week 12 servo control

advertisement

:5usec

OPERATING TRAVEL

:40�/ONE SIDE PULSE TRAVELING 400usec

DIRECTION

:CLOCK WISE/PULSE TRAVELING 1500 TO 1900usec

MOTOR TYPE

:CORED METAL BRUSH

POTENTIOMETER TYPE

:4 SLIDER/DIRECT DRIVE

AMPLIFIER TYPE

:ANALOG CONTROLLER & TRANSISTOR DRIVER

DIMENSIONS

:40x20x36.5mm(1.57x0.78x1.43in)

WEIGHT

:43g(1.51oz)

BALL BEARING

:TOP/RESIN BUSHING

MATERIAL

:RESIN

DEPARTMENTGEAR

OF MEDIA

STUDY / SUNY BUFFALO

HORN GEAR SPLINE

:24 SEGMENTS/�5.76

SPLINED HORNS

:SUPER/R-XA

CONNECTOR WIRE LENGTH

:300mm(11.81in)

CONNECTOR WIRE STRAND COUNTER :40EA

CONNECTOR WIRE GAUGE

WEEK 12

SERVO CONTROL

MEDIA ROBOTICS LAB /

26.5

36.5

16.6

OVERVIEW

40

52.8

47.8

3

10.2

1

20

4

2

2.FEATURES

LONG LIFE POTENTIOMETER, TOP RESIN BUSHING

3.APPLICATIONS

AIRCRAFT 20-40 SIZE,STEERING AND THROTTLE SERVO FOR CARS, TRUCK AND BOATS

4.ACCESSORY & OPTION

CASE SET/

HS322T:1EA

HS322M:1EA

HS322L:1EA

PH/T-2 2x30 NI:4EA

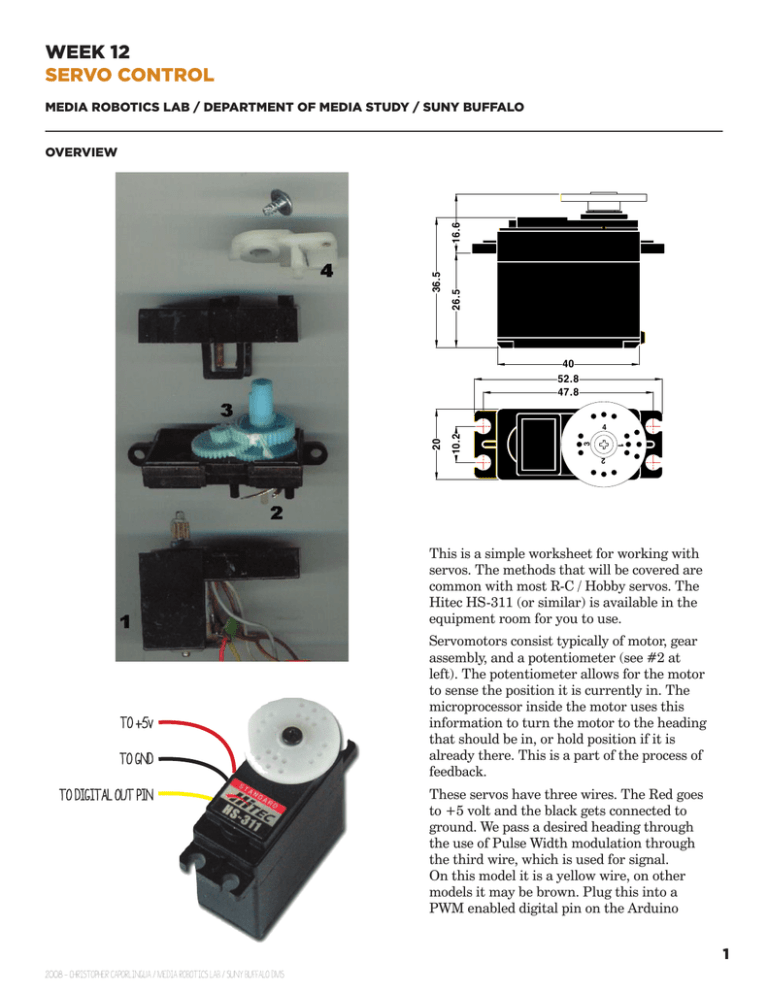

This is a simple worksheet for working with

servos.

beSET/

covered are

GEAR The

SET/ methods that will

HORN

HS322G1:1EA

R-XA:1EA

common

with most R-C / Hobby

servos. The

HS322G2:1EA

Hitec

HS-311 (or similar) is available in the

HS322G3:1EA

equipment

room for you to use.

HS322G4:1EA

HS300RB:1EA

TO +5v

TO GND

TO DIGITAL OUT PIN

Servomotors consist typically of motor, gear

assembly, and a potentiometer (see #2 at

left). The potentiometer allows for the motor

to sense the position it is currently in. The

microprocessor inside the motor uses this

HITEC

RCD

KOREA

INC.

information

to turn

the motor

to the heading

that should be in, or hold position if it is

already there. This is a part of the process of

feedback.

These servos have three wires. The Red goes

to +5 volt and the black gets connected to

ground. We pass a desired heading through

the use of Pulse Width modulation through

the third wire, which is used for signal.

On this model it is a yellow wire, on other

models it may be brown. Plug this into a

PWM enabled digital pin on the Arduino

1

2008 - CHRISTOPHER CAPORLINGUA / MEDIA ROBOTICS LAB / SUNY BUFFALO DMS

WEEK 12

SERVO CONTROL

MEDIA ROBOTICS LAB / DEPARTMENT OF MEDIA STUDY / SUNY BUFFALO

CODE

/* Servo Example

* Code based on AnalogInput by DojoDave <http://www.0j0.org>

*

*/

int potPin = 2;

// select the input pin for the potentiometer

int val = 0;

// variable to store the value coming from the sensor

int servoPin = 7;

// Control pin for servo motor

int pulseWidth = 0;

// Amount to pulse the servo

long lastPulse = 0;

// the time in millisecs of the last pulse

int refreshTime = 20;

// the time in millisecs needed in between pulses

int minPulse = 600;

// minimum pulse width

void setup() {

pinMode(servoPin, OUTPUT);

}

void loop() {

// read the value from the sensor

val = val * .175; // convert 10 bit val to derees (1024/180 = .175 )

pulseWidth = (val * 10) + minPulse;

updateServo();

Wire in a voltage divider

as we saw in the previous

worksheets, connect it to

analog pin 2.

The servo has its red wire in

+5v, its black in GND, and its

yellow in digital pin 7

Every time we call

updateServo();

The servo will seek to the

location calculated into

pulseWidth.

If the servo is already there it

will hold position with power;

if an outside force tries to

rotate it in a different direction

it will counteract until its is

oriented correctly.

pinMode(potPin, INPUT);

val = analogRead(potPin);

This code takes in an analog

value, coverts it to degrees and

turns the servo proportionately

to it.

// convert angle to microseconds

// update servo position

delay(10);

To take advantage of

this aspect, try to call

updateServo(); very often,

as we are doing by putting it

into the main loop.

}

void updateServo() {

// pulse the servo again if rhe refresh time (20 ms) have passed:

if (millis() - lastPulse >= refreshTime) {

digitalWrite(servoPin, HIGH);

// Turn the motor on

delayMicroseconds(pulseWidth);

// Length of the pulse sets the motor

position

digitalWrite(servoPin, LOW);

// Turn the motor off

lastPulse = millis();

// save the time of the last pulse

}

}

2

WEEK 12

SERVO CONTROL

MEDIA ROBOTICS LAB / DEPARTMENT OF MEDIA STUDY / SUNY BUFFALO

EXPLANATION

1500 Microseconds

90 degrees

1050 Microseconds

45 degrees

1950 Microseconds

135 degrees

600 Microseconds

0o degrees

(minimum pulse width)

2400 Microseconds

180 degrees

The servo receives a position through

a PWM signal sent through the signal

(yellow) wire from the micro controller.

Knowing this, we can abstract the

conversion from degrees to microseconds

to be:

The signal is pulsed high for an amount of

time that corresponds to the desired angle.

The minimum length of this pulse is 600

microseconds, which corresponds to its

counterclockwise limit. The clockwise

limit is approx 180 degrees from the

origin and corresponds to a pulse of 2400

microseconds.

The difference between the two positions

is 180 degrees, or 1800 microseconds.

(degrees x 10) + 600 = pulse width

Which is represented in our code by

In updateServo() we put all of these

numbers together to form a pulse. The pin

is written to HIGH and left that way while

the program delays for however many

microseconds the pulse width is. At that

point the pin is written low.

if (millis() - lastPulse >= refreshTime)

pulseWidth = (val * 10) + minPulse;

Where val is a number in degrees.

We need to pause in between pulses so

that the servo can distinguish them from

each other. This is known as a refresh

time and needs to be a minimum of 20

milliseconds for this application.

will make sure that this pulse will only

be written if the 20ms refresh time has

passed since the last pulse.

lastPulse = millis();

lets us use compare the time from this

current pulse to see if the 20 milliseconds

has passed the next time we evaluate

if (millis() - lastPulse >= refreshTime).

Example PWM Signal:

1500 Microseconds

for 90 o (center)

600 Microseconds

for 0 o ( full counterclockwise )

<---- 2 0 m i l l i s e c o n d r e f r e s h t i m e

---->

( refresh )

(signal held low)

3