17.27

IPS STAINLESS STEEL PIPE PRODUCTS

Stainless Steel Flange Solutions

Victaulic offers a variety of stainless steel flange adapters designed for directly incorporating

stainless steel flanged components into Victaulic’s stainless steel grooved piping systems.

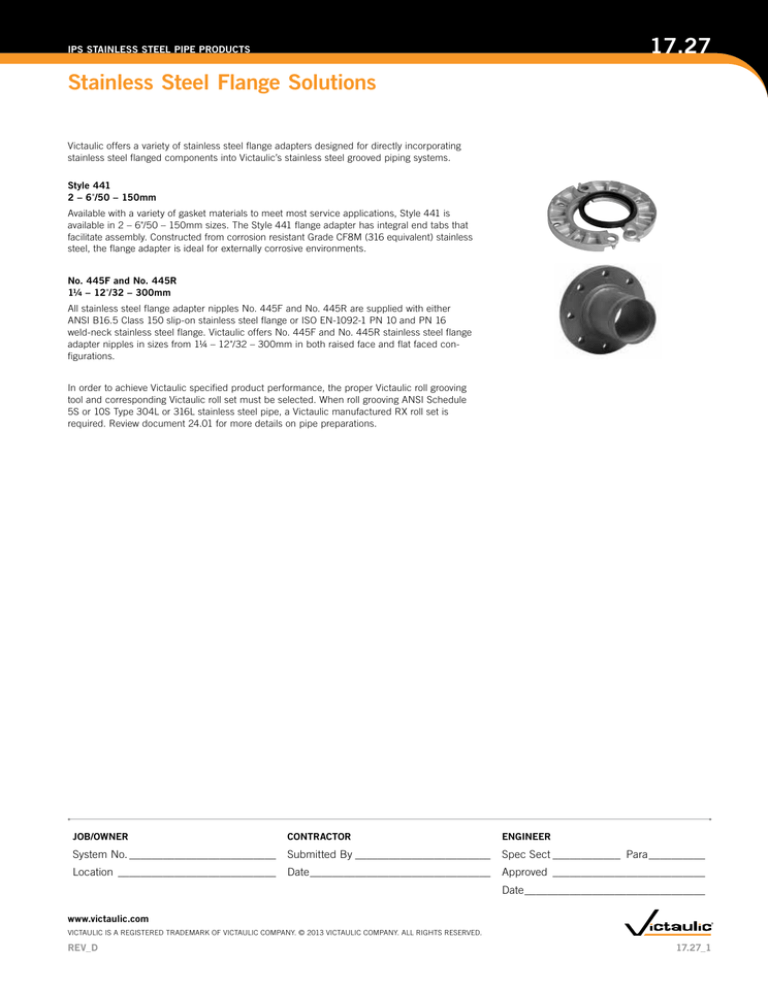

Style 441

2 – 6"/50 – 150mm

Available with a variety of gasket materials to meet most service applications, Style 441 is

available in 2 – 6"/50 – 150mm sizes. The Style 441 flange adapter has integral end tabs that

facilitate assembly. Constructed from corrosion resistant Grade CF8M (316 equivalent) stainless

steel, the flange adapter is ideal for externally corrosive environments.

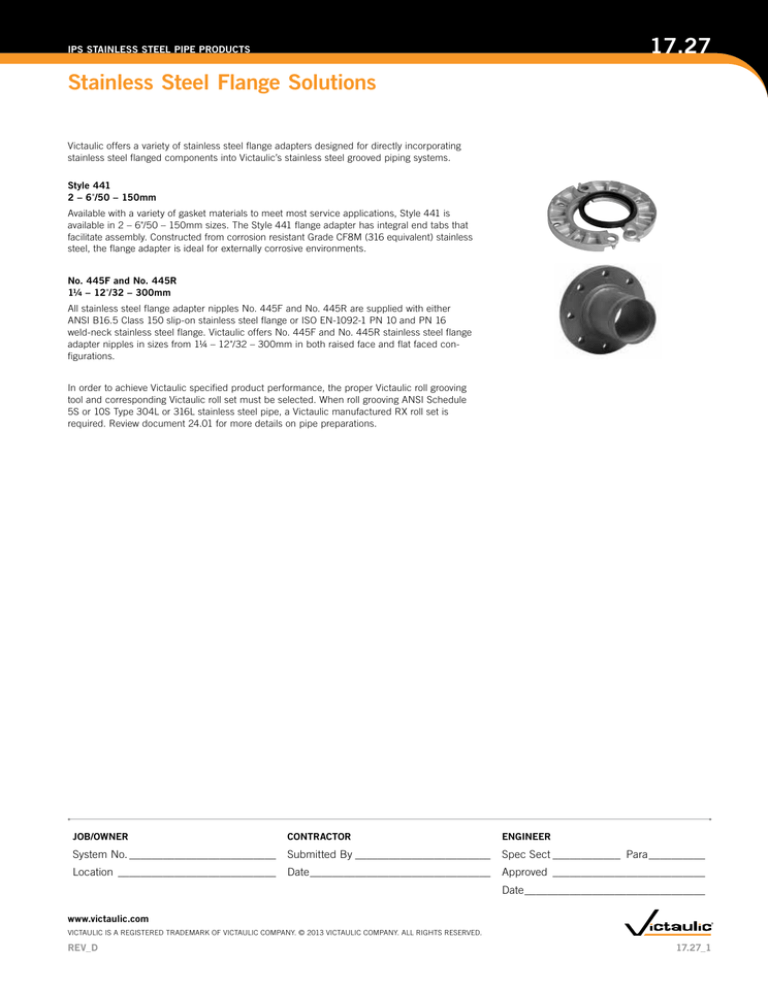

No. 445F and No. 445R

1¼ – 12"/32 – 300mm

All stainless steel flange adapter nipples No. 445F and No. 445R are supplied with either

ANSI B16.5 Class 150 slip-on stainless steel flange or ISO EN-1092-1 PN 10 and PN 16

weld-neck stainless steel flange. Victaulic offers No. 445F and No. 445R stainless steel flange

adapter nipples in sizes from 1¼ – 12"/32 – 300mm in both raised face and flat faced configurations.

In order to achieve Victaulic specified product performance, the proper Victaulic roll grooving

tool and corresponding Victaulic roll set must be selected. When roll grooving ANSI Schedule

5S or 10S Type 304L or 316L stainless steel pipe, a Victaulic manufactured RX roll set is

required. Review document 24.01 for more details on pipe preparations.

JOB/OWNER

CONTRACTOR

ENGINEER

System No.___________________________

Submitted By_________________________

Spec Sect_____________ Para___________

Location_____________________________

Date________________________________

Approved____________________________

Date________________________________

www.victaulic.com

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY. © 2013 VICTAULIC COMPANY. ALL RIGHTS RESERVED.

REV_D

17.27_1

17.27

IPS STAINLESS STEEL PIPE PRODUCTS

Stainless Steel Flange Solutions

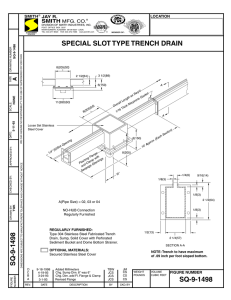

Style 441

DIMENSIONS

Stainless Steel

Vic-Flange Adapter

Z

A

B

Note: Gray area of mating

face must be free from

gouges, undulations or

deformities of any type for

effective sealing.

Max.

End

Load

No.

Bolts †

Bolt

Size †

Nominal

Size

Inches

mm

Actual

Outside

Diameter

Inches

mm

PSI*#

kPa

Lbs.*

N

Req’d.

Inches

2

50

2.375

60.3

275

1896

1220

5429

4

2 1/2

65

2.875

73.0

275

1896

1785

7943

3

80

3.500

88.9

275

1896

4

100

4.500

114.3

6

150

6.625

168.3

Size

Style 441

X

Max.

Work

Pres.

YW

Sealing

Surface

Inches

mm

Dimensions Inches/millimeters

Approx.

Weight

Each

“A”

Max.

“B”

Min.

W

X

Y

Z

Lbs.

kg

5/8 x 2 3/4

2.40

61

3.40

86

6.84

174

6.00

152

4.75

121

0.82

21

3.0

1.4

4

5/8 x 3

2.90

74

3.90

99

7.72

196

7.00

178

5.50

140

0.88

22

4.3

2.0

2645

11770

4

5/8 x 3

3.50

89

4.50

114

8.22

209

7.50

191

6.00

152

0.94

24

4.8

2.2

275

1896

4375

19469

8

5/8 x 3

4.50

114

5.50

140

9.72

247

9.00

229

7.50

191

0.94

24

6.9

3.1

200

1379

6895

30683

8

3/4 x 3 1/2

6.60

168

7.80

198

11.78

299

11.00

279

9.50

241

1.00

25

9.5

4.3

*Refer to notes on Page 3.

†Total bolts required to be supplied by installer. Bolt sizes for conventional flange-to-flange connection.

#Based on Schedule 10S pipe roll grooved with Victaulic “RX” stainless steel rolls.

PERFORMANCE ON ANSI WALL

THICKNESSES

Pipe Diameter

Nominal

Pipe Size

Actual

Outside

Diameter

Inches

mm

Inches

mm

2

50

21/2

65

3

80

4

100

6

150

2.375

60.3

2.875

73.0

3.500

88.9

4.500

114.3

6.625

168.3

Style 441

Pipe

Wall

Thickness

Inches

mm

0.217

5.5

0.154

3.9

0.110

2.8

0.067

1.7

0.276

7.0

0.205

5.2

0.122

3.1

0.083

2.1

0.299

7.6

0.217

5.5

0.122

3.1

0.083

2.1

0.339

8.6

0.236

6.0

0.122

3.1

0.083

2.1

0.280

7.1

0.134

3.4

0.110

2.8

Grooving Method

ANSI

Schedule

Number

St = Standard Roll Set

RX = SS Roll Set

C = Cut Groove

80S

C

40S

St/C

10S

RX

5S

RX

80S

C

40S

St /C

10S

RX

5S

RX

80S

C

40S

St/C

10S

RX

5S

RX

80S

C

40S

St/C

10S

RX

5S

RX

40S

St/C

10S

RX

5S

RX

Maximium

Working

Pressure End Load

PSI

kPa

Lbs

N

275

1896

275

1896

275

1896

200

1379

275

1896

275

1896

275

1896

200

1379

275

1896

275

1896

275

1896

200

1379

275

1896

275

1896

275

1896

200

1379

275

1896

200

1379

125

862

1218

5419

1218

5419

1218

5419

886

3941

1785

7941

1785

7941

1785

7941

1298

5776

2646

11679

2646

11679

2646

11679

1924

8560

4374

19454

4374

19454

4374

19454

3181

14150

9479

42166

6895

30668

4310

19171

www.victaulic.com

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY. © 2013 VICTAULIC COMPANY. ALL RIGHTS RESERVED.

17.27_2

REV_D

17.27

IPS STAINLESS STEEL PIPE PRODUCTS

Stainless Steel Flange Solutions

PERFORMANCE ON ISO WALL

THICKNESSES

Pipe Diameter

Style 441

Nominal

Pipe Size

Actual

Outside

Diameter

Pipe

Wall

Thickness

Grooving Method

Inches

mm

Inches

mm

Inches

mm

St = Standard Roll Set

RX = SS Roll Set

C = Cut Groove

2

50

3

80

4

100

6

150

2.375

60.3

3.500

88.9

4.500

114.3

6.625

168.3

0.220

5.6

0.157

4.0

0.142

3.6

0.126

3.2

0.114

2.9

0.102

2.6

0.091

2.3

0.079

2.0

0.063

1.6

0.315

8.0

0.220

5.6

0.157

4.0

0.142

3.6

0.126

3.2

0.114

2.9

0.102

2.6

0.091

2.3

0.079

2.0

0.346

8.8

0.248

6.3

0.177

4.5

0.142

3.6

0.114

2.9

0.102

2.6

0.079

2.0

0.433

11.0

0.280

7.1

0.280

7.1

0.197

5.0

0.177

4.5

0.157

4.0

0.126

3.2

0.102

2.6

0.079

2.0

C

St/C

St

St

St

RX

RX

RX

RX

C

St/C

St

St

St

RX

RX

RX

RX

C

C

St

St

RX

RX

RX

C

St

C

St

St

St

RX

RX

RX

Maximium

Working

Pressure End Load

PSI

kPa

Lbs

N

275

1896

275

1896

275

1896

275

1896

275

1896

250

1724

250

1724

225

1551

200

1679

275

1896

275

1896

275

1896

275

1896

275

1896

250

1724

232

1600

200

1379

200

1379

275

1896

275

1896

275

1896

275

1896

250

1724

232

1600

200

1379

275

1896

275

1896

275

1896

232

1600

225

1551

200

1379

175

1207

1218

5419

1218

5419

1218

5419

1218

5419

1218

5419

1108

4927

1108

4927

997

44334

886

3941

2646

11769

2646

11769

2646

11769

2646

11769

2646

11769

2405

10699

2232

9929

1924

8559

1924

8560

4374

19454

4374

19454

4374

19454

4374

19454

3976

17686

3690

16413

3181

14150

9479

42166

9479

42166

9479

42166

7997

35574

7756

34501

6894

30667

6033

26836

N/R

www.victaulic.com

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY. © 2013 VICTAULIC COMPANY. ALL RIGHTS RESERVED.

REV_D

N/R Not rated. Contact Victaulic for more information.

17.27_3

17.27

IPS STAINLESS STEEL PIPE PRODUCTS

Stainless Steel Flange Solutions

Style 441

VIC-FLANGE ADAPTER NOTES

1.Working Pressure and End Load are total, from all internal and external loads, based on Schedule

10S stainless steel pipe, roll grooved with Victaulic “RX” stainless steel rolls in accordance with

Victaulic specifications. Contact Victaulic for performance on other pipe.

WARNING: FOR ONE TIME FIELD TEST ONLY, the maximum Joint Working Pressure may be

increased to 1½ times the figures shown.

2.The Style 441 does not rigidly attach to the grooved pipe. Some axial, angular and rotation

flexibility of the pipe is to be expected.

3.The Style 441 is designed for use with Class 150 raised-face flanges, in accordance with ANSI

B16.5. When a Style 441 is used with a flat-faced flange, the raised projections on the outside

edge and around the mating holes of the flange adapter must be ground flush to the body. Refer

to the Style 441 Installation Instructions.

4.The Style 441 cannot be used, unless it mounts flush to the mating flange; therefore, flange

washers, or anything else that prevents flush mounting, cannot be used. Please use the No. 445F

or No. 445R.

5.The Style 441 must not be used as anchor points for tie rods across non-restrained joints.

6.The Style 441 must not be used against rubber coated surfaces or with wafer or lug-type valves,

or when the flange adapter does not mount flush with the mating flange. For those types of

applications, use a groove by flange adapter nipple, such as the No. 445F or No. 445R.

7.Because of the outside flange dimension, the Style 441 must not be used 90° to one another

on a standard fitting.

8.Area A-B noted in the accompanying drawing (page 2) must be free from gouges, undulations or

deformitities of any type for effective sealing

9.Style 441 Flange adapter gaskets must always be assembled with the color coded lip on the pipe

and the other lip facing the mating flange. The markings on the outside of the gasket must face

the Style 441 flange adapter.

10. WARNING: Depressurize and drain the piping system before attempting to install, remove, or adjust any Victaulic piping products.

www.victaulic.com

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY. © 2013 VICTAULIC COMPANY. ALL RIGHTS RESERVED.

17.27_4

REV_D

17.27

IPS STAINLESS STEEL PIPE PRODUCTS

Stainless Steel Flange Solutions

ANSI Class 150 No. 445F & No. 445R

DIMENSIONS

ANSI Flange Adapter Nipple

No. 445F

ANSI B16.5 Class 150 Flat Face

E to E

No. 445R

ANSI B16.5 Class 150 Raised Face

E to E

Size

Maximum

Work

Pressure

Maximum

End

Load

Dimensions

Approx.

Weight

Each

Nominal

Size

Inches

mm

Actual

Outside Diameter

Inches

mm

PSI #

kPa

Lbs.

N

E to E

Inches

mm

Lbs.

kg

1¼

32

1½

40

2

50

2½

65

3

80

4

100

5

125

6

150

8

200

10

250

12

300

1.66

42.2

1.90

48.3

2.38

60.3

2.88

73.0

3.50

88.9

4.50

114.3

5.56

141.3

6.63

168.3

8.63

219.1

10.75

273.0

12.75

323.9

275

1896

275

1896

275

1896

275

1896

275

1896

275

1896

275

1896

275

1896

275

1896

275

1896

275

1896

600

4137

780

5378

1218

8398

1785

12307

2645

18237

4370

30130

6680

46057

9480

65362

16060

110730

24960

172093

35110

242075

4.00

102

4.00

102

4.00

102

4.00

102

4.00

102

6.00

152

6.00

152

6.00

152

6.00

152

8.00

203

8.00

203

3.3

1.5

3.9

1.8

6.2

2.8

9.9

4.5

11.4

5.2

18.4

8.3

21.3

9.7

27.5

12.5

41.3

18.8

59.8

27.1

88.2

40.0

Please contact Victaulic for other ANSI Class flange adapter solutions.

MATERIAL SPECIFICATIONS

Pipe Nipple: ANSI Schedule 10S or equivalent, Type 304L/316L stainless steel.

Flange: ANSI B16.5 stainless steel, slip-on flat face/ slip-on raised face.

www.victaulic.com

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY. © 2013 VICTAULIC COMPANY. ALL RIGHTS RESERVED.

REV_D

17.27_5

17.27

IPS STAINLESS STEEL PIPE PRODUCTS

Stainless Steel Flange Solutions

ISO No. 445F & No. 445R

DIMENSIONS

Maximum

End

Load

Size

ISO Flange Adapter Nipple

No. 445F

ISO EN1092-1 PN 10 and PN 16 Flat Face

E to E

No. 445R

ISO EN1092-1 PN 10 and PN 16 Raised

Face

E to E

Dimensions

Approx.

Weight

Each

Nominal

Size

Inches

mm

Actual

Outside Diameter

Inches

mm

PN 10

PN 16

E to E

Inches

mm

Lbs.

kg

1¼

32

1½

40

2

50

2½

65

3

80

4

100

5

125

6

150

8

200

10

250

12

300

1.66

42.4

1.90

48.3

2.38

60.3

2.88

76.1

3.50

88.9

4.50

114.3

5.56

139.7

6.63

168.3

8.63

218.1

10.75

273.0

12.75

323.9

314

1397

411

1828

645

2869

945

4204

1395

6205

2306

10258

3521

15662

5006

22268

8482

37730

13161

58543

18513

82350

502

2233

658

2927

1032

4590

1511

6721

2232

9928

3690

16414

5633

25057

8009

35626

13571

60367

21057

93666

29621

131761

4.00

102

4.00

102

4.00

102

4.00

102

4.00

102

6.00

152

6.00

152

6.00

152

6.00

152

8.00

203

8.00

203

3.3

1.5

3.9

1.8

6.2

2.8

9.9

4.5

11.4

5.2

18.4

8.3

21.3

9.7

27.5

12.5

41.3

18.8

59.8

27.1

88.2

40.0

Lbs.

N

Please contact Victaulic for other ISO flange adapter solutions.

MATERIAL SPECIFICATIONS

Pipe Nipple: Stainless steel EN 1.4404 (SS2348).

Flange: ISO EN1092-1 stainless steel, weld-neck flat face/ weld-neck raised face.

INSTALLATION

Reference should always be made to the I-100 Victaulic Field Installation Handbook for the product

you are installing. Handbooks are included with each shipment of Victaulic products for complete

installation and assembly data, and are available in PDF format on our website at www.victaulic.com.

WARRANTY

Refer to the Warranty section of the current Price List or contact Victaulic for details.

NOTE

This product shall be manufactured by Victaulic or to Victaulic specifications. All products to be

installed in accordance with current Victaulic installation/assembly instructions. Victaulic reserves the

right to change product specifications, designs and standard equipment without notice and without

incurring obligations.

For complete contact information, visit www.victaulic.com

17.27

3313 REV D

UPDATED 03/2013

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY. © 2013 VICTAULIC COMPANY. ALL RIGHTS RESERVED.

17.27