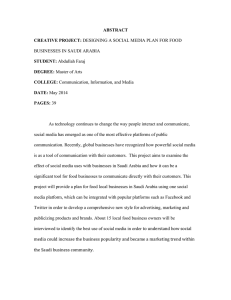

German-Saudi Business Magazine

October 2014

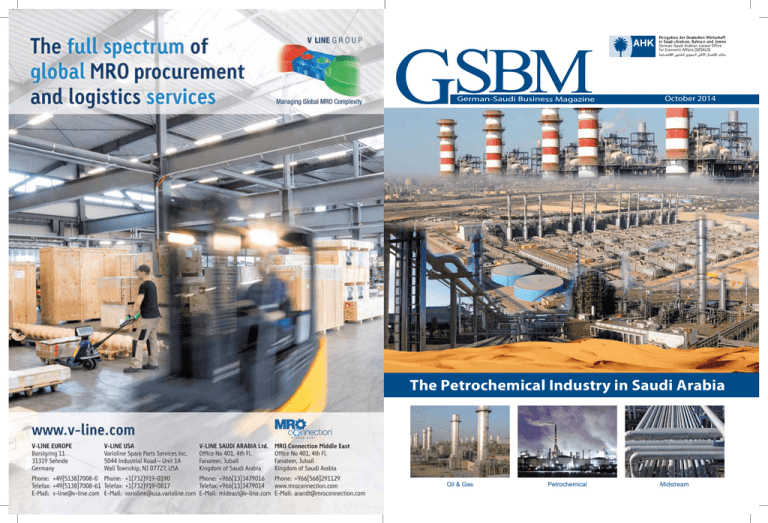

The Petrochemical Industry in Saudi Arabia

Oil & Gas

Petrochemical

Midstream

German - Saudi Business Magazine

Editorial

Dear readers,

Andreas Hergenröther

Delegate of German

Industry & Commerce

for Saudi Arabia and Yemen

Saudi Arabia is maintaining its leading position as the region’s largest

petrochemical producer with an annual 86.4 million tons of capacity. Home to

more than a quarter of the world’s proven oil reserves, Saudi Arabia boasts over

257.8 trillion cubic feet of gas reserves, 40 percent of which is non-associated,

making the Kingdom’s quantity of reserves the fourth largest in the world after

Russia, Iran, and Qatar. Since more than 95 percent of the Saudi Arabia’s basic

petrochemicals are derived from methane and natural gas feedstock, the

country’s commitment to expanding its natural gas infrastructure will enhance its

competitive advantage in the global petrochemical and plastics markets.

According to the Royal Commission for Jubail & Yanbu, Saudi Arabia produces

over 50 unique petrochemical products. There are around 60 petrochemicals

projects currently in the pipeline. German companies have been strong partners

for sustainable long-term business relations in the petrochemical sector in Saudi

Arabia for decades. Chemical giant BASF plays an active part in the Saudi

construction landscape, supplying construction chemicals to mega projects

including the two Holy mosques in Makkah and Madinah, the building of the

King Abdul Aziz International Airport in Jeddah, King Abdullah Economic City,

the Maaden Aluminium Smelter in Ras Al Khair. BASF also supplies products to

prominent clients such as the Royal Commission for Jubail and Yanbu. Another

example is the family-owned company Bischof+Klein that has been producing

FFS packaging solutions on the basis of co-extruded films as well as stretch hood

and shrink films. The plant in Dammam has a total output of almost 24,000 metric

tons. German company Evonik Industries and Saudi Acrylic Acid Company

(SAAC) have established a joint venture called Saudi Acrylic Polymers Company

(SAPCo) for the production of superabsorbents. SAAC is a joint venture of the

Saudi companies National Industrialization Company (Tasnee) and Sahara

Petrochemicals. The production facility has an annual capacity of 80,000 metric

tons. Other major investments were made in the petrochemical sector by Fuchs

Petroleum which owns a modern industrial complex in Yanbu on an area of

10,000 square meters with an annual capacity of 160,000 metric tons of oils and

lubricants, Henkel with manufacturing facilities in Dammam, Erndtebrücker

Eisenwerk and Thyssen Krupp Uhde. “Made in Germany” is renowned around

the world for its attributes of premium quality, state-of-the-art technology and

know-how. The latter takes a pivotal role in the success story that “made in

Germany” achieved and it is here that the German industry is a strong partner for

many industries and regions, helping spread it to local production sites. To create

a better awareness of the high potential of German-Saudi Arabian business

relations we would like to present in this current edition the portfolios of some of

the major petrochemical companies in the Kingdom.

Andreas Hergenröther

AHK Saudi Arabia - www.saudiarabien.ahk.de

1

Contents

05

54

06

11

08

Editorial

01

Alhamrani-FUCHS

28

AHK Saudi Arabia

04

OKS

30

German Desk Opens in Jubail

05

Zeppelin

32

Petrochemicals

06

Chemanol

34

Saudi Aramco

08

Linde Engineering

36

SABIC

10

ThyssenKrupp AG

38

Lurgi

40

Zamil Group

12

EEW Global Pipe Company

42

Ma’aden

16

LISEGA Arabia Co. Ltd.

44

Henkel Polybit

17

Draeger Saudi Arabia

46

Tasnee Petrochemicals

18

V-Line

48

SADARA

20

IBE

50

Evonik Industries

22

Trade Fairs

52

Bischof + Klein

24

AHK Services

56

58

BASF

26

Your contact persons at

AHK Saudi Arabia

31 28

36

41

38

46

42

Design & Developed by:

26

www.fawazadvertising.com

In accordance with GESALO

Disclaimer:

German–Saudi Business Magazine

(GSBM), Issue October 2014

Editor-in-Chief

Andreas Hergenröther

Head of Public Relations

Christian Engels

Responsible for Printing

AHK Saudi Arabia

© Copyright GSBM 2014.

All rights reserved.

No part of this magazine may be reproduced

without GSBM’s written permission.

The opinions expressed in GSBM do not

necessarily reflect the views of the German

Delegation of Industry and Commerce for

Saudi Arabia and Yemen (AHK Saudi Arabia).

GSBM is not responsible for the validity of

contents in articles written by external

authors.

German - Saudi Business Magazine

HISTORY

AHK Saudi Arabia

The official representation of the German economy in Saudi Arabia

The Delegation of German Industry

& Commerce for Saudi Arabia and

Yemen (AHK Saudi Arabia) has been

founded in 1978 by Royal decree

under the name of German-Saudi

Arabian Liaison Office for Economic

Affairs (GESALO). AHK Saudi

Arabia is part of the German Chamber Network and the official German

Foreign business promotion. With

130 offices worldwide AHKs offer

their experience, connections and

services to German and companies of

their partner countries. With a staff of

20 employees, AHK Saudi Arabia

supports Saudi and German companies with its services. AHKs are

closely connected to the Chambers of

Industry and Commerce (IHKs) in

Germany. Together, they represent in

total 3.6 million companies in

Germany.

AHK Saudi Arabia is the official

representative of German economy

in Saudi Arabia. Besides this AHKs

are service providers to companies

under the brand “DEinternational”

AHKs provide services to companies

both from Germany and their host

countries in order to support their

foreign business activities. These

services include conducting market

studies and providing sector information, matchmaking, business consulting, organization and representation

of trade shows, issuing business

publications,

legal

information,

medical treatment support and

vocational training, etc.

the first office for German–Saudi

economic relations, which has been

established by Royal Decree.

Since

October

2010

Andreas

Hergenröther is the current Delegate

of German Industry and Commerce

for Saudi Arabia and Yemen. Under

his lead the German-Saudi business

relations tightened within one year

even more and many projects are on

the way deepening these relations. In

December 2010 the first GermanSaudi Arabia Desk has been

established at the Bielefeld Chamber

of Industry and Commerce. It

functions as an information platform

about Saudi Arabia for all German

companies. Under the lead of Mr.

Hergenröther more than 100 events

in Germany and Saudi Arabia have

been organized by AHK Saudi

Arabia in order to promote GermanSaudi business relations. With its

services for German and Saudi

companies AHK Saudi Arabia is in a

key position for the bilateral

economic relations. Every businessman, who is interested in doing

business in Saudi Arabia or in

Germany will find an individual

concept of entering the market,

promoting its business through trade

fairs and find the perfect business

partner from the other country.

It is also Saudi companies, business

representatives and the Saudi Chambers network that clearly profit from

GESALO’s work in the context of the

German foreign trade promotion.

AHK Saudi Arabia more than

30 years of experience

On average, GESALO organizes 250

4

German-Saudi Arabian business

relations follow a long tradition In

1978 the Joint German-Saudi

Economic Committee composed by

representatives of the German Ministry for Economics and the Saudi

Ministry of Finance decided to establish a German foreign trade commission in Saudi Arabia. On August

22nd 1978 was the inauguration of

individual Business Partner Searches

annually. This opens investment

opportunities to Saudi companies as

well as partnerships for technology

and knowledge transfer. Numerous

information events are being held by

GESALO staff in Germany to

promote Saudi Arabia as an investment location and advocate for

technology partnerships with Saudi

companies. This contributes remark-

ably to making Saudi Arabia visible

in the German economy. GESALO’s

connections to the internationally

important German fair sites foster

the making of contacts between

Saudi companies and German

business partners with innovative

technologies. For this reason,

GESALO

organizes

numerous

business delegations for Saudi

Arabian exhibitors and visitors to

trade fairs, aiming at promoting

export and connecting Saudi companies with German cooperation

partners.

By delivering key technologies and

providing know-how “Made in

Germany”, German companies have

been contributing for many years to

the realization of projects that are of

strategic value for Saudi Arabia, for

example in the oil and gas sector, in

petrochemicals, in the construction of

power plants and grids, but also in

border hedging.

Beyond this, the matter of vocational

training has gained importance for

Saudi Arabia. Also in this field,

German companies and German

know-how belong to the global top.

GESALO has established itself as

important relay station for optimized

knowledge

transfer

and

will

continue to hold that position.

Both countries are the major players

in their respective regions. Bilateral

trade has risen from 4 bn US $ in 2003

to 10.8 bn US $ today by more than

170 %. Not only has the economic

opening brought this success about,

but also did the work of GESALO as

a catalyst for business have a decisive

share in that intense cooperation.

Unlike bilateral trade, the field of

investments is still waiting for more

mutual engagement. GESALO is in

the focus here, too. It serves as

important contact point for both

sides, to accompany potential

investors professionally.

German - Saudi Business Magazine

HISTORY

German Desk Opens in Jubail to

Facilitate Transfer of Technology

The ‘German Desk’ opened at the

Jubail Branch of Asharqia Chamber

aiming at facilitating transfer of

technology

for

the

industrial

development at the twin cities

of Jubail.

Dr. Peter Ramsauer, Chairman of the

Committee of the German Parliament

for Economic Affairs & Energy,

inaugurated the event last month.

Mr.

Hassan

M.

Al

Zahrani,

Vice-Chairman of Asharqia Chamber,

Michael Ohnmacht, Acting German

Ambassador to the Kingdom and

Mr. Andreas Hergenrother, Delegate of

German Industry and Commerce for

Saudi Arabia were present.

Germany is keenly interested in

participating in the Kingdom’s

on-going economic development, said

Dr. Peter Ramsauer adding that he was

amazed witnessing tremendous industrial development in Jubail. German

technology and industrial equipment

are of high quality compared to other

countries, he noted.

Mr. Al Zahrani pointed out that the

opening of the German Desk in the

Kingdom’s industrial hub of Jubail will

give a fresh boost to the already strong

trade and commercial relations

between Saudi Arabia and Germany.

Many globally recognized petrochemical plants built by the Saudi Arabian

Basic Industries Corporation (SABIC)

are based in the Jubail Industrial CitiesOne and Two. In addition, Saudi

Aramco has several large-scale new

projects such as Sadara Chemical

Company and Saudi Aramco Total

Refining & Petrochemical Company

located in the twin industrial cities,

he said.

German companies have strong

presence in the Saudi market offering

high-tech products and expertise. Over

100 German companies are now

represented in Saudi Arabia and their

combined investments, according to

the Saudi Arabian General Investment

Authority, reached over $8 billion,

noted Mr. Zahrani.

He invited German firms to take advantage of liberalized economic policy and

a package of incentives announced by

the Saudi government for foreign

investors. The liberalized economic

policy has made Saudi Arabia the most

favorable country for businesses in the

Arab world, Middle East and North

Africa region, observed Mr. Zahrani.

Currently, the annual two-way average

trade has reached over SR42.7 billion,

of which, Saudi imports from Germany

are valued at around SR41.3 billion

while Saudi exports to Germany are

worth only 1.4 billion Riyal.

Mr. Zahrani offered Chamber’s willingness to cooperate with German

companies in order to support them in

their efforts to identify trade and

investment opportunities in the

Kingdom. Mr. Hergenrother noted that

Germany is a key supplier of

technology and know-how to the

Kingdom particularly to its Eastern

Province where many German companies have established their production

bases. These German firms included

Linde (industrial gases), Siemens (gas

turbines), BASF (construction chemicals), Kenkel (industrial coatings),

Evonik (suberabsorbants), Bischof &

Klein (packaging) and Erntebruecker

Eisenwerke (pipelines).

Mr. Hergenrother mentioned the

strong presence of the German logistic

giant DHL which has become the

largest German employer in the

Kingdom employing over 4,000

people. For creating employment

opportunities, DHL has been honored

with the Prince Nayef Award for the

highest Saudization quota of a foreign

company in the Kingdom.

AHK Saudi Arabia - www.saudiarabien.ahk.de

5

German - Saudi Business Magazine

Petrochemicals

Expansion of Downstreaming

on a Large Scale in Saudi Arabia

The Saudi Arabian petrochemicals

sector is expected to advance and

expand due to private and

government incentives and initiatives

to diversify the country’s export

portfolio.

The

downstreaming

initiatives already bear fruit and are

set to quickly become a stable pillar in

what is still considered an upstream

economy. According to industry

insight, Saudi Arabia’s petrochemical

industry exports are set to reach 100

million tons by 2016. Ten percent of

the global petrochemical export

products have been manufactured in

Jubail and Yanbu in the kingdom’s

economically vibrant coastal regions.

Both cities form the center of the petrochemical industry and have played a

key part in the Kingdom’s determination to develop hydrocarbon-based

industries. The Saudi Central Department of Statistics and Information

(CDSI), numbers the total value of

Saudi Arabia’s petrochemical exports

with 66.64 billion SAR, approx. 14.206

billion € for 2012, growing at a

12-year CARG of 15 percent.

The Saudi Arabia petrochemical

sector is well positioned in the region

and driven by a positive global

demand outlook. With an annual

capacity of 86.4 tons of petrochemical

products, Saudi Arabia is the region’s

largest petrochemical producer. For

ethylene, it is the world’s third largest

producer, accounting for 11 percent of

global ethylene production.

Petrochemical production capacities

are forecast to remain at their already

high level until 2016, when output is

set to grow on a rapid pace through

the coming-on-stream of Sadara’s

petrochemical complex. Saudi Arabia

06

is challenged by rising prices of

exploration and production of

non-associated gas, as well as

potentially rising petrochemical

output of global competitors, whose

competition will result in thinner

profit margins. Recently discovered

North American shale gas and oil

which is currently flooding the

market and driving down the world

market price is likely to have an

impact on the Saudi petrochemical

sector, regardless the fact that the

technology needed to extract it is still

in its preliminary stage.

MEED analyses the situation as

follows: “While cracking liquid

feedstock will not provide as high

margins, the process produces a

wider range of co-products that can

increase the range of chemicals manufactured in the region.”

The petrochemical industry depends

on four main building blocks for

developing end products. Petrochemical cracking units produce ethylene,

propylene, butadiene and benzene.

These organic components are the

byproduct of either natural gas or

naphtha, which count as light or

heavy feedstock respectively.

While most of Europe’s and Asia’s

industries rely on naphtha, which is a

crude oil derivate, most of the

Americas and the Middle East

consume more of the light feedstock

ethane and liquefied petroleum gas

(LPG). Due to the abundance of oil in

Saudi Arabia, the petrochemical

sector will rely mostly on heavy

feedstock.

The Saudi petrochemical sector is

expected to grow due to several

factors. First, Saudi Arabia has

substantial

proven

feedstock

reserves, with 264 billion barrels of

crude oil, 297.7 trillion cubic feet (tcf)

of natural gas and an estimated 600

Petrochemicals

tcf of unconventional shale gas.

Second, albeit the strength of Saudi

Arabia is in the production of simple

petrochemical products in the

present, companies such as Saudi

ARAMCO and SABIC can calculate

with government-guaranteed, low

input prices, which are currently

around 90 % cheaper than on the

world market. By September 2014

U.S. natural gas costs stood at

$4.29/mmbtu, whereas Saudi natural

gas prices were have been fixed at

Saudi

Aramco’s

pricing

of

$0.75/mmbtu for many years. Hence

Saudi companies are expanding their

petrochemical production capacities.

On the contrary, European companies

buy raw materials at world market

prices. However, in reality the

production costs of natural gas

extraction in Saudi Arabia are much

higher than the fixed price. Gas the

Karan

gas

field

costs

in

production $3.5/mmbtu, gas from the

more difficult Arabiyah field will be

even higher after launching production, up to $5.50/mmbtu. Third, the

country has strong industrial and

regulatory infrastructure, which have

been inte-grated into specially

built-up industrial cities.

The Saudi Arabian Oil Company

(ARAMCO) and the Saudi Basic

Industries Corporation (SABIC) are

the major actors in the sector. Being

the world’s largest oil producer,

ARAMCO is in a key position: The

state-owned company invests in

multi-billion-dollar projects, acts as a

shareholder of many joint ventures

and provides the feedstock for numerous petrochemical plants. SABIC as

the biggest company in the entire

Middle East region was founded in

1976 to push forward the diversification of the local industry.

According to Gulf Petrochemicals

and Chemicals Association, GCC

member states were producing 39

million tons of petrochemical

products in year 2000. Eight years

later, in 2008, the production

increased to 100 million tons. All in

all, Saudi Arabia contributes three

quarters to the production of

petrochemicals

in

the

entire

Gulf region.

German - Saudi Business Magazine

Today, industrial products make up

more than 90 percent of the

Kingdom’s non-oil exports. Saudi

Arabia

exports

petrochemicals,

plastics, metal goods, construction

materials and electrical appliances to

some 90 countries.

Saudi

decision

makers

put

unprecedented efforts in the diversification of the down-stream industry to

establish a labor intensive industry.

SABIC

and

Saudi

ARAMCO

to-gether with many additional

players in Saudi Arabia are undertaking the implementation process. In

addition to increase the mass production of basic petrochemicals like

polyethylene and polypropylene,

Saudi Arabia focuses on expanding

its downstream activities. Downstream products like acetone, carbon

oxide, polyethylene etc., which are

the basis of higher value added

products, shall be produced in the

Kingdom. Within the next five years,

the production of 120 new chemicals

will begin. The Middle East business

intelligence MEED lists 26 projects in

the Saudi petrochemical sector with

an investment volume of 15 billion

USD that are under construction.

Another 42 planned petrochemical

projects are 46 billion USD worth.

The goal of the country is to become a

global leader in the petrochemical

industry in the near future. Saudi

Arabia has direct access to the

required raw materials oil and gas

and will be able in the future to

extract shale gas, too. It thus has

plenty of energy, which is needed to

produce petrochemical products.

This dynamic trend will intensify in

the future. Beneficiaries of this reform

could be German suppliers of machinery, the chemical industry, equipment, technologies and services.

Moreover, the transfer of Know-How

from Germany to Saudi Arabia is a

major field of business to flourish.

The preconditions for German companies are promising. Many German

companies already have their share in

the ascent of Saudi petrochemicals.

An example how the future can look

like is the joint venture Saudi Acrylic

Polymers Company (SAPCo). In

August 2011 the company was

founded by Evonik, Tasnee and

Sahara Petrochemicals to produce

80.000 tons per year of superabsorbent polymers in Jubail, starting in

2014.

Another player on the Saudi market

is The Linde Group which is collaborating with Sa-dara. The German

company invests 380 million USD in

Jubail to supply Sadara with carbon

monoxide, hydrogen and ammonia at

a chemical complex now being built

by Sadara in Jubail.

Bischof + Klein produces flexible

packaging solutions in Al-Khobar

and Zeppelin is active in Jubail in the

plant

manufacturing

business.

German plant and mechanical

engineering companies, providers of

technology and external suppliers

will

find

vast

investment

opportunities

concerning

the

expansion of petrochemical plants in

Saudi Arabia and the Gulf region.

Among the largest projects currently

planned or under execution in Saudi

Arabia is a refinery and petrochemical complex in Jubail that is being

commissioned at the moment. The

project is projected to 14 billion USD

by Saudi Aramco Total Refining and

Petrochemical Company. The plant

will, among other facilities, include: a

multi feed cracker, an aromatics

complex, auxiliary utilities, a cooker

unit, a conversion unit and crude

storage tanks. Further plants being

planned or constructed with a

projected value of at least 1 billion

USD are: refinery for clean

transportation

fuel

(Aramco),

Dammam 7 - Acrylic Acid and

Acrylates Complex, an elastomers

project (KEMYA), the Rabigh

Refining and Petrochemical Complex

Expansion

(Petrorabigh).

Major

investments like Sadara’s Jubail

Petrochemicals

Complex

and

Aramco’s/Mitsubishi’s/Nabaa’s

Yanbu Integrated Refinery and Petrochemical Complex will be covered in

the company’s respective profiles in

the forthcoming articles.

AHK Saudi Arabia - www.saudiarabien.ahk.de

07

German - Saudi Business Magazine

Saudi Aramco

Saudi Aramco

German - Saudi Business Magazine

In order to achieve that goal, Saudi

Aramco has taken all possible steps to

develop the country’s natural gas

potential. The company is the sole

producer of the feedstock in the

kingdom. This includes not only the

development of conventional small

and large fields but also drilling of

shale gas resources and further

exploration of the kingdoms geological areas to discover further potential

drilling sites. Promising wells are

being expected in the so far largely

unexplored Saudi Arabian Red Sea

coastline. Gas makes already 50 % of

the Saudi Arabian energy mix.

Saudi Aramco

The Saudi Arabian Oil Company

(Saudi Aramco) is Saudi Arabia’s

fully state-owned oil company. It

ranks first among oil companies

worldwide in terms of crude oil

production and exports, and natural

gas liquids (NGL) exports, and is

among the leading producers of

natural gas. Saudi Arabia administers

the world’s largest crude oil reserves

roughly one fifth of the global total at

nearly 260.1bn barrels. It has a

production capacity of 12.5 million

barrels a day (b/d). Aramco makes an

estimated $1bn a day from its vast oil

exports, accounting for 51 per cent of

Saudi Arabia’s GDP and 80 per cent

of government revenues. Saudi

Aramco is a fully integrated oil

8

company with operations in exploration, production, refining, marketing and international shipping. It is

rapidly progress-ing towards becoming the world’s leading integrated

energy and chemicals company. The

company has 57,000 employees and is

headquartered in Dhahran in the

Eastern Province of Saudi Arabia.

Aramco has had a major share in the

Kingdom’s achievements in integrating its refining and petrochemicals

facilities to realize further economic

diversification. In recent years, the

company has moved away from

being a predominantly upstream

operator to a fully diversified

hydrocarbons company.

Recently, Aramco has made massive

investments in its downstream operations, which aim to increase the

amount of refined products for

domestic use and export, as well as

drive industrial diversification. In

this context, Aramco has invested

almost $30bn in new refineries in the

kingdom since 2009, with several

billion more being spent on upgrading and expanding existing facilities.

Aramco operates seven refineries in

the kingdom with an overall capacity

of 2.5 million b/d. The overall

capacity is forecast to increase by

800,000 b/d until 2017 with two new

refineries to start operations. The

refineries are going to be built in the

petrochemical and industrial hubs of

the Kingdom, Jubail and Yanbu. A

third refinery is under construction in

the country’s remote and economically

relatively

underdeveloped

southern Jazan region, which lies at

the Yemeni border. The 400,000 b/d

complex, including a large network of

petrochemicals plants, will be fully

owned by Aramco and serve as one of

the major job suppliers of planned

Jazan Economic City that is set to

stimulate the region’s economic

development.

Internationally, Saudi Aramco holds

substantial joint venture and investment interests in refining and marketing activities in the United States, the

Republic of Korea, Japan, and China.

Key market service support offices

are located in major cities in North

America, Europe and the Far East.

Sadara Chemical Company is one of

Aramco’s successful Joint Ventures. It

was

established

in

2011

in

collaboration with US based Dow

Chemical. As already mentioned in

the article above, the Joint Venture is

setting up 26 production facilities

in Jubail, capable of producing

3 million tons of products every year.

This refining and petrochemicals

integration

initiative

will

ensure downstream petro-chemicals

facilities have ample supplies of

liquid feedstock, such as naphtha,

and natu-ral gas liquids (NGLs) to

create a more diverse product slate,

which can then be used for

conversion industries.

The new downstreaming platforms

will be based on technology and

backed by initia-tives for fostering

innovation. Currently, Aramco is

strengthening its R&D program

with a technology agenda that

incorporates both the upstream and

downstream sectors.

According to MEED Vol 58/No 36,

Saudi Aramco has to invest $ 40bn

over the next decade to keep oil

production capacity steady and

double gas production. Saudi

economy will need close to 40 million

b/d of new capacity in the next

twenty years to meet forecast demand

growth.

AHK Saudi Arabia - www.saudiarabien.ahk.de

9

German - Saudi Business Magazine

SABIC

SABIC (Saudi Basic

Industries Corporation)

SABIC (Saudi Basic Industries Corporation) was established by Royal

decree in 1976 and its growth has

been nothing short of miraculous.

Today it is the Middle East’s largest

listed company. SABIC’s creation was

a bold step for a developing country.

It marked a move into using the

by-products of oil extraction to

produce value-added commodities

such as chemicals, polymers and

fertilizers for export. SABIC is now

the world’s largest ethylene producer.

These commodities were also

intended to create new industries,

helping Saudi Arabia to diversify and

to develop. Today, the company has

operations in over 40 countries with a

global workforce of over 40,000

individuals.

Ranked

among

the world’s largest petrochemicals

manufacturers, SABIC is a public

company based in Riyadh, Saudi

Arabia. 70% of the Company’s shares

are owned by the Saudi Arabian

government, with the remaining 30%

held by private investors in Saudi

Arabia and other countries of the Gulf

Cooperation Council. SABIC is

composed of six business units, each

headed by an Executive Vice

President. These are: Chemicals,

Polymers, Performance Chemicals,

Fertilizers, Metals and Innovative

Plastics. These six operating units

make four distinctly different kinds of

products:

• Chemicals - Chemicals and

Performance Chemicals

• Plastics - Polymers and Innovative

Plastics

• Fertilizers

• Metals

SABIC’s principle corporate offices

and headquarters are in Riyadh,

Saudi Arabia with major industrial

operations in the industrial city of

Al-Jubail on the Arabian Gulf, as well

10

SABIC and MRC (Mitsubishi Rayon

Company)

have

confirmed

incorporation of The Saudi Methacrylates Company (Saudi Methacrylates) in the beginning of the year

and the appointment of CTCI

Corporation as the EPC construction

partner for the plants be-ing built in

Al-Jubail, Saudi Arabia. SABIC and

MRC each have a 50% stake inthe

joint venture. Under construction are

acrylates plants for olefins and

aromatics with a project volume of

520,000,000 US$. The plants will have

a capacity of 250,000 t/y of MMA and

40,000 t/y of PMMA.

SABIC Europe and SABIC

in Germany

as in Yanbu on the Red Sea. Net

profits in 2013 touched SR 25.3 billion

(US$ 6.7 billion). Total assets stood at

SR 339.1 billion (US$ 90.4 billion) at

the end of 2013. SABIC’s overall

production has increased from 35

million metric tons in 2001 to 68.5

million metric tons in 2013. SABIC’s

global presence continues to grow

rapidly. Plans for expansion are

matched by the development of an

infrastructure of manufacturing

plants, distribution centers, offices

and storage facilities worldwide. The

company’s manufacturing, sales,

technology and innovation facilities

are located throughout the globe and

are managed by four regional offices:

the Middle East and Africa, Asia, the

Americas and Europe.

SABIC has awarded Munich-based

The Linde Group with a contract to

build the world’s largest carbon

dioxide (CO2) purification and

liquefaction plant for Jubail United

Petro-chemical Company (UNITED),

a manufacturing affiliate of SABIC.

The plant will be designed to

compress and purify around 1,500

tons per day of raw carbon dioxide

coming from two nearby ethylene

glycol plants. The purified gaseous

CO2 will be pipelined through the

piping corridor of the Royal

Commission of Jubail to three SABICaffiliated companies for enhanced

methanol and urea production. In

summary, an estimated 500,000 tones

of CO2 emissions will be saved each

year.

Linde Engineering Dresden will be

responsible for the concept and basic

engineering, front end engineering

design (FEED) and detailed engineering, procurement and con-struction

(EPC) of the facility to be completed

on a fast-track schedule. Mechanical

completion is set to be achieved in

2015.

The plant is the first carbon capture

and utilization (CCU) project of this

size to be real-ized in Saudi Arabia.

The reduction of CO2 emissions is an

important aim in both SABIC's and

Linde’s sustainability strategy.

German - Saudi Business Magazine

SABIC

SABIC Europe BV is a SABIC

subsidiary that includes all SABIC

Polyolefin activities in Europe and

employs nearly 6,000 people. Headquartered in Sittard, the Netherlands,

SABIC Europe has a European wide

network of sales offices and logistic

hubs, as well as three petrochemical

production sites in Europe: at Geleen

(the Netherlands), at Teesside (United

Kingdom), and at Gelsenkirchen

(Germany).

SABIC Deutschland was established

in 1972 to support the strong growth

of SABIC activity in the German,

Austrian and Swiss market. It has

currently 23 employees working in

Germany. Based in Düsseldorf,

SABIC Deutschland GmbH currently

serves more than 300 various sized

companies in the plastics sector. Most

of the polyethylene and polypropylene is processed by SABIC’s customers into end products for the

consumer market, mainly films for

packaging, but also applications such

as bottles, containers and pipes, as

well as automotive parts.

In Gelsenkirchen, SABIC Europe

produces several grades of polyethylene and polypro-pylene. It is the main

site for HDPE products in its bimodal

HDPE plant. The logistical facilities in

Gelsenkirchen are state of the art with

an innovative technology in the high

rise warehouse.

Oil-To-Chemicals

SABIC has announced plans to

develop the Middle East’s first oil-tochemicals complex in the Kingdom.

Construction works will be launched

after the completion of feasibility

studies. Competition is mooted for

2020. The project will be located in

Yanbu at the Red Sea coast. It is

expected to create 100.000 new jobs.

Yanbu complex will be able to process

200,000 barrels of oil a day.

When complete, a petrochemicals

refinery will process crude and feed

the produce into three steam crackers.

One will crack NGLs and liquefied

petroleum gas, while a second

will crack naphtha and a third

fuel oil.

The product slate of the three crackers

will include ethylene, propylene,

butadiene, ben-zene, toluene and

xylene. These will be fed into downstream processing facilities at the

complex.

Conservative

budget

estimates number the project to

$ 30bn.

SABIC has about $ 7.5bn-worth of

projects under execution, including

its $ 3.4bn elas-tomers joint venture

with the US’ Exxon Mobile at Jubail,

whereas Saudi ARAMCO has $ 30bnworth of petrochemicals schemes

under execution in the Kingdom.

The project would be the largest

project ever realized in the Kingdom

of Saudi Arabia. In fact, it would

outnumber everything ever projected

in the Kingdom two- or even threefold.

Oil-to-chemicals technology entails

crude oil entering the complex at one

end and an extremely diverse product

slate coming out the other. Processing

200.000 barrels per day would mean

that between 50.000 to 80.000

additional barrels would be required

every day to keep production

running.

Each $ billion invested in the downstream sector is producing four times

more employ-ment than the same

$ billion in the upstream side.

SABIC is set to spearhead the region’s

petrochemicals industry in its conversion to-wards a more diversified,

downstream-based future.

AHK Saudi Arabia - www.saudiarabien.ahk.de

11

German - Saudi Business Magazine

Zamil Group

Zamil Group

Sahara & Sipchem

Petrochemicals Co.

Zamil Group dates back as an

enterprise to the early 20th century,

but it has established its core industrial base only in the seventies. The

range of products the company

produces spans air-conditioning

manufacturing, plastics and steel

abrication, paints, cranes and heavy

process equipment. They are further

engaged in shipbuilding and repair,

port operations and maintenance,

petrochemicals

and

chemicals,

industrial investment and general

construction.

(Saudi International Petrochemical

Company), and Sahara Petrochemical

Company.

Today, the company

employs about 19,000 people in more

than 60 countries.

Zamil group has led the formation of

major successful local petrochemical

companies. These are Sipchem

Sahara

Petrochemicals Co.

Sahara Petrochemicals Company

(known as: Sahara) is a public

company, listed on Tadawul since July

2004. Its biggest shareholder is Zamil

Group with a 7.90 % share. 85.03 %

are owned by the public. The firm is

headquartered in Riyadh and

employs about 500 people. Sahara

Petrochemicals is involved in several

downstream projects in partnership

with major local and international

firms. It has three joint venture

production facilities that are located

in Jubail Industrial City. The company

further holds indirect stakes in five

petrochemicals firms.

Sahara operates within the materials

sector focusing on commodity chemicals. Its sub-sidiaries manufacture

propylene, polypropylene, acrylic

acid, mixed acrylate polymer,

ethylene, low and high density

polyethylene, caustic chlorine and

ethylene dichloride.

12

Sahara is based in Jubail, Saudi

Arabia and was established in

May 2004.

Sahara Petrochemicals participates in

the formation of some limited liability

companies in Jubail Industrial City, as

Joint

Ventures

with

foreign

companies to produce and market

primary materials like propylene,

polypropylene and polyethylene. It

has the capacity to produce 467,000

tons of propylene per year in addition

to 450,000 tons of polypropylene.

German - Saudi Business Magazine

Zamil Group

Sipchem

Saudi International Petrochemical

Company (Sipchem) was established

in 1999. It manufactures and markets

methanol, butanediol, tetrahydrofuran, acetic acid, acetic anhydride,

vinyl acetate monomer, as well as

carbon monoxide through its various

affiliates. Sipchem ranks among the

top 17 companies in the Arab World

in the category Petrochemicals. It has

been listed on Saudi Stock Market

since 2006. Sipchem serves its

customers in the construction,

solvents, automotive, electronics,

polymer, coatings, and pharmaceutical industries. Following its success

during the last decade, Sipchem

expands by launching several

down-stream projects to manufacture

Ethylene Vinyl Acetate, Low Density

Polyethylene, Ethyl Acetate, Butyl

Acetate, Cross Linkable Polyethylene, and Semi conductive Compound

that started in 2013.

Saudi International Petrochemical

Company (Sipchem) has chosen

Jubail Industrial City to build its

industrial complex for producing

various chemicals because this city is

con-sidered one of the leading industrial areas in the world having all

necessary infrastructure for such

14

large projects. The availability of raw

materials in the Eastern province, the

presence of Saudi Aramco that

supplies required feedstock at very

competitive prices and in large

quantities, the ease of export from the

city via King Fahd Industrial Port and

its relative proximity to South East

Asian countries to which most petrochemicals are exported, are other

reasons for this choice.

The site of Sipchem occupies an

area of over one million square

meters in the basic industries part

of Jubail Industrial City. Sipchem's

strategy aims at integrating present

and future petrochemical and

chemical products to form a series of

final added-value products in order

to contribute to increasing the

national production of Saudi Arabia.

Sipchem announced that its affiliate

the Sipchem Chemicals Company

(LLC), has awarded an engineering

design, procurement, construction,

and commissioning (LSTK) contract

for

building

a

polybutylene

terephthalate (PBT) Resin Plant to

ThyssenKrupp Industrial (former

ThyssenKrupp Uhde) company of

Germany on 18 June 2013. The plant

will produce PBT Resin with an

annual production capacity of 63

thousand metric tons and will be

located in Al-Jubail Industrial City.

The estimated project cost is

ap-proximately SR 600 million and

the plant is expected to start full

operations at the end of 2014. PBT

resin is a highly specialized thermoplastic polymer used in manufacturing compounds in the automotive,

the electrical, electronics and IT

material industries. new PBT project

will position the company as a

global player in the polymers and

engineering plastics industry.

German - Saudi Business Magazine

Ma’aden

German - Saudi Business Magazine

Henkel Polybit

Henkel Polybit

Industries Ltd.

Henkel KGaA, leading solution

provider for adhesives, sealants and

functional coatings, entered into a

joint venture agreement in 2005 with

Polybit Industries Ltd, an established

manufacturer of bitumen based

waterproofing products in the UAE to

form one of the largest companies

manufacturing waterproofing and

construction chemicals products in

the GCC region.

Ma’aden

The Saudi Arabian Mining Company

(Ma’aden) was formed by Royal

decree in 1997 to facilitate the

development of Saudi Arabia's

mineral resources and was originally

wholly owned by the Saudi

Government before 50% of its shares

were floated on the Saudi Stock

Exchange (Tadawul) in 2008.

Ma'aden has also developed its

activities beyond gold with the

development of Ma'aden Phosphate

Company, which started production

in 2011, its aluminium project which

is currently under construction and a

number of other projects. Ma'aden's

exploration teams are working to

expand available resources in existing

business areas as well as to broaden

the company's mineral portfolio.

16

Ma’aden created a Joint Venture with

SABIC for building a phosphate and

fertilizer production plant in Ras Al

Zour, which is an important project

for the Saudi petrochemical industry.

The 5.6bn USD project is set out to

produce

3

million

tons

of

diammonium hydrogen phosphate

(DAP), 400,000 tons of ammoniac and

200,000 tons of phosphoric acid

annually.

Another

Ma’aden

phosphate project, located in a new

industrial city called Waad Al Shimal

City, is anticipated to commence in

2016. Moreover, the company runs 18

mines in the country in which it

extracts mainly gold, aluminum,

phosphates and bauxite.

ThyssenKrupp from Germany, one of

the world’s largest steel producers,

employing approximately 160,000

people in 80 countries, has been

chosen to provide its ammonia

technology for Ma'aden’s new

ammonia plant II in close proximity

to Ras al Khair sea port on the Persian

Gulf. ThyssenKrupp also provides

components and systems for the

automotive

industry,

elevators,

escalators, material trading and

industrial services. The contract

of

ThyssenKrupp

Industrial

(former ThyssenKrupp Uhde), as

subcontractor of Dealim, comprehends

licensing,

engineering,

planning, and delivery as well as key

equipment and technology. The new

plant will be producing on a capacity

of 3,300 tons starting from 2016. It will

thus be one of the largest ammonia

plants worldwide. A new dual

pressure process, engineered by the

plant engineering specialist ThyssenKrupp will be deployed in Ma’aden’s

ammonia plant. This internationally

unique technique ensures that the

plant’s output is reliable and steady,

and

environment-friendly

in

addition. What is more, this

technique allows single-train plants

to produce 3,000 to 4,000 tons of

ammonia per day.

To date there are only two plants of

this size in operation worldwide,

with a third under construction. The

world’s biggest ammonia plant is also

operated by Ma’aden and went into

service in 2011. All plants use the

dual-pressure ammonia process

and

other

technologies

from

ThyssenKrupp Industrial.

“We are able to offer the latest

technologies

and

best-in-class

services to the customers in the fast

moving and growing construction

market in the region with the latest

technical know-how from Henkel”

says Naveen Antony, General

Manager Sales.

With manufacturing facilities in

Umm Al Quwain (UAE) and

Dammam (K.S.A.) with Sales offices

in UAE, Qatar, Bahrain, Oman,

Kuwait, and the Kingdom of Saudi

Arabia, the conglomerate with over

1000 personnel across all departments

is well represented in the GCC and

North Africa.

Competitive Advantage

In addition to offering extensive

range of waterproofing products,

Henkel Polybit also provides

complete system solutions for tiling,

industrial as well as interior floorings,

Polyurethane

insulating

foam

chemicals, structural joint sealants

and structural repair products.

Roofcare, a subsidiary of Henkel

Polybit, is one of the leading application contractors offering unique roof

waterproofing/thermal insulation as

well as external thermal insulation

systems assuring state of the art

application of high end products.

“We provide real solutions because

we manufacture all the products in

our portfolio, unlike other manufactures in the waterproofing industry,

who manufacture only limited

products of certain categories and

compliment it with an array of

outsourced

products,”

explains

Naveen Antony. “Being innovative

and having a lean structure and

strong customer orientation, strengthens our competitive edge and

maintains our leading position. This

approach, aligned with Henkel’s

global sustainability strategy, is the

driver for all new product developments in line with international and

GCC green building codes.”

Henkel Polybit’s technical service

team

works

closely

together

with contractors, engineering &

architectural consultants and authorities to ensure close customer

communication and react quickly to

international

demands.

market

trends

and

“Our technical service team also

conducts product trainings for

consultants and specialised applicators to support them in understanding our product’s chemistry and

scope of use” confirms Naveen

Antony.

Henkel Polybit Collaboration

The Joint Venture (JV) is growing

stronger and has enhanced the

enterprise potential by leveraging the

competence of Henkel in the Middle

East

&

Africa

region

and

implementation of international

business practices.

“We have had many synergies in the

JV which has worked in our favor, the

most prominent ones are in the

promotion of Henkel products

through our channels which resulted

in the largest parquet flooring job in

the Middle East for the tallest tower

in the world today (Burj Khalifa). We

have also had synergies in supply

chain and logistics which has helped

us to improve our efficiency in these

domains.

Working in a booming economy, the

heady growth rates also tested the

organization and stretched it to its

limit to respond to market demands.

Settling in with a JV where two

different schools of thought strive to

work together in such demanding

situation was the biggest challenge”,

says Naveen Antony.

AHK Saudi Arabia - www.saudiarabien.ahk.de

17

German - Saudi Business Magazine

Tasnee Petrochemicals

German - Saudi Business Magazine

Tasnee Petrochemicals

plants are owned by TASNEE and

Sahara Olefins Company and Basell

Moyen Orient Investments.

Tasnee has a further branch, the Saudi

Acrylic Acid Company (SAAC)

which is an integrated production

complex, the only one of its kind in

the Middle East. It produces various

chemical products using hydrocarbon

derivatives; 230.000 ton of Acrylic

Acid and Butyl Acrylates, 340.000 ton

of Butanol, and 80.000 ton of

Superabsorbent Polymers (SAP).

Tasnee Cristal Global

Tasnee Petrochemicals

The

National

Industrialization

Company (TASNEE) was established

in 1985 as the first joint-stock

industrial company fully owned by

the private sector. Tasnee made a net

profit of 65 million USD in the

three months ending September 30.

Tasnee (National Industrialization

Company) has a Polyether Polyol and

Advanced Polyol and Derivatives

plant under execution in Rabigh. The

total investment for that project

amounts

to

106,600,000

US$.

The plant shall produce 125,000 tons

of polyol yearly.

factory with an annual production

capacity of 455.000 ton, which was,

then, the largest of its kind worldwide, and the polypropylene (PP)

factory with an annual production

capacity of 450.000 ton.

TASNEE has constructed TASNEE

Petrochemical Complex in Jubail

industrial city which consists of two

projects:

TASNEE owns 75% of SPC, whereas

Basell ME Holding GMBH owns 25%,

and production goes back to early

2004. The company has increased

the annual production capacity of

Polypropylene by 270.000 ton which

lifts the total annual capacity of

this factory to 720.000 ton of

Polypropylene.

Saudi Polyolefin’s Company

(SPC)

The Company has two integrated

factories namely, the propylene

18

Saudi Ethylene and Polyethylene Company (SEPC)

SEPC has a unit for production of

ethylene and propylene and two

unites for production of polyethylene,

and propylene. The company’s

annual production capacity is one

million ton of ethylene, 285.000 ton of

propylene and 400.000 ton of high

density polyethylene (HDPE), and

400.000

ton

of

low

density

polyethylene (LDPE).

Cristal Global is the world’s second

largest producer of titanium dioxide

and commercial and specialized

titanium chemicals and environmental and personal care products. It is

one of the leading companies in the

area of titanium dioxide applications.

Tasnee holds a majority stake of

Cristal Globe. Cristal Globe is

supervising operation of eight plants

in five continents namely: Ashtabula

in Ohio, Baltimore in Maryland,

Salvador in Bahia, Stallingborough in

the UK, Thann in France, Yanbu in

Saudi Arabia, Bunbury in Australia

and a mine site in Barabia, Brazil. The

Company mainly focuses on the

customer satisfaction and the technical research and development

services.

Saudi Acrylic AcidCo. (SAAC)

Acrylic Acid Company is a Joint

Venture between Tasnee and German

Evonic AG. Evonic is one of the

world’s leading specialty chemicals

producers. It has been active in the

MENA-region for more than forty

years. Evonic has a 25 % share in the

Joint Venture. SAAC is a subsidiary of

Tasnee & Sahara Olefins (TSOC),

which is owned by Tasnee and Sahara

Petrochemicals. Distribution of the

superabsorbers produced in Jubail in

selected countries in the region will

be undertaken by a marketing joint

venture with SAAC, in which Evonic

has a 75 % share.

Production of ethylene/propylene

goes back to August 2008, and production of HDPE started in November

2008, and that of LPDE in March 2009.

The polyethylene two factories are

the largest of their kind worldwide.

The total investment cost of the

whole complex is SR 9.5 billion. The

AHK Saudi Arabia - www.saudiarabien.ahk.de

19

German - Saudi Business Magazine

SADARA

SADARA

German - Saudi Business Magazine

SADARA

The SADARA Chemical Company is

a Joint Venture of Saudi Aramco

(65 %) and Dow Chemical Company

(35%), established in 2011. In this

Joint Venture, one of the world’s

leading suppliers of energy is collaborating with one of the world’s leading

science and technology companies.

Sadara is constructing in Jubail

Industrial City, Saudi Arabia, the

world’s largest chemical complex

ever built in a single phase, with 26

integrated world-scale manufacturing plants that will produce more

than three million tons of diversified

chemicals and plastic products every

year. The complex will consist of a

hydrocarbon and chlorine-based

production facility. The facilities will

be integrating the refining, chemicals

and lubes for value addition and

portfolio diversification of Aramco.

Sadara will be a Fortune 500 company

within the first year of full operation.

The investment value for the project

is set to $20bn. Producing such vast

amounts of diversified chemicals and

plastic products will enable SADARA

to introduce new value-chains and

high-performance products throughout the kingdom. Production of

plastic and chemical products will

start in the first half of 2015.

20

Chemical Company (Sadara) recently

signed a long-term contract that will

see Linde supply Sadara with carbon

monoxide (CO), hydrogen (H2) and

ammonia (NH3) at Jubail complex.

Linde's Engineering Division will

design, deliver and construct the new

The complex will be, upon completion, among the largest fully

integrated chemical plants worldwide. The output will generate an

estimated $ 10bn in revenues within a

decade of commencing operations.

Sadara will be the first chemical

complex to crack naphtha in the

countries of the Gulf Cooperation

Council (GCC). This advance will

open the door to new specialty chemical plants and businesses in the

Kingdom and take the Saudi chemical

industry far beyond its existing

commodity

products.

Cracking

naphtha will make it possible to

produce new intermediate products,

which in turn will open up a whole

new range of additional downstream

opportunities.

Sadara is on track to deliver its first

products in the second half of 2015,

with the complex in full operation in

2016, according to MEED.

Product portfolio of SADARA will

include, besides oil and gas

chemicals, construction materials,

cosmetics and shampoos, detergents

and different kinds of elastomer

products. The Linde Group stock

company from Germany and Sadara

turnkey gases facilities at Sadara's site

in the Jubail 2 petrochemical cluster.

The company will be building a

two-stream HyCO plant, plus a

single-stream NH3 unit producing

waterless liquid ammonia. Linde will

also install a large NH3 storage tank.

The production units are scheduled to

be ready in 2015. Once built, they will

be operated by Linde's Gases

Division. Linde is setting up a local

gases company for on-site support.

Sadara will use carbon monoxide,

hydrogen and ammonia primarily for

the

production

of

aromatics,

isocyanates (MDI and TDI), amines

and hydrogen peroxide. Methylene

diphenyl diisocyanate (MDI) and 2,4

toluene diisocyanate (TDI) are used in

the production of polyurethanes an

essential component in many

products ranging from synthetic

fibers through insulating foam and

adhesives to mattresses and car seats.

More than half of the products Sadara

offers will be targeted for expanding

Asia Pacific markets, while the majority of the remainder will be sold in

other key growth countries in Central

and Eastern Europe, Africa and India.

AHK Saudi Arabia - www.saudiarabien.ahk.de

21

German - Saudi Business Magazine

German - Saudi Business Magazine

Evonik Industries

Evonik, the creative industrial group

from Germany, is one of the world

leaders in specialty chemicals.

Profitable growth and a sustained

increase in the value of the company

form the heart of Evonik’s corporate

strategy. Its activities focus on the key

megatrends

health,

nutrition,

resource efficiency and globalization.

Evonik benefits specifically from its

innovative prowess and integrated

technology platforms and is active in

over 100 countries around the world.

In fiscal 2013 more than 33,500

employees generated sales of around

€12.7 billion and an operating

profit (adjusted EBITDA) of about

€2.0 billion.

Evonik has been very successful in

the Middle East and North Africa for

more than four decades with offices

in Egypt, Aman, Jeddah and Dubai.

In view of its attractive geographical

position between Europe and Asia

and the plentiful supply of

petrochemical feedstock in the Gulf

States, Evonik regards this region as

strategically important and intends

to participate in regional growth and

expand its presence constantly.

22

Evonik’s activities within the

Kingdom of Saudi Arabia have been

stepped up considerably in 2014, as

the

Superabsorbents

80

kt/a

production joint venture with

TASNEE and Sahara in Al Jubail

came on stream and the sales and

marketing activities for the whole

Evonik product portfolio were

bundled into the newly established

Saudi Head quarters, Evonik Tasnee

Marketing LLC (ETM), a joint

venture between Evonik and Tasnee

Marketing. ETM, which has just

moved into its new offices located in

the Business Gate in Riyadh is not

only in charge of the sales of the

Superabsorbents from the plant in Al

Jubail to the baby diaper industry,

but also for the technical marketing

of important Evonik products for the

animal feed industry as well as

specialty chemicals and additives for

the petrochemical, polymer and

coatings industry.

The ETM office is headed by

General Manager Hassan Wardani,

an Egyptian/German Industrial

Engineer already experienced in

representing German Chemical firms

in the Middle East. He has been

successfully building up the new

joint venture in Riyadh in order to

further strengthen Evonik’s market

position in Saudi Arabia. Hassan is

supported by a strong team

of professionals with financial,

customer

service,

sales

and

marketing

backgrounds.

They

combine specialty product know-

how with an understanding of the

regional market and the Saudi

business environment in particular.

Hassan and his team very much

look forward, together with local

customers

and

partners,

to

continuing the long tradition of

Evonik in Saudi Arabia by seizing

further opportunities for the great

solutions Evonik products offer.ease

refer to our homepage for more

detailed product information:

http://www.evonik.com

Kingdom of Saudi Arabia, Riyadh,

address and contact details:

Evonik Tasnee Marketing

Company Ltd.

Phone +966 11 210 7179

Fax +966 11 455 9854

Qurtuba Business Gate,

Building C2

King Khalid International

Airport Road

11496 Riyadh

Saudi Arabia

www.evonik.com

Hassan Wardani (right), General Manager and Sulaiman M. AlKhereiji,

Director Marketing & Sales

AHK Saudi Arabia - www.saudiarabien.ahk.de

23

German - Saudi Business Magazine

German - Saudi Business Magazine

Middle East Company

Middle East Company

tonnes of stretch films according to

B+K MEC's managing director,

Yousif Al-Suwailem. 30% of the

regular workforce come from Saudi

Arabia;

their

colleagues

are

Lebanese, Filipinos, Indians, Bangladeshi, Egyptians and Sudanese.

Freddie de Mey has been head of

production since 2010. The Belgian

national was previously employed as

technical director at B+K France in

Pont Audemer. However, he was

already very familiar with the region

thanks to working at B+K MEC from

2002 to 2004.

In 2001, B+K MEC began producing

printed tubular films for automatically packaging PE granules plus

pallet protection films with 35

employees. To date, the plant

offers the most state-of-the-art film

production in the region. In addition,

B+K MEC is the only local producer

of stretch hood film.

Leading role in the region

B+K MEC joint venture very successful in Saudi Arabia

24

In the Arabian Peninsula region,

B+K MEC is assuming a leading

role in the plastic industrial

packaging market. For over ten years

now, the successful joint venture

undertaken by German familyowned

company Bischof + Klein and the two

Saudi family-owned companies

H. A. Al-Zamil & Bros. Co. and

Al-Rajhi House Enterprises plus

Ahmed A. M. Al-Ohali has been

producing FFS packaging solutions

on the basis of co-extruded films as

well as stretch hood and shrink

films. The company is based in

Al-Khobar, not far from the

Al Jubail industrial complex near to

Dammam.

A second plant is being planned in

the Rabigh petrochemicals complex.

“We are profiting from the petrochemicals industry’s strong growth

and our outstanding reputation in

the region”, explains Dr. Volker

Pfennig, managing director of the

B+K-GROUP. “Co-operation with the

Saudi companies is outstanding. We

are extremely satisfied.” Abdulaziz

Al Zamil, the former chairman of the

Royal Commission and one of the

leading lights of the Kingdom’s

industrialisation, is an honorary

mem-ber of B+K MEC's advisory

board. Since Saudi Arabia took the

decision not only to extract its raw

materials but also to further process

them itself, the petrochemicals

industry within the country has been

booming. B+K MEC's biggest

customer is SABIC (Saudi Basic

Industries

Corporation),

which

boasts various production locations.

In addition to Saudi companies, B+K

MEC also supplies numerous companies in the neighbouring states.

So far, B+K MEC has carried out

production on nine FFS lines and two

machines for the Smart-Flex® stretch

hood range. At the end of October

2011, two additional FFS film lines

will enter operation. The company's

annual capacity will then amount to

24,500 tonnes of FFS films and 5,400

The B+K-GROUP is a leading

European full-service supplier of

flexible plastic and paper packaging

and technical films which boasts a

strong worldwide network. In 2010,

B+K employed a total of around

2,400 staff at six production plants

in Germany, France, the United

Kingdom, Poland and Saudi Arabia.

The company generated turnover of

around 450 million Euros.

The B+K-GROUP’S product range

encompasses the entire range of

flexible packaging from traditional

industrial packaging and consumer

packaging to special films for

technical applications.

Bischof + Klein manufactures its

products using the latest systems for

m o n o / c o - e x t r u s i o n ,

gra-vure/flexographic

printing, solvent-based/solvent free

lamination and coating as well as for

extrusion lamination and coating.

Highly

developed

conversion

technology with product-specific

facilities for sealed, welded and

adhesive designs enable individual

production

according

to

customers’ wishes.

Bischof + Klein enjoys outstanding

relationships with all customers

within the local petrochemicals

industry and is anticipating further

growth. Dr. Volker Pfennig: “The

region is developing into a

crucial location for the production

of PE granules. We wish to continue

participating in this growth. At the

same time, we are contributing

towards the creation of jobs for the

young, up-and-coming generation.”

About Bischof + Klein

Bischof + Klein (2010: 2,400

employees, turnover approx. €450m)

is one of Europe's leading full-service

suppliers of flexible plastic and paper

packaging and technical films. The

B+K-GROUP manufactures at six

production plants in Germany,

France, the United Kingdom, Poland

and Saudi Arabia, and has a worldwide network of sales offices. B+K's

product range encompasses the

entire range of flexible packaging

and technical films from traditional

industrial packaging and consumer

packaging to special films for

technical applications.

If you have any further questions,

please contact:

Gudula Benning

Kommunikation

Tel. +49 (0) 54 81/9 20 - 1 99

Fax +49 (0) 54 81/9 20 - 98 1 99

gudula.benning@bk-packaging.de

AHK Saudi Arabia - www.saudiarabien.ahk.de

25

German - Saudi Business Magazine

German - Saudi Business Magazine

BASF The Chemical Co.

At BASF, we create chemistry for a

sustainable future. Our expertise

spans 150 years, during which time

the company has been committed to

combining economic success with

environmental protection and social

responsibility. Through science and

innovation, customers across various

industries are able to meet the

current and future needs of society

while conserving resources, ensuring

nutrition and improving the overall

quality of life.

BASF’s Innovation across

Industries

BASF’s petrochemicals division has

amassed a huge amount of production and application expertise,

supplying customers all over the

world with sustainable and intelligent solutions. Thanks to its global

presence, the division is represented

in Europe, North America as well as

the growing regions across Asia

Pacific and South America. The petrochemicals division is at the heart of

the unique BASF ‘Verbund’ and the

cornerstone of the petrochemicals

value chain. The petrochemicals

division produces and sells an

extensive range of high-quality basic

and industrial chemicals and

products tailored to the specific

needs of customers. These are used to

manufacture a variety of products

including PET-bottles, antifreezes,

coatings, superabsorbent polymers,

and cling film.

BASF’s main products in this area

include crackers, PVC and plasticizers, alcohols and oxygenated

solvents, industrial gases, and

alkylene oxides and glycols. Most of

these

performance

enhancing

products contribute to quality and

strength in other manufacturing

processes and end-products. The

Chemicals segment includes basic

chemicals and intermediates. Its

portfolio ranges from solvents,

plasticizers and high-volume monomers to glues and electronic

chemicals as well as raw materials for

detergents, plastics, textile fibers,

paints and coatings, plant protection

and pharmaceuticals. In addition to

supplying customers in the chemical

industry and numerous other sectors,

BASF also ensures that other BASF

segments

are

supplied

with

chemicals for producing downstream

products.

BASF’s Performance Products lend

stability, color or improved application properties to many everyday

items. The portfolio includes

vitamins and other food additives as

well as ingredients for pharmaceuticals and for hygiene, household,

cosmetic and personal care items.

Other products from this segment

improve processes in the paper

industry, oil and gas production,

mining and water treatment. They

help enhance the efficiency of fuels

and lubricants, the effectiveness of

adhesives and coatings and the

stability of plastics.

BASF’s Functional Materials and

Solutions segment offers bundle

system solutions, services and

innovative products for specific

sectors and customers, particularly

for the automotive, electrical,

chemical and construction industries.

The portfolio comprises of catalysts,

battery

materials,

engineering

plastics,

polyurethane

systems,

automotive and industrial coatings

and concrete admixtures as well as

construction systems such as tile

adhesives and decorative paints.

These solutions are also beneficial in

household applications and for

sports and leisure.

The Agricultural Solutions segment

provides innovative solutions in

chemical and biological crop

protection as well as seed treatment

and solutions to manage water,

nutrients and plant stress.

BASF’s research in plant biotechnology aims for greater efficiency in

agriculture, better nutrition and use

as renewable raw materials. The

company focuses its exploration and

production on oil and gas-rich

regions in Europe, North Africa,

South America, Russia and the

Middle East. Together with their

Russian partner Gazprom, BASF is

active in the transport, storage and

trading of natural gas in Europe.

26

In the Natural Gas Trading business

sector, sales were above the level of

the previous second quarter. Lower

gas prices were more than offset

by higher volumes. Because of

sharply falling gas prices on the

European spot markets for gas,

we were able to optimize our

procurement portfolio and considerably increase.

We emphasize on

sustainability

Constant innovation is vital to

BASF’s success and its sustainable

solutions. The company’s sustainable

management focusses on minimizing

risks, optimizing business opportunities and stakeholder engagements.

Globally, we are also committed to

establishing uniform standards for

environmental,

safety,

security,

health and labor standards. In line

with this, BASF was recognized in

the Dow Jones Sustainability Index in

2013 for its risk management system.

BASF integrates and diligently

adheres to sustainable criteria into its

processes. Using a data-based,

lifecycle monitoring approach, we

assess impact of our projects and

solutions.

Across the company,

we encourage sustainability on a

daily basis by helping employees

contribute to resource optimization,

conducting information sessions,

and facilitating constructive dialogue

between all stakeholders. The

company also participates in the

‘Together for Sustainability’ initiative

with leading chemical companies

in order to establish global standardization of supplier evaluations

and auditing.

BASF’s commitment

to Saudi Arabia

Saudi BASF is part of the Germanyheadquartered multinational BASF

the Chemical Company. Saudi BASF

was incorporated in January 2001,

when it started operations and

production of construction chemicals

in the Second Industrial Area in

Dammam.

Saudi BASF plays an active part in

the Saudi construction landscape,

supplying construction chemicals to

mega-projects including the two holy

mosques in Makkah and Madinah,

the building of the King Abdul Aziz

International Airport in Jeddah,

King Abdullah Economic City, the

Maaden Aluminium Smelter in

Ras Al Khair. BASF also supplies

products to prominent clients such as

the Royal Commission for Jubail

and Yanbu.

AHK Saudi Arabia - www.saudiarabien.ahk.de

27

German - Saudi Business Magazine

Alhamrani-FUCHS

Alhamrani-FUCHS

Petroleum Saudi Arabia Ltd.