Design for Reliability (DfR) Presentation

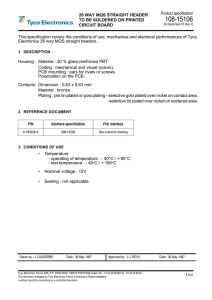

advertisement