F-MFC Curriculum final June2010-v2 - The Angenent Lab

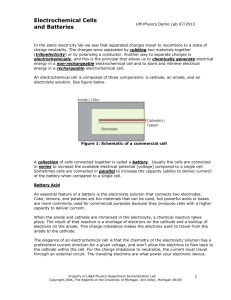

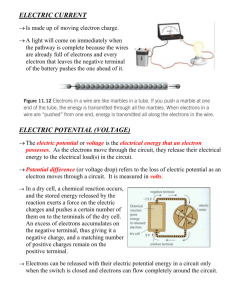

advertisement