Tightness in gasketed flanged unions

advertisement

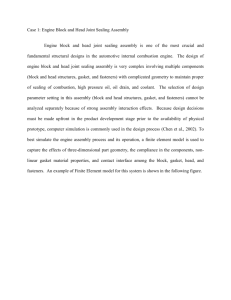

COLUMN European Sealing Association e.V. Tightness in gasketed flanged unions PART II: New Standards for Calculation and Testing. The early attempts in the USA and Germany By Francisco J. Montero, ESA member 6.- New pressure equipment calculation standards and new gasket testing methods To summarize Part I, new materials and environmental concerns brought forward the need to introduce new variables in the design, calculation, operation and maintenance of industrial pressure systems. The first attempts were made in the USA and Germany. Additionally, as we shall see in Part III, Europe must harmonize the applicable legislation and standards to ensure single market conditions as required by the Treaty of Rome. 6.1.- USA The search for “better” m and y factors started in 1974 at the Pressure Vessel Research Council (PVRC) on the initiative of the ASME Boiler and Pressure Vessel Code and ASTM committees. This goal was found too simplistic. Research was needed on gasket properties behind quantitative leak levels. In 1984, the PVRC widened its remit to include concerns about high temperature reliability of the new asbestos-free materials coming to the market. A new testing programme was launched at the École Politechnique de Montréal under the auspices of PVRC and the Material Testing Institute for the Chemical Process Industries (MTI). The main new test procedure was ROTT (Room Temperature Operational Tightness Test), designed to obtain the gasket parameters needed for the flanged connection calculation. A new dimensionless number, Tp (Tightness parameter), was introduced to link the tightness level of a connection with the internal pressure. On a given connection, for each gasket stress there is a Tp value. www.valve-world.net The higher the Tp value, the higher the tightness of the connection. The ROTT test is a combined compression, relaxation and helium leakage test at room temperature using 4” NB flanges. It consists of two parts. The first refers to the assembly conditions. Growing stresses are applied on the gasket and leakage measurements are taken with different inner helium pressure levels. The second part represents the changes on gasket stresses in service (unloading from hydraulic fluid pressure, external loads, etc.) by applying successive loading and unloading cycles and measuring the changes in leak rates at a constant inner pressure. Representing, in ordinates, the logarithm of the loading and unloading gasket stress and in abscissae, the logarithm of Tp, a graph (Fig.1) is obtained with three new gasket factors, Gb, a, Gs. Gb, is the loading stress corresponding to Tp=1, (log Tp=0). a, is the slope of the gasket loading line. Combined values of Gb and a describe the seating characteristic of a gasket and its capacity to develop tightness upon initial sealing. Fig.1 Log-Log gasket stress versus tightness parameter. Gs, is a theoretical point, representing the intercept of the set of possible unloading lines with the Tp=1 line. It represents the gasket potential to maintain tightness after pressurization and during operation. The PVRC drafted a new version of the calculation method, (Non-mandatory Appendix BFJ), incorporating the following aspects: • • • • • Introduction of the Tightness Class concept as a design criterion defining higher or lower tightness levels Introduction of the tightness-linked gasket parameters Introduction of a flange rigidity index Consideration of forces and moments external to the connection Consideration of the loads on the gasket’s bars at heat exchangers divisions. The PVRC presented the new calculation method, with these new factors, as an alternative method to the traditional and still valid ASME Code, Section VIII, Div 2, Appendix 2. The ROTT test itself gives interesting gasket data. The tests will be used later as the basis of the new DIN and EN standards, very similar to the ROTT test, but not to the subsequent PVRC graphic elaboration of the data. This graphic stage of the procedure is contradictory to results obtained in practice. The unproven hypothesis of a common intersection point with the Tp=1 axis for all the possible unloading lines has been proven wrong by experimental data. Generation of the three gasket factors, Gb, a, Gs, is thus not reliable and Non-mandatory Appendix BFJ remains only an alternative to the traditional calculation. November 2012 163 COLUMN - 6.2.- Germany A tentative first attempt was made in 1986 with standard DIN V 2505, revised into DIN 2505 E 4/90. This new calculation method did not use tightness-linked gasket parameters and was superseded in 2001 when EN 1591-1 was approved. In September 1995 the new DIN 28090 and DIN 28091 standards were approved and published to become the German reference for the asbestos-free sheet gasket materials, addressing fully the tightness quantification concerns. Based however in a small experimental basis, these standards have seen most of their content replaced by the new European EN standards. Their main traits were as follows: - DIN 28090 and DIN 28091 were conceived as complementary. The first refers to test methods and the resulting gasket parameters. The second refers to technical conditions - - of supply. The respective contents are summarized below. DIN 28090, Part 1, defines the test methods required to complete the qualification programme of all static gaskets and obtain the factors or parameters needed for the calculation of flanged connections. The tests themselves are quite similar to the North-American ROTT tests and are shown on the tables below: DIN 28090, Part 2, contains the test methods to be applied as part of the manufacturer’s quality control procedures. The requirements for the different materials are defined by DIN 28091. DIN 28090, Part 3, defines the tests for chemical resistance of the gasket materials. The main test is made with a flanged test rig containing the chemical fluid. The weight and compressive load on the rig are recorded and the rig is heated in an oven to the desired temperature. The weight loss and the fasteners relaxation are measured at frequent intervals during 1000 hours. DIN 28091-1 defines general requirements regarding dimensions and markings. Technical delivery conditions are defined for compressed fibre materials (DIN 28091-2), PTFE gasket materials (DIN 28091-3) and graphite gasket materials (DIN 28091-4). Leakage tests to determine the following parameters: Leak rate λ, for sealability classes: Compressive stresses on gasket L1,0≤ 1,0 mg.s-1m-1 σVU/L, minimum initial stress L0,1≤ 0,1 mg.s-1m-1 σBU/L, minimum service compressive stress L0,01≤ 0,01 mg.s-1m-1 Compression and creep tests to determine the following parameters: Compression Test Creep Test σVO maximum initial compressive stress ∆hD compression set under constant load σBO maximum service compressive stress σBO maximum service compressive stress ED elastic modulus 164 November 2012 In December 2004 EN 13555 became effective as the European Standard and DIN 28090, Part 1, was automatically superseded. However DIN 28090-2 and DIN 28091 are still in force in Germany and its area of influence. 6.3.– European Union. EN Standards In April 2001 the new EN-1591-1 standard was approved, within the framework of Directive 97/23/CE PED which requires the harmonization of everything related to pressure equipment. Its title: “Flanges and their joints – Design rules for gasketed circular flange connections – Part 1: Calculation method”. These rules are the basis for Annex G of EN 13445-3, as an alternative to the Chapter 11 method of the same standard. In 2009 a new version of EN 1591-1 was approved. We thus reach the new European standardization system that will be described on Part III of our series. The European Sealing Association (ESA) has produced this article as a guide towards Best Available Techniques for sealing systems and devices. These articles are published on a regular basis, as part of their commitment to users, contractors and OEM’s, to help to find the best solutions for sealing challenges and to achieve maximum, safe performance during the lifetime of the seal. The ESA is the voice of the fluid sealing industry in Europe, collaborating closely with the Fluid Sealing Association (FSA) of the USA. Together, they form a key source of technical information on sealing technology, which is the basis for these articles. For more information, please visit www.europeansealing.com www.valve-world.net