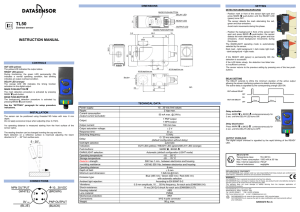

Technical information Table of contents

advertisement