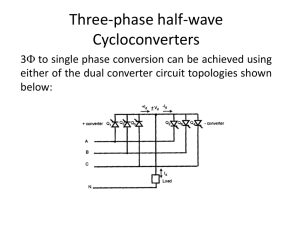

System Aspects and Modulation Strategies of an HVDC

advertisement