ru olf ni at na lp fo sei til au q yr os ne s dn al ai bo

advertisement

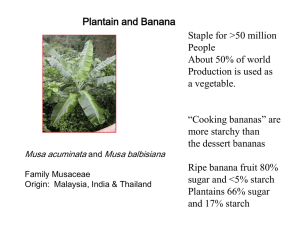

DE The Federal University of Technology, Akure, Nigeria JoST 2011 NT AN D Centre for Research and Development (CERAD) FOR RESE C EN T E CH AR R VE LO PM Microbial and sensory qualities of plantain flour and its reconstituted dumpling (amala) as influenced by blanching temperatures and duration E OLUWALANA, I. B.*, OLUWAMUKOMI, M. O., FAGBEMI, T. N. and OLUWAFEMI, G. I. Department of Food Science and Technology, The Federal University of Technology, Akure, Ondo State. Nigeria. 1 ABSTRACT: The effect of blanching conditions on the microbiological quality of flour produced from plantain (Musa AAB) and sensory qualities of reconstituted plantain flour (dumpling or amala) w ere investigated. Results show ed that vary ing the blanching temperature and time had considerable effects on the microbial quality of the plantain flour. The total viable counts of samples of unripe plantain pulp blanched at 60 oC for 5 minutes (UPB60 – 5 ), unripe plantain pulp blanched at 60 oC for 10 minutes (UPB60 – 10 ) and unripe plantain pulp blanched at 80 oC for 5 minutes (UPB80 – 5) w ere the same (2.0 cfu/gx 103). Whereas, extending the duration of blanching at 60 oC to 15 minutes (UPB60 – 15) and dipping the samples in hot water at 80 and 100 oC for 10 and 15minutes (UPB80 – 10, UPB80 – 15, UPB100 – 10 and UPB100 – 15) reduced the total viable count significantly. The control unblanched sample (UPUBCO) had the highest total viable count of 3.0 cfu/g x 103. Coliform w as not found in any of the blanched samples. Mould and yeast grow th were also higher in the control and samples blanched at a low er temperature of 60 oC for 5 and 10 minutes compared to the other samples treated at higher temperatures and longer duration. For the sensory quality evaluation, the samples blanched at 60 oC for 10 and 15 minutes w ere rated best for taste, colour and tex ture. Amala produced with plantain slices blanched at 60OC for 5 min had a similarly preferred tex ture but w as less acceptable in terms of c o l o ur a nd t a s t e . T he P a ne l i s t s do w ng r a de d pr o du c t s f r o m pl a nt a i n s l i c e s di ppe d i n ho t w a t e r a t temperatures above 80OC for more than 10 minutes particularly in terms of colour, taste and tex ture. Keyw ords: Plantain, Blanching, Sensory attributes, Microbial quality. JoST. 2011. 2(2): 70-73. Accepted for Publication, August 1, 2011 I NT R O D UC T I O N Plantain, the edible fruit of the genus Musa, is one of the major crops of the humid lowland tropical areas, whose production in Nigeria has gained considerable importance in recent years. Ogazi (1982) reported that over 80% is harvested during the period of September to February and that there is much wastage at this time as some of the products do not store for a long period. Plantain is a remarkable example of a neglected food crop because the proportion of research r e s o u r c e s a l l o c a t e d t o i t fa l l s fa r f r o m o t h e r s t a r c h y f r u i t s . T h e f r u i t r i p e n s u s u a l l y a ft e r harvest to soft sweet fruits of high sugar and l o w a c i d c o n t e n t . O n e o f t h e r e a s o n s fo r t h e neglect of plantain by researchers is its close relationship to banana which has received more attention earlier and the common but erroneous belief that plantain and banana are similar in physiological pattern (Wilson, 1986). Plantain is known to have an advantage over other starchy staple foods like yam, cassava and cocoyam where labour is an important factor of production as a result of its high energy returns per unit of labour. Plantain is widely consumed * Corresp on den c e t o: Dr. Olu wa la n a , I. B . ; i olu wa lan a 2 0 02 @ yah oo. com; Journal of Sustainable Technology, Vol. 2, No. 2 (November 2011), ISSN: 2251-0680 Pp 7 0 Microbial and sensory qualities of plantain flour by the whole pop ulation and many different dishes from a wide range of cultural groups are prepared from it (Stover and Simmonds, 1987). It is important to study the quality of the plantain flour to determine its suitability for use in the production of a thick traditional dumpling called “ A m a l a ” wh i c h i s p o p u l a r i n s o u t h we s t e r n Nigeria among the Yorubas. Amala is prepared by reconstituting two parts of the flours with about one part of boiling water which is mixed thoroughly with a wooden spatula over a heating medium (Ogazi, 1998). The objective of this work was to produce and examine the micro bio logical quality of flo ur produced from blanched plantain as well as the sensory qualities of the reconstituted plantain flour known as Amala. MATERIALS AND METHODS Mature green and healthy plantain (Musa, AAB g r o u p ) b u n ch e s wer e o b ta i ne d f r o m th e International Institute of Tropical Agriculture (IITA), Oyo Road, Ibadan. All reagents used were of analytical grade. Preparation of Plantain Flour T he fruits which were hard and green were subsequently defingered, washed, hand-peeled and manually sliced into cylindrical pieces of 2mm thickness. Blanching was carried out on the sliced samples in hot water at 60oC, 80oC and 100oC. For each temperature chosen, the timing was varied for 5, 10 and 15 minutes and dried in t h e a i r o v e n a t 6 5 oC f o r 2 4 h r s , w h i l e t h e unblanched samples (Control) were also dried using the air oven at the same temperature and time as recommended by Baiyeri and Ortiz (2000). The dehydrated pieces were milled in a hammer mill to prod u c e f l o u r w h i c h p a s s e d th ro u g h a 1 5 0 �m s c re e n . T h e p l a n ta i n f l o u r o b ta i n e d w a s p a c k a g e d i n p o l y e th y l e n e b a g s l a b e l e d a n d s to re d a t ro o m te m p e ra tu re f o r f u rth e r a n a l y s i s . T h e f l o u rs w e re c o d e d a s f o l l o w s : U P B 60-5 = Unripe plantain blanched at 60oC for 5 minutes; UPB60-10 = Unripe plantain blanched at 60oC for 10 minutes; UPB60-15 = Unripe plantain blanched at 60oC for 15 minutes; UPB80-5 = Unripe plantain b lanched at 8 0 oC fo r 5 minutes; UP B 80-10 = Unripe plantain blanched at 80oC for 10 minutes; UPB80-15 = Unripe plantain blanched at 80oC for 15 minutes; UPB100-5 = Unripe plantain dipped in hot water at 100oC for 5 minutes, UPB100-10 = Unripe plantain dipped in hot water at 100oC for 10 minutes, UPB100-15 = Unripe plantain dipped in hot water at 100oC for 15 minutes and UPUBc = Unripe and un-blanched plantain (Control). Microbiological examination The samples were evaluated for microbiological e xa mi na t i o n a s d e s c r i b e d b y A n d e r so n a n d Hollorook (1980). Plantain flours were examined for viable count of Bacteria, Coliform, Yeast and Moulds using Nutrient Agar (NA), MacConkey Agar (MCA) and Potato Dextrose Agar (PDA) respectively. The pour plate method was used t o e n u me r a t e t h e t o t a l n u mb e r o f v i a b l e micro o rgani sms in the p lantain fl o ur. Serial dilution was done using normal saline diluted to 10-3 dilution and 1ml of 10-3 dilution was added into each sterile Petri dish. Molten Plate Count Agar (MPCA) was added into the plates, agitated and allowed to solidify and incubated at 37oC for 48hrs. The number of colonies counted on t h e p l a t e s t a k e n i n t o c o n s i d e r a t i o n wi t h t h e dilution factor. The presence of coliform was determined by inoculating plantain flour samples on MCA and incubating at 37 oC for 18 hrs. The presence of y e a s t s a n d mo u l d s we r e e n u me r a t e d b y inoculating the serial dilution of plantain flour samples on PDA. The plates were incubated at 25oC for 3 days as recommended by Harrigan and McCance (1976). Sensory evaluation A total of 10 semi–trained panelists drawn from the Department of Food Science and Technology, F e d e r a l U n i v e r s i t y o f Te c h n o l o g y A k u r e a sse sse d t he se nso r y q ual i ty of the r e c o nst it ute d p la nt a in f lo u r “a ma l a ” . T he Journal of Sustainable Technology, Vol. 2, No. 2 (November 2011), ISSN: 2251-0680 Pp 7 1 Microbial and sensory qualities of plantain flour Statistics Analysis All the experiments were conducted in triplicates a n d t h e me a n ± s t a n d a r d d e v i a t i o n we r e repo rted. Data were subjected to analysis of variance (ANOVA) and means sep arated b y D u n c a n M u l t i p l e R a n g e Te s t ( D M RT ) a t a significance level of Pd” 0.05 sensory quality of amala made from each flour sample was measured on a standard nine-point Hedonic scale. The panelists rated the amala samples for colour, taste and texture on a scale varying from 1 = dislike extremely to 9 = like extremely (Larmond, 1982). RESULTS AND DISCUSSION The microbiological evaluation of the plantain flour and sensory attributes of the reconstituted flour ‘amala’ samples are presented in Table 1. The Total viable count range between 1 - 3 x 103 c fu / g wh i l e t h e u n b l a n c h e d c o n t r o l h a d t h e highest value of 3 x 103 cfu/ g Table 1: Microbiological Quality of plantain flour blanched at 60, 80 and 100 OC for 5, 10 and 15 minutes Samples UPUB60 UPUB80 UPUB100 U PU B CO 5 TVC 2. 0 cfu/gx103 Coliform cfu/gx103 ND Mould & Yeast sfu/gx103 3 .5 ND = Not Detected 10 15 5 10 2 .0 1. 0 2. 0 ND ND ND ND 3. 2 1 .4 2 .4 2. 2 N o v i a b l e c o u n t s we r e d e t e c t e d o n s a m p l e s UPB80-15 and UPB100-15 indicating that blanching at 80 to 100 oC for 15 minutes greatly hindered the microbial growth and thereby guaranteed the microbial safety of the flour products. Total viable count of sample: UPB60-5, UPB60-10, UPB80are not different from one another (2.0cfu/gx103) 5 while that of the UPB60-15, UPB80-10, UPB100-5 and UPB100-10 which are treatments at either higher temperatures or longer durations are 1.0, 1.5, 1.4 and 1.0 cfu/gx103 respectively. These counts are minimal and are within safe levels and may not c o n s t i t u t e h e a l t h h a z a r d s p r o v i d e d t he f l o u r s amp le s a r e we ll ke p t t o p r ev e nt r e contamination and other microbial proliferation after processing. Coliform was only found in the Control sample (1.0cfu/gx103) indicating that t he b l anching p ro c es s given to t he ot he r samples were effective against Coliform. Mould 1. 5 15 5 10 15 ND 1. 4 1. 0 ND 3. 0 ND 1 .0 ND 1 .0 ND 2 .0 ND 2. 0 1. 0 4 .0 and Yeast count ranged between 1.0 to 4.0 cfu/g x 103. The UPB60-5 had 3.5cfu/g x103 while the h i g h e s t c o u n t wa s f o u n d i n t h e u n b l a n c h e d Control (4.0 cfu/gx103). The results of senso ry evaluation in Table 2 showed that UPB60 – 10 was rated best in terms of taste which was significantly different (Pd” 0.05) from other treated samples and the Control except sample UPB60 – 15. Sample UPB80 – 10 was r a te d b e st in c o lo ur a nd wa s f o und to b e significantly preferred (P d” 0.05) to samples UPB60 – 5, UPB80-5, UPB100-5, UPB100-10 and UPB100 – 15. The texture of sample UPB60 – 5, UPB60 – 10, UPB60 – 15 and the Control were found to be higher and better and were significantly different (Pd” 0.05) from samples UPB80 – 5, UPB100 – 5, UPB100 – 10 and UPB100 – 15. This means that dipping the plantain pulp in hot water at 100oC is not advisable. Journal of Sustainable Technology, Vol. 2, No. 2 (November 2011), ISSN: 2251-0680 Pp 7 2 Microbial and sensory qualities of plantain flour Table 2: Sensory Properties of Reconstituted Plantain Flour (Amala) Sample Taste Colour Texture 5.8b,c 6.9a,b 7.7a UPUBCO UPB60 – 5 6.7b 5.4b,c 7.2a UPB60 – 10 8.7a 6.6a,b 7.5a UPB60 – 15 8.5a 7.6a 7.4a UPB80 – 5 4.6c 4.5c 5.2b UPB80 – 10 6.6b 8.0a 6.9a UPB80 – 15 6.7b 6.8a,b 7.3a UPB100 – 5 3.4d 5.8b 4.8c UPB100 – 10 4.6c 5.5bc 4.6c UPB100 – 15 3.8c,d 4.6c 4.4c Values in the same column with different letters in superscript are significantly different at p< 0.05 CO NC LU SI O N Blanching plantain pulp at temperatures of 60oC t o 1 0 0 oC f o r 1 0 t o 1 5 m i n u t e s s i g n i f i c a n t l y reduced the microbial load and could therefore serve as a means of prolonging the shelf life of the chips from pulp or flour produced from it. Likewise the sensory qualities of taste, colour and texture appear to be enhanced at blanching at 60-80oC for 10-15 minutes. At 100oC for 1015oC, the texture of the amala from this sample is found to be adversely affected. The temperature range of 60-80 and blanching time of 10 minutes is therefore found to be more suitable for the he a t p r o c e s s i n g o f p l a n t a i n c hi p s i n o r d e r t o produce acceptable quality flour. REFERENCES ANDERSON, J.M. and HOLLOROOK, K. (1980). The Rapid Detection of Escherichia coli in Food by using Direct Plating Method. Journal of Food Technology, 32: 78 – 83. BAIYERI, K.P. and ORTIZ, R. (2000). Agronomic e v a l u a t i o n o f p l a n t ai n a n d o t h e r t r i p l o i d Musa. In: Proceedings of First International Co nfer e nc e o f B a na na and P l a nt ai n i n Africa, Kampala, Uganda, 12-18 October, 1996 (Craenen, K., Karamura, E.B. and Vuylsteke, D.R. eds.), International Society for Horticulture, 540: 125-135. HARRIGAN, W.F. and cCance, M.E. (1976). L ab o r at o r y M e th o d s in F o o d an d Da ir y Microorganisms Academic Press, London. Pp 362. LARMOND, E. (1982). Laboratory methods for s e n s o r y e v a l u a t i o n o f fo o d s . C a na d i a n Agriculture Development Publication No: 1673: 31-36. OGAZI, P.O. (1982). Plantain utilization and n u tr i t i o n . I n: F o o d s C r o p s P r o d u c ti o n Utiliza tio n Nutrition (M b a , B .N. and Nnanyelugo, D.O. eds.), Dothan Publication Ltd. pp. 135-144. OGAZI, P. O. (19 98 ). Plantain Storage and Processing. In: Post-Harvest Techno logy and Commodity Marketing. Proceedings of a Post-Harvest Conference on Technology and Commodity Marketing in West Africa (Ferris, R.S.B. ed.) held in Accra, Ghana, Nov. 2 – Dec. 1st. 1998. Published by IITA, Ibadan. STOVER, R.H. and SIMMONDS, N.W. (1987). Bananas: Tropical Agriculture Series (3rd Edition), Longman Publishers, London. Pp 468. WILSON, G.F. (1986). Plantain Research In West Africa: An example of regional Collaboration. I nt e rna ti o na l I nst i t ut e o f T r op i ca l Agriculture, IITA, 1st ed. pp 8-12. Journal of Sustainable Technology, Vol. 2, No. 2 (November 2011), ISSN: 2251-0680 Pp 7 3