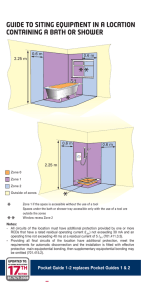

Locations containing a bath or shower

advertisement

Locations containing a bath or shower BS 7671: 2008 Section 701 This leaflet summarises the new requirements of BS7671: 2008 IEE Wiring Regulations (17th Edition) that relates to locations containing a bath or shower. This guidance note refers to situations in dwellings, whereas the actual regulations relate to a bath or shower location in any type of building. BS7671: 2008 was published in January 2008, and all electrical installations being designed after July 1st 2008 must comply with the requirements of the new edition. For further detailed reading, Chapter 701 of BS7671 outlines all the requirements, with additional practical guidance also being given in the IEE’s ‘On-Site Guide’. Locations containing a bath or shower Section 701 1. Scope (regulation 701.1) The scope now covers any location containing a fixed bath (‘bath tub’) or shower. It should be noted that this could also apply to, for example, a bedroom which has a shower or bath It should also be noted that zones generally end at ceilings, walls, floors, doors and partitions. Although the illustrations at the end of this leaflet generally give all the permutations of the commonly encountered zone facility within. boundaries, the following fundamental conditions now apply: As well as applying to such facilities in dwellings, the scope Zone 0 (regulation 701.32.2) also applies to all types of buildings – for example communal showers in commercial buildings as well such facilities in industrial buildings. It should be noted that the requirements do not apply to wash facilities that may be provided as ‘emergency facilities’, but a note is made that for bath or shower facilities for medical treatments, special additional requirements may also apply. This is still the interior of the bath or shower basin, and for practical measuring purposes, the top of the zone would still be taken as to the point at where water would overspill if the basin were allowed to overflow. For showers with no basin, such as a ‘wet room’, the Zone 0 has an upper limit height of 0.1m from the floor, with its horizontal extent being the same as that defined for zone 1 – that being 1.2m from the fixed water outlet (see figures 7 & 8). 2. Classification of zones As with BS7671: 2001, the new BS7671: 2008 document bases its requirements on the concept of zones, which can be clearly and unambiguously defined by simple measurement. The zone boundaries effectively limit the type of installation possible and the type of equipment that is allowable within a particular zone. Pictorial representations of all zones are given in the illustrations at the back of this leaflet. Firstly, it should be noted that the upper limit of all zones is now 2.25m, with no ‘hook-over’ of zones above other zones as was previously the case in the 16th Edition. 2 Zone 1 (regulation 701.32.3) This is defined as being directly above Zone 0 to a height of up to 2.25m or up to the highest fixed showerhead or water outlet if this is above 2.25m. In the case of a shower basin with no defined ‘edge’ the vertical edge of the zone is taken to be 1.2m from the centre point of the fixed water outlet. Note: Zone 1 does not contain Zone 0, but does include the space under an open-sided bath. However, if the space under a bath is accessible only by the use of a tool, it is deemed to be outside of the zones. 3 Zone 2 (regulation 701.32.4) This is defined as extending horizontally from the edge of Zone 1 by a further 0.6m and vertically to the limiting 2.25m or height of the highest water outlet. For showers without a defined basin, there is no Zone 2, due to the extended Zone 1 Zone 3 This no longer exists and its definition has been removed from It is considered due to the very specialist nature of implementing electrical separation that it will be rarely used in dwelling applications. Extra low voltage – SELV and PELV (regulation 701.414.4.5) This regulation permits the use of these systems in zones 0, 1 and 2, but makes the requirement that even if used, basic insulation must still be employed and barriers and enclosures must be provided, meeting at least IPXXB or IP2X. the regulations. 3.Protection for safety: protection against shock (regulation 701.41) Additional Protection – supplementary equipotential bonding (regulation 701.415.2) This regulation governs the application of supplementary bonding and is often a requirement that has been misread and Prohibited methods of shock protection (regulations 701.410.3.5 & 701.410.3.6) misunderstood. The first requirement in this series of regulations is that the BS7671: 2001 regulations, in that it requires supplementary protective measures of ‘obstacles’, ‘placing out of reach’, ‘non bonding between all extraneous conductive parts and circuit conducting locations’ and ‘earth free local equipotential bonding’ protective conductors supplying equipment within the location, defined and being permissible elsewhere in BS7671 are not specifically mentioning metal pipework systems, heating permitted for use in locations containing a bath or shower. pipework, air conditioning ductwork and accessible metal These measures are seldom encountered in dwelling applications structural parts. in any case. Additional protection by RCDs (regulation 701.411.3.3) This new regulation now requires that all circuits of the location shall be provided with additional protection of RCDs which operate at a residual current of 30mA and trip within 40mS It basically continues the requirement of the 16th Edition It must be remembered that metal items fed by plastic pipes, window frames, door frames, architraves and the like are normally considered to be ‘isolated’ unless in contact with metallic structural parts or systems. As such bonding to such items would normally be unnecessary. The golden rule to consider here is, do the metallic parts enter when tested at (x5) their residual current rating. or leave the room and therefore capable of introducing a It also requires that suitable splitting and arrangement of circuits they may be considered to be isolated parts – subject to testing and protection be such so as to minimise inconvenience if a single of course. device were to trip out. Best practice here is of course to use RCBOs, or, if using the now common dual RCD split boards, to potential into the room from other parts of the building? If no, Any such supplementary bonding does not actually have to arrange circuits carefully across the two or more RCDs. be within the location itself – it could be in an adjacent airing Electrical separation (regulation 701.413) bonds are as near as practical to the point of entry of the This regulation allows the concept of ‘electrical separation’ to be only used for circuits supplying one item of current using equipment, or one single socket outlet. It is not permitted to use ‘electrical separation’ in conjunction with electric floor heating systems. cupboard for example. Best practice would be to ensure the extraneous conductive parts into the room – and of course accessible, if using screwed or bolted connections! Where the 17th Edition BS7671: 2008 has changed, is that the These requirements do not differ significantly from the 16th regulation permits such bonding as described (and required since Edition regulations. 2001), to be omitted, provided that four basic conditions are all met, these being: • The building has main bonding conductors in place meeting the regulations Erection of switchgear, control gear and wiring accessories (regulation 701.512.3) This regulation ties in the regulations concerning external influences, and regulations relating to shock protection, into • And all final circuits within the location meet the required disconnection time as stipulated in regulations 411.3.2.2, 411.3.2.3 and 411.3.2.4. • And all final circuits in the location have 30mA RCD simple easy to follow requirements: Zone 0 no switchgear or accessories can be installed Zone 1only accessories for SELV circuits (maximum 12V AC RMS or 30V ripple free DC) to be used, with protection the safety source outside the zones 0, 1 and 2. • And, if in the case of extraneous conductive parts entering or leaving the room, and therefore not ‘isolated metalwork’, Zone 2generally switchgear and accessories with switches or sockets must not be installed. However such it can be proven that such parts are effectively connected to equipment fed by SELV circuits (with the source the main bonding conductors located outside zones 0,1 and 2), and shaver supply In practice, the provision of main bonding should not be an issue, since regulation 131.8 requires it to be in place before any alteration or addition is undertaken in any case. units complying with BSEN 61558-2-5 may be used. Note: It is this regulation that now permits ‘standard’ socket outlets to be used in locations containing a bath or shower, Similarly, the requirements to provide 30mA RCD protection to provided that the socket is mounted at least 3m from the the bathroom circuits can be undertaken in a number of different boundary of zone 1. ways, depending on what other work is involved in the building. It is also worth remembering, that a 30mA RCD achieving the In practice in the majority of typical bathrooms in dwellings, the room size will still effectively prohibit the use of socket outlets. 40mS disconnection time at (x5) residual current will invariably satisfy whatever disconnection time is required by regulations 411.3.2.2, 411.3.2.3 and 411.3.2.4. Current using equipment (regulation 701.55) This regulation ties in the regulations concerning external influences, and regulations relating to shock protection, into 4.Selection and erection of equipment (regulation 701.5) Zone 0 External influences (regulation 701.512.2) Only current using equipment complying with all of the following This regulation gives clear requirements for ingress protection, requirements may be used in this zone: according to installed zones: • Zone 0 IPX7 minimum • Zones 1 and 2IPX4 minimum, unless splashing is likely – then IPX5 A notable requirement is that shaver supply units which comply • Must comply with the relevant standard, be suitable for use in this zone, and be installed fully in accordance with manufacturer’s instructions • Must be fixed and permanently connected • Must be SELV at a nominal voltage not exceeding 12V AC with the new BSEN 61558-2-5 installed in zone 2 where RMS or 30V ripple free DC, with safety source located unlikely to be splashed by direct sprays from showers, will not outside zones 0, 1 and 2. have to meet the IPX4 or 5 requirement. 4 simple easy to follow requirements: 5 Zone 1 Only the following current using equipment may be used in this zone, provided manufacturer’s instructions make it clear that such equipment is suitable for this zone: • Whirlpool units • Electric showers • Shower pumps • Equipment protected by SELV or PELV at a nominal voltage not exceeding 25V AC RMS or 60V ripple free DC, with safety source located outside zones 0, 1 and 2. (Note – different SELV range to zone 0) • Ventilation equipment • Towel rails • Water heating appliances • Luminaires Electric floor heating systems (regulation 701.753) This regulation ties in the regulations concerning external influences, and regulations relating to shock protection, into simple easy to follow requirements relating to typical heating element wires or sheets, requiring that they; • Comply with a relevant product standard • Have a metal sheath, or • Have a metal enclosure, or • Be covered in fine metallic mesh In all of the above cases, the metal sheath, enclosure or mesh must be connected to the circuit protective conductor of the supply circuit, unless the protective measure of SELV is also used. In addition to the specific requirements in chapter 701, chapter 753 outlines generic requirements for electric floor heating systems, which would of course also apply to such systems installed in locations containing a bath or shower. Figure 1 Zone dimensions (plan) Bath tub Figure 2 Zone dimensions (plan) bath tub (fixed partition) Zone 2 Window recess Zone 1 Zone 1 Zone 2 Zone 2 Zone 0 Zone 0 0.6 m 0.6 m s Window recess (0.6-s) m Zone 2 s = thickness of partition Figure 3 Zone dimensions (elevation) bath tub Ceiling Outside zones Window recess zone 2 Outside zones zone 1 zone 2 2.25 m zone 0 * 0.6 m Figure 4 Zone dimensions (plan) shower with basin Zone 0 Zone 1 Zone 2 0.6 m Figure 5 Zone dimensions (plan) shower basin (fixed partition) Zone 0 Zone 2 Zone 1 s (0.6-s) m s = thickness of partition 6 7 Figure 6 Zone dimensions (elevation) shower with basin Luminaire e R Recess above ceiling Ceiling Outside zones zone 1 Outside zones zone 2 2.25 m zone 0 * 0.6 m Figure 7 Zone dimensions (plan) shower without basin (fixed) Figure 8 Zone dimensions (plan) Shower without basin Fixed water outlet Fixed water outlet y 1.20 m x (1.2-y-s) m s Zone 1 Zone 0 Zone 1 Zone 0 1.20 m s = thickness of partition partition y = radial distance from the fixed water outlet to the inner corner of the partion NB * See also Figure 9 Figure 9 Zone dimensions (elevation) shower without basin Ceiling Outside zones zone 1 Outside zones zone 2 2.25 m 0.10 m zone 0 zone 0 Permanent partition *Zone 1 if the space is accessible without the use of a tool. Spaces under the bath accessible only with the use of a tool are outside the zones. For additional information contact the ELECSA Technical Helpline on 0845 634 9029 EC Certification Limited Mansfield Business Centre, Ashfield Avenue, Mansfield NG18 2AE. T +44 (0) 845 634 9043 F +44 (0) 845 634 9039 E enquiries@elecsa.co.uk W www.elecsa.co.uk The information included in this document is for guidance only. Always refer to definitive source material.