Pulling Tension (2)

Cables Buried Direct

When pulling cables into trenches an adequate number of rollers should be used, say one every

six metres but spaced to avoid contact with the ground. Side rollers should be set to take the

cable safely around corners. Pulling tensions given in following table are those to be expected on

horizontal routes with smoothly running supporting and corner rollers when the cable is to be

pulled by a winch.

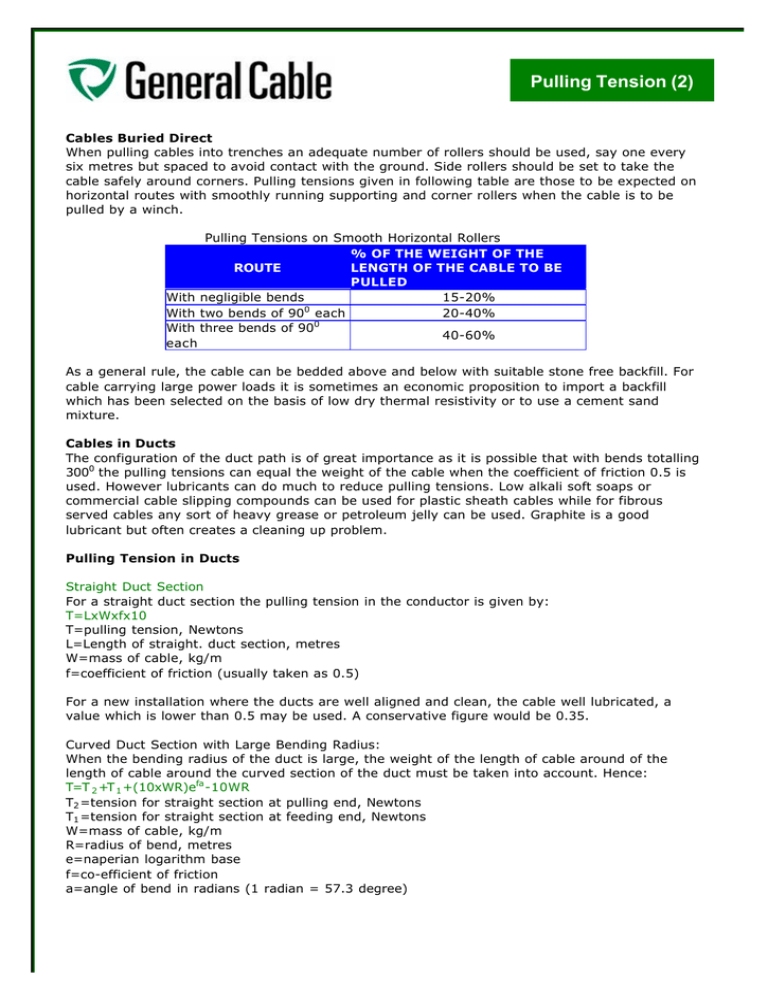

Pulling Tensions on Smooth Horizontal Rollers

% OF THE WEIGHT OF THE

ROUTE

LENGTH OF THE CABLE TO BE

PULLED

With negligible bends

15-20%

0

With two bends of 90 each

20-40%

With three bends of 900

40-60%

each

As a general rule, the cable can be bedded above and below with suitable stone free backfill. For

cable carrying large power loads it is sometimes an economic proposition to import a backfill

which has been selected on the basis of low dry thermal resistivity or to use a cement sand

mixture.

Cables in Ducts

The configuration of the duct path is of great importance as it is possible that with bends totalling

3000 the pulling tensions can equal the weight of the cable when the coefficient of friction 0.5 is

used. However lubricants can do much to reduce pulling tensions. Low alkali soft soaps or

commercial cable slipping compounds can be used for plastic sheath cables while for fibrous

served cables any sort of heavy grease or petroleum jelly can be used. Graphite is a good

lubricant but often creates a cleaning up problem.

Pulling Tension in Ducts

Straight Duct Section

For a straight duct section the pulling tension in the conductor is given by:

T=LxWxfx10

T=pulling tension, Newtons

L=Length of straight. duct section, metres

W=mass of cable, kg/m

f=coefficient of friction (usually taken as 0.5)

For a new installation where the ducts are well aligned and clean, the cable well lubricated, a

value which is lower than 0.5 may be used. A conservative figure would be 0.35.

Curved Duct Section with Large Bending Radius:

When the bending radius of the duct is large, the weight of the length of cable around of the

length of cable around the curved section of the duct must be taken into account. Hence:

T=T 2 +T 1 +(10xWR)efa -10WR

T2 =tension for straight section at pulling end, Newtons

T1 =tension for straight section at feeding end, Newtons

W=mass of cable, kg/m

R=radius of bend, metres

e=naperian logarithm base

f=co-efficient of friction

a=angle of bend in radians (1 radian = 57.3 degree)

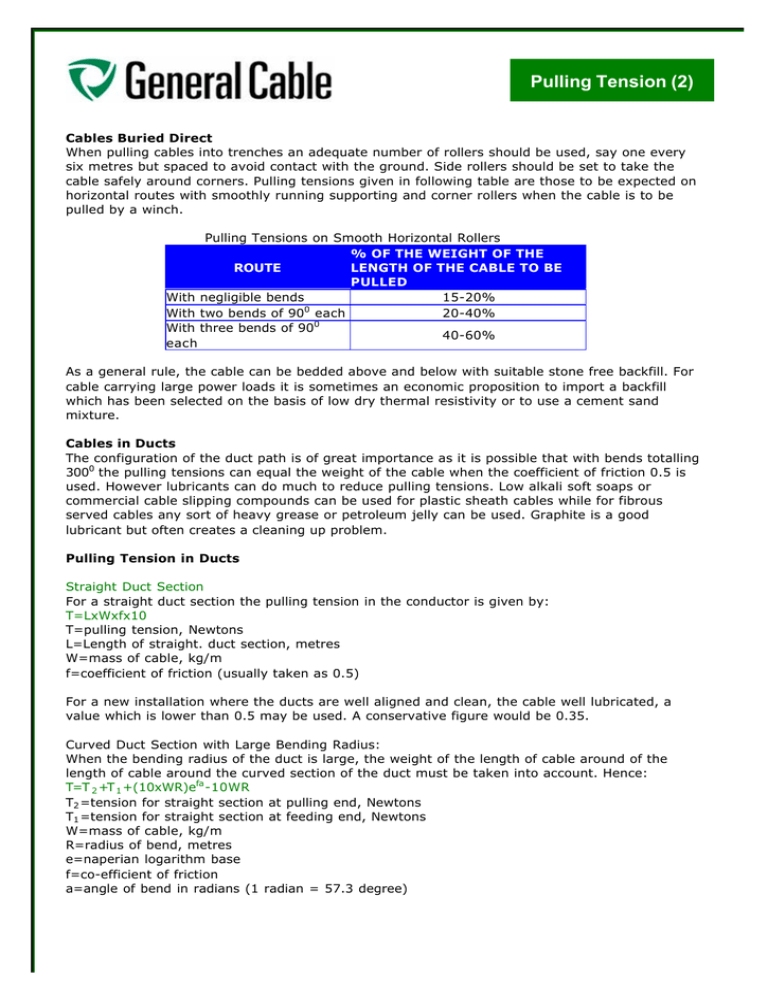

Value of efa for some common angles are shown in below:

Value Of efa

ANGLE OF

BEND

DEGREES

15

30

45

60

75

90

f=0.7

f=0.6

f=0.5

f=0.4

f=0.3

1.20

1.44

1.73

2.08

2.50

3.00

1.17

1.37

1.60

1.87

2.19

2.57

1.14

1.3

1.48

1.68

1.92

2.19

1.11

1.23

1.37

1.52

1.69

1.87

1.08

1.17

1.27

1.37

1.48

1.60

Curved Duct Section With Small Bending Radius:

When the bending radius of the duct is small the weight of the cable around the curved section of

the duct may be ignored. The above equation is reduced to:

T=T 2 +T 1efa Newton

Immediately prior to the pulling of cable, ensure that the conduit is clean and free of dirt, stones,

water, scale or similar substances.

Tension at bends to limit sidewall pressure to safe level = 3,725R where R is in metres.

If it is necessary to pull cable in very cold weather, the minimum installation temperature of the

cable should be observed. Extra care in handling should be exercised and, in some cases, preheating of the cable may be desirable immediately before pulling.

Cable should be pulled into ducts at a constant speed throughout the entire pull. The cable should

not be allowed to stop midway through the pull; the drag due to friction is greatly increased when

pulling is restarted. The recommended speed is 10-20 m/minute. If this speed cannot be

achieved, the minimum speed of 5 m/minute should be maintained.

When a long length of cable is pulled in a duct where maximum tension would be exceeded, it is

necessary to use caterpillar type cable helpers or similar equipment at the entrance to the duct

system and in extreme cases in pits along the duct run.

Pulling tensions at all times should be restricted to 20kN for duct installations.

With many duct runs there is a preferred end at which the drum should be set up. As a rule of

thumb this should be at the end nearest the sharpest bend. A worked example is given for the

duct configuration shown in following figure pulling from end A, the end closer to the first bend,

and the alternative pulling from end F.

500mm2 copper conductor, XLPE insulated, heavy duty copper wire screened and heat resistant

PVC sheathed single core 19/33kV cable with an overall diameter of 58mm and a mass of 7.14kg

per metre.

The maximum tension T m with pulling eye attached to conductor = 35,000N (limited to 20kN) or

with stocking over PVC sheath=16,800N.

Assume coefficient of friction f=0.5

Pulling from A to F:

Tension

Tension

Tension

Tension

Tension

at

at

at

at

at

B(T1 ) = 20x7.14x0.5x10 =714N

C(T2 ) = T1 efa =714x1.92 =1370N

D(T3 ) = T 2 +60x7.14x0.5x10 =3510N

E(T4 ) = T3 efa = 3.510x1.14 =4000N

F(T 5 ) = T4 +70x7.14x0.5x10 =6500N

Pulling from F to A:

Tension at E(T1 ) = 70x7.14x0.5x10 =2500N

Tension at D(T2 ) = T 1 efa =2500x1.14 =2850N

Tension at C(T3 ) = T2 +60x7.14x0.5x10 =4990N

Tension at B(T4 ) = T3 efa = 4990x1.92 =9580N

Tension at A(T5) = T4 +20x7.14x0.5x10 =10300N

Maximum pulling tension (limited by side wall pressure) around bend B-C; 3725*radius of bend in

metres=3,725x3 =11,200N.

Maximum pulling tension (limited by side wall pressure) around bend D-E; 3725*radius of bend in

metres=3,725x2 =7,450N.

The example illustrates a number of points:

• Feeding from A, the end closest to the first bend requires much less tension than feeding

from end F.

• With the pulling eye attached to the conductor or with a stocking grip over the PVC sheath,

the cable may be pulled from either end as the pulling tension around each bend and the

exit tensions at A & F are below the recommended relevant maximum values.

General Cable New Zealand

HEAD OFFICE

75-89 Main South Rd

PO Box 8044

Riccarton

Christchurch

Ph: (03) 348 5199

Fax: (03) 348 2009

Website: www. generalcable.co.nz

General Cable Australia Pty Ltd

Sales:

1300 363 282

Fax:

1300 363 382

www.generalcable.com.au

Diagrams of cables are illustrative only and are not necessarily to scale.

This brochure is distributed with the understanding that the authors and editors are not responsible for the results of any actions taken on the basis of information in this work , or any errors or omissions.

Further, General Cable is not engaged in rendering professional services. General Cable expressly disclaims all and any liability to any person in respect of anything and of the consequences of anything done

or omitted to be done by any such person in reliance whether whole or partial of the whole or any of the contents of this publication. All rights reserved. No part of this work covered by copyright may be

reproduced or copied in any form or by any means without the written permission of General Cable.