Motor Starters, Soft Starters and Load Feeders

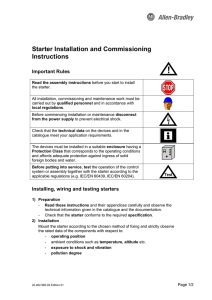

advertisement