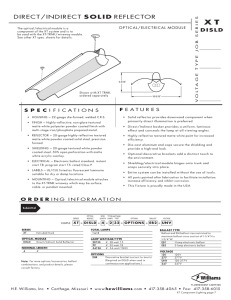

DIRECT/INDIRECT PERFORATED REFLECTOR

advertisement

O P T I C AL / E L E C T R I C AL MO D U L E XT DIPRF VO LTA G E TYPE JOB The optical/electrical module is a component of the XT system and is to be used with the XT-TRNK/wireway module. See other XT spec. sheets for details. SERIES DIRECT/INDIRECT P E R F O R AT E D REFLECTOR 7-1/16” Shown with XT TRNK, ordered separately 16-9/16” S P E C I F I C AT I O N S • • • • • • • F E AT U R E S HOUSING – 22-gauge die-formed, welded C.R.S. FINISH – Highly-reflective, non-glare textured matte white polyester powder coated finish with multi-stage iron/phosphate prepared metal. REFLECTOR – 20-gauge highly-reflective textured matte white powder coated 50% open perforated steel, precision formed. SHIELDING – 20-gauge textured white powder coated steel, 50% open perforation with matte white acrylic overlay. ELECTRICAL – Electronic ballast standard, instant start T8, program start T5, rated Class P. LABELS – UL/CUL listed as fluorescent luminaire suitable for dry or damp locations. MOUNTING – Optical/electrical module attaches to the XT-TRNK wireway which may be surface, cable, or pendant mounted. • • • • • • • • • Perforated reflector provides a pleasing up-light component to softly accentuate the ceiling. Direct/Indirect basket provides a uniform, luminous effect and conceals the lamp at all viewing angles. Highly-reflective textured matte white paint for increased efficiency. Die-cast aluminum end caps secure the shielding and provide a high-end look. Decorative brackets add a distinct touch to the environment. Shielding/electrical module hinges onto trunk and snaps securely into place. Entire system can be installed without the use of tools. All parts painted after fabrication to facilitate installation, increase efficiency, and inhibit corrosion. This fixture is proudly made in the USA. O R D E R I N G I N F O R M AT I O N Submittal EXAMPLE: SERIES XT SERIES OPTICAL MODULE NOM. TOTAL WATTAGE/ LENGTH LAMPS TYPE OPTIONS BALLAST VOLTAGE XT - DIPRF - 4 - 2 32 - OPTIONS - EB2 - UNV Extruded Trunk OPTICAL MODULE D I P RF Direct/Indirect Perforated Reflector NOMINAL LENGTH 4 4’ N o t e : For more options/accessories, ballast combinations, and product details, please consult factory. TOTAL LAMPS 1 or 2 LAMP WATTAGE/TYPE 28T5S 4’, 28-watt T5 32 4’, 32-watt T8 54 T5H 4’, 54-watt T5HO BALLAST TYPE Ballast and EM ballast size restricted to maximum ballast cross-section of 1-1/4”H x 1-3/4”W. E B1 1-lamp electronic ballast EB2 2-lamp electronic ballast VOLTAGE 1 20 2 77 U NV 3 47 1 2 0V 277V 1 20-277V 347V H.E. Williams, Inc. • Carthage, Missouri • www.hewilliams .com • 417-358-4065 • Fax: 417-358-6015 XT Component Lighting page 6 DIPRF S E R I E S XT P H O T O M E T R Y I N F O R M A T I O N Williams Catalog # XT-DIPRF-4-232-EB2 Lamp Type: F32WT8/835/RS Test Report #13862.0, Dated 12/28/07 Lamp Quantity: 2 CANDLEPOWER DISTRIBUTION VERT. ANG. 0 5 15 25 35 45 55 65 75 85 90 95 105 115 125 135 145 155 165 175 180 HORIZONTAL ANGLE 0 45 90 760. 760. 760. 773. 773. 773. 777. 790. 800. 692. 730. 761. 596. 669. 718. 487. 608. 705. 355. 520. 630. 239. 433. 565. 135. 340. 470. 41. 203. 307. 8. 112. 221. 0. 54. 168. 28. 61. 140. 82. 76. 143. 129. 124. 171. 156. 191. 230. 180. 219. 267. 193. 204. 243. 207. 216. 217. 200. 200. 198. 191. 191. 191. L U M E N S U M M A RY ZONE 0 - 30 0 - 40 0 - 60 0 - 90 90 - 120 90 - 130 90 - 150 90 - 180 0 - 180 LUMENS 635. 1052. 1974. 2942. 255. 379. 664. 843. 3785. ZONAL LUMENS 73.9 223.6 337.4 417.1 467.7 454.6 416.2 341.8 210.3 80.1 79.9 95.1 123.6 147.3 138.1 99.0 60.6 19.0 % LAMP 10.8 17.8 33.5 49.9 4.3 6.4 11.3 14.3 64.2 Z O N A L C AV I T Y C O E F F I C I E N T S EFFECTIVE FLOOR CAVITY REFL. = .20 % FIXTURE 16.8 27.8 52.2 77.7 6.7 10.0 17.5 22.3 100.0 CEILING WALL RCR .70 .50 .30 .50 .30 .10 0 .73 .73 .73 .70 .70 .70 .63 .63 .63 2 .59 .53 .49 .56 .5 1 .47 .46 .43 .40 3 4 5 6 7 8 9 10 M O U N T I N G .50 .70 .50 .30 1 T O T A L LUMINAIRE OPTICAL E F F I C I E N C Y = 64.2% .80 .70 .66 .54 .49 .45 .4 1 .38 .35 .32 .30 .62 .47 .4 1 .36 .32 .29 .26 .23 .2 1 .59 .4 1 .35 .30 .26 .23 .20 .1 8 .1 6 .62 .5 1 .46 .42 .39 .36 .33 .30 .28 .59 .45 .39 .35 .3 1 .28 .25 .22 .20 .56 .40 .34 .29 .25 .22 .20 .1 7 .1 5 .54 .4 1 .36 .32 .28 .25 .23 .20 .1 9 .52 .37 .32 .27 .24 .2 1 .1 8 .1 6 .1 4 .50 .33 .28 .23 .20 .1 7 .1 5 .1 3 .1 1 Maximum distance between mounting points = 12’ Variable Mounting Points A NOMINAL DIMENSION (A) (LENGTH OF EXTRUSION) 4 ft. unit 48-1/2” 12 ft. unit 145-1/2” 8 ft. unit 97” H.E. Williams, Inc. • Carthage, Missouri • www.hewilliams .com • 417-358-4065 • Fax: 417-358-6015 Information contained herein is subject to change without notice. HEWJP47763 12/01/11RJ