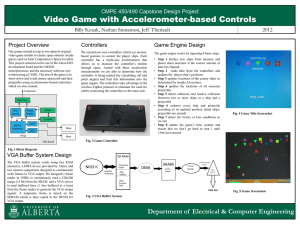

Vapor Generation Accessory VGA 77

advertisement