Fact Sheet

Fact Sheet

BKT6091 is a high-speed power take-off for propeller shaft operation. The PTO is connected directly to the rear end of the gearbox housing and is powered by the gearbox’s countershaft.

Extensive development work, involving both rig and field tests, has resulted in an extremely reliable power take-off that is specially matched to its range of application.

This creates the prerequisites for achieving high vehicle productivity. The power take-off can be engaged and disengaged by means of an easily accessible switch on the dashboard.

This switch actuates an electric pneumatic system which controls engagement of the power take-off with the help of compressed air.

The simple yet reliable design of the power take-off results in flexible use, long service life, and good availability resulting from a low service requirement.

A complete hydraulic system developed by Volvo, incorporating hydraulic pumps, oil tanks, and connecting parts, is available for each power take-off.

The BKT6091 has the following characteristic product features:

• A compact power take-off with few constituent parts, resulting in low weight.

• Drive by means of the gearbox’s countershaft results in insignificant power losses and high operational reliability.

• Direct engagement and disengagement performed from the driver cockpit gives increased driver efficiency.

Power take-off

BKT6091

Specification

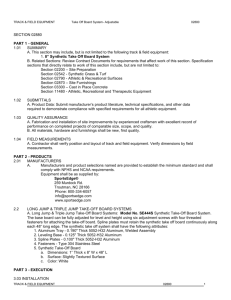

Type designation ............................................ BKT6091

Weight .............................................................. 13.5 kg

Type ............................... Clutch-dependent, high-speed

Location ............................ Rear end of gearbox housing

Max. permitted torque ..................................... 300 Nm

Max. permitted power rating ............................ 60 kW 1)

Direction of rotation of PTO viewed towards the recess ............................ Counter-clockwise

Flange size ......................................................... DIN90

Ratio in combination with gearbox:

T600A/T700A .................................................... 0.84:1

T600B/T700B ..................................................... 1.00:1

TO800 .............................................................. 1.245:1

1) The specified value applies to normal operating conditions. In the case of continuous operation for more than 15 minutes, the power output is limited to 50 kW.

2003-06-02 ENG Version 01

Pump flow l/min at an engine speed of:

Pump *)

T600A/T700A T600B/T700B

1000 rpm 1500 rpm 1000 rpm 1500 rpm

25 20.1

30.2

24 36

41

51

31.9

41.2

47.9

61.75

38

49

57

73.5

61 51.2

76.9

61

81 67.2

100.8

80

53/53 45.3/43.7

68/65.5

54/52

91.5

120

81/78

70/35 58/30.3

87/45.3

69/36 103.5/54

Pump *)

TO800

1000 rpm 1500 rpm

25 29.9

44.8

41

51

61

47.3

61

75.9

71

91.5

113.8

81 99.6

149.4

53/53 67.2/64.7 100.8/97.1

70/35 85.9/44.8 128.8/67.2

*) F1 Plus and F2 pumps from VOAC Hydraulics Division.

Refer to the data sheets issued by VOAC Hydraulics

Division for more detailed information on the pumps.

Fact Sheet

Power take-off

BKT6091

Easy to install power take-off with high level of operational reliability

The BKT6091 is a high-speed power take-off that is used for applications involving propeller shaft operation.

The PTO consists of a cylindrical gear wheel with an engagement and disengagement mechanism.

Because the PTO is designed to match the gearbox from the outset, in terms of both installation and power output, the installation costs will be low and the level of operational reliability high.

Engagement and disengagement from the driver cockpit

The power take-off can be engaged and disengaged by means of an easily accessible switch on the dashboard. This switch actuates a solenoid valve which opens or closes the supply of compressed air to the power take-off's operating cylinder.

When the switch is turned ‘on’, the piston (1) is pushed into the operating cylinder by compressed air from the solenoid valve.

The piston forces a lever (2) to turn so that the clutch sleeve (3) connects the teeth on the input shaft (4) with the gearbox's countershaft (5).

When the power take-off is to be engaged, the clutch pedal must be depressed for 5 seconds at the same time as the engine is allowed to idle.

This is to enable the countershaft speed to be reduced.

Complete hydraulic system gives high vehicle productivity

The power take-off can be integrated with a complete hydraulic system developed by Volvo and which can be matched to most ranges of application in which the work is performed by hydraulic means.

The hydraulic system comprises: robust single- and dual-circuit hydraulic pumps that are powered by a propeller shaft.

Single-circuit pumps cover the displacement range 20–110 cm 3 /rev, and the dual-circuit pumps have a displacement distribution of 55/45 and

70/35 cm 3 /rev.

The power take-off is powered by means of an input shaft (1) connected to the gearbox’s countershaft (2).

The drive power is transmitted from the input shaft to the output shaft (3) to which a companion flange (4) is connected.

The input shaft is journalled in a needle bearing in the gearbox’s countershaft and in a roller bearing in the PTO housing, while the output shaft is journalled in two robust roller bearings in the PTO housing.

1

4

Power take-off disengaged

3

2

1

2

1

4

Power take-off engaged

3

2

5

4 3 hydraulic tanks with optional volymes of 50, 75, 95, 130 och 200 litres.

They are fitted with disposable types of oil return and air filters, a level glass with thermometer and indicator for the oil return filter.

The fronts of the tanks are set at an angle to facilitate filling and topping up with hydraulic oil and replacing the oil return filter cartridge.

Mounting brackets matched to all truck variants are provided for the tanks.