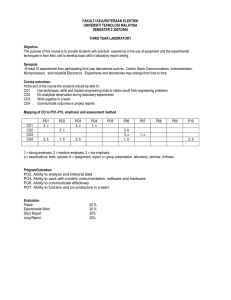

Faculty of Mechanical Engineering

advertisement