Binary Distillation

advertisement

SHR Chapter 7

Binary Distillation

1

BinaryDistillation.key - March 28, 2014

SHR §7.1

Introduction

st

Dates back to 1 century AD

• first used in a batch mode (distillate changes in time)

Goal: separate “heavy key” (less volatile) from

“light key” (more volatile) by exploiting α≠1.

• for α≫1 or α≪1, this can be done very effectively

unless an azeotrope exists (where α=1).

‣ then we recover the azeotrope and the light or heavy key,

depending on which side the feed lies.

th

• By 16 century, multiple stages were in use to

improve separation.

By 1976, distillation accounted for nearly 3% of

the US energy consumption!

• mostly in petroleum refineries

Binary distillation is simplest & most wellunderstood.

• we will limit our discussion to binary distillation

Third Law of Thermo - typically low

thermodynamic efficiency.

2

BinaryDistillation.key - March 28, 2014

Design Considerations

Operating pressure - “knob 1”

• below ambient pressure requires vacuum operation

• many things may influence choice of operating pressure

‣ Thermo: azeotrope formation, α, etc.

‣ Column operating temperature range (avoiding reactions,

corrosion, etc.)

• most analyses do not account for pressure variation

V

L

F

through the column

Operating temperature - “knob 2”

• Reboiler & Condenser:

D

V

B

L

‣ Bottoms above ambient requires additional energy input to the

reboiler

‣ Distillate below ambient requires energy removal from the

condenser.

• Thermodynamics: critical points of fluids

3

BinaryDistillation.key - March 28, 2014

Batch Distillation

Conceptually, follows

the T-x-y diagram.

More rigorous analysis

in SHR chapter 13

4

BinaryDistillation.key - March 28, 2014

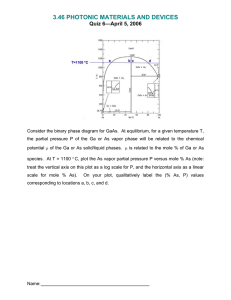

SHR §7.2

The McCabe-Thiele

Graphical Method

1925

Continuous (staged) distillation

5

BinaryDistillation.key - March 28, 2014

Nomenclature

Results

Specifications

F

total (molar) feed rate

D

Distillate (molar) flow rate

z

LK mole fraction in feed

B

Bottoms (molar) flow rate

P

Column operating pressure

N

minimum number of stages

x

LK mole fraction in distillate

R

minimum reflux flow rate

x

LK mole fraction in bottoms

V

Boilup ratio

reflux ratio

N

Number of equilibrium stages

R/R

Feed phase condition

Feed stage location

VLE data (y/x plot)

Type of condenser (partial/total)

Stage compositions (

Type of reboiler (partial/total)

• “Light Key” (LK) - more volatile component

• “Heavy Key” (HK) - less volatile component

6

BinaryDistillation.key - March 28, 2014

Preliminaries

Rectifying section - like an absorber

• Feed & reboiler supply vapor

• Condenser supplies liquid

Stripping section - like a stripper

• Feed & condenser supply liquid

• Reboiler supplies vapor

overall mole balance: F = D + B

light-key mole balance: F zF = xD D + xB B

combine to eliminate

D=F

B & solve for D:

7

✓

zF

xD

xB

xB

◆

BinaryDistillation.key - March 28, 2014

SHR §7.2.1

Rectifying Section Operating Line

Overall mole balance: V = L + D

Light key mole balance: V yn+1 = Lxn + DxD

yn+1 =

L

D

xn + xD

V

V

relates light-key compositions in passing streams (streams on a stage are assumed to be in equilibrium)

If L and V are constant, then this is a straight line.

The “McCabe-Thiele Assumptions”

• Both components have equal and constant molar

enthalpies of vaporization (latent heats).

• Sensible heat, CpΔT, is negligible compared to latent heat.

• Column is insulated (no heat loss on each stage).

• Column pressure is constant (thermodynamics can be

done at a single pressure).

Big assumptions, but allow for simple analysis, since

L and V are constant under these assumptions.

li

ing

ne

rat

e

op

L/D

L

L

R

L reflux

R⌘

=

=L

=

D ratio

V

L+D

/D + D/D

R+1

D

1

✓

◆

✓

◆

=

1

R

V

R+1

x+

xD

y=

R+1

R+1

8

BinaryDistillation.key - March 28, 2014

Range of Reflux Ratios

y=

0

•

•

L

D

x + xD

V

V

✓

L

R

=

V

R+1

R=

◆

L

D

1 because 0 R 1

What happens at R = 0?

What happens at R = ∞?

What is the minimum R that allows separation?

(We will answer this question shortly)

9

BinaryDistillation.key - March 28, 2014

SHR §7.2.2

Stripping Section Operating Line

Overall mole balance: L = V + D

Light key mole balance: Lxm = V ym+1 + BxB

McCabe-Thiele assumptions

have been applied.

The feed stage material balance relates L and V to L and V

1

VB

◆

xB

lin

V boilup

B ratio

ing

VB ⌘

x

✓

relates light-key compositions in passing streams (streams on a stage are assumed to be in equilibrium)

e

VB + 1

VB

◆

B

xB

V

rat

y=

✓

L

xm

V

op

e

ym+1 =

10

BinaryDistillation.key - March 28, 2014

SHR §7.2.3

Feed Stage & the “q-Line”

rectifying

section

stripping

section

q=

q=

L

subcooled liquid

saturated liquid

q>1

q=1

L

F

F

vapor

hsat.

F

vapor

hsat.

F

saturated vapor

superheated vapor

q=0

q<0

V liquid flow increase across feed

V

=1+

partially vaporized

q = LF/F

rate normalized by feed rate.

hF

liquid

hsat.

F

Operating lines & qline must intersect at

a single point.

∴ cannot specify q, VB

and R independently.

11

BinaryDistillation.key - March 28, 2014

More on the q-line

rectifying section:

stripping section:

L

y= x

V

L

D

y = x + xD

V

V

B

xB

V

q=

L

L

F

=1+

V

V

F

subtract

y V

V =x L

L + DxD + BxB

|

{z

}

F zF

y

✓

V

F

y (1

V

◆

=

✓

L

L

◆

x + zF

F

q) =

qx + zF

✓

◆

q

zF

x

y =

q 1

q 1

Typically the feed condition is

known (specifying q).

Then we can choose VB or R.

Note: specifying R implies VB.

12

BinaryDistillation.key - March 28, 2014

SHR §7.2.4

Feed Stage & Number of Stages

too low

just right

too high

Locate feed stage nearest to the intersection of

the operating lines & q-line as possible (just after

the horizontal line on the staircase passes “P”

13

BinaryDistillation.key - March 28, 2014

Partial Reboilers & Condensers

Total Reboiler:

• all liquid is turned back to vapor

Partial reboiler:

• bottoms product is liquid, boilup is vapor

• This is another equilibrium stage!

• very common...

Total condenser:

• all vapor is condensed back to liquid

Partial condenser:

• distillate is vapor, reflux is liquid

• This is another equilibrium stage!

14

D

V

L

F

V

B

L

BinaryDistillation.key - March 28, 2014

SHR §7.2.4

Limiting Cases: Rmin, Nmin.

D

V

“Total reflux”

•

•

•

•

•

“Minimum reflux”

• N = ∞.

L

R = ∞, VB = ∞.

L = V, D = B = F = 0.

F = 0, N = Nmin.

y = x is operating line.

No product...

Rmin

Rmin + 1

(L/V )min

Rmin =

1 (L/V )min

⇥

⇤

L

(VB )min =

/V max 1

(L/V )min =

F

V

B

L

1.0

1.0

1.0

1

“pinch

point”

ve

cur

y

3

y

x=

x

y

x=

x = zF

x = xD

x = xB

x = xB

1.0

ilibr

ium

x=

equ

y

equ

y

ilibr

ium

cur

ve

2

0

1

0

x

higher operating costs

y

x = zF

x = xD

x = xD

x = xB

1.0

0

x

1.0

higher capital costs

15

BinaryDistillation.key - March 28, 2014

SHR §7.2.4

Perfect Separation - Another “Limiting Case”

operating line = Rmin/(Rmin+1).

1.0

y

Perfect separation: xB = 0, xD = 1.

Pinch points form in each section

of the column.

Theoretical value for minimum

reflux ratio and boilup to achieve

perfect separation.

To find this:

• Obtain x-y data from thermo.

• Determine q-line

• Determine slope of rectifying

x=

y

x = zF

0

For saturated liquid feed, Rmin =

16

x

1.0

1

zF (↵ 1)

BinaryDistillation.key - March 28, 2014

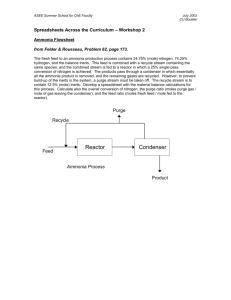

Example

We want to separate a mixture of n-heptane and n-octane using distillation at

atmospheric pressure.

If the feed is 40 mole% n-heptane as a saturated vapor, determine the

minimum reflux ratio and minimum number of stages required to obtain

product streams with 95% and 5% n-heptane.

D

V

Known:

Needed:

• xD = 0.95

• K-values (equilibrium curve)

• xB = 0.05

• q-line • zF = 0.4, saturated vapor

• operating lines

L

F

V

B

L

17

BinaryDistillation.key - March 28, 2014