includes main and

auxiliary circuits' apparatus on a three-dimensional

cassette or on a common mounting plate, such as:

typical or customized functional unit of apparatus, a

plug-in circuit breaker and a plug-in fuse-switch. The

main moving contact of the removable (plug-in) part

main circuits connects it with distribution busbars.

There are types:

P04, P02, P1, P1,5, P2, P3, P4 mounted on a threedimensional cassette,

R1, R1,5, R2, R3, R4 mounted on a plate,

disconnecting switch blocks.

Removable parts P04 i P02

Removable parts R1,5

The main contact of the removable part of circuit:

Removable part

CASSETTE

P04

P02

P1÷P4

main

auxiliary

Notice

36

The other

configuration

output/input

is also

available

PLATE

–

–

R1÷R4

2, 3, 3 + N

Disconnecting switches

arranged vertically

Disconnecting switches

arranged horizontally

Fixed parts

Fixed parts include apparatus

permanently mounted on

crossbeams or mounting plates

and connected to the main

circuits. The size of the part is a

multiple of a basic module:

125x50x50 mm.

Sections with fixed parts are

used as switchgear, controlgear

and sets for reactive power

compensation, usually

individually design.

A section without division into compartments

An assembly with meters

Separated functional areas

5

ELEKTROBUDOWA SA

Rated currents of busbars

The busbars compartment

In

The main busbars run along the whole length of the

switchgear in the upper part of its sections. The arrangement and

size of copper conductors depend on technical parameters.

Busbars can be divided into sections to facilitate assembly or

transport. Sections of busbars are joined by special connectors

without the need to make holes.

Ipk

Icw

Size of a copper

conductor

Diagram

tcw

s

A

kA

kA

400

750

1250

1600

2000

80

80

100

100

150

40

31,5

40

40

60

0,1

0,5

0,5

1,0

1,0

2500

176

80

1,0

3200

4000

5000

6300

7500

176

176

231

231

231

80

80

105

105

105

1,0

1,0

1,0

1,0

1,0

mmxmm

3

30x5

3 (5)

30x10

2x(30x10)

1 (6)

1

2x(40x10)

1

2x(50x10)

2x(80x10)

1

2x[2x(50x10)] *

4*

2x(100x10)

2x[2x(80x10)]

2x[2x(100x10)]

3x[2x(80x10)]

3x[2x(100x10)]

1

2

2

7

7

applied at the reduction of the system, load symmetrically top-bottom

Neutral bus N is half a phase bus size unless different

construction and design assumptions.

Inside the busbars compartment

L1

L2

L3

L1 L2 L3 N

N

7

L1

L2

L3

N

L1

L2

L1

L3

L2

L3

N

L1

L2

L3

N

L1

L2

L3

N

L1

L2

L3

Arrangement of busbars – diagrams 1-7

The distribution busbars compartment

Vertical busbars are run in the rear of the section. Busbars

can have 2-, 3- or 4-pole arrangement, as:

Holeless busbar joint

flat copper conductors consisting of one, two or three strips to

connect mechanically operated switches with busducts; flat

bars from P30x10 to P100x10 are used,

channel bar conductors in isolating elements to connect

withdrawable and removable parts.

For optimal arrangement of distribution busbars it is

recommended to group the withdrawable, removable and fixed

parts.

Rated current

Size of channel

shaped busbars

C400

C630

C1000

C1600

6

Fault duration time

In

Ipk

Icw

tcw

A

kA

kA

s

400

630

1000

1600

80

100

150

150

31,5

40

60

60

0,5

0,5

0,5

1,0

Flat conductors

Channel shaped distribution busbars

The auxiliry/common circuits compartment

In the auxiliry circuits compartment there are apparatus of control

circuits, signalling, measurement, data processig, etc. circuit breakers and

some functional unit for which that circuits don't have enough place in

withdrawable units.

Common circuits (circuitous) there are placed in separate compartment

of circuitous circuits. If there are not any circuitous circuits it is possible

installing in that compartment some auxiliry circuits. In particular cases in

circuitous circuits compartment can be take out terminals for installing

earthing units.

Section

The common/auxiliary circuits compartment

height

depth

width

The compartmemt

for circuits:

With a circuit breaker

auxiliary

common

with

busbars

with fixed parts

witch a withdrawable/

/removable parts

With the external

compartment from the side

Without the external

compartment from the side

without busbars

auxiliary

common

auxiliary

common

auxiliary

common

auxiliary

common

400, 600,

750, 1000

600

mm

2M ÷ 9M

prefered 5M

2M

350

any to 14M

350

700, 850, 1000

2M

usually doesn't exist

2M

as for the section

Usually

usually doesn't exist

2M

as for the section

The compartment of

circuitous circuits

100

100

100

100

usually doesn't exist

The circuitous circiuts of switchgear

and auxiliary circuit of circuit

breaker compartment

The external connections compartment

The external connections compartment there is in every

segment equipped with withdrawable and plug-in functional units

and sometimes there is in segments with fixed units. In segment

can be located:

on the right side,

on the left side only segments with fixed units,

on the beck side the free-standing switchgear,

at the bottom,

at the upper.

The side compartment with width 250 mm can be used when

number and sections of outgoing cables are not big. With

exploitation reasons prefered is compartment with width 400 mm.

The compartment under the circuit breaker is designed for cable

or rails connections and for terminals for installing earthing units.

In standard version the bottom of the compartment isn't

covered. On special request in version with IP55 the bottom of

compartment is covered by metal plate with glands.

Insertion cebles from uper side is possible by glands or hole in

top cover. For segments with rails only after agreement.

Connections with busbar

bridge from the top

Connections compartment

from the right side

Connections compartment Connections with

cables from the top

from the bottom

Connections compartment

from the beck

Connections compartment

from the left side

7

ELEKTROBUDOWA SA

Enclosures

Total dimensions of the assembly depend on dimensions of its sections

and external enclosures.

enclosure thickness

remarks

mm

20

end section

side enclosure

17

rear enclosure

17

front door

free-standing section

17

rear door

1,0

A partition between sections

A standard door

opens right. The

maximum size of a glass

panel is 200 mm smaller

than the door size.

Optionally, a section

can have an extra door,

which covers the handles

of the operating

mechanism. Then the

section's depth is 150 mm

greater.

Type of enclosure

min. 100

min. 100

A single section has two side enclosures.

2M

5M

2M

d

d

d

w

Connections from the bottom

d

w1

w

500*

1M

2x50

4M

5M

3M

14M

5M

2150

5M

2M

50

3.1. SECTIONS WITH AN AIR CIRCUIT BREAKER

w

400

Connections from the right side

Connections from the top

w1 = 250mm dla In ≤ 2500A

w1 = 400mm dla In > 2500A

In

of the circuit

breaker

A

1600

2000

2500

3200

4000

5000

6300

7500

width w

Minimal size of a section with a circuit breaker

number of main busbars

3

4

depth d

depth d

width w a bottom cable

a top

a top

a bottom cable

connection

connection

connection

connection

500*

600

550

550

600

600(750)

750(1000)

750(1000)

1200

1200

550(750)

550(750)

750(1000)

750(1000)

1200

1200

750

750

750

750

1000

1000

1400

1400

mm

600

750

550

550

750

750

750

750

1000

1000

1400

1400

550(750)

550(750)

750(1000)

750(1000)

1200

1200

750

750

1000

1000

1400

1400

500* - for ACB with reduced dimension, type (ABB), NT06÷NT1,6 (Schneider), IZMX16 (MOELLER).

Dimensions in brackets to be applied for coupling panels and whereas busbar trunking system

(busduct) is connected to a section.

8

Sections with air mechanical circuit breakers perform the function of supply feeders, outgoing

feeders or coupling cubicles. Two circuit breakers with rated current up to 1600A can be installed in

one section. The preferred circuit breakers and standard schematic diagrams are specified in item 4.

Circuit breakers can be installed as fixed or withdrawable. Auxiliary and common circuits should

be located in the auxiliary circuits compartment. A standard height of such compartment is 5M.

A special truck (item 5.5) produced by ELEKTROBUDOWA SA is offered to facilitate operation of

the circuit breaker.

2M

3.2. SECTIONS WITH WITHDRAWABLE AND REMOVABLE PARTS

Units with withdrawable and removable parts can perform the

function of supply or outgoing feeders or for reactive power

compensation. Standard schematic diagrams and preferred

apparatus are specified in item 4.

The remaining space in the functional units compartment can

be:

filled with a dummy ,

used for stand-by withdrawable parts,

used as a compartment for further extension of the switchgear

(additional door),

used as an auxiliary circuits compartment.

Additional equipment for operation of the withdrawable and

removable part is specified in item 5.5.

1,5M 1,5M ³¹cznie 3,5M

2M

Units with a disconnecting switch

Units with a moulded case circuit breaker and a contactor

Minimal size of the withdrawable part/removable cassette

In (A)

P (kW)

No. of the schematic diagram

of a circuit power of the

operating

breaker

device

17

up to 32 up to 15

up to 63 up to 22

up to 160 up to 55

up to 250 up to 75

up to 400 up to 110

400

up to 160

W04

W02

W1,5

W2

W3

W4

20

23

or P04

or P02

or P1,5

or P2

or P3

or P4

W4 or P4

W4 or P4

W4 or P4

W4 or P4

A

A

A

4M

The tables show dimensions of the most frequent

withdrawable parts or removable cassette.

Minimal size of the withdrawable part/removable cassette

No. of the schematic diagram

In (A)

of a disconnecting switch

15

13 14

up to 32

W04 or P04

up to 63

W02 or P02

W1,5

P1,5

or

up to 160

or

up to 250

W2

P2

up to 400

W3

P3

or

or

up to 630

W4

P4

A

V

1M 1,5M

h = 2150

14M

A

600

w

w1

w1 = 400 mm preferred

w1= 250 mm small quantity of cables

w1 = 600 mm and more big quantity of cables

Units with a disconnecting switch and a contactor

Minimal size of the withdrawable part/removable cassette

In (A)

P (kW)

of a circuit power of the

operating

breaker

device

up to 32 up to 15

up to 63 up to 22

up to 160 up to 55

up to 250 up to 75

up to 400 up to 110

400

up to 160

No. of the schematic diagram

18

W04 or P04

W02 or P02

W1,5 or P1,5

W2 or P2

W3 or P3

W4 or P4

21

W1,5 or

W4 or

W3 or

W4 or

24

P1,5

P4

P3

P4

W4 or P2

W4 or P4

W4 or P4

W4 or P4

Units with a contactor

Minimal size of the withdrawable part/removable cassette

No. of the schematic diagram

In (A)

P (kW)

of a circuit power of the

operating

breaker

device

up to 32 up to 15

up to 63 up to 22

up to 160 up to 55

up to 250 up to 75

up to 400 up to 110

up to 630 up to 160

18

W04

W02

W1,5

W2

W3

W4

or

or

or

or

or

or

P04

P02

P1,5

P2

P3

P4

Standard auxiliary equipment: two auxiliary relays, a fuse and a miniature circuit breaker.

9

ELEKTROBUDOWA SA

3.3. SECTIONS WITH A DIGITAL CONTROL AND SUPERVISION SYSTEM

One of the essential advantages of the NGW R switchgear system is its

facility to cooperate with the digital systems of protection, monitoring, control

and supervision.

A digital system is of a dissipated nature. It is based on microprocessor

apparatus of recognised producers, which enable to come on stream and

communicate in the PROFIBUS-DP (SIMOCODE), or MODBUSRTU

(MICOM P211 with the possibility of communication) protocol.

Microprocessor modules facilitate the performance of the following functions

in the motor drive supply units:

complete protection against overload and overheating,

ground fault detecting,

protection against operation with the phase currents unbalance and

phase decay,

motor control,

electrical ratings measuring ,

measuring and recording of work time and number of operations (only

SIMOCODE).

The control function can be performed from a control and supervision

station through a digital network with a suitable communication protocol or

through individual inputs of modules. In the latter case it is realised either by

individual push-buttons or directly from the front panel of the unit (in case of

SIMOCODE an additional operator panel must be provided).

Owing to the digital network it is possible to read such parameters as

module input and output state, measured electrical values, event recording,

etc., from the control and supervision station.

It is possible to incorporate the units with a circuit breaker or a

disconnector switch into the digital network of the switchgear: directly, if they

are provided with a suitable communication interface, or through an adapter,

if they are not.

The preferred dimensions of sections are shown in the table on page 2.

Digital control and supervision system

for drives and circuit breakers

Withdrawable part W02 with digital module

3.4. REACTIVE POWER COMPENSATION SECTIONS

Another advantage of the NGW R switchgear is the provision for bank of

capacitors on the withdrawable parts or in the sections, in one set of a

distribution assembly. It results in cost reduction, as it is not necessary to buy

a cable and a supply unit. Sections of the battery are fed directly from the

switchgear busbars through internal protection devices and contactors. 120

kvar batteries can be placed on the withdrawable parts, batteries with greater

power in sections with appropriate dimensions.

Withdrawable part according to

the schematic diagram 30

Size of the withdrawable part

power of the battery

P (kvar)

10 ÷ 50

30 ÷ 120

10

number of

No of the schematic diagram

regulation grades

30

2M

3M

2

4

Reactive power compensation section NGW R-1

3.5. LIGHTING SWITCHGEARS

Lighting switchgears are designed for protection and

control of lighting and heating installations, ventilation or airconditioning circuits and plug-in sockets in public buildings,

production bays, shopping centres, etc. They are usually

sections 250 or 400mm deep. Available widths are specified in

the table on page 2. Doors can have a sight glass for

inspecting the status of apparatus.

Sections with plug-in sockets on the side enclosure or

behind the door are used for feeding a construction site or a

building under repair. Sections used for this purpose usually

are 450 or 650 mm deep. Available widths are specified in the

table of the preferred dimensions on page 2. The height

depends on the requirements and can be a multiple

of M = 125mm.

Lighting switchgears

3.6. SECTIONS WITH BLOCKS OF DISCONNECTING SWITCHES

h3

Sections with blocks of disconnecting switches are applied in

industrial and power plants. They are particularly fit for municipal,

district or plant transformer substations.

3.1 3.2 3.3 3.4 3.5

4.1 4.2 4.3 4.4 4.5

h1

h2

2.1 2.2 2.3 2.4 2.5

d

50

w

w

w

w

Sections with blocks of disconnecting switches vertical

10M

13M

16M

height

h3

0

3M

6M

h (mm)

1400

1775

2150

depth

d (mm)

250, 450, 550

width

w (mm)

any width

from 400 to 1500

every 100mm

Dimensions of the switchgear with blocks of disconnecting

switches depend on current ratings and number of consumers.

With the supply of maximum current In 1600A the following

devices can be used:

a moulded case circuit breaker,

a disconnecting switch,

a disconnector,

direct busbar connection.

Rated continuous current of consumers is In 630A.

Switchger with blocks of fuse-switches

The preferred dimensions of sections

are shown in the table on page 2

11

Functional units with

fixed parts

Functional units witch

removable parts up to 630A

Functional units

with withdrawable parts

Functional units with

fixed parts

Functional units witch

removable parts up to 630A

Functional units

with withdrawable parts

ELEKTROBUDOWA SA

4. MAIN CIRCUITS

12

M

M

M

M

M

M

M

M

M

M

M

M

M

BUSDUCT

M

BUSDUCT

Main diagrams in ALBUM, available on an ask.

M

M

M

M

M

M

M

M

M

M

M

M

M

M

13

ELEKTROBUDOWA SA

Prefered equipment mounted in the sections of NGW R-1 is shown in the table below

Device

Type

Air circuit breaker

E-max

IZM

Masterpact

3WL1

M-PACT

Isomax / T-max

NZM

NS

3VF

Record Plus

OETL / OESA / OS

DMM / DMV

SIRCO

RA / RAB / RBK

SR / XR

SL

A / EH

DILM

LC

3RT10

CI

LSV

CL / CK

various

various

various

MICOM P210 / P211

FANOX

Simcode DP

AZRS / APZ

various

Moulded case circuit breaker

Switch / fuse-switch

Slim-line disconnecting switch

Contactor

Current transformer

Protection devices

ACO units

Auxiliary relays

Motor circuit breakers

Signalling lights and control buttons

Signalling diode

various

MS / MO

PKZM

GV

MBS

various

various

various

various

various

Ammeters, voltmeters, meters

Voltmeter switch

EA / MA / PA / FA and other

4G10

OMV

TZ-2

Connection pieces

WDU

various

various

ZRK / RK

Producer

ABB

MOLLER

Schneider Electric

SIEMENS

GE

ABB

MOELLER

Schneider Electric

SIEMENS

GE

ABB

Holec

Socomec

APATOR

ABB

JEAN MÜLLER

ABB

MOELLER

Schneider Electric

SIEMENS

Danfoss

ORAM

GE

ABB ZWAR SA

Polcontact Sp. z o.o.

MBS

AREVA

FANOX POLSKA

SIEMENS

Energotest-Energopomiar Sp. z o.o.

Relpol SA

FINDER

ABB

MOELLER

Schneider Electric

GE

ABB

MOELLER

Schneider Electric

PROMET

TWELVE

LUMEL SA

APATOR SA

ABB

MOELLER

..

Weidmuller

WAGO

Phoenix

CONTA-CLIP

In NGW R-1, 2 switchgear practically any devices can be mounted . Other functional units can be designed on request.

14

5. OPERATIONAL CHARACTERISTICS

5.1.

DEGREE OF PROTECTION

In order to provide protection against contact with live parts and

ingress of solid foreign bodies and water, the switchgear is designed as:

Assembly / element

Degree of protection

NGW R-1

NGW R-2

After opening the door

The withdrawable part in the removed position

up to IP42

IP55

IP2X

IP2X

The switchgear can be designed as an open-type assembly with a

lower degree of protection; this must be indicated in the engineering

design.

Number of vent openings is designed by ELEKTROBUDOWA SA. In

the IP55 design no vent openings can be foreseen.

5.2.

A section IP55 NGW R-2

INTERLOCKS

According to PN-EN 60439-1:2003/A1:2006 the withdrawable parts can be inserted to the connected position or

withdrawn only when the main circuit is interrupted. Provision is made for additional interlocking with padlocks or keyoperated locks.

The door of the functional unit/group can be provided with the interlock of opening in case of voltage presence. The door

may have a provision of sealing.

5.3.

PROTECTION AGAINST ELECTRIC SHOCK

Protection against direct contact is provided by barriers and enclosures.

Protection against indirect is provided by using protective circuits. The construction together with a protective conductor

provides a suitable impedance of fault loop, so the fault protection devices can operate. Either neutral earthing or

protective earthing is applied, according to the user's needs.

5.4.

EQUIPMENT SUPPLIED TOGETHER WITH THE SWITCHGEAR

A NGW assembly is delivered together with operation and maintenance manual and:

bolts for connecting the cubicles

a set of busbar connecting pieces

0,4l of paint

keys for the doors.

5.5.

OPERATION EQUIPMENT

An earthing part

earthing parts

For the time of repair or replacement of the equipment being

fed the parts which supplies the consumer is replaced with a

specially marked earthing part which has the function of closing

and earthing the outgoing contacts of the unit.

Withdrawable part tester

An extension cord

for removable parts

a cubicle for earthing and replacement parts

a withdrawable part tester

For the time of measurements and identification of damage

the inspected part of the switchgear is replaced with the

withdrawable part of a tester. The inspected part shall be

inserted onto the guide rails of the tester upper shelf. The

control circuits close automatically.

extension cord for the removable part

The extension cord is provided with a socket and a multi-pin

plug connected by a multi-core conductor. Connection of the

control circuits of the inspected removable part with the

switchgear is provided through this connector.

a hand operated lifting truck.

Hand operated lifting truck

A cubicle for earthing

and replacement parts

15

ELEKTROBUDOWA SA

2

A

A

5.6. Nameplates and labels

Examples:

A

A

A

Elements of the NGW system are identified by

nameplates according to PN-EN 60439-1:2003/A1:2006.

Numbering and descriptions of functional units shall be

given in the engineering design. A number of the functional

unit is created in the following way:

1.4 Feeding from RS2

A

1.5.3 Valve 3

V

A

1.8 Pump P2

x - number of a section, counting from the left side of the

assembly

y - number of a functional unit of full width of the section,

counting from the top of the switchgear

z - number of the functional unit counting from the left side of

the section (parts 1/4M and 1/2M)

6. MOUNTING

The switchgears are usually arranged in one or two rows. It is

also possible to arrange the sections in a broken line. They can

be connected by an attachment box or a section of busduct.

Minimum distance between the switchgear and the wall of a

room is 100 mm. Recommended height of the switchgear room

is h + 500 mm. For rooms which are not so high or when

busducts are applied, please consult the manufacturer.

Preparation of the room for mounting the switchgear consists of:

Main busbars connection of sections arranged at right angle

w

50

50

cubicle’s contour

50

w-100

maximal hole in the floor

50

w - cubicle’s width

w1 - connetions compartment’s

width

d - cubicle’s depth

Holes in the floor

Assemblies with various depths of the cubicles can be

leveled to the deepest cubicle.

L

L1

L2

L3

50

d

d - 100

d

50

w1-70

w

d

When the switchgear has been levelled the sections shall be

fixed:

on the foundation frame mounted in the floor or on the fake

floor made from steel shapes, with bolts or by welding in a

few spots from inside, the welds shall be protected with

anti-corrosive paint,

¢ directly on the floor, using anchor sleeves, e.g. TKKM-8.

w

w1

d - 100

¢ completion of construction and painting

¢ completion of ventilation and water-sewage systems

¢ completion of lighting installation

preparation of the mounting floor:

mounting and levelling the foundation frames with

accuracy ± 2 on the whole length

levelling the part of the floor with holes,

mounting the floor tiles on the fake floor,

provision of the door opening width w + 100 mm and

height h + 100 mm,

provision of key-lock or a padlock in the entrance door,

provision of an entry in the wall if the switchgear is fed

from the busduct situated in another room or from the

outside.

a foundation frame

- foundation frame’s width

- sum of widths cubicles with minimum depth d1

- sum of widths cubicles with minimum depth d2

- sum of widths cubicles with minimum depth d3

an anchor

Foundation frames

16

7. TRANSFORMER CHAMBER

Technical data

NGW K

Rated voltage

higher up to 7,2 kV, lower up to 690 V

Resistance to electric arcing

consequences, at current 65 kA in 0.1 s

65kA / 0,1s

Degree of protection of enclosures

Power of transformer up to

Chamber dimensions

width

mm

height

depth

IP4X

up to 1250 kVA

up to 630 kVA

1800

2200

2150

1400

660 kg

2150

1100

550 kg

Mass of the chamber without transformer

up to 3150 kVA

2600

2600

1600

760 kg

The transformer chamber NGW K for dry-type

transformer of maximum rated higher voltage up to

7,2 kV and power 3150 kVA has the following

features:

enclosure made of sheet painted with quality

powder paint

easy dismantling of front enclosures facilitates

inspections and drawing out of the transformer

characteristic lifting of enclosures

enclosures have no connecting elements

outside

inside: a section of low voltage busbar.

A chamber located next to the switchgear is

connected with busbars. Cable or busduct

connections are possible.

Switchgear 15kV

Transformer chamber

NGW K

Switchgear NGW R

Convenient dismantling of front enclosure of the chamber

15/0,4kV assembly for industrial use

17

ELEKTROBUDOWA SA

8. BUSDUCT

The enclosed busbar trunking system NGW M-1 is applied as a

primary or stand-by supply circuit and the interconnection between

sections. Its self-supporting structure has the following features:

the encapsulation, made of shaped and perforated aluminium

sheet, performs the function of an enclosure

conductors for any alternating or direct current systems are

manufactured

double-bar conductors are symmetrically laid

holeless connections of phase bars sections

straight sections, elbows and connection pieces are serially

manufactured in numerically controlled machining centres

¢ convenient location of inspection windows

¢ the enclosure is painted with quality powder paint, standard colour

RAL 7032, other colours possible.

Busbar supply of the switchgear

from the transformer room

Straight horizontal (vertical) section

h

h

b

b

NGW M-1

a

1,25 ÷ 2,0

2,5 ÷ 4,0 up to 3000

5,5

a

b

mm

350

550

850

h

200

250

250

a

Connection box

NGW M-1

h

b

1,25 ÷ 2,0

2,5 ÷ 3,15

4,0 ÷ 5,5

a

a

600

600

800

b

mm

600

600

1000

h

250

300

300

Vertical elbow

a

NGW M-1

h2

1,25 ÷ 2,0

2,5 ÷ 3,15

4,0 ÷ 5,5

h1

a

400

600

1000

h1

mm

350

400

400

h2

250

300

300

Horizontal elbow

h

1,25 ÷ 2,0

2,5 ÷ 3,15

4,0 ÷ 5,5

b

a

Clamp

18

NGW M-1

Wall passage enclosure

a

517

717

1117

b

mm

400

600

1000

h

250

300

300

Technical data of busduct

NGW M-1

Unit

Characteristic value

/1,25

/1,6

/2,0

/3,15

/4,0

/5,5

2500

3150

4000

5500

170

75

205

90

205

90

231

105

/2,5

Rated voltage of insulation

V

1000

Impulse withstand voltage 1.2/50 ms

kV

14,5

Rated current:continuous

Rated current peak

A

1250

1600

2000

kA

kA

110

45

110

45

150

60

Rated current withstand 1s

The Cu phase conductor

mm 2xP30x10 2xP40x10

Mass of 1m busduct

Cross-sectional area of the busbar

impedance

Mean value:

reactance

resistance

kg

mm

2

mÙ/m

2xP50x10

2xP80x10 2xP100x10 2x[2xP80x10] 2x[2xP100x10]

35

40

50

75

90

135

175

400x250

400x250

400x250

600x300

600x300

1000x300

1000x300

0,110

0,110

0,110

0,091

0,091

0,091

0,052

0,100

0,100

0,100

0,090

0,090

0,090

0,051

0,017

0,017

0,017

0,009

0,009

0,009

0,004

Degree of protection

9

up to IP43

10 6

1 7 11

7 11 6

9

3

8 12 4 1

1

4 2 3

5 3

9

1

8 3

8

le

po il.

s

za

le

po il.

s

za

ja

c

ek

II

s

1. straight horizontal section

2. straight vertical section

3. connection box

4. vertical elbow

5. horizontal elbow

6. clamp

ja

c

ek

k

blorzê.

sp

I

s

7. wall passage enclosure

8. level raiser

9. support sling

10. support gantry

11. wall bracket

12. supporting structure

Application of the NGW M-1 enclosed busbur trunking system in the transformer and switchgear rooms

19

ELEKTROBUDOWA SA

9. DESIGNING

ELEKTROBUDOWA SA offers to make a design of the

switchgear.

9.1. Contents of the engineering design

Customers are requested to read the following

recommendations before designing the switchgear.

Technical design of the switchgear should include:

1. technical description of the switchgear, including:

layout of network in which the switchgear will work,

required degree of protection,

table of panels application descriptions,

numbering and process descriptions,

methods of separating the functional units,

2. main circuits diagram with the apparatus and

connections (type, number, cross-section, capacity;

arrangement of busbar connections, phase

sequence)

3. arrangement of a section,

4. glass window in the door,

5. development of the auxiliary circuits:

selection of apparatus

circuit and installation diagrams

location of apparatus

method of entering the cables of the auxiliary circuits

(type, quantity, cross sections)

6. selection of interlocks,

7. summary of main and auxiliary circuit apparatus with

names of manufacturers on diskettes

8. drawings of foundation and arrangement of sections,

with busbar connections, in the room,

9. division into transport units,

10. colours of front covers (as a standard RAL 7032 grey

recommended)

Meter on the connections compartment’s door

9.2. Hints for designing

It is most convenient to design standard units specified in

the catalogue, following the guidelines:

1. functional units with withdrawable parts need the least space

2. functional units with withdrawable or removable parts are more

convenient and safer in operation

3. functional units with withdrawable or removable parts and

fixed-type units can be situated in the same section

4. in units consisting of several panels:

functional units of the highest operating currents shall be

arranged in the middle part of the section

functional units performing the same functions shall be

grouped together

External connections and foundation frames ca be

subject to agreement. Equipment other than from the

catalogue shall be agreed with the LV Construction Unit

in Konin.

NGW R-1 switchgear with digital modules- arrangement of a section

20

5. in functional units which are to perform a small number of

operations, a circuit breaker or a contactor can be replaced

with a mccb with a motor (M) or electromagnetic (S) operating

device

6. common circuits of the switchgear shall be arranged in the

common circuits compartment

7. provision shall be made for auxiliary circuits compartment of

suitable height to house the extended auxiliary circuits

8. in NGW R-2 IP55 assemblies and in assemblies filled with heat

emitting equipment the capacity of electric fuses shall be

corrected by a 0,8 ÷ 0,9 factor

9. the album of unified diagrams sent on request

10. the same depth of all assemblies is recommended

11. for any queries please contact the LV Construction Unit in

Konin, +48 63 2466 286.

NGW R-1 - controlgear in SKP substation

L1, L2, L3

1. 2

1.1

0,4kV; 1250A

ISN

500/5A

NH00

125

2. 2

2. 3

2. 4. 2

3RV134

100A

NT 1.6

1600A

I>

I>

STEROWANIE

LS 17

Ls4

LSV400

D0 16x24VDC

D1 16x24VDC

2x3RT1034

3RT1046

2x

STEROWNIK

PS-307 S7-300

5A 315-2DP

2. 5

OS 40

40A

3RV133

100A

3RV134

100A

M

DP/3WN6

2. 4. 3

1

QSA400

400A

DEHN

quard

2. 4. 1

3UF50

41-3.N0-1

SIMCODE

3UF50

2x

1

2

2

2

3UF50

21-3.N0-1

SIMCODE

3UF50

SIMCODE

3UF50

SIMCODE

3UF51

SIMCODE

3UF52

PI 81

3x

B77T

3x

1

3UF50

21-3.N0-1

2x

1

3x

BATERIA

KONDENSATORÓW

1

5A/4-20mA

15kW

30A

ZASILANIE

200kW

350A

M

POMPA

45kW

84A

M

M

POMPA

15kW

30A

M

M

POMPA

A schematic diagram of the NGW R switchgear with digital modules

10.

TRANSPORT

The switchgear is designed for transport on truck.

Other means, like a container or ship shall be specified

with your order. Transport units consist of a single section

or 2 ÷ 4 sections of total width not exceeding 3 m. Total

mass of a transport unit shall not exceed 600 kg.

Dimensions of the transport units shall be specified in the

design or an order. Not shock-resistant apparatus,

busbar sections and auxiliary equipment (lift truck, tester,

keys, etc.). are transported in separate packages.

Loading and unloading with a hoisting crane or

travelling crane.

Storing is not recommended. The switchgear should

be delivered directly to the installation place, suitably

prepared.

Switchgear’s transport

11. ORDERING

An order should include technical data of the switchgear, engineering design developed according to the guidelines of

chapter 9 “DESIGNING” and number and kind of equipment from item 4.8..

Product warranty terms are specified in the “Guarantee Certificate”.

To maintain the guarantee the user shall follow the manufacturer's requirements and rules stated in the operation and

maintenance manual (O&M). The guarantee for the switchgear does not cover apparatus supplied by the Client.

ELEKTROBUDOWA SA offers:

technical assistance

overall low and middle voltage electric power installation

professional fabrication and mounting of the foundation frame in the prepared room

transport of switchgear to the place of destination

installation of switchgears together with connections in the prepared room

supervision of installation performed by another company

21

Company Head Office

ELEKTROBUDOWA SA

Power Distribution Division

62-505 Konin, ul. Przemys³owa 156

tel. 48 63 2466 200 fax 48 63 2427 292

e-mail: dystrybucja@elbudowa.com.pl

40-246 Katowice, ul. Porcelanowa 12

tel. 48 32 2590 100

fax 48 32 205 27 60

e-mail: elbudowa@elbudowa.com.pl

http://www.elbudowa.com.pl

© Copyright by ELEKTROBUDOWA SA

All rights reserved. Subject to change without prior notice

® If not stated otherwise on the individual pages on this catalog, we reserve the right to include modifications, especially

regarding dimensions and weights.

Drawing are not binding.

All product destignations used are trademarks product names of ELEKTROBUDOWA SA and other suppliers.

We are in your disposal in any questions.

Edition Number Konin April 2009

MARKETING OFFICE

Marketing Office - Overseas Market

62-505 Konin, ul. Przemys³owa 156

tel. +48 63 2466 371/348, fax +48 63 2466 304

e-mail: dystrybucja.expzachod@elbudowa.com.pl