Non-Evaporable Getter (NEG) Coating

advertisement

Non-Evaporable Getter (NEG)

Coating

Narong Chanlek

• NEG is a Ti-Zr-V (Titanium

Zirconium Vanadium) alloy

film deposited inside

vacuum chamber walls.

NEG Coating

• Ti–Zr–V NEG films sorbs H2, CO, CO2, H2O, and N2

providing distributed pumping and also reduce

outgassing from the walls.

• Using for narrow and long vacuum chambers –

much easier and quicker to provide the required

vacuum

• Suppressing e-cloud

However

• Low pumping capacity

• Technical problems - design and operation

Coating Techniques

Coating Techniques

Chemical Vapour Deposition - CVD

• Creates thin films of material on a substrate via

the use of chemical reactions.

• Reactive gases are fed into a vacuum chamber

and these gases react on a substrate and form a

thin film or a powder.

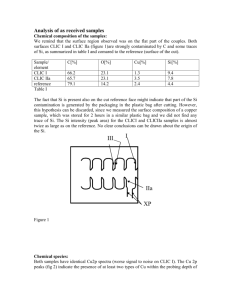

XRD Technique

Detector

X-ray Source

d sin θ = n λ

Sample

X-ray Diffraction (XRD)

Technique

• Giving detailed information about the chemical

composition and crystallographic structure of

materials.

• A monochromatic X-ray beam is projected onto

a crystalline material diffraction occurs following

Bragg's Condition.

• Varying the angle, the Bragg's Law conditions

are satisfied by different d-spacings in

polycrystalline materials. Plotting the angular

positions and intensities of the resultant

diffracted peaks of radiation produces a pattern,

which is characteristic of the sample.

XRD result of Ti – Zr –V film growth by cylindrical magnetron

deposition

XRD result of Zr film growth by cylindrical magnetron

deposition

Pumping property measurements

Research Objectives

Two main objectives of the research are:

To analyse the impact of frequency errors in the cavities.

To obtain cavity misalignments from frequency spectrum.

Bands in 9-Cell Structure – Simulation vs Circuit Model

The simulation was performed in Poisson Superfish

and the points corresponding to resonant frequencies

were plotted on the graph (dots) along with

eigenmodes from circuit model (circles). Dispersion

curves of single cavity are plotted for comparison.

Legend

Solid

line – light line

Solid curves – dispersion

curves from circuit model

Dashed curves –

approximated dispersion

curves from circuit model

Circles – eigenfrequencies

from circuit model

Dots – resonant

frequencies from

simulations

Bands in Single Cell – Extended Circuit Model

The model was extended to include

coupling between cavity (n) and four

nearest cells (n-2, n-1, n+1, n+2).

Legend

Solid line – light line

Solid curves – dispersion

curves from circuit model

Dots – resonant

frequencies from

simulations

Last Measurements

The tuner plate has been machined and the cavity with its tuner has been measured

Measured frequency

100.885 MHz

Simulation

100.816 MHz

‐32 kHz (air)

+77 kHz (shorter antenna)

100.861 MHz

∆ Frequency

24 kHz

Goal frequency

~100.900 MHz

2

Comments

• The goal for the hot frequency has been fully achieved

• The tuner plate thickness of 0.35mm could give a possible sensitivity to the mechanical resonances

• Next tuner design will provide for a larger thickness in order to avoid the previous drawback

• The reduced coarse range of the new tuner design will be not a trouble as we have enough tuning range and also this will meet one of the suggestion of the review committee

• The last point will also make easier the LLRF controls 3

The line

2000

5

6

4

131

3

10

2

63

1

Top of the cryostat

The line has been divided in 5 pieces. The dimensions are in mm

6

Coupler

7

Q0 values

ISOLDE

(Eacc=6MV/m)

Pcav (W)

Rs (nΩ)

Q0=Γ/Rs

5

33

109

7

46

6.6∙108

10

65

4.6∙108

12

79

3.9∙108

15

98

3.1∙108

TRIUMF*: Q0=7∙108 with Pcav=7W and Eacc=8.5MV/m SPIRAL2**: Q0=109 with Pcav=10W and Eacc=6.5MV/m * V. Zvyagintsev et al., “Development, Production And Tests Of Prototype Superconducting Cavities For The High Beta Section Of The Isac‐ii Heavy Ion Accelerator At Triumf”, RuPAC 2008, Zvenigorod, Russia

** G. Olry et al., “Tests Results Of The Beta 0.12 Quarter Wave Resonators For The Spiral2 Superconducting Linac”, 8

LINAC 2006, Knoxville, Tennessee USA

Transmission Line Input parameters

Let us assume Q0=6.6x108, β=200 and a resonant frequency of 101.28MHz Δf

1

1

(1 + β ) ⇒ Δ f ≈ f 0 ≅ 30 Hz

≈

=

f 0 Qload Q0

Qload

Pf =

Pcav

⎛ β −1 ⎞

1 − ⎜⎜

⎟⎟

⎝ β +1⎠

2

= [for Pcav = 7 W ] = 350W

β −1

≡ ΓL = 0.98

β +1

9

The Model

2000

6

131

5

4

3

10

2

63

1

Top of the cryostat

The line has been divided in 5 pieces. The dimensions are in mm

We will propagate the reflection coefficient Γ along the line

Zg

Γ5

Γ4

Γ3

Γ2

Γ1

Vg

5

4

3

2

1

x L5

L4

L3

L2

L1

ΓL

0

10

1st block

V1+ = 2 Z L1 Pf

Propagation of the Reflection Coefficient

Γ1 ( x) = ΓL e −2γ 1 x

Voltage and Current in the line

⎧V1 ( x) = V1+ e γ 1 x (1 + Γ1 ( x) )

⎨

+ γ1 x

(1 − Γ1 ( x) )

I

(

x

)

I

=

1 e

⎩ 1

+

1

I = 2

With

Propagation coefficient

Attenuation Factor

γ 1 = α1 + j β1

α1 = α c1 + α d 1

Rs (1 / Rin ) + (1 / Rout )

α c1 =

2η ln( Rout / Rin )

Attenuation Factor of the conductors

β1 =

2π

λ0

Pf

Z L1

εr

Propagation constant

α d1 =

π f

c

tan δ

Attenuation Factor of the dielectrics

11

nd

2

block

The equations stay formally the same but the propagation coefficient γ is changing then we have to impose the continuity of the fields on the border surface

Zg

Γ5

Γ4

Γ3

Γ2

Γ1

Vg

5

4

3

2

1

x L5

L4

L3

L2

ΓL

L1

0

A1

Γ1 ( x) L = Γ2 ( x) L

1

1

⎧⎪V1 ( x) L = V2 ( x) L

1

1

⎨

⎪⎩ I1 ( x) L1 = I 2 ( x) L1

Γ2 ( x) = Γ1 ( L1 ) e 2γ 2 L1

V 2+

⎧V2 ( x) = V1+ e L1 (γ 1 −γ 2 )

⎨

+ L1 ( γ 1 −γ 2 )

I

(

x

)

I

=

1 e

⎩ 2

I 2+

∙

∙

∙

e −2γ 2 x

e γ 2 x (1 + Γ2 ( x) )

e γ 2 x (1 − Γ2 ( x) )

12

Total Voltage and Current in the line By generalizing from the previous results

Ai = Γi −1 ( Li −1 ) e 2γ i Li−1

Γi ( x) = Ai

⎧Vi + = Vi −+1 e Li−1 (γ i−1 −γ i )

⎨ +

Li −1 ( γ i −1 −γ i )

+

I

I

e

=

i −1

⎩ i

⎧Vi ( x) = Vi +

⎨

+

I

(

x

)

I

=

i

⎩ i

∙

e −2γ i x

∙

∙

e γ i x (1 + Γi ( x) )

e γ i x (1 − Γi ( x) )

From the full profile of the current and voltage in the line will get easily the dissipated power

n

⎧

⎪⎪V ( x) = ∑ Vi ( x)

i =1

⎨

n

⎪ I ( x) = ∑ I i ( x)

⎪⎩

i =1

1

Pactive ( x) = ℜ{V ( x) I ( x)}

2

This represents the total power dissipated: Line + Load dissipation; if we want only the line dissipation we have to subtract the load (7W)

13

Voltage, Current and Γ in the line

14

Power

15

Summary table

16

Comments

• We have not yet evaluated the contribution of the N connectors (4 connectors) as we have not yet decided their position

• Even if the total power is almost the double with respect for instance to the one dissipated on the Triumf coupler, we foresee a lower thermal charge on the cavity wall as we have only a thermal capacitance between internal and external conductor while in Triumf there is a direct contact (loop) giving a thermal resistance

• To use a thermal shielding material between the cavity wall and the coupler is always possible 17

CLIC Plans

19

Realization of RDDS structure (1)

• Presently the “0‐order” structures meet the design criterion

• Practical realization means to go to the “1st ‐

order” structures meaning to investigate the influence of the machining errors on the efficiency of the wake damping

• Powerful circuit model giving the opportunity of analyzing single cell frequency shift (machining errors)

20

Realization of RDDS structure (2)

• Understanding better the circuit model

• Interaction with Vasim (it would be nice to foresee a period here at CERN)

• Interaction with Walter Wuensch and Alexej

Grudiev.

21

Wakefield Monitors

• I saw Riccardo Zennaro who is (weakly) involved at present on this subject

• There is already some work done by F. Peauger at CEA in Saclay

• The main problem seems to be the (non) attenuation of the accelerating mode (antenna position?)

22

CLIC_DDS1 : Long iris thick. (4.0-0.7) & bigger iris ellipticity (1.0-2.0).: Presented at SLAC

CLIC_DDS2 : Short iris thick. (3.0-0.7) & bigger iris ellipticity (1.0-2.0).

CLIC_DDS3 : Short iris thick. (3.0-0.7) & smaller iris ellipticity (0.5-2.0).

CLIC_DDS4 : Short iris thick. (3.0-0.7) & smallest possible iris ellipticity (0.5-1.5)

CLIC_DDS4 simulations are in progress.

Short iris thickness structure results in a reduced dipole bandwidth by ~ 240 MHz

Yet, no dipole simulations are run except CLIC_DDS1

CLIC_DDS1

(SLAC_WS09)

CLIC_DDS: 2 & 3

CLIC_DDS1 : Black

CLIC_DDS2 : Red

CLIC_DDS3 : Blue

Surface fields

CLIC_DDS1 : Black

CLIC_DDS2 : Red

CLIC_DDS3 : Blue

Input power

P in =

2

E acc

vg

(

ω R' Q

CLIC_DDS1 : Black

CLIC_DDS2 : Red

CLIC_DDS3 : Blue

)

CLIC_DDS3

Dashed curve : Unloaded condition

Solid curve : Beam loaded condition

Esur (MV/m)

Eacc (MV/m)

Pin (MW)

∆T (K)

CLIC_DDS1 : Long iris thick. (4.0-0.7) & bigger iris ellipticity (1.0-2.0).: Presented at SLAC

CLIC_DDS2 : Short iris thick. (3.0-0.7) & bigger iris ellipticity (1.0-2.0).

CLIC_DDS3 : Short iris thick. (3.0-0.7) & smaller iris ellipticity (0.5-2.0).

CLIC_DDS4 : Short iris thick. (3.0-0.7) & smallest possible iris ellipticity (0.5-1.5)

CLIC_DDS4 simulations are in progress.

Short iris thickness structure results in a reduced dipole bandwidth by ~ 240 MHz

Yet, no dipole simulations are run except CLIC_DDS1

Parameters

CLIC_DDS1

CLIC_DDS2

CLIC_DDS3

Pin (MW)

72

75.5

73

Esurmax. (MV/m)

232

250

244

∆Tmax (K)

47.3

44

48.5

Rf‐to‐beam effi. (%)

24.11

23.61

24.24

Corrected

Rf‐to‐beam effi. (%)

26.62

25.85

26.61

24 cell structure

SALCWS09

CLIC_DDS1

Dashed curve : Unloaded condition

Solid curve : Beam loaded condition

Esur (MV/m)

Allowable

limit on

Esur

Eacc (MV/m)

Pin (MW)

∆T (K)

Avg.

Eacc

Allowable

limit on ∆T

CLIC_DDS2

Esur (MV/m)

Eacc (MV/m)

Pin (MW)

∆T (K)