Storing forklift liquefied petroleum gas cylinders

advertisement

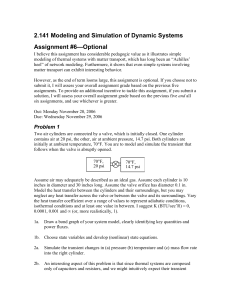

A Health and Safety Solution Storing forklift liquefied petroleum gas cylinders What is the problem? What is a solution to the problem? Forklift liquefied petroleum gas (LPG) cylinders being placed upside down. The risk of death or injury can be eliminated or reduced by: • keeping used and unused LPG cylinders in the correct upright position when not fitted to a forklift • ensuring the relief valve is oriented upward when the cylinder is horizontal, such as when attached to a forklift • locating unused and used forklift gas cylinders in separate areas or implementing a system to tag or mark used cylinders for collection and refilling • ensuring workers are fully trained in the handling and transferring of LPG cylinders. What are the risks? Forklift gas cylinders are fitted with relief valves designed to face upwards in the upper portion of the cylinder where the vapour space is. When a cylinder is placed upside down, the relief valve may be submerged within the liquid of the lower portion of the cylinder. This can cause liquid content to be discharged if the relief valve opens as a result of excessive pressure, such as during a fire or in high temperatures. This pressure means the valve can release a greater than normal amount of liquid, expanding the gas volume outside the cylinder. If the relief valve discharges liquid content, workers are at risk of death from a potential explosion or fire and serious injury, such as severe burns. Further Information WorkSafe Advisory Service Toll-free: 1800 136 089 Email: info@worksafe.vic.gov.au worksafe.vic.gov.au Australian Standard AS/NSZ 1596 – The storage and handling of LP Gas The problem A solution Storing forklift LPG cylinders upside down submerges the valve in liquid content and can result in an explosion or fire. Ensure LPG cylinders are stored upright. If they are lying down, the valve should be in the vapour space, not submerged in liquid. HSS0120/01/10.09 WorkSafe Victoria is a trading name of the Victorian WorkCover Authority.