PC - CCW - ProMation Engineering

advertisement

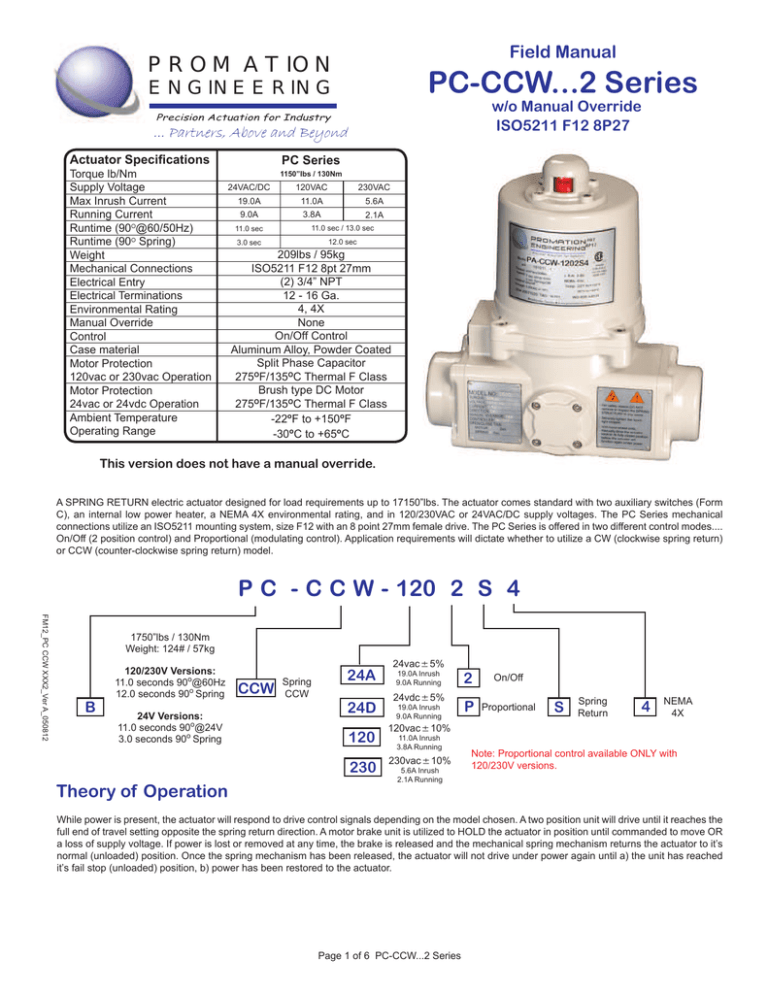

Field Manual PROMATION PC-CCW...2 Series ENGINEERING w/o Manual Override ISO5211 F12 8P27 Precision Actuation for Industry ... Partners, Above and Beyond Actuator Specifications PC Series Torque lb/Nm Supply Voltage Max Inrush Current Running Current Runtime (90O@60/50Hz) Runtime (90O Spring) Weight Mechanical Connections Electrical Entry Electrical Terminations Environmental Rating Manual Override Control Case material Motor Protection 120vac or 230vac Operation Motor Protection 24vac or 24vdc Operation Ambient Temperature Operating Range 1150”lbs / 130Nm 24VAC/DC 120VAC 230VAC 19.0A 11.0A 5.6A 9.0A 3.8A 2.1A 11.0 sec 11.0 sec / 13.0 sec 3.0 sec 12.0 sec 209lbs / 95kg ISO5211 F12 8pt 27mm (2) 3/4” NPT 12 - 16 Ga. 4, 4X None On/Off Control Aluminum Alloy, Powder Coated Split Phase Capacitor 275OF/135OC Thermal F Class Brush type DC Motor 275OF/135OC Thermal F Class -22oF to +150oF -30oC to +65oC This version does not have a manual override. A SPRING RETURN electric actuator designed for load requirements up to 17150”lbs. The actuator comes standard with two auxiliary switches (Form C), an internal low power heater, a NEMA 4X environmental rating, and in 120/230VAC or 24VAC/DC supply voltages. The PC Series mechanical connections utilize an ISO5211 mounting system, size F12 with an 8 point 27mm female drive. The PC Series is offered in two different control modes.... On/Off (2 position control) and Proportional (modulating control). Application requirements will dictate whether to utilize a CW (clockwise spring return) or CCW (counter-clockwise spring return) model. P C - C C W - 120 2 S 4 FM12_PC CCW XXX2_Ver A_050812 1750”lbs / 130Nm Weight: 124# / 57kg 120/230V Versions: 11.0 seconds 90o@60Hz 12.0 seconds 90o Spring B 24V Versions: 11.0 seconds 90o@24V 3.0 seconds 90o Spring CCW Spring CCW 24A 24D 120 230 24vac±5% 19.0A Inrush 9.0A Running 24vdc±5% 19.0A Inrush 9.0A Running 2 On/Off P Proportional S Spring Return 4 NEMA 4X 120vac±10% 11.0A Inrush 3.8A Running 230vac±10% 5.6A Inrush 2.1A Running Note: Proportional control available ONLY with 120/230V versions. Theory of Operation While power is present, the actuator will respond to drive control signals depending on the model chosen. A two position unit will drive until it reaches the full end of travel setting opposite the spring return direction. A motor brake unit is utilized to HOLD the actuator in position until commanded to move OR a loss of supply voltage. If power is lost or removed at any time, the brake is released and the mechanical spring mechanism returns the actuator to it’s normal (unloaded) position. Once the spring mechanism has been released, the actuator will not drive under power again until a) the unit has reached it’s fail stop (unloaded) position, b) power has been restored to the actuator. Page 1 of 6 PC-CCW...2 Series The following procedure is to be followed for set-up, calibration, testing and use of the PC-CCW...2 Series Spring Return quarter-turn electric actuators. Each unit is shipped from the factory with initial calibration of mechanical stops, cams and switches completed. However, these are general settings and serve as a starting point for proper calibration of the actuator in its’ real-world application This actuator has been factory calibrated to 0 operate between 0 and 900. Most quarter-turn products will not require recalibration of these settings. 1. The actuator is shipped from the factory in its full CCW position. (PC Series has No manual override handwheel). E BRN NO ANC COM * 85° - 90° * ACC AOP 0° - 85° * COM * * CONNECTIONS OPTIONAL ANO AS4 D WHT C GRY B BLU AS3 RED COM 7 NO GRN CAM A 15W 1K8 HEATER AUXILIARY SWITCH (STANDARD) LS2 4 NO NC NO Blu GRN CAM COM 5 FIELD CONTROL DEVICE LOAD DRV 1 NEU Blu 1 Red GND Screw GND 24dc 24ac/120 230 - H L1 + N L2 LD2 LD1 Capacitor 18uF/250v Blk 3 Red LD4 OPEN showing in indicator window = FULLY LOADED (CW) CLOSED showing in indicator window = FULL SPRING RTN (CCW) Actuator ships in the fully UNLOADED (CCW) position! ProMation Engineering Precision Actuation for Industry. 24V BRAKE Blk LOGIC AND SAFETY INTERLOCK J3 BLOCK LD3 3 H N NC J2 J1 2 4 Red Wht RED CAM LS1 6 85° 90° 95° Wht NC COM Wht -5° 0° 5° F E D COM SW4 C B A COM SW3 NC COM AOC HOT RED CAM AUXILIARY SWITCH (STANDARD) Page 2 of 6 PC-CCW...2 Series THERMAL SWITCH M 120V AC DRIVE MOTOR FM12_PC CCW XXX2_Ver A_050812 5° - 90° * BLK SPRING RTN (FULL CCW) ACL F Gry 0° - 5° * LOAD SPRING (FULL CW) Bottom view of actuator showing the 27mm 8 point drive shaft and the ISO 5211 F12 mounting hole pattern. 3. Mount the actuator to the valve or damper to be actuated. Remember, the actuator is shipped in the spring return (unloaded) position. When viewed from ABOVE the actuator, the spring CCW units spring closed in a CCW direction. Make sure your valve or damper are in their CORRECT FAIL position before mounting the actuator to them. Refer to step 5 4. Once the two components are bolted together, apply power to the actuator (referencing page 2 of this manual) and drive the actuator to the FULLY WOUND position. Then remove power to allow the spring return system to drive the device back to the fail position. Warning: Make NO adjustments to this device until you have contacted the factory (352-544-8436) for assistance. Damage to product as a result of incorrect cam and/or mechanical adjustments will NOT be covered under warranty! Refer to step 5 5. If it is determined that the end-stop position is not correctly aligned, it will be necessary to ADJUST the mechanical END STOP. To do this, remove the adjustment housing cover using a 6mm hex key. There will be an adjustment nut and a lock nut inside the housing. Loosen the lock nut using a 30mm hex wrench, and while holding the nut, use a 23mm open end wrench to turn the STOP ASSEMBLY. (CW to move the end stop more towards the FULLY WOUND direction, or CCW to move the end stop further AWAY from the FULLY WOUND direction). Do NOT turn the stop more than 4 turns in either direction! 6. Tighten the 30mm locknut to secure the adjustment. Replace the cover. Refer to step 6 FM12_PC CCW XXX2_Ver A_050812 7. It will now be necessary to re-adjust the electrical travel cam to coincide with the new mechanical stop adjustment made in the steps above. With NO POWER APPLIED to the actuator, use a 2.5mm hex key to loosen the #2 cam (RED) set screw. Once it is free, rotate the hex key to the RIGHT a few degrees to reset the switch roller arm. Then snug the set screw up against the camshaft (CW) until slight pressure is felt. Then SLOWLY rotate the hex key pushing the cam to the LEFT until you hear the “click” on the second switch indicating that correct adjustment has been achieved. Tighten the cam set screw. NOTE: Incorrectly adjusted cams will prevent the actuator from running under power. Refer to step 7 ProMation Engineering Precision Actuation for Industry. Page 3 of 6 PC-CCW...2 Series 8. Apply power to terminals 1 & 3 to drive the actuator approximately 20 degrees CW. Remove power to let the spring return system drive back to the new end adjustment. Check the setting and repeat from step 5 if necessary. Refer to step 10 9. Again apply power to terminals 1 & 3 to drive the actuator to the FULLY WOUND position. The actuator will stop and HOLD when it reaches it’s end of travel. DO NOT attempt to adjust the CW end of travel unless it is absolutley necessary. This can ONLY be done with power applied. If you remove power, the actuator will spring closed, making it impossible to make the adjustment. If you move the cam too far to the LEFT, the motor will drive the geartrain into the spring stops. This will DAMAGE the spring system. USE EXTREME CAUTION IF ADJUSTMENT IS NEEDED. 10. If the open STOP point is incorrect, the #1 cam (GREEN) must be adjusted. Use a 2.5mm hex key to loosen the cam set screw. SLOWLY rotate the hex key pushing the cam to the LEFT to drive FURTHER CW, or to the RIGHT to drive LESS CW. Do NOT rotate the GREEN cam more than 3 degrees to the LEFT...Serious Damage to the actuator will result if the motor is allowed to drive the gear train into the mechanical stop!! 10. Tighten the cam set screw. Refer to step 13 13. The fourth cam (RED) is the CLOSED auxiliary switch adjustment. Spring return the actuator to its CLOSED position. Then use a 2.5mm hex key to free up the cam set screw. Once it is free, rotate the hex key to the RIGHT a few degrees to reset the switch roller arm. Then snug the set screw up against the camshaft (CW) until slight pressure is felt. Then SLOWLY rotate the hex key and cam to the LEFT until you hear the “click” on the fourth switch. Continue to rotate the cam between 3 and 5 degrees to the LEFT to make sure the auxiliary cam switch changes state before the actuator reaches its end of travel electrically. Tighten the cam set screw. NOTE, THIS ACTUATOR MUST HAVE THE EMT FITTINGS WATER TIGHT WITH CONDUIT DRAINAGE INSTALLED AND POWER SUPPLIED TO UNIT TO KEEP THE HEATER WARM AT THE TIME OF INSTALLATION . This unit should NOT be stored outside unless it is powered up. When this unit is NOT powered up, it should be stored in a clean, dry environment at all times. Sequence of Operation: (reference the wiring diagram on Page 2 for LD location on PCB) Upon power-up, LD1 & LD3 will be ON for 1 second. After 1 second, LD3 will turn OFF, LD1 & LD2 will be ON and the motor will drive until it reaches it’s fully wound position whereupon the motor brake will engage. At that point, LD2 will turn OFF, and LD1 & LD3 will be ON and will remain ON until there is a power failure (PF). Upon PF, the brake will release and the unit will spring closed. If the PF clears BEFORE the actuator fully spring returns, LD1 & LD4 will be ON until the actuator reaches FULL spring return, at which time the unit repeats a standard power-up sequence. IF the manual override (if so equipped) is used to position the actuator during a PF, upon return of POWER, LD1& LD4 will be ON and will remain ON until the handwheel is returned to the FULL spring return position. ProMation Engineering Precision Actuation for Industry. Page 4 of 6 PC-CCW...2 Series FM12_PC CCW XXX2_Ver A_050812 Refer to step 12 12. The THIRD cam (GREEN) is the OPEN auxiliary switch adjustment. Drive the actuator to its OPEN position. Then use a 2.5mm hex key to free up the cam set screw. Once it is free, rotate the hex key to the LEFT a few degrees to reset the switch roller arm. Then snug the set screw up against the camshaft (CW) until slight pressure is felt. Then SLOWLY rotate the hex key to the RIGHT until you hear the “click” on the third switch. Continue to rotate the cam between 3 and 5 degrees to the RIGHT to make sure the auxiliary cam switch changes state before the actuator reaches its end of travel electrically. Tighten the cam set screw. Application Notes: 1. These actuators are designed to be used in either a horizontal or upright position. Do NOT mount the actuator with the top below a horizontal position. 2. When installing conduit, use proper techniques for entry into the actuator. Use drip loops to prevent conduit condensate from entering the actuator. 3. Both NPT conduit ports MUST use proper equipment to protect the NEMA 4x integrity of the housing. 4. The internal heater is to be used in ALL applications. 5. Do NOT install the actuator outdoors or in humid environments unless it is powered up and the heater is functioning. 6. Use proper wire size to prevent actuator failure (see chart below for proper wire sizing). 7. Mechanical travel stops are factory calibrated for 90 degree operation. These stops are NOT designed to adjust mechanical rotation by more than +/- 3 degrees. PC CCW Series Easily distinguishable yellow/red position indicator Exploded View Aluminum Casting 4X Protection Motor Brake Heavy Duty Drive Motor Auxiliary Switches (2) Spring Wind-Up Travel Control Switches ModularControl Cards Aluminum Casting 4X Protection Heater Piston/Rack Component (2) Spring Pack (2) Rack Guidance Thrust Bearings (2) End Cap (2) FM12_PC CCW XXX2_Ver A_050812 ISO5211 Base Mounting System, Size F12 A modular cast aluminum housing incorporates the mechanical drive train, the spring pack and rack assemblies, the output drive shaft, motor and control section. The spring pack is NOT field servicable and spring failure direction mode must be selected at time of order. CAUTION!.....spring packs are under EXTREME tension and must NOT be altered or modified under any circumstances. Do NOT remove any bolts or screws from the actuator housing other than the (4) TOP COVER SCREWS. Failure to comply with this warning could cause severe bodily injury. ProMation Engineering Precision Actuation for Industry. Page 5 of 6 PC-CCW...2 Series Wire Sizing Data MAX distance between Actuator and Supply (feet) Wire Gage 18 16 14 12 10 8 PCX-24XS4 PCX-120XS4 PCX-230XS4 5.6A 11.0A 19.0A 34 57 86 191 292 496 740 Dimensional Data PC CCW Series 444 718 1098 1867 2786 Wire sizing data is provided in the table above to assist in the selection of the proper wire size for ProMation PB series actuators using various wire sizes over distance. Please make sure to reference the correct voltage and do not exceed the indicated length of the wire run for each model. 438mm 17.244" Ø 305mm 12.008" 600mm 23.622" 876mm 34.5" (Cover Removal) (2) 3/4" EMT 577mm 22.717" 133mm 5.236" Switch Logic Map and 305mm 12.008" 45mm 1.772" Ø85mm 3.346" 5mm .197" Ø170mm 6.693" Switch/Cam Arrangement Switch sequencing data is provided in the tables below to show the change-of-state points during the rotation of the actuator from CW to CCW and back again. The LOWER 2 cams are set at the factory and MUST NOT be changed. The INCLUDED auxiliary switches SW3 & SW4 are for terminals A thru F and those set points may be modified if need be. Ø125mm 4.921" 27mm 1.063" (4) M12*1.75 25mm Deep (CW) o o o 85 90 95 } } D:F D:E A:C A:B 3 4 FM12_PC CCW XXX2_Ver A_050812 (CCW) o o o -5 0 5 AUX SW4 (Factory Set - Adj) AUX SW3 (Factory Set - Adj) SW2 OPEN Stop (Factory Set - Fixed) SW1 CLOSE Stop (Factory Set - Fixed) Switch/Cam arrangement for Proportional control (CCW) o o o -5 0 5 D:F D:E A:C A:B 3 (CW) o o o 85 90 95 } } AUX SW4 (Factory Set - Adj) AUX SW3 (Factory Set - Adj) SW2 OPEN Stop (Factory Set - Fixed) SW1 CLOSE Stop (Factory Set - Fixed) Switch/Cam arrangement for On/Off control 16138 Flight Path Drive Brooksville, FL 34604 l Ph (352) 544-8436 Fx (352) 544-8439 l Page 5 of 6 PC-CCW...2 Series www.promationei.com