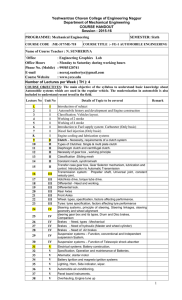

Automobile Technology - SCERT - The State Council Educational

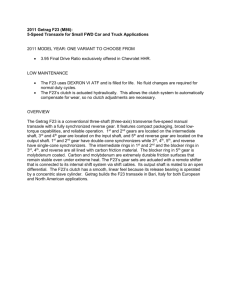

advertisement