CentraLizeD CuStomization anD Configuration Center enSureS

advertisement

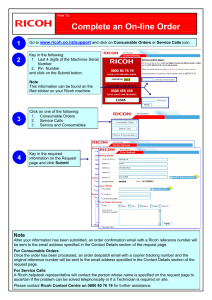

Technology Centralized customization and configuration center ensures efficient European fulfillment Ricoh provides technology that transforms business processes. By streamlining professional document and information management, Ricoh helps businesses become more productive and profitable. Operating in 180 countries, Ricoh has global annual revenues of 14 billion Euros and over 100,000 employees. The company’s European Distribution Center (EDC) for EMEA in Bergen op Zoom, Netherlands is managed by DHL Supply Chain. Following a successful 16–year relationship, DHL is now managing warehousing and value added services within Ricoh’s EDC facility. This includes the supply of complex, Pre-Sales Technical Services for printers and multi-function devices before delivery. customer challenge Ricoh EDC delivers and installs around 600,000 MultiFunctional Products (MFP) and printers a year for customers across 19 European countries. Of these, one in eight requires extensive pre-configuration before delivery for end customer use. Historically, Ricoh-owned operating companies performed the last-minute configuration for end customer requirements themselves. Alternatively, engineers visited the customer site. Both scenarios were costly, duplicating skills and labor. Over the years, thanks to DHL’s involvement, Ricoh has achieved a centralized customer configuration operation in the Bergen op Zoom EDC using DHL’s Pre-Sales Technical Services. Customer Challenge •• Optimize centralized configuration of MFP and printers •• Reduce per unit cost •• Manage technical complexity •• Fluctuating volumes between 100 – 800 units per week DHL Supply Chain Solution •• Manage Ricoh’s EDC warehouse •• Pre-Sales Technical Services including customization and configuration •• 60 expert technicians with flexible contracts •• 70,000 MFP and printers configured per year Customer Benefits •• Cost per unit reduced by 26% over 18 months •• Seven figure savings •• Skilled and flexible staff to ensure cost efficiency, quality and accuracy of complex orders Technology Customer Benefits The level of customer configuration required for a product is complex and technically demanding. Ricoh needed configuration completed by well-trained staff. Their product quality standards are also exceptionally high. Any outsourced configuration activities needed to comply with current Ricoh factory protocols for technical processes and final product testing. Configuration volumes fluctuate between 100 – 800 MFP and printers a week, demanding a scalable, yet highly skilled, labor supply. Ricoh required a solution that reflected a competitive tariff for each configured product, comparable to that achieved by Ricoh operating companies themselves. DHL Supply Chain Solution New Ricoh copiers and multi-functional printers arrive at the warehouse from Asia Pacific and two factories in Europe, equipped only with standard, basic equipment and software. Ricoh operating companies place their orders for each customer on their central system. Taking this order data DHL, through pre-sales technical services, configures each MFP or printer to the agreed end customer’s specification. A banking customer, for example, might order 500 printers from a Ricoh operating company. On carrying out a central configuration order, the DHL Supply Chain team will: •• •• •• •• •• Un-pack the printer Assemble, by adding requested components like paper trays, document feeder, scanner screen, fax unit Configure, by installing software, setting language, network data/IP address, country information, service call number and adding any customer data Test and quality assure printer to factory quality standards Re-pack the printer ready for dispatch to the operating company’s mall partner The average DHL workforce for the process is 120 employees, of which 60 are trained pre-delivery install technicians. Flexible contracts provide efficient labor management for both high and low configuration volumes. DHL Supply Chain has delivered considerable savings through continuous improvement. In 2011, this figure stood at 600,000 Euros. Adopting the DMAIC (Define, Measure, Analyze, Improve and Control) improvement process, part of the group’s First Choice program, DHL has accomplished savings while safeguarding process quality and accuracy for complex Ricoh orders. Over the last 18 months, by implementing further lean projects and process improvements, the average cost to configure a printer has fallen by 26%. This reduction is despite a rise in the average configuration workload required. With 70,000 MFP and printers currently configured in one year, this alone generates seven figure savings. By 2014, the configuration forecast is 100,000 MFP and printers per year. In addition to the savings generated by the process improvement, the solution brings more flexibility and cost reduction due to the expert flexible workforce that ensures a high quality service. Looking ahead, DHL is in discussions to explore further opportunities for Ricoh in other logistics disciplines, including global forwarding, freight, service parts logistics and supply chain. “The central solution made possible by DHL means it’s very efficient for us to fulfill complex configuration orders accurately, to a high quality. We are delighted with DHL’s ability to work seamlessly with us to achieve continuous improvement.” Eugene Kersjes VP Ricoh Europe Supply Chain Management BV For further information Contact our supply chain experts: supplychain@dhl.com www.dhl.com/supplychain