Goodman GMNT

advertisement

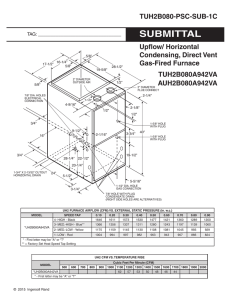

PRODUCT SPECIFICATIONS GMNT SERIES 92.6% AFUE 4-Way, Multi-Position Condensing Gas Furnace The GMNT multi-position condensing gas furnace is equipped to be installed in a utility room, attic, basement or closet. Standard Features • Corrosion-resistant, 29-4C secondary heat exchanger that extracts energy from the gas and converts it to usable heat • Energy saving Hot Surface Ignition system • Capable of multi-position installation – upflow, downflow or horizontal • Completely assembled, factory run-tested furnace for heating or combination heating/cooling application • Energy-saving PSC, multi-speed, direct drive blower motor • Quiet, corrosion-resistant, plastic-induced blower motor assembly • Vertical or horizontal venting with 2” PVC for 40k and 60k; 3” PVC for 80k, 100k and 120k • For direct vent (2 pipe) or non-direct vent (1 pipe) installations • All model design certified by ITS to be in compliance with ANSI Z21.47 and CAN/CGA 2.3 (Canada) safety standards • Complies with California NOX Standards • 40VA transformer for heating and air conditioning control service • Tubular heat exchanger (primary) • Aluminized-steel inshot burners • Combination redundant gas valve and regulator • Integrated furnace control with diagnostics • Blower door safety switch • Multiple-flame roll-out switches • Outlet air limit switch • Pressure switch for proof of combustion air • Drain kit contains vent screens, drain trap, hoses and clamps SS-312D Cabinet Construction • Heavy-gauge, reinforced, wrap-around insulated steel cabinet with durable baked enamel finish • Bottom or side air inlet • Completely insulated cabinet • Convenient left- or right-hand connection for gas, electric service, combustion air and vent • Removable solid bottom block-off Optional Equipment • L.P. Conversion Kit (LPT-01) • Concentric Vent Kit (CVK-00) www.goodmanmfg.com 12/03 PRODUCT SPECIFICATIONS Performance Ratings Model Natural Gas Input BTUH Natural Gas Output BTUH Propane Gas Input BTUH Propane Gas Output BTUH DOE AFUE Temperature Rise (°F) GMNT040-3B GMNT060-3B GMNT080-4B GMNT100-4B GMNT120-5D 40,000 60,000 80,000 100,000 120,000 37,000 55,000 73,500 92,000 110,000 37,000 55,000 73,000 92,000 111,000 34,000 51,000 67,000 85,000 102,000 92.6 92.6 92.6 92.6 92.6 25 – 55 35 – 65 35 – 65 40 – 70 40 – 70 Specifications Circulator Blower Model Size (D x W) HP GMNT040-3B GMNT060-3B GMNT080-4B GMNT100-4B GMNT120-5D 10” x 6” 10” x 6” 10” x 8” 10” x 10” 10” x 10” 1/3 1/3 1/2 1/2 3/4 Filter Size (in.2) Vent Speeds Diameter1 4 4 4 4 4 2” 2” 3” 3” 3” Perm. Disp. 290 290 385 385 480 580 580 770 770 960 Minimum Circuit Ampacity2 (amps) Maximum Overcurrent Protection3 (amps) Shipping Weight (lbs.) 8.1 8.1 12.5 12.5 14.7 15 15 15 15 15 170 180 205 225 265 1) Vent and combustion air diameters may vary depending on vent length. Refer to furnace installation instructions. 2) Minimum Circuit Ampacity = (1.25 x Circulator Blower Amps) + ID Blower amps. 3) Maximum Overcurrent Protection refers to maximum recommended fuse or circuit breaker size. NOTES: 1. All furnaces are manufactured for use on 115 VAC, 60 Hz, single-phase electrical supply. 2. Gas Service Connection 1⁄2” FPT. 3. IMPORTANT: It is required to size fuses and wires properly and make electrical connections in accordance with the National Electrical Code and/or all existing local codes. Dimensions COMB. AIR INLET COMB. AIR INLET GAS INLET GAS INLET VENT VENT LOW VOLTAGE LOW VOLTAGE ELEC. ELEC. Model A B Combustible Floor Base GMNT040-3B GMNT060-3B GMNT080-4B GMNT100-4B GMNT120-5D 14” 14” 171⁄2 21” 241⁄2 121⁄2” 121⁄2” 16” 191⁄2” 23” SBT14 SBT14 SBT17 SBT21 SBT24 Clearances from Combustible Materials Sides 1” Rear 0” Front* 3” Vent 0” Approved for line contact in the horizontal position. *36” clearance for serviceability recommended. 2 Top 1” PRODUCT SPECIFICATIONS Blower Performance Specifications CFM & Temperature Rise vs. External Static Pressure Model (Heating Speed as Shipped) Motor Speed Tons AC @ 0.5” ESP GMNT040-3B (MED-LO) HIGH MED MED-LO LOW GMNT060-3B (MED) External Static Pressure, (Inches Water Column) 0.6 0.7 0.8 CFM Rise CFM Rise CFM Rise CFM Rise CFM Rise CFM CFM CFM 3.0 2.5 2.0 1.5 1,395 1,132 905 718 ------30 38 47 1,340 1,103 913 702 25 31 37 49 1,282 1,089 897 693 27 31 38 49 1,227 1,048 880 668 28 33 39 51 1,163 1,005 854 640 29 34 40 53 1,096 954 814 617 1,015 897 762 576 940 817 701 526 HIGH MED MED-LO LOW 3.0 2.5 2.0 1.5 1,352 1,084 894 680 37 47 57 -------- 1,293 1,081 860 666 39 47 59 -------- 1,239 1,054 867 658 41 48 58 -------- 1,185 1,016 847 635 43 50 60 -------- 1,126 971 807 607 45 52 63 -------- 1,062 921 777 575 980 867 734 548 907 796 688 502 GMNT080-4B (MED-LO) HIGH MED MED-LO LOW 4.0 3.5 3.0 2.5 1,911 1,686 1,419 1,153 35 40 48 59 1,823 1,623 1,385 1,147 37 42 49 59 1,747 1,531 1,350 1,126 39 44 50 60 1,638 1,473 1,306 1,099 41 46 52 62 1,546 1,412 1,230 1,069 44 48 55 63 1,464 1,342 1,197 1,015 1,355 1,247 1,131 957 1,264 1,160 1,040 879 GMNT100-4B (MED) HIGH MED MED-LO LOW 4.0 3.5 3.0 2.5 2,222 1,734 1,426 1,231 38 49 59 69 2,146 1,717 1,405 1,186 40 49 60 -------- 2,035 1,672 1,407 1,130 42 51 60 -------- 1,954 1,618 1,357 1,087 43 52 62 -------- 1,810 1,547 1,327 1,029 47 55 64 -------- 1,671 1,463 1,266 945 1,533 1,354 1,203 870 1,422 1,257 1,120 787 GMNT120-5D (MED) HIGH MED MED-LO LOW 5.0 4.0 3.5 3.0 2,407 1,825 1,493 1,274 43 57 69 -------- 2,329 1,764 1,486 1,285 44 59 70 -------- 2,214 1,703 1,453 1,251 47 61 --------------- 2,088 1,646 1,433 1,224 49 63 --------------- 1,994 1,598 1,385 1,182 52 65 --------------- 1,806 1,486 1,034 1,035 1,645 1,336 1,023 916 1,445 1,058 900 784 1. 2. 3. 4. 5. 6. 7. 0.1 0.2 0.3 0.4 0.5 CFM in chart is without filter(s). Filters do not ship with this furnace, but they must be provided by the installer. If the furnace requires two return filters, this chart assumes both filters are installed. All furnaces ship as high-speed cooling. Installer must adjust the blower cooling speed as needed. For most jobs, about 400 CFM per ton when cooling is desirable. INSTALLATION IS TO BE ADJUSTED TO OBTAIN TEMPERATURE RISE WITHIN THE RANGE SPECIFIED ON THE RATING PLATE. The chart is for information only. For satisfactory operation, external static pressure must not exceed value shown on the rating plate. The shaded area indicates ranges in excess of maximum static pressure allowed when heating. The dashed (----) areas indicate a temperature rise not recommended for this model. The above chart is for U.S. furnaces installed at 0-2000 feet. At higher altitudes, a properly de-rated unit will have approximately the same temperature rise at a particular CFM, while ESP at the CFM will be lower. 3 PRODUCT SPECIFICATIONS Cased U Coil Application Options Coil Model Number Furnace Model Number GMNT040-3 GMNT060-3 GMNT080-4 GMNT100-4 GMNT120-5 Furnace Width 14” 171⁄2” 21” 241⁄2” Coil Width U-18 U-29 U-30 U-31 U-32 U-35 U-36 U-42 U-47 U-49 U-59 U-60 U-61 U-62 14” 14” 171⁄2” 14” 171⁄2” 14” 171⁄2” 171⁄2” 171⁄2” 21” 21” 241⁄2” 241⁄2” 21” X X X(1) X X(1) X X(1) X(1) X(2) X(2) X(2) X(2) X X(1) X(1) X(1) X(2) X(2) X(1) X(1) X(2) X(2) X(2) (1) Using the factory installed bottom cabinet filler plates (2) Discard bottom cabinet filler plates Due to the rating mix/match of various coils with outdoor units, it is important to match the furnace airflow for the total system capacity. Refer to furnace, heat pump and/or condensing unit specification sheets. Goodman Manufacturing Company, L.P., reserves the right to discontinue, or change at any time, specifications or designs without notice or without incurring obligations. Copyright © 2003 Goodman Manufacturing Company, L.P. • Houston, Texas • Printed in the USA. • Goodman products are made proudly in the USA. 4