Contact time and disinfectants

advertisement

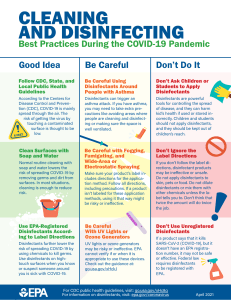

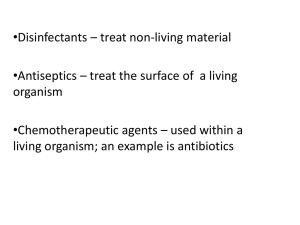

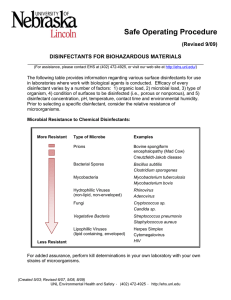

Contact time and disinfectants Every year 1.7 million Americans acquire an infection while in the hospital.1 The incidence of Clostridium difficile infection has surpassed Methicillin Resistant Staphylococcus Aureus as the leading Hospital Acquired Infection (HAI). Environmental surfaces have been linked to the spread of pathogens within hospitals. Using EPA-registered disinfectants is critical to achieving improved environmental outcomes, and it’s just as important to ensure that the disinfectants stay wet on surfaces for the required contact time. As stated in the CDC Guidelines for Disinfection and Sterilization in Healthcare Facilities, 20082, federal law requires all applicable label instructions on EPA-registered products to be followed. If the user selects use conditions (e.g., contact time) that differ from those on the EPA-registered product label, the user assumes liability for any injuries resulting from off-label use and is potentially subject to enforcement action under Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA). Contact time (or dwell time) is the length of time a disinfectant’s label states that it must remain wet on a surface in order to achieve efficacy. This time is determined through laboratory testing, the results of which are reviewed and approved by the Antimicrobials Division of the United States Environmental Protection Agency. As it is usually unknown which specific microorganisms are on surfaces, it is generally recommended that users follow the longest contact time listed on the product label. Most dilutable, quaternary-based disinfectants (quats) currently available in the market are very effective at killing a broad range of microorganisms, and have a ten minute contact time. However, a single application of quat usually does not leave surfaces wet for ten minutes. Non-compliance with contact times may mean that surfaces are not being properly disinfected and that pathogens could survive even after application. In order to meet a contact time of ten minutes, additional applications of product are usually needed, thus reducing operational efficiency. It has been noted that in some states auditing bodies such as the Joint Commission and the Centers for Medicare & Medicaid Services (CMS) are monitoring compliance with proper contact time. There 1 2 www.cdc.gov/ncidod/dhqp/pdf/hicpac/infections_deaths.pdf http://www.cdc.gov/hicpac/pdf/guidelines/disinfection_nov_2008.pdf is a risk of product non-compliance for disinfectants if surfaces do not remain wet for the longest contact time prescribed by the product label. There are a number of factors that affect how long it takes a disinfectant to dry on a surface, including the type of surface. Environmental factors such as temperature, humidity and air flow will all influence the evaporation rate. Also, the method of application (spray, pour, wipe), and type of wipe used (cotton, microfiber, disposable) will affect how much product is delivered to the surface and how long it will stay wet. Additionally, the composition of the disinfectants and how rapidly the ingredients evaporate will also affect how long the disinfectant remains on the surface. Alcohol, for instance, evaporates more quickly than water. The images below illustrate an example of two disinfectants compared in a controlled setting. The disinfectants are applied simultaneously on the same surface, with the same method and cloth type, and with equal pressure and volume of product. The rate of evaporation for each of the disinfectants is recorded and evaluated against the appropriate contact time. Environmental conditions are also uniform for each. The disinfectant on the right is a standard dilutable quat-based disinfectant with a label contact time of ten minutes. A still frame image of the surface at the ten minute mark shows that most of the product has evaporated and would require reapplication. In comparison, OxyCideTM Daily Disinfectant Cleaner has a contact time of five minutes and demonstrates the ability to keep the surface wet for this duration (image at left). Using a disinfectant with a shorter contact time can increase compliance with labeled contact times and can help improve operational efficiency by eliminating the need to re-wipe surfaces. Like standard quats, OxyCideTM is designed for daily use in hospitals and has efficacy against a broad range of microorganisms. However, unlike quats, OxyCideTM has a contact time of only five minutes and also has efficacy against Clostridium difficile spores. Therefore, it is also designed to help improve environmental outcomes and target the pathogen responsible for the #1 Hospital Acquired Infection. Worldwide Headquarters 370 Wabasha Street N St. Paul, MN 55102 www.ecolab.com 1.866.781.8787 2013 Ecolab Inc. All rights reserved. 903810/0713