Section 71 Duct

advertisement

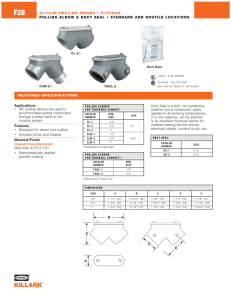

<Project Name> Special Provisions ___% Submittal Date SECTION 71 – AIRPORT UNDERGROUND ELECTRICAL DUCTS AND CONDUIT (FAA L-110) 71-1 GENERAL The Contractor shall perform all work required by the plans and specifications for construction of electrical ducts and conduits for airfield electrical systems in accordance with the Standard Specifications, except as specified otherwise in FAA Specification Item L-110, as included and modified hereafter, and as shown on the Plans. It shall also include all trenching, backfilling, removal, and restoration of any paved areas; concrete encasement (where required), mandreling installation of pulling rope and duct markers, capping, and the testing of the installation as a completed duct system ready for installation of cables, to the satisfaction of the Owner and Engineer. The Contractor shall protect the existing pavements from damage by use of any equipment with tracks, stabilization feet, hydraulic fluids, etc., during the construction of this item. ITEM L-110 AIRPORT UNDERGROUND ELECTRICAL DUCT BANKS AND CONDUITS DESCRIPTION 110-1.1 This item shall consist of underground electrical conduits and duct banks (single or multiple conduits encased in concrete) installed in accordance with this specification at the locations and in accordance with the dimensions, designs, and details shown on the plans. This item shall include furnishing and installing of all underground electrical duct banks and individual and multiple underground conduits. It shall also include all turfing trenching, backfilling, removal, and restoration of any paved or turfed areas; concrete encasement, mandreling, pulling lines, duct markers, plugging of conduits, and the testing of the installation as a completed system ready for installation of cables in accordance with the plans and specifications. This item shall also include furnishing and installing conduits and all incidentals for providing positive drainage of the system. Verification of existing ducts is incidental to the pay items provided in this specification. EQUIPMENT AND MATERIALS 110-2.1 GENERAL. a. All equipment and materials covered by referenced specifications shall be subject to acceptance through manufacturer's certification of compliance with the applicable specification when so requested by the Engineer. <LOGO> Airport Electrical Ducts and Conduits Page 71-1 <Project Name> Special Provisions ___% Submittal Date b. Manufacturer's certifications shall not relieve the Contractor of the Contractor’s responsibility to provide materials in accordance with these specifications and acceptable to the Engineer. Materials supplied and/or installed that do not materially comply with these specifications shall be removed, when directed by the Engineer and replaced with materials, which do comply with these specifications, at the sole cost of the Contractor. c. All materials and equipment used to construct this item shall be submitted to the Engineer for approval prior to ordering the equipment. Submittals consisting of marked catalog sheets or shop drawings shall be provided. Submittal data shall be presented in a clear, precise and thorough manner. Original catalog sheets are preferred. Photocopies are acceptable provided they are as good a quality as the original. Clearly and boldly mark each copy to identify pertinent products or models applicable to this project. Indicate all optional equipment and delete non-pertinent data. Submittals for components of electrical equipment and systems shall identify the equipment for which they apply on each submittal sheet. Markings shall be boldly and clearly made with arrows or circles (highlighting is not acceptable). Contractor is solely responsible for delays in project accruing directly or indirectly from late submissions or resubmissions of submittals. d. The data submitted shall be sufficient, in the opinion of the Engineer, to determine compliance with the plans and specifications. The Contractor's submittals shall be neatly bound. The Engineer reserves the right to reject any and all equipment, materials or procedures, which, in the Engineer’s opinion, does not meet the system design and the standards and codes, specified herein. e. All equipment and materials furnished and installed under this section shall be guaranteed against defects in materials and workmanship for a period of at least twelve (12) months from final acceptance by the Owner. The defective materials and/or equipment shall be repaired or replaced, at the Owner's discretion, with no additional cost to the Owner. 110-2.2 STEEL CONDUIT. Rigid galvanized steel conduit and fittings shall be hot dipped galvanized inside and out and conform to the requirements of Underwriters Laboratories Standard 6, 514B, and 1242. 110-2.2 PLASTIC CONDUIT. Plastic conduit and fittings-shall conform to the requirements of Fed. Spec. W--C-1094, Underwriters Laboratories Standards UL-651 and Article 347 of the current National Electrical Code shall be one of the following, as shown on the plans: a. Type I–Schedule 40 PVC suitable for underground use either directburied or encased in concrete. <LOGO> Airport Electrical Ducts and Conduits Page 71-2 <Project Name> Special Provisions ___% Submittal Date b. Type II–Schedule 40 PVC suitable for either above ground or underground use. Non-metallic conduit and fittings shall conform to the requirements of Fed. Spec. W-C-1094 and shall be Type II, Schedule 40. Conduit shall be heavy-wall polyvinylchloride (PVC) conduit listed by an independent testing laboratory for Above Ground Exposed, Underground Concrete Encased (CE) and Underground Direct Earth Burial (DEB) for applications as described in Article 352 of the current National Electrical Code. All joints shall be solvent welded in accordance with the recommendation of the manufacturer. The plastic conduit, fittings, expansion joints and joint adhesive/solvent shall be products of one manufacturer to assure compatibility. The type of adhesive shall be as recommended by the conduit/fitting manufacturer. 110-2.4 SPLIT CONDUIT. Split conduit shall be pre-manufactured for the intended purpose and shall be made of steel or PVC. 110-2.5 CONDUIT SPACERS. Conduit spacers shall be prefabricated interlocking units manufactured for the intended purpose. They shall be of double wall construction made of high grade, high density polyethylene complete with interlocking cap and base pads, They shall be designed to accept No. 4 reinforcing bars installed vertically. 110-2.6 CONCRETE. Concrete encasement with red dye shall conform to Section 54 of these Specifications (FAA Item P-610, Structural Portland Cement Concrete, using [ ] inch maximum size coarse aggregate with a minimum 28 day compressive strength of [ ] psi). Where reinforced duct banks are specified, reinforcing steel shall conform to ASTM A 615 Grade 60. Concrete and reinforcing steel are incidental to the respective pay item of which they are a component part. 110-2.7 FLOWABLE BACKFILL. Flowable material used to back fill conduit and duct bank trenches shall conform to the requirements of Section 24 of these specifications (FAA Item P-153) "Controlled Low Strength Material". 110-2.8 DETECTABLE WARNING TAPE. Plastic, detectable, color as noted magnetic tape shall be polyethylene film with a metallized foil core and shall be 4-6 inches (75-150 MM) wide. Red detectable conduit marker tape shall be inert polyethylene plastic, 4-mil thickness, impervious to all known alkalis, acids, chemical reagents, and solvents, and at least 4 inches wide with the word "ELECTRICAL" or similar imprinted on it. Contractor shall install marker tape <LOGO> Airport Electrical Ducts and Conduits Page 71-3 <Project Name> Special Provisions ___% Submittal Date over ducts, 6 inches below surface. Detectable tape is incidental to the respective bid item. 110-2.9 DUCT MARKERS. The location of duct bank terminations shall be marked by a concrete slab marker 2 ft square and 4 inches thick extending approximately 1 inch above the surface. The markers shall be located above the ends of all ducts or duct banks, except where ducts terminate in a hand hole, manhole, or building. Where duct banks terminate, provide a duct marker labeled, “DUCT ENDS”. He shall also impress on the slab the number and size of conduit or ducts beneath the marker. The letters shall be 4 inches high and 3 inches wide with width of stroke 1/2 inch and 1/4 inch deep or as large as the available space permits. 110-2.10 MARKERS GROUND ROD INSPECTION PITS USED AS DUCT Ground rod inspection pits may be used as the required cable markers, at ground rod locations, provided the concrete anchor is marked per the cable marker requirements. Markers shall be installed immediately above the cable. 110-2.11 CONDUIT PULLING LUBRICANT Thomas and Betts, Kopr-Kote or approved equal shall be applied to all steel metallic thread type fittings for underground conduits. CONSTRUCTION METHODS 110-3.1 GENERAL. The Contractor shall install underground duct banks and conduits at the approximate locations indicated on the plans. The Engineer shall indicate specific locations as the work progresses, if required to differ from the plans. Duct banks and conduits shall be of the size, material, and type indicated on the plans or specifications. Where no size is indicated on the plans or in the specifications, conduits shall be not less than 2 inches inside diameter or comply with the National Electrical Code based on cable to be installed, whichever is larger. All duct bank and conduit lines shall be laid so as to grade toward access points and duct or conduit ends for drainage. Unless shown otherwise on the plans, grades shall be at least 3 inches per 100 feet. On runs where it is not practicable to maintain the grade all one way, the duct bank and conduit lines shall be graded from the center in both directions toward access points or conduit ends, with a drain into the storm drainage system or aggregate pit. Pockets or traps where moisture may accumulate shall be avoided. No duct bank or underground <LOGO> Airport Electrical Ducts and Conduits Page 71-4 <Project Name> Special Provisions ___% Submittal Date conduit shall be less than 18 inches below finished grade. Where under pavement, the top of the duct bank shall not be less than 18 inches below the sub grade. The Contractor shall mandrel each individual conduit whether the conduit is direct-buried or part of a duct bank. An iron-shod mandrel, not more than 1/4inch smaller than the bore of the conduit shall be pulled or pushed through each conduit. The mandrel shall have a leather or rubber gasket slightly larger than the conduit hole. The Contractor shall swab out all conduits/ducts and clean base can, manhole, pull boxes, etc. interiors IMMEDIATELY prior to pulling cable. Once cleaned and swabbed the base cans, manhole, pull boxes, etc. and all accessible points of entry to the duct/conduit system shall be kept closed except when installing cables. Cleaning of ducts, base cans, manholes, etc. is incidental to the pay item of the item being cleaned. All raceway systems left open, after initial cleaning, for any reason shall be recleaned at the Contractor’s expense. All accessible points shall be kept closed when not installing cable. The Contractor shall verify existing ducts proposed for use in this project as clear and open. The Contractor shall notify the Engineer of any blockage in the existing ducts. For pulling the permanent wiring, each individual conduit, whether the conduit is direct-buried or part of a duct bank, shall be provided with a 200 pound test polypropylene pull rope. The ends shall be secured and sufficient length shall be left in access points to prevent it from slipping back into the conduit. Where spare conduits are installed, as indicated on the plans, the open ends shall be plugged with removable tapered plugs, designed for this purpose. All conduits shall be securely fastened in place during construction and shall be plugged to prevent contaminate from entering the conduits. Any conduit section having a defective joint shall not be installed. Ducts shall be supported and spaced apart using approved spacers at intervals not to exceed 5 feet. Unless otherwise shown on the plans, concrete encased duct banks shall be utilized when crossing under pavements expected to carry aircraft loads. Where turf is well established and the sod can be removed, it shall be carefully stripped and properly stored. Trenches for conduits and duct banks may be excavated manually or with mechanical trenching equipment unless in pavement, in which case they shall be excavated with mechanical trenching equipment. Walls of trenches shall be essentially vertical so that a minimum of shoulder surface is disturbed. Blades of graders shall not be used to excavate the trench. The bottom surface of trenches shall be essentially smooth and free from coarse aggregate. Unless otherwise <LOGO> Airport Electrical Ducts and Conduits Page 71-5 <Project Name> Special Provisions ___% Submittal Date specified, cable trenches shall be excavated to a minimum depth of 21 inches below finished grade, except when off the airport or crossing under a roadway or driveway, the minimum depth shall be 36 inches unless otherwise specified. Trenching across existing runway or taxiway pavements shall not be allowed. Conduits crossing existing runways or taxiways shall be installed via jack and bore. Trenching across existing abandoned pavements shall disturb the minimum amount of pavement possible. Depth of existing pavements may vary; contractor is responsible for potholing in order to determine depth of concrete. Saw cut (concrete) or Vermeer wheel (asphalt) for width of trench before excavating. When rock is encountered, the rock shall be removed to a depth of at least 3 inches below the required conduit or duct bank depth and it shall be replaced with bedding material of earth or sand containing no mineral aggregate particles that would be retained on a 1/4-inch sieve. Flowable backfill may alternatively be used The Contractor shall ascertain the type of soil or rock to be excavated before bidding. All such rock removal shall be performed and paid for under Section 23 Earthwork (FAA Item P-152). Underground electrical warning (caution) tape shall be installed in the trench above all underground duct banks and conduits in unpaved areas. Contractor shall submit a sample of provide a submittal for the proposed warning tape for approval by the Engineer. If not shown on the plans, the warning tape shall be located six inches above the duct/conduit or the counterpoise wire if present. Joints in plastic conduit shall be prepared in accordance with the manufacturer's recommendations for the particular type of conduit. Plastic conduit shall be prepared by application of a plastic cleaner and brushing a plastic solvent on the outside of the conduit ends and on the inside of the couplings. The conduit fitting shall then be slipped together with a quick one-quarter turn twist to set the joint tightly. Where more than one conduit is placed in a single trench, or in duct banks, joints in the conduit shall be staggered a minimum of 2 feet. Changes in direction of runs exceeding 10 degrees, either vertical or horizontal, shall be accomplished using manufactured sweep bends. Whether or not specifically indicated on the drawings, where the soil encountered at established duct bank grade is an unsuitable material, as determined by the Engineer, the unsuitable material shall be removed in accordance with item P152 Section 23 Earthwork and replaced with suitable material. Alternatively, additional duct bank supports that are adequate and stable shall be installed, as approved by the Engineer. All excavation shall be unclassified and shall be considered incidental to the respective pay item of which it is a component part. Dewatering necessary for <LOGO> Airport Electrical Ducts and Conduits Page 71-6 <Project Name> Special Provisions ___% Submittal Date duct installation, erosion and turbidity control, in accordance with Federal, State, and Local requirements is incidental to its respective pay item as a part of the item L-110. The cost of all excavation regardless of type of material encountered, shall be included in the unit price bid for the L-110 item. Unless otherwise specified, excavated materials that are deemed by the Engineer to be unsuitable for use in backfill or embankments shall be removed and disposed of offsite. Any excess excavation shall be filled with suitable material approved by the Engineer and compacted in accordance with item P-152 Section 23 Earthwork. It is the Contractor's responsibility to locate existing utilities within the work area prior to excavation. Where existing active cables cross proposed installations, the Contractor shall insure that these cable(s) are adequately protected. Where crossings are unavoidable, no splices will be allowed in the existing cables, except as specified on the plans. Installation of new cable where such crossings must occur shall proceed as follows: (1) Existing cables shall be located manually. Unearthed cables shall be inspected to assure absolutely no damage has occurred (2) Trenching, etc., in cable areas shall then proceed with approval of the Engineer, with care taken to minimize possible damage or disruption of existing cable, including careful backfilling in area of cable. In the event that any previously identified cable is damaged during the course of construction, the Contractor shall be responsible for the complete repair. All ducts, installed under runways, taxiways, aprons, and other paved areas shall be encased in a concrete envelope, extending 5 feet beyond edge of traffic area. 110-3.2 DUCT BANKS. Unless otherwise shown in the plans, duct banks shall be installed so that the top of the concrete envelope is not less than 18 inches below the bottom of the base or stabilized base course layers where installed under runways, taxiways, aprons, or other paved areas, and not less than 18 inches below finished grade where installed in unpaved areas. Unless otherwise shown on the plans, duct banks under paved areas shall extend at least 3 feet beyond the edges of the pavement or 3 feet beyond any underdrains that may be installed alongside the paved area. Trenches for duct banks shall be opened the complete length before concrete is placed so that if any obstructions are encountered, proper provisions can be made to avoid them. Unless otherwise shown on the plans, all duct banks shall be placed on a layer of concrete not less than 3 inches thick prior to its initial set. Where two or more conduits in the duct <LOGO> Airport Electrical Ducts and Conduits Page 71-7 <Project Name> Special Provisions ___% Submittal Date bank are intended to carry conductors of equivalent voltage insulation rating, the Contractor shall space the conduits not less than 1-1/2 7-1/2 inches apart (measured from outside wall to outside wall center of conduit to center of conduit). Where two or more conduits in the duct bank are intended to carry conductors of differing voltage insulation rating, the Contractor shall space the conduits not less than 3 12 inches apart (measured from outside wall to outside wall center of conduit to center of conduit). All such multiple conduits shall be placed using conduit spacers applicable to the type of conduit. As the conduit laying progresses, concrete shall be placed around and on top of the conduits not less than 3 inches thick unless otherwise shown on plans. End bells or couplings shall be installed flush with the concrete encasement at access points. Conduits forming the duct bank shall be installed using conduit spacers. No. 4 reinforcing bars, where indicated on the plans, shall be driven vertically into the soil a minimum of 6 inches to anchor the assembly into the earth prior to placing the concrete encasement. For this purpose, the spacers shall be fastened down with locking collars attached to the vertical bars. Spacers shall be installed at 5 foot intervals. Spacers shall be in the proper sizes and configurations to fit the conduits. Locking collars and spacers shall be submitted to the Engineer for review prior to use. Where specified on the plans, the Contractor shall reinforce the bottom side and top of encasements with steel reinforcing mesh or fabric or other approved metal reinforcement. When directed, the Contractor shall supply additional supports where the ground is soft and boggy, where ducts cross under roadways, or where shown on the plans. Under such conditions, the complete duct structure shall be supported on reinforced concrete footings, piers, or piles located at approximately 5 foot intervals. All pavement surfaces that are to have ducts installed therein shall be neatly sawcut to form a vertical face. All excavation shall be included in the contract with price for the duct. Install a plastic, detectable, color as noted, 4-6 inch wide tape 8 inches (200mm) minimum below grade above all underground conduit or duct lines not installed under pavement. When existing cables are to be placed in split duct, encased in concrete, the cable shall be carefully located and exposed by hand tools. Prior to being placed in duct, the Engineer shall be notified so that he may inspect the cable and determine that it is in good condition. Where required, split duct shall be installed as shown on the drawings or as required by the Engineer. 110-3.3 CONDUITS WITHOUT CONCRETE ENCASEMENT. Trenches for single-conduit lines shall be not less than 6 inches (150 mm) nor more than 12 <LOGO> Airport Electrical Ducts and Conduits Page 71-8 <Project Name> Special Provisions ___% Submittal Date inches (300 mm) wide, and the trench for 2 or more conduits installed at the same level shall be proportionately wider. Trench bottoms for conduits without concrete encasement shall be made to conform accurately to grade so as to provide uniform support for the conduit along its entire length. Unless otherwise shown on the plans, a layer of fine earth material, at least 4 inches (100 mm) thick (loose measurement) shall be placed in the bottom of the trench as bedding for the conduit. The bedding material shall consist of soft dirt, sand or other fine fill, and it shall contain no particles that would be retained on a 1/4-inch (6 mm) sieve. The bedding material shall be tamped until firm. Flowable backfill may alternatively used. Unless otherwise shown on plans, conduits shall be installed so that the tops of all conduits are at least 18 inches (45 cm) below the finished grade. When two or more individual conduits intended to carry conductors of equivalent voltage insulation rating are installed in the same trench without concrete encasement, they shall be spaced not less than 2 inches (50 mm) apart (measured from outside wall to outside wall) in a horizontal direction and not less than 6 inches (150 mm) apart in a vertical direction. Where two or more individual conduits intended to carry conductors of differing voltage insulation rating are installed in the same trench without concrete encasement, they shall spaced not less than 3 inches (75 mm) apart (measured from outside wall to outside wall) in a horizontal direction and lot less than 6 inches (150 mm) apart in a vertical direction. Trenches shall be opened the complete length between normal termination points before conduit is installed so that if any unforeseen obstructions are encountered, proper provisions can be made to avoid them. Conduits shall be installed using conduit spacers. No. 4 reinforcing bars shall be driven vertically into the soil a minimum of 6 inches to anchor the assembly into the earth while backfilling. For this purpose, the spacers shall be fastened down with locking collars attached to the vertical bars. Spacers shall be installed at 5 foot intervals. Spacers shall be in the proper sizes and configurations to fit the conduits. Locking collars and spacers shall be submitted to the Engineer for review prior to use. 110-3.4 MARKERS. The location of each end and of each change of direction of conduits and duct banks shall be marked by a concrete slab marker 2 feet (60 cm) square and 4-6 inches (100-150 mm) thick extending approximately 1 inch (25 mm) above the surface. The markers shall also be located directly above the ends of all conduits or duct banks, except where they terminate in a junction/access structure or building. <LOGO> Airport Electrical Ducts and Conduits Page 71-9 <Project Name> Special Provisions ___% Submittal Date The Contractor shall impress the word “DUCT” or “CONDUIT” on each marker slab. The Contractor shall also impress on the slab the number and size of conduits beneath the marker along with all other necessary information as determined by the Engineer. The letters shall be 4 inches (100 mm) high and 3 inches (75 mm) wide with width of stroke 1/2-inch (12 mm) and 1/4-inch (6 mm) deep or as large as the available space permits. Furnishing and installation of duct markers is incidental to the respective duct pay item. 110-3.5 BACKFILLING FOR CONDUITS. For conduits, 8 inches (200 cm) of sand, soft earth, or other fine fill (loose measurement) shall be placed around the conduits ducts and carefully tamped around and over them with hand tampers. The remaining trench shall then be backfilled and compacted in accordance with Item P-152 "Excavation and Embankment" except that material used for back fill shall be select material not larger than 4 inches in diameter. Flowable backfill may alternatively be used Trenches shall not contain pools of water during back, filling operations. The trench shall be completely backfilled and tamped level with the adjacent surface: except that, where sod is to be placed over the trench, the backfilling shall be stopped at a depth equal to the thickness of the sod to be used, with proper allowance for settlement. Any excess excavated material shall be removed and disposed of in accordance with instructions issued by the Engineer. 110-3.6 BACKFILLING FOR DUCT BANKS. After the concrete has cured, the remaining trench shall be backfilled and compacted in accordance with item P152 “Excavation and Embankment” Section 23 Earthwork, except that the material used for backfill shall be select material not larger than 4 inches in diameter. In addition to the requirements of P-152 Section 23, where duct banks are installed under pavement, one moisture/density test per lift shall be made for each 250 linear feet of duct bank or one work period's construction, whichever is less. Flowable backfill may alternatively be used Trenches shall not contain pools of water during backfilling operations. The trench shall be completely backfilled and tamped level with the adjacent surface: except that, where sod is to be placed over the trench, the backfilling shall be stopped at a depth equal to the thickness of the sod to be used, with proper allowance for settlement. <LOGO> Airport Electrical Ducts and Conduits Page 71-10 <Project Name> Special Provisions ___% Submittal Date Any excess excavated material shall be removed and disposed of in accordance with instructions issued by the Engineer. 110-3.7 RESTORATION. Where sod has been removed, it shall be replaced as soon as possible after the backfilling is completed. All areas disturbed by the work shall be restored to its original condition. The restoration shall include seeding shown on the plans, and included in the specifications. The Contractor shall be held responsible for maintaining all disturbed surfaces and replacements until final acceptance. All restoration shall be considered incidental to the respective L-110 electrical pay item. METHOD OF MEASUREMENT 110-4.1 See Section 71-2 Underground conduits and duct banks shall be measured by the linear feet (meter) of conduits and duct banks installed, including encasement, locator tape, trenching and backfill with designated, resolution, and for drain lines, the termination at the drainage structure, all measured in place, completed, and accepted. Separate measurement shall be made for the various types and sizes. BASIS OF PAYMENT 110-5.1 See Section 71-3. Payment will be made at the contract unit price per linear foot for each type and size of conduit and duct bank completed and accepted, including trench and backfill with the designated material, and, for drain lines, the termination at the drainage structure. This price shall be full compensation for furnishing all materials and for all preparation, assembly, and installation of these materials, and for all labor, equipment, tools, and incidentals necessary to complete this item in accordance with the provisions and intent of the plans and specifications. Payment will be made under: Item L-110-5.1 Electrical Duct Bank, [# and Size] —per linear foot (meter) Item L-110-5,2 Electrical Conduit [# and size]—per linear foot (meter) MATERIAL REQUIREMENTS Fed.Spec.W-C-1094 <LOGO> Conduit and Conduit Fittings; Plastic, Rigid (cancelled; replaced by UL 514 Boxes, Nonmetallic Outlet, Flush Device Boxes, & Airport Electrical Ducts and Conduits Page 71-11 <Project Name> Special Provisions ___% Submittal Date Covers, and UL 651 Standard for Conduit & Hope Conduit, Type EB & A Rigid PVC) Underwriters Laboratories Standard 6 Rigid Metal Conduit Underwriters Laboratories Standard 514B Fittings for Cable and Conduit Underwriters Laboratories Standard 651 Schedule 40 and 80 Rigid PVC Conduit (for Direct Burial) Underwriters Laboratories Standard 651A Type EB and A Rigid PVC Conduit and HDPE Conduit (for concrete encasement) END OF ITEM L-110 71-2 METHOD OF MEASUREMENT Duct bank or conduit shall be measured by the number of linear feet of counterpoise wire installed in trenches, duct bank or conduit, including ground rods and grounding connectors, and trench marking tape ready for operation, and accepted as satisfactory. Separate measurement shall be made for each counterpoise wire, duct bank or conduit installed in trench. The measurement for this item shall not include additional quantities required for back filling trenches. The cost of all excavation, backfill, dewatering and restoration regardless of the type of material encountered shall be included in the unit price bid for the work. 71-3 BASIS OF PAYMENT Payment will be made at the contract unit price for trenching, bare counterpoise wire and duct bank or conduit, installed by the Contractor and accepted by the Engineer. This price shall be full compensation for furnishing all materials and for all preparation and installation of these materials, and for all labor, equipment, tools, and incidentals, including ground rods and ground connectors and trench marking tape, necessary to complete this item. No separate payment will be made for constructing the item under construction sequencing restrictions, including limited access or nighttime work areas. Trenching and backfilling will not be measured for payment but will be considered incidental to the associated bid item. <LOGO> Airport Electrical Ducts and Conduits Page 71-12 <Project Name> Special Provisions ___% Submittal Date END OF SECTION 71 <LOGO> Airport Electrical Ducts and Conduits Page 71-13