introduction to nuclear power student handout ppf200.02.ho.01

advertisement

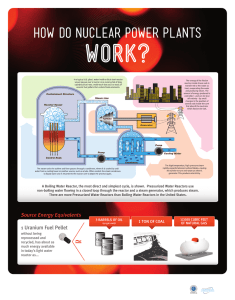

INTRODUCTION TO NUCLEAR POWER STUDENT HANDOUT PPF200.02.HO.01 PPF200.02.HO.01 Rev. 1 PAGE 1 OF Error! Bookmark not defined. INTRODUCTION The development of the Nuclear Power industry occurred within the last 60 years of the 20th century. The major types of commercial Nuclear Reactors in use in the United States are the Pressurized Water Reactor (PWR) and the Boiling Water Reactor (BWR). These terms describe the basic differences in the method of heat removal from the nuclear fuel, and will be covered in more detail later in this lesson. Today's large modern Nuclear Power Plants typically have the capacity of generating more than 1,000 Megawatts of electrical energy. While these plants are very complicated and sophisticated, there are many aspects that can be discussed sufficiently in general terms so that we will be able to have an overall understanding of how they work. OBJECTIVES • LIST the four basic requirements for a Nuclear Reactor • DEFINE the terms PWR and BWR. • LIST two differences between a BWR and a PWR. • . NAME three major buildings at a nuclear power site. THE REACTOR AND ITS COMPONENTS The real heart of the Nuclear Power Plant is the nuclear reactor, which we will refer to as the reactor. The four basic requirements for any reactor are its fuel, coolant, moderator, and control material. TMCR: 201170 PPF200.02.HO.01 Rev. 1 PAGE 2 OF Error! Bookmark not defined. The discovery that the nucleus of a large atom can be fissioned or split into two or more fragments by a neutron was made in the years preceding World War II. The discovery offered no immediate possibility for a useful application until it was further discovered that each fission of Uranium-235 also released approximately 2.4 neutrons. This surplus of neutrons made a self-sustaining or so-called chain nuclear reaction theoretically possible. Once the principle of the chain reaction was established, the possibility of constructing a nuclear reactor became promising. During the afternoon of December 2, in 1942 the first reactor went into operation in the football stadium under the west stands of Stagg Field at the University of Chicago. A pound of Uranium-235, when completely fissioned, will produce something on the order of 3 x 1010 BTUs of energy. This is equivalent to the energy contained in 3 billion pounds of coal. However this Uranium fuel cannot be used in a normal power plant. It takes a specialized Nuclear Power Plant with many important design features, and specialized support systems to utilize this special fuel. Certain atoms can fission when struck by a neutron. This fission usually results in the splitting of the nucleus into two parts of unequal mass. These parts are known as fission fragments. Along with the fission fragments, some free neutrons are also produced (the average number of these free neutrons being produced is approximately 2.4 neutrons for each Uranium-235 fission event). They are called free neutrons because they are loose and are not attached to any atoms or nucleases. In order for any reaction, chemical or nuclear to be practical, it must be selfsustaining. Most power today is produced from the combustion of natural gas, oil or coal. In order to start combustion it is necessary to raise the fuel above its ignition temperature. Once the combustion process has started the temperature of the furnace in a Boiler becomes high enough so that the reaction remains selfsustaining as long as sufficient fuel and oxygen are continually added. For each fission that occurs in a nuclear plant, there must be one net neutron available from the previous fission event to cause the next fission. There are several processes within the reactor that compete for these vital neutrons. Materials within the core will absorb some of the neutrons, and some will leak out of the sides. If either the absorption within the core or the leakage from the core is excessive, there will not be an average of one neutron left available from each fission to sustaining the nuclear reaction. If this happens the reactor will start shutting down. TMCR: 201170 PPF200.02.HO.01 Rev. 1 PAGE 3 OF Error! Bookmark not defined. The energy released by the fission process appears mainly in the form of the kinetic energy of the fission fragments. As these fission fragments are still contained within the fuel rods, the transfer of energy from the fission fragments appears to us as an increase in the temperature of the fuel material. Heat is transferred from the fuel elements to the reactor coolant by virtue of the temperature difference between them, and thus the heat produced in the reactor fuel is removed while the temperature of the coolant flowing around the fuel increases. Most reactors use Uranium Dioxide for fuel. The Uranium Dioxide molecule contains one Uranium atom and two Oxygen atoms. The Uranium that is used is generally 2-8% enriched in Uranium-235. Some reactors, however, use natural Uranium fuel, and some use Uranium Carbide fuel. TP 10 shows a typical Fuel Assembly. Reactor fuel is generally compacted into pea sized pellets, which are inserted into hollow tubes or rods made of Zirconium. The Zirconium rods contain and protect the fuel, and when the fuel pellets within heat them, they transfer this heat to the whatever touches them. The fuel rods are bundled together in fuel assemblies and inserted into the reactor as the nuclear fuel. In most reactors, ordinary purified water acting as coolant flows past the fuel rods to remove the heat from the fuel, however some reactors in other countries use gas as their coolant. In most reactors, water serves as both the coolant and the moderator. The purpose of the moderator is to slow down the fast neutrons produced in the fission process to slow neutrons (thermal neutrons) so that they can cause additional fissions. Thermal neutrons are more readily absorbed to produce fissions than fast neutrons are. Some reactors use Graphite as the moderator and some use heavy water (water with a different type [isotope] of Hydrogen in the molecule). Control material, in the form of rods, are also inserted into the reactor to absorb excess neutrons and, therefore, regulate the number of fission events. Control rods come in different shapes and sizes, depending on the reactor type. Liquid control material can also be added to the coolant to absorb neutrons. NEUTRON LEAKAGE TMCR: 201170 PPF200.02.HO.01 Rev. 1 PAGE 4 OF Error! Bookmark not defined. Neutron leakage from the core is a core surface effect; the production of neutrons within the core is a volume effect. In order to have good fuel economy we must minimize the neutron leakage. In order to minimize leakage it is desirable to have as small a surface-to-volume ratio as possible. Obviously, the best shape would be a sphere or ball. It can be demonstrated that as a body becomes larger in volume the ratio of the surface area to the volume area becomes smaller. Once the materials for use in a given reactor have been chosen, the neutron economy of the reactor may be improved and the leakage cut down merely by increasing its size. If the reactor is too small the leakage will be excessive, and a chain reaction cannot be sustained. The minimum size that will be able to achieve a selfsustaining reaction within it, is called the critical size for that design. Reactors are built larger than critical size, so that they can run for long periods, and the excess neutrons available due to the resultant lower leakage are usually controlled by means of neutron absorbers in the core. These absorbers, are typically in the form of control rods or liquid chemical solutions. A reactor operating in the United States will typically contain anywhere from two to eight kilograms of highly enriched Uranium fuel and ten or more tons of natural Uranium. As a reactor is operated, the fission fragments build up within the fuel assemblies. Many of the fission fragments act as absorbers of neutrons and are harmful to the neutron economy. After a period of time the fission fragments may have built up to the point where a self-sustaining nuclear reaction is no longer possible. At this time some of the fuel assemblies in the reactor must be removed and replaced if the reactor is going to continue operating TYPES OF REACTORS Reactors are classified on the basis of the coolant and the type of neutron that causes most of the fission events. In terms of coolant, there are four reactor types: (1) The Light Water Reactor, which uses ordinary purified water; (2) The Heavy Water Reactor, which uses heavy water, often along with regular water; (3) The Gas-Cooled Reactor, which uses gas, usually Helium, and (4) The Liquid Metal Reactor, which uses a liquid metal, usually Sodium Potassium (NaK). In terms of the neutron uses to cause most of the fission events, there are two Reactor types: (1) the Fast Reactor, which uses fast neutrons, and TMCR: 201170 PPF200.02.HO.01 Rev. 1 PAGE 5 OF Error! Bookmark not defined. (2) the Thermal Reactor, which uses thermal neutrons. The major Reactor of the Light Water Reactor type in the world today is the Thermal Light Water Reactor. As stated previously, the coolant is ordinary purified water and this reactor uses thermal neutrons to cause most of the fission events. Two common types of the Thermal Light Water Reactor are the Boiling Water Reactor and the Pressurized Water Reactor. Pressurized Water Reactor The most common Nuclear Power Plant is the Pressurized Water Reactor, or PWR as it is commonly called. The PWR has both a primary and a secondary loop. (ref. TP 23) The fluid in the primary loop is maintained in a liquid by intense pressure. It remains in liquid form as it continues its repeating cycle throughout the loop. A self-sustaining nuclear reaction occurs inside the core. This reaction heats the fuel elements in the core, which in turn heats the fluid as it passes through the core. After the fluid has left the Reactor core it proceeds to a heat exchanger that we call a “Steam Generator”. In the steam generator the pressure in the open area is lower than it is inside the primary loop. The primary coolant inside the tubes, heats the lower pressure water outside the tubes to the boiling point. When this water boils it forms steam. This steam then flows to a turbine that is used to drive an electrical generator, which of course produces electrical power. After leaving the turbine the steam goes to a “condenser” where it is condensed and returned by the “feed pumps” to the steam generators, where the cycle starts all over again . A PWR plant may have as many as two, three or four primary loops. The STP Units each have four primary loops, with each primary loop having its own steam generator. Steam leaving the steam generators, is equalized in pressure by a common header that pipes the steam from all four steam generators to the turbine. Water from the primary loop enters the reactor vessel, flows down the sides and then up through the core, picking up the heat from the fuel as it flows over it. The heated water leaves through the outlet nozzle and flows to the steam generator, where it gives up its heat to the cooler water of the secondary systems. In the PWR, there are essentially two basic ways to control the number of fission events during normal operations: control rods and a liquid control material (Boron) in the coolant. TMCR: 201170 PPF200.02.HO.01 Rev. 1 PAGE 6 OF Error! Bookmark not defined. The control rods in a PWR are attached together in cluster assemblies and are inserted into the Reactor from the top, while the rods in a BWR are inserted from the bottom. The liquid control is a chemical (Boron) that is added to the water in the Primary System to absorb neutrons and thus provide additional control. Additional non-variable neutron controls can also be provides through the use of neutron poisons installed with the fuel when it is loaded into the reactor vessel. If any abnormal conditions occur, a reactor “trip” will cause the control rods to be automatically released so that the force of gravity will drive them down into the reactor. In addition, a backup system would inject increased amounts of the liquid control material (liquid neutron absorbers) into the reactor if the trip system failed. There are many other safety systems in a PWR, each with at least one redundant backup system. The entire primary loop and the steam generators are enclosed within the Reactor Containment Building to protect personnel from nuclear radiation coming from within the reactor core during normal operations. This containment also protects the general public and plant personnel from the effects of a major system failure during the unlikely event of a primary system failure. A PWR plant includes the Containment Building, the Turbine Building , the Auxiliary Building, and the Fuel Handling Building. The Reactor Containment Building is a large, dome-shaped structure. The Boiling Water Reactor The Boiling Water Reactor (BWR) is the other of the two major types of Thermal Light Water Reactors. A BWR plant includes the Containment, the Turbine, the Auxiliary Building, and the Fuel Handling Building. The Containment Building is sometimes a large, square structure. The BWR also contains the four major components necessary for a reactor - fuel, coolant, moderator, and control material. The BWR also includes three other components that are not found in the other major reactor types. These are the: (1) Moisture Separators and (2) Steam Dryers, which together separate steam from water, and (3) Jet Pumps, which increase flow through the fuel. TMCR: 201170 PPF200.02.HO.01 Rev. 1 PAGE 7 OF Error! Bookmark not defined. TP 24 shows a typical BWR flowpath inside the reactor. Feedwater enters the reactor vessel and travels through the jet pumps, where its velocity is increased. It then flows up through the reactor core, picking up heat from the fuel as it goes. In the upper regions of the core, the water boils, producing steam. The steam is separated from the moisture within it by the “moisture separators” and “steam dryers”. The steam then leaves the reactor vessel, and the moisture (water) falls back down to mix with the feedwater entering the reactor vessel. The steam leaving the reactor vessel flows to the “turbine”, where it causes the turbine and the attached electrical generator to turn, thus producing electricity. The steam leaving the turbine is condensed back to water in the “condenser”, and the water is then pumped back to the reactor. The major difference between the PWR and the BWR is that the coolant (water) flowing through the BWR reactor is allowed to boil in the reactor, directly producing steam, and therefore does not need or use a "steam generator" as a PWR does. In the BWR, there are two basic ways to control the number of fission events during normal operations - control rods and recirculation flow. The control rods in a BWR are inserted from the bottom of the reactor (remember, this is also considered a major difference, as in the PWR the control rods are inserted from the top). The recirculation flow system is also shown in TP 24. This system controls the rate that the water flows through the core. As the flow in this system is increased, water flows faster through the core, and fewer steam bubbles are allowed to form. Since water is a better moderator than steam, with this fast flow, more neutrons are slowed down to thermal energies, and there will be more fissions. If recirculation flow is decreased, more steam bubbles are formed, so in this condition there would be less moderation and fewer fissions would occur. If any abnormal conditions occur in the BWR, a reactor trip or scram will cause the control rods to be inserted automatically up into the reactor. In addition, a backup system would inject a liquid control substance into the reactor if the trip system failed. There are many other safety systems in the BWR, each with at least one redundant backup system. OTHER REACTOR DESIGNS Another type of commercial reactor that uses light water as the coolant, but Graphite as the moderator is a design from the former Soviet Union, the RBMK. TMCR: 201170 PPF200.02.HO.01 Rev. 1 PAGE 8 OF Error! Bookmark not defined. This variant of the Boiling Water reactor design uses Steam Generators (called Steam Drums in the RBMK), the design is shown in TP 28) . Originally intended as a small military plutonium production design, the RBMK was brought into commercial use because its modular design was found to be easy to scale up, manufacture and install. It is a boiling water reactor that uses numerous but identical, power producing chambers or modules, all installed parallel to each other. These individual modules are used together, instead of a large common reactor vessel. This reactor type is not licensable in the United States as a commercial reactor, and it is not found in commercial applications outside the Commonwealth of Independent States (CIS), [the former Soviet Union]. The Heavy-Water Reactor, a PWR variant is shown in TP 29. The hydrogen molecules in “heavy water” water have an added neutron in their nucleus. Because the Hydrogen atoms in heavy water already have a neutron, they do not normally take any of the free neutrons that are available from the fission process. This increases the number of available neutrons in the core to a sufficient quantity, such that natural (NON-enriched) " Uranium may be used as the fuel. A further advantage of the Heavy Water Reactor is that they are designed to allow refueling while still operating at full power. The High-Temperature Gas-Cooled Reactor shown in TP’s 32 & 33 uses Helium gas as the coolant. Helium is blown through the reactor core, where it picks up heat from the fuel. The high-temperature Helium then circulates through a heat exchanger, where it gives up its heat to water. The primary reason for using Helium as the coolant is that Helium is an inert gas; it will not react with other materials. The rest of the cycle is the same basic steam/water cycle described for the Light Water Reactors. The water turns to steam and the steam flows to the turbine. An evolution of this reactor type is the Advanced Gas Cooled Reactor. This reactor uses high temperature Carbon Dioxide as the coolant instead of Helium. Both of these types were developed extensively in Great Briton, with the earlier type going all the way back to the 1950s (it is the oldest commercial nuclear design in operation). For fuel, the Gas-Cooled Reactors uses enriched Uranium fuel. Graphite is used as the moderator and control rods containing neutron absorbers are used to control the fission process. TMCR: 201170 PPF200.02.HO.01 Rev. 1 PAGE 9 OF Error! Bookmark not defined. The next two Reactor types are not in commercial or even common use at present, but technology may develop to the point where their use is more widespread. These two Reactor types are (1) the Breeder Reactor and (2) the Fusion Reactor. The Breeder Reactor (TP’s 37 through 39) works on the principle that it will produce, or breed, more fuel than it started with*. When certain types of materials absorb neutrons, the eventual results are atoms that will readily fission. For example, Uranium-238 will absorb neutrons and eventually produce Plutonium239, which will readily fission. These reactors use fast neutrons for fission and use either high temperature liquid metal or liquid salt as their coolants. All Reactors (breeders and non-breeders) that have Uranium-238 or Thorium-232 in them will produce fissionable fuel. However, in the Light Water Reactors, more fuel is used up than is produced. The final type of reactor is the Fusion Reactor. (TP’s 41 through48) Some scientists call this reactor the energy of the future. In the fusion process, two light Hydrogen Isotopes are fused together to form helium and a free neutron. As this occurs, energy is emitted. One problem with the fusion reactor is that the temperature required to fuse two atoms together is around 100,000,000°F. The fuel supply for this type of reactor, however is unlimited; it is a type of Hydrogen that is found in the ocean. Experimental facilities have shown the feasibility of fusion power, and it is expected that technology will develop to the point where fusion may be a prime source of power sometime during this century. Major Buildings Modern power plants generally contain several main buildings or structures. The five major ones are: 1. The Containment Building, a massive structure that houses the Reactor and associated equipment, and is capable of withstanding hurricanes, earthquakes, and other adverse events of nature; *Note: A breeder reactor is not a "perpetual motion machine". It can only make fissionable fuel from the non-readily fissionable Uranium-238 and Thorium-232 fuel that is already in the core. Thus the fuel supply will run out just as in a normal reactor, when there is an insufficient amount of material left to fission and maintain the necessary steady state power level. TMCR: 201170 PPF200.02.HO.01 Rev. 1 PAGE 10 OF Error! Bookmark not defined. 2. The Turbine Building, which houses the Turbine, the Generator, the Condenser, pumps, and the other equipment that supports these systems; 3. The Auxiliary Building, which houses support systems such as the Ventilation Systems, the Water Purifying Systems, and the Water Disposal Systems, 4. The Fuel Handling Building, which houses the fuel transfer equipment and fuel storage pits, as well as pit cooling and purifying equipment, and 5. The Emergency Diesel Generator Buildings that contain the emergency power sources that might be needed to help shut down the reactor if normal power sources were all unavailable. The plant site also contains a large Switchyard, where the generated electrical power is fed into circuit breakers that route the electricity to areas where it is used. The plant site also includes administrative buildings and security buildings. All plants have some means of cooling the water from the condenser. Some plants use cooling towers, while others such as the South Texas Project use a reservoir or other large body of water such as a lakes, or a river. A Nuclear Power Plant requires a central location to provide control for the complicated operations involved in producing safe, reliable, and economical electrical power. The Control Room, which is manned 24 hours a day by Federally Licensed Operators, contains the controls and monitoring devices associated with every major system in the plant: switches, indicating lights, gauges, and other devices that tell the status of the plant at a glance. There are also Annunciator Panels that alert the operator to the existence of abnormal conditions. A computer provides additional specific information such as the temperature and pressure of the systems, and aids the interaction between the operator and the plant. SUMMARY: TMCR: 201170 PPF200.02.HO.01 Rev. 1 PAGE 11 OF Error! Bookmark not defined. The major commercial Nuclear Power Plants in use in the world are the Thermal Light Water Reactors. This type includes the BWR and PWR or Boiling Water Reactor and Pressurized Water Reactor. In both versions, the major buildings are the (1) Containment Building which encloses the reactor and supplies steam to (2) the Turbine Building to drive the Turbine Generator and other steam loads, (3) the Auxiliary Building, which encloses equipment and systems necessary for plant operation, (4) the Fuel Handling Building, which is used to handle, store, and cool fuel assemblies, and (5) the Emergency Diesel Generator Building, which is the structure that protects the emergency electrical generators. The Reactor and support systems are operated from a centrally located Control Room. Common to all reactors is the need for fuel, coolant, moderator, and control material. The BWR boils the coolant in the reactor into steam, which then turns the turbine generator. The PWR uses a secondary loop as the steam cycle, with the reactor coolant pressurized in the primary loop as the heat source. Both the BWR and PWR insert a control material to regulate the amount of neutrons allowed to cause fission in the reactor. A BWR plant in the United States inserts control rods up into the reactor while a PWR inserts its control rods down into the reactor. TMCR: 201170