Point sur la mesure de l`arrachemlent d`une finition sur bois

advertisement

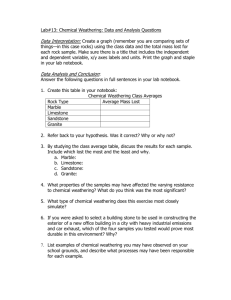

Analysis of the wood coating ageing and prediction of the durability through calorimetric investigations Laurence Podgorski CTBA Technical Centre for Wood and Furniture Bordeaux, France Background • Performances of wood coatings evaluated through artificial (prEN927-6) and natural weathering test (EN927-3) • Visual assessments (cracking, flaking, blistering…) rated from 0 to 5. • To avoid subjective interpretations in the degradations the wood coating ageing has been analysed thanks to an analytical method Objective • To study the coating ageing through the changes in its glass transition temperature (Tg) for different types of weathering (artificial and natural) • To use Tg as means of prediction of the durability The glass transition temperature Tg • Tg is the temperature at which an amorphous polymer changes from the glassy state to the rubbery state • Tg is a useful parameter since it changes when the structural parameters of the polymer change Effect on Tg Tg ↑ Molecular weight X branching degree X Structural cross-linking degree X parameters bulking of substituents X plasticization polarity of constituents Tg ↓ X X X Changes in Tg for an alkyd stain Materials and methods • • • • 3 coats of an alkyd stain applied on oak, meranti and moabi Weathering – Natural weathering during 12 months near Paris – Artificial weathering Wheel 1 cycle = • 12 min water • 27 min ambient atm • 24 min UV lamps • 27 min ambient atm Total = 1300h • • QUV 1 cycle = • 5 hours UVB-313nm • 1h water spray Total = 500h Changes in Tg for an alkyd stain Materials and methods • Calorimetric analysis – 10 mg of coating cut off with a scalpel – Analysed by Differential Scanning Calorimetry (heating rate 5°C/min) • Tg measurements at different times of weathering Changes in Tg for an alkyd stain Results • Wheel Changes in Tg for an alkyd stain Results-Analysis • For the three types of weathering and the three wood species, same Tg variations Tg ∞ Tg(t) Tg Tg (t) = Tg0 + (Tg∞ - Tg0)(1-exp(-t/τ )) Tg = Tg0 when t=0 Tg → Tg∞ = Tg0+Tg1 when t→∞ τ is a time constant. Tg0 τ Exposure time t Changes in Tg for an alkyd stain Result-Analysis Tg (t) = Tg0 + (Tg∞ - Tg0)(1-exp(-t/τ )) This equation describes a first order kinetic model when (Tg∞ - Tg (t)) is taken as a parameter: d [Tg∞ −Tg(t)] = −k [Tg∞ −Tg(t)] dt Integrating this equation leads to: Tg∞ −Tg(t) = exp(−kt) with k = 1 Tg∞ −Tg0 τ Changes in Tg for an alkyd stain Results-Analysis The equation of Dibenedetto links Tg to the conversion rate x Tg0 Tg(t)−Tg0 λ x λ= = Tg∞ Tg∞ −Tg0 1−(1−λ)x with Tg0 corresponds to x=0 Tg∞ corresponds to x=1 (polymer completely cured) With our model and the Dibenedetto equation it is possible to express the cure rate of the coating as follows : dx = 1 (1− x)²+ 1 x(1− x) dt τλ τ Changes in Tg for an alkyd stain Results-Analysis Comparison of Tg0, Tg∞ and τ for the different types of weathering (meranti) Weathering Natural Artificial / wheel Artificial / QUV Tg0 (°C) 3.8 3.8 6.2 Tg∞ (°C) 27.4 24.8 16.5 τ (h) 714 60 50 • The wheel reproduces Tg variations observed in natural weathering. The cycle used in the QUV does not reproduce these variations • The phenomena observed in natural weathering are accelerated by about 12 times with the wheel and 14 times with the QUV Changes in Tg for an alkyd stain Influence of a UV absorber • Alkyd stain modified with 3% of UV absorber (hydroxyphenylbenzotriazole) 30 Tg in °C 25 without UV absorber 20 15 with UV absorber 10 5 exposure time in hours 0 0 • 100 200 300 400 500 600 700 800 900 Model still valid but lower Tg • Plasticization effect possible due to the additive • The additive absorbs the UV radiations which are not available anymore to decompose the hydroperoxides and polyperoxides into free radicals necessary to the curing of alkyd resins • No cracking with the UV absorber because of the low Tg (better flexibility of the coating) Changes in Tg for an alkyd stain Natural weathering: influence of the period of exposure Exposure from April to April Exposure from January to December Suitability of the model for different kinds of coating • Material and methods – Five coating systems applied on pine System Resin SB1 SB2 alkyd alkyd modified acrylicalkyd acrylic acrylic WB1 WB2 WB3 Primer Solid content 36% 69% Topcoat Solid content 50% 76% 30% Nb of Resin coats 1 alkyd 1 alkyd modified 1 acrylic 43% 2 37% 29% 1 1 2 2 acrylic acrylic 42% 31% Nb of coats 2 1 Suitability of the model for different kinds of coating • Material and methods – Weathering • Natural weathering during 13 months near Paris • Artificial weathering • • Wheel 1 cycle = • 12 min water • 27 min ambient atm • 24 min UV lamps • 27 min ambient atm Total = 1200h • • QUV 1 cycle = • 48 h freezing(-20°C) • 24h condensation • (3h UVA-340nm then 1h spray) 96h Total = 2016h Suitability of the model for different kinds of coating • Coating system SB1 35 35 Tg (°C) Tg (°C) 30 30 25 25 20 15 experim model 20 experim model 15 Coating system SB1 10 Coating system SB1 10 5 5 0 0 0 500 1000 1500 2000 2500 Exposure time in the QUV (hours) QUV 3000 0 500 1000 Exposure time on the wheel (hours) Wheel 1500 Suitability of the model for different kinds of coating • Coating system WB3 30 30 Tg (°C) Tg (°C) 25 25 20 20 15 experim model 15 experim model 10 10 Coating system WB3 5 Coating system WB3 5 0 0 0 500 1000 1500 2000 2500 exposure time in the QUV (hours) QUV 3000 0 500 1000 Exposure time on the wheel (hours) Wheel 1500 Suitability of the model for different kinds of coating Comparison of Tg0, Tg∞ and τ for the different types of weathering weathering system SB1 SB2 Wheel WB1 WB2 WB3 SB1 SB2 QUV-340nm WB1 WB2 WB3 SB1 SB2 Natural WB1 WB2 WB3 Tg0 (°C) 8.3 -9.1 -1.7 8.6 15.3 6.3 -8.3 1.9 8.2 15.4 7.0 -8.6 1.7 5.8 16.2 Tg∞ (°C) 29.1 17.2 6.0 11.2 21.4 26.7 17.2 8.3 10.0 24.4 26.8 17.2 6.3 11.2 24.8 τ (h) 151 187 2 35 30 602 607 163 10 164 7225 5932 780 7129 2831 r² 0.96 0.98 0.60 0.33 0.71 0.87 0.88 0.90 ns* 0.93 0.98 0.97 0.95 0.55 0.87 Suitability of the model for different kinds of coating • The model is suitable for all coatings • The second QUV cycle tested is adapted to reproduce Tg variations observed in natural weathering Cycle 1 • • QUV 1 cycle = • 5 hours UVB-313nm • 1h water spray Total = 500h Cycle 2 • • QUV 1 cycle = • 48 h freezing(-20°C) • 24h condensation • (3h UVA-340nm then 1h spray) 96h Total = 2016h Relation Tg - Durability • 2 years of natural weathering • Tg = 15°C Relation Tg - Durability • 2 years of natural weathering • Tg = 36°C Relation Tg - Durability • 2 years of natural weathering • Tg = 9°C Conclusions • The DSC is a useful analytical method to access to a quantified parameter: Tg • The changes in Tg during different types of weathering has been studied for an alkyd stain • A model has been developed • This model is suitable to describe Tg variations of most coatings • The method is useful to validate artificial weathering cycles • The durability of the coating is higher if Tg < 25-30°C