Low Carbon Powertrain Development

advertisement

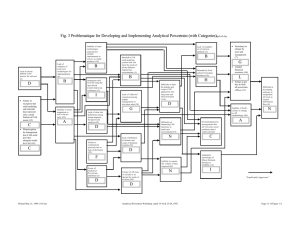

Powertrain & Vehicle Research Centre Low Carbon Powertrain Development S Akehurst, EPSRC Advanced Research Fellow Lean Powertrain The vehicle powertrain is the system that converts Realism Vehicle Vehicle TestTest raw fuel into tractive motion at the wheels. It is a Lean Powertrain Development Lean complex combination of interacting sub-systems Powertrain ct du under computer control with multiple actuators and Development o aims to Pr sensors. The lean powertrain development project maximise the Mistakes accuracy and al identified late aims to increase the validity and realism of the early realism of n i in the F Rolling Road early s development stages of the vehicle development process, by rd powertrain a process cause w increasing the utilisation and accuracy of simulation development costly To tasks to Advanced Engine Test recycling of tools and applying novel experimental techniques reduce costs the powertrain and time to Basic Engine Test development and procedures to evaluate prototype hardware market process before it is readily available. This should deliver Powertrain Simulation Cost & Complexity future, more efficient vehicles to market in a shorter timeframe and at reduced development costs. Engine Modelling Engine modelling in the powertrain development process is often separate from the experimental Applying Design of Experiments to Develop Models program. Techniques developed in the lean Experimental Experiments Build Models powertrain project utilise design of experiments “One Click” Simulink Design Model Block (DoE) techniques to maximise the use of simulation and experimental data, which can be combined to develop response surface models for important Cycle Simulation engine responses. These responses, to a range of Classical or Polynomial Models Space Filling actuator inputs, can be rapidly optimised using Neural Networks Designs mathematical algorithms to identify desired operating Radial Basis Functions Engine Test conditions and requirements for future hardware. A further benefit is that the response surface models may be utilised in real time engine modelling tasks for controller development and in Complete Historical Data Powertrain Emulation as described below Advanced Boosting Strategies Complete Powertrain Emulation Increasing air flow through an engine is the primary means of increasing power and fuel economy. Techniques developed in the lean powertrain project enable advanced boosting systems to be emulated before the prototype hardware is available. This allows early proof of Exhaust back benefit and reverse engineering of pressure valve to the new technology to meet desired emulate turbine performance requirements Forced induction simulator Boost Temp to supply controlled air To Co m flow to engine under test pr hardware e Mass Air Flow From Engine Manifold Pressure ss or To r Complete powertrain emulation allows the entire vehicle powertrain to be conceived early in the product development cycle. Real powertrain components (in this case the transmission) are integrated with virtual models of the engine and the vehicle. This enables early performance assessments to be made at minimal cost. At this early stage integrated control development and optimisation between the engine and transmission can be undertaken to support tasks later on in the development process. Integrated Calibration and Optimisation of Engine & Transmission Controller Calibration tool Advanced Transmission Facility Utilised for Complete Powertrain Emulation Virtual Engine & Driver Models in Real Time Software qu e Inlet Pressure Shaft Speed VGT Position (ECU) Pressure Ratio Pulsating exhaust pressure used T ne rbi Tu u orq Real Transmission & Controller Shaft Model e ω shaft = ∫ Tq turb − Tq comp J shaft Virtual Vehicle Model in Real Time in Software Real Engine Controller Exhaust Temp Exhaust Mass Flow Viewing Trade-Offs and Finding Optima dt Engine set point to input dynamometer Input Dynamometer Emulates Engine Output Dynamometer Emulates Vehicle Dynamometer Control Virtual software models of boosting hardware send set point commands to emulation hardware Control & Data Acquisition System (Includes Safety) Funded Under EPSRC Project Codes EP/C540883/1 & EP/C540891/1 Vehicle set point to output dynamometer