Dormitory Motion Sensor Lighting (2012)

advertisement

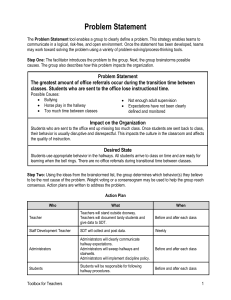

Dormitory Motion Sensor Lighting ETA KAPPA NU Electrical, Computer, and Software Engineering Honor Society Project Leader: Jeannie Piekarz Email: piekarjm@clarkson.edu Cell: (845) 803-2146 President: Gregory Mesagna Email: mesagnga@clarkson.edu Cell: (315) 271-4658 Vice President: Roy Berger Email: bergerrh@clarkson.edu Cell: (603)-361-8841 Secretary: David Illig Email: illigdw@clarkson.edu Cell: (603)-759-2001 Page | 1 1 Problem Need Hallway lights in the dorms are on 24 hours a day, 7 days a week. These lights may not be needed every hour of the day, as students are often away from the dorms for classes or other events, as well as in their rooms to sleep. In order to reduce the amount of energy that the dorms use, some of those lights could be turned off for periods of time when students are not in the hallways, while some are kept on for safety purposes. We project that the installation of this system can save an estimated 27% in lighting use in dorm hallways. In New York State 79% of our electricity comes from coal and other nonrenewable resources (New York Independent Systems Operator, 2011). Fossil fuels, which make up nearly half of New York State’s generation, degrade our health and pollute our environment. Burning fossil fuels has contributed to acid rain in the nearby Adirondacks, resulting in animals disappearing and the acidification of lakes. Therefore, every kilowatt-hour we can save works toward a healthier society and planet, and a more sustainable campus. Our university uses $4.6 million worth of utilities each year (Director of Facilities, 2012), so every opportunity for reducing energy use can help reduce that amount, freeing up funds for curriculum improvements, tuition reductions, and other measures important to the sustainability of the university. 2 Project Approach We have installed motion sensors to control the lighting in the dorm hallways, so the lights can be turned off when not in use. After consulting with facilities staff, we have found that a similar lighting system is already in place in the new wings of another dormitory. Therefore, we retrofitted an older dormitory hallway with three motion sensors per wing, using a model that is familiar to facilities staff. This includes two power packs to supply the sensors and an energy meter for monitoring. The hallway is already wired with an emergency circuit with three lights meeting the minimum illumination required by building codes. Therefore, we worked with the remaining 12 fixtures on the circuit. Also, there is a trade-off between sensitivity and the number of sensors to purchase. While we want to use the minimum number of sensors per floor, we must also make sure that the system is sensitive enough to detect all students entering from each room and from the stairwells. The project required minimal rewiring, with labor needed only for the installation of the sensors and the energy meter. While there are motion sensors in new additions to campus dorms, we had no means to quantify the energy savings before this project. Therefore, we will measure the impact of the project using a watt meter on the affected circuits. One in-line meter will be installed at the circuit breaker box, measuring the energy used by the lighting circuit on the updated floor. While the energy meter could not be installed in time for this report, another meter was used to measure some data to improve estimates until the permanent meter can be installed. Students will measure the energy use on a daily basis after the motion sensor installation to measure the impact of the project on energy use. Until this is possible, we have taken some data for the power use of the circuit, which we can use to makes more accurate estimates of the impacts of the project. Upon speaking with construction management and facilities staff, we received an estimate of $1472 for capital expenditures to implement the project, including the energy meter. 2.1 Background Lighting accounts for a substantial amount of a building’s energy budget. Estimates vary in the literature, with percentages from 20% to 40% being reported (Guo, Tiller, Henze, & Waters, 2010; Delaney, O’Hare, & Ruzzelli, 2009; Kleissl & Agarwal, 2010). Some of this variation comes from the variation in building designs. One study found that between 440 Wh and 1400 Wh of electricity were wasted per day on unneeded lighting in three office environments (Delaney, O’Hare, & Ruzzelli, 2009). Over an entire year, this would correspond to waste between 160 kWh and 511 kWh. These wastes will continually impact the budget of the building owners, Page | 2 whereas installing a lighting control system would provide a one-time cost to eliminate this waste, saving both money and energy. Previous projects in which motion-controlled lighting has been installed in a variety of settings have shown substantial energy savings. We were unable to find much published work presenting measurements for a university setting. However, results were found for a variety of office and public school settings. We believe it is reasonable to expect such results to also occur in a university setting. In 1996, Floyd et al. of the Florida Solar Energy Center installed occupancy sensor based systems in a small office building and two public schools, finding that total energy savings were between 10% and 19% (Floyd, Parker, & Sherwin, 1996). A study in 1997 by Pacific Gas and Electric Company found that it was possible to obtain 25% to 50% energy savings in regularly occupied spaces, with an ability to save up to 75% of lighting energy in irregularly occupied buildings (Pacific Gas and Electric Company, 1997). Richman et al. saw a wide range of energy savings from 3% to 50% in regularly occupied spaces, increasing to 86% in other spaces (Richman, Dittmer, & Keller, 1996). In two studies, Maniccia et al. saw energy savings of 43% in a private office scenario where lights were continuously on for 10 hours a day with control the rest of the day, and they saw savings between 28% to 38% in a second study which varied occupancy sensor settings (Maniccia, Rutledge, Rea, & Morrow, 1999; Maniccia, Tweed, Bierman, & Neida, 2001). Savings of 20% to 26% were also seen in a study of private office (Jennings, Rubinstein, DiBartolomeo, & Blanc, 2000). Finally, Kleissl and Agarwal achieved a 78% reduction in energy usage in an academic building at University of California San Diego (Kleissl & Agarwal, 2010). 3 Methods and Materials 3.1 Energy Use Estimates and Use Data Baseline energy use was estimated during the feasibility phase of the project, and then updated with a power use reading from the lighting circuits. A Fluke power quality meter was used to measure the voltage and current of the hallway lighting circuits to be modified, as well as power usage. This data was then used to compute the energy use over a given day. The same meter was then used to log data about energy use when the motion sensors were installed. The electricians from S&L Electric have assisted the team in using the meter’s energy data recording feature to record data until the permanent energy meter is installed. 3.2 Sensor Used and Installation Using information from facilities staff, the team chose motion sensors that are already implemented elsewhere on campus. An electrical contractor installed the three motion sensors - W2250 Ultra Sonic Watt Stoppers which use two BZ150 Power packs. Each sensor, as shown in the appendix, has a 90ft range for hallways, and the hallways that have been retrofitted are 220ft long. This also required a small amount of wire molding and cable. 3.3 Survey In order to determine which hallway should be retrofitted, construction management was consulted about feasibility for each of the three dorms with long hallways on campus. The team decided to exclude first floor hallways, as they have the most students passing through them and may not have as much energy savings. Once suitable locations were available, the team sent a survey to residents from six possible hallways to determine what would be the most accepted location. The hallway with the most positive responses was chosen. After installation the hall residents were surveyed again to determine future needs for the project as well as acceptance. Page | 3 4 Impacts and Assessment To determine the impact of our proposed project, we determined the wattage of the light bulbs in use in the hallway. We then researched which lights needed to remain on for safety and building code requirements. Each 64W fixture houses two 32W bulbs, both of which are lit for 24 hours per day. There are 15 light fixtures per floor in a typical dorm building on campus, three of which must always remain on to meet building codes (New York State Department of State, 2010). This means that the theoretical power consumption per day of the hallway lights is: After measuring the power use of the circuit with a meter and finding that each light fixture actually uses 58.3W, we determined that the circuit uses 21kWh per day: This is the baseline energy use. Using these numbers in our initial estimations, we then calculate our estimated savings if the hallway is not in use for eight hours each day: ( ) If three lights are always lit for building code requirements and safety, they will be used for 24 hours a day, while the 12 controlled lights are projected to only be needed 16 hours a day, resulting in a reduction in energy use to 15.4kWh per day. 4.1 Peak Use Data With the help of the electrical contractor, we obtained data for a high-use period on a typical weekday. Between the hours of 11:15 AM – 3:15 PM, with a 2 minute setting on the sensors, the average energy use was 0.67 kW. This corresponds to a 4% reduction from the typical 0.7 kW for the controlled lights. This suggests that our energy savings estimates are low, as energy can even be saved during high use times of the day. Combining the estimates with this data, we can estimate that the energy use with the sensors installed would be: ( ) This corresponds to a 29% savings in energy use for this circuit. While more data is needed to confirm these estimates, this suggests that even when students are going to and from class some energy saving is possible. This implies that before the installation, the amount of electricity used to light one dorm hallway for a day is 21 kWh. Further, assuming that every light is lit every day of the year, the electricity consumed to light a single dorm hallway is 7665 kWh per year. With the implemented system, we are saving 2226.5 kWh per floor per year. 4.2 Off-Peak Data More energy use is possible during weekends, when there is less class-bound traffic in the hallway. Energy use was logged for a weekend beginning on 3:15pm on 4/6/12 until 4/9/12 at 9:15am. The average usage level was 0.39kW for the motion sensing circuit, resulting in the energy use calculation: ( ) Page | 4 This results in energy use of 13.44kWh per day on the weekend for all of the hallway lights, representing a 36% savings on the weekends from the baseline 21kWh per day with the lights constantly on. 4.3 Eight Day Data The meter was able to store data for eight days at a time, so more long-term data was taken for a typical week plus one weekday. The result was an average power use of 0.69kW, resulting in the following calculation: ( ) This results in energy use of 16.4kWh per day on a typical day for all of the hallway lights, representing a 22% savings from the baseline 21kWh per day with the lights constantly on. 4.4 Environmental Implications To put these numbers in perspective, consider that it takes 12.6 barrels of oil or 7902 pounds (about 4 tons) of coal to produce enough electricity to light one dorm hallway for a year (Energy Information Administration, 2012). By reducing energy consumption by 6.1 kWh per day, we are saving 3.65 barrels of oil, or 2300 pounds (1.2 tons) of coal each year for every hallway that converts to this system. This means we have the potential to save 65.7 barrels of oil by implementing this system on the 18 similar hallways in dorms on campus, reducing our impact on the environment. 4.5 Economic Implications This decreased use of electricity will also equate to a monetary savings. We are not aware of the exact method by which the university is billed for electricity. In order to quantify the savings to the university and for others who may be interested in implementing the system, we have used average electricity prices in New York State to compute the potential monetary savings. The average cost of electricity in New York State in January was 14.67 cents per kWh (Energy Information Administration, 2012). The system will likely save the university 1620.6 – 2,226.5 kWh per year per hallway, so the estimated savings is $237 – 327 per year, resulting in a payback period of just over three years. This is a commonly accepted payback period in industry, and makes the system marketable to other sectors outside of college campuses. Implemented on all eighteen floors of our university at this electric rate, the systems could save the school $4279 – 5879 per year on lighting costs in dorm hallways alone. The academic building in which the authors work also has six similar hallways with 70W fixtures. Installing the system there could result in savings of up to 7562.8 kWh ($1109) in yearly savings by controlling 14 of the 17 lights in these hallways, for a total of up to 45.4MWh ($6656.8) for that part of the building. More lighting savings are still available in other areas of campus, including classrooms and atriums. This savings could mean lower tuition or more scholarships for students. 4.6 Student Feedback After surveying the residents of the floor, we found that 50% of the students loved the project, and would like to see the project implemented on other floors on campus. There were no students who felt that the project should not be used, and some even provided suggestions for its improvement. Some students noted that the sensors did not always detect them due to the pipes and other obstacles in the hallway, and others wished the two circuits could be controlled independently for further energy use. While this would have been difficult with the pilot floor due to the need for metering, it is a great suggestion for future project implementation. Page | 5 5 Conclusion 5.1 Recommendations This project was successfully implemented, and could be installed elsewhere on campus, as well as at other universities and businesses. We estimate that the system can save 29% of the lighting energy use in similar hallways, resulting in a savings of 1620.6 – 2226.5 kWh per floor per year, equating to saving up to 3.65 barrels of oil or 1.15 tons of coal per year. This could also equate to a savings of $237 – 327 per year for each hallway, resulting in a payback period of 4 – 5.5 years, with a shorter payback period if the hallways are used less in the summer. The hallways cost $1200 to convert per floor without the energy meter, and even more energy can be saved on split circuits where only half the lights turn on as needed, as the students on the floor suggested. Facilities staff should consider drop-down mountings or additional motion sensors to increase the sensitivity of the system around sprinkler pipe or other obstacles. 5.2 Future Work These values are still based on estimates and limited data, and can be improved by collecting more energy use data on the floor. If data were taken over an entire year, for example, we would know the actual energy savings in one year. Despite these conservative estimates, however, it is clear that the system will likely pay for itself in a few short years, and can help reduce the energy costs as well as energy footprint for a university or business, and should be used wherever possible. Page | 6 6 Appendix 6.1 6.2 Final Budget Calculation Item Estimated Cost Motion Detection - Parts and Labor (Wire mold, motion detectors, power packs) $1200 Energy Meter $272 Total Cost: $1472 Implementation Photo Motion Sensor Installed in Cubley II Hallway Page | 7 6.3 Sensor Specifications Page | 8 Page | 9 6.4 Power Packs BZ-150 Power Pack For More information: http://www.wattstopper.com/products/details.html?id=227 7 References Delaney, D. T., O’Hare, G. M., & Ruzzelli, A. G. (2009). Evaluation of Energy-Efficiency in Lighting Systems using. BuildSys (pp. 61-66). Berkeley: ACM. Director of Facilities, a. S. (2012, April 5). Sustainability Presentation on Campus. Energy Information Administration. (2012, January). Electric Power Monthly. Retrieved April 4, 2012, from http://www.eia.gov/electricity/monthly/epm_table_grapher.cfm?t=epmt_5_6_a Energy Information Administration. (2012, March 2012). FAQ: How much coal, natural gas, or petroleum is used to generate a kilowatt-hour of electricity? Retrieved April 6, 2012, from http://www.eia.gov/tools/faqs/faq.cfm?id=667&t=6 Floyd, D. B., Parker, D. S., & Sherwin, J. R. (1996). Measured Field Performance and Energy Savings of Occupancy Sensors: Three Case Studies. ACEEE96. American Council for an Energy-Efficient Economy. Guo, X., Tiller, D., Henze, G., & Waters, C. (2010). The performance of occupancy-based lighting control systems: A review. Lighting Research and Technology, 42, 415-431. Page | 10 Jennings, J., Rubinstein, F., DiBartolomeo, D., & Blanc, S. (2000). Comparison of control options in private offices in an advanced lighting controls testbed. Journal of the Illuminating Engineering Society, 29, 3960. Kleissl, J., & Agarwal, Y. (2010). Cyber-Physical Energy Systems: Focus on Smart Buildings. DAC10 (pp. 749754). Anaheim: ACM. Maniccia, D., Rutledge, B., Rea, M., & Morrow, W. (1999). Occupant use of manual lighting controls in private offices. Journal of the Illuminating Engineering Society, 28, 42-56. Maniccia, D., Tweed, A., Bierman, A., & Neida, B. V. (2001). The effects of changing occupancy sensor timeout settings on energy savings, lamp cycling and maintenance costs. Journal of Illuminating Engineering Society, 30, 97-110. New York Independent Systems Operator. (2011, April). 2011 Load & Capacity Data, "Gold Book". Retrieved April 4, 2012, from NYISO Web site: http://www.nyiso.com/public/webdocs/services/planning/planning_data_reference_documents/2011_Go ldBook_Public_Final.pdf New York State Department of State. (2010). Fire Code of New York State. NY: Division of Code Enforcement and Adminstration. Pacific Gas and Electric Company. (1997). Occupancy Controls for Lighting. Retrieved from http://www.pge.com/003_save_energy/003c_edu_train/pec/info_resource/pdf/OCCONTRL.pdf. Richman, E., Dittmer, A., & Keller, J. (1996). Field Analysis of occupancy sensor operation: Parameters affecting lighting energy savings. Journal of the Illuminating Energy Society, 25, 83-92. Page | 11