Safety Center Tower Grounding - Copper Development Association

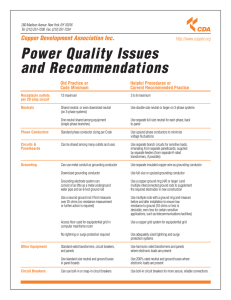

advertisement

Safety Center Tower Grounding Professionally Installed and Maintained Lightning Protection and Grounding Systems Ensure Uptime and Reduce County’s Costly Repairs Municipal safety centers typically combine police, fire, 9-1-1 and other emergency services – they must remain operational at all times. If communications systems fail, dispatchers are helpless, emergency workers can’t find each other and the public could be at risk. Victoria Wolber is the director of emergency management and communications for Macomb Country, Michigan. She is based at COMTEC, the county’s impressively rebuilt, 25,000 square feet safety center in Mt. Clemens, Michigan in the southeastern part of the state, (Cover). “It’s critical that our communications services remain up and running because we’re often dealing with life-and-death situations in our 9-1-1 dispatch center, and we have to get our personnel to the injured as fast as possible,” said Wolber. All communications systems need antenna towers, which naturally invite lightning strikes that can cause damage to a center’s sensitive equipment. The solution: equip the towers with robust, correctly designed and properly installed lightning protection and grounding systems to direct lightning energy away from sensitive equipment and harmlessly into the earth before it damages equipment. COPPER ELECTRICAL APPLICATION - POWER QUALITY | WWW.COPPER.ORG The Macomb County, Michigan COMTEC safety center was rebuilt from an existing structure and upgraded to modern codes, including those dealing with grounding and lightning protection. It has never suffered lightning-induced damage. “We knew that we had to call in experts who understood the lightning protection and grounding fields, knew our systems and knew what to do to protect our critical assets,” said Wolber. “We did that, and we’ve never had any lightning-caused downtime here at COMTEC.” Wolber and her electrical contractor hired Greg Fair, a project manager and field superintendent with Guardian Equipment Company, a Michiganbased firm that specializes in lightning protection. Since COMTEC was relocating to an existing structure with a pre-existing tower, the challenge was to formulate a system that met the applicable codes and accommodate the site’s components. FIGURE 1. The COMTEC center’s transmission tower was grounded when built, but age and corrosion had deteriorated the connections. Upgrades during restoration of the center included exothermically welded connections, new grounding electrodes and a buried copper ring ground. During re-construction, the building’s open walls helped Guardian Equipment advised the engineers on designing and concealing the new grounding system. The building’s antenna tower (Figure 1) had previously been grounded, but the existing mechanical connection method was found to be inadequate. Existing connections to the tower showed signs of aging. They were mechanical, in one case using a simple water pipe connector, and they had become loose over time. There was also some corrosion, which increases ground resistance (Figure 2). FIGURE 2. Tower-grounding cables were originally bonded with mechanical clamps such as the one shown at the far left foreground, but age and corrosion had loosened the connections, raising ground resistance. The facility upgrade included replacing those connections with exothermically welded bonds and 28R Class II lightning conductor cable, center. COPPER ELECTRICAL APPLICATION - POWER QUALITY To aid in the new grounding system design, Fair and his team referenced several codes that dealt specifically with grounding for lightning protection: Underwriters Laboratories’ UL96A: Installation Requirements for Lightning Protection Systems,” the National Fire Protection Association’s NFPA 780: Standard for the Installation of Lightning Protection Systems, NFPA 780 and the Lightning Protection Institute’s LPI 175: Standard for the Design – Installation – Inspection of Lightning Protection Systems. The well-known and often used Motorola 56A, which also deals with towers, did not fall within the scope of work. Fair and his team began with a site survey to guide their engineers in designing the work. Following the survey, the team installed air terminals (also called lightning rods, Franklin rods and strike termination devices, STDs) at 20 foot intervals along the roof’s perimeter and elsewhere on the roof. The perimeter cable was used as a ring ground from which to drop down-conductors to driven 10 feet x ¾-inch copper-clad electrodes in the ground below. Approximately 15 driven electrodes were spaced about 100 feet apart surrounding the structure. Two of them specifically bonded to the ring-ground surrounding the tower. FIGURE 3. Copper lightning cable is unobtrusive when mounted against brown or red-brown surfaces such COMTEC’s brick walls. This property of the red metal is architecturally advantageous when installing rooftop lightning protection systems. “We grounded the tower with 28R cable, which is a special Class II lightning conductor consisting of 28 strands of bare, braided AWG 14-Gage wire,” said Fair. “We sometimes use tinned wire when our engineer of record thinks that it would give the conductor a longer service life, but that wasn’t the case here.” Class II cable is used for structures taller than 75 feet. It is also good when conductors have to be exothermically welded to ground rods, building steel, or in this case, to the tower itself. “On the two-story side of the structure, which is less than 75 feet tall, we used 29-strand x 17-Gage Class I wire. It’s a little thinner and less obtrusive to the eye,” said Fair (Figure 3). FIGURE 4A. A proper grounding cable connection to a gas service line. The silvery, copper-alloy, UL-approved cable clamp is cadmium plated to prolong corrosion resistance. COPPER ELECTRICAL APPLICATION - POWER QUALITY All services, such as electric, water and gas were bonded together at a common ground potential and bonded to the building’s grounding system, in accordance with code requirements (Figures 4a and 4b). Fair tags his installations where appropriate to inform workers of the Codesensitivity of those connections. FIGURE 4B. Grounding of the center’s water and gas service entrances is provided by the heavy-gage copper cable, right. The tag shown on the left alerts technicians that grounding to gas and other services is code-mandated. “We also bonded to exposed building steel,” said Fair. “There are people who believe that using building steel is not advisable because it can lead to side flashes since the entire structure becomes energized when a strike hits. But it won’t do that if the building is properly grounded and if the sizes of the conductors are adequate to provide the path the lightning current preferentially follows, i.e. through the path of lowest resistance and/or impedance (emphasis by Fair). We provide that path.” FIGURE 5. When lightning strikes one of the nine auxiliary sites that the county operates, energy is bled off the coax on the vertical run (Fig. 7), the coax where it penetrates the firewall (see above), and the interior side of the firewall (Fig 9). COPPER ELECTRICAL APPLICATION - POWER QUALITY Bonding the grounding system to building steel is also a code-mandatory practice. However, while building steel might provide a de facto ground/earth connection, a continuous electrical path cannot always be verified and grounding connections should properly be made via adequately sized copper down-conductors bonded to appropriately spaced, driven electrodes. A rooftoplevel ring-ground surrounding the structure might also be employed, as was done at the COMTEC facility. The ring simplified installation of the lightning protection/ grounding system, and its copper down-conductors, blended in well with the center’s brick walls. FIGURE 6. One of several auxiliary transmission towers operated by Macomb County. The towers extend emergency communications well beyond the range of the COMTEC headquarters tower. All towers are equipped with the same high-quality, all-copper grounding systems as those installed at COMTEC. FIGURE 7. A copper grounding bar is mounted on the tower approximately 10 feet above grade. The six small-diameter cables leading upward from the bar connect to shields on cables and/or waveguides leading down from antennas above. The two heavy grounding cables leading downward from the bar are the down-conductors shown in Figure 9. Auxiliary Transmission Facilities Equally Well Protected Macomb County operates several auxiliary transmission facilities that are located such that they provide emergency communications to the county’s 850,000 residents throughout the large 479 square miles jurisdiction. The auxiliary facilities are each equipped with a tower (Figure 6). The towers, as well as the facilities themselves, are protected from lightning strikes by robust, all-copper grounding systems. • Grounding connections from antennas, cables and shielded wave guides on the tower are made to a ¼-inch thick copper grounding bar affixed to the tower steel about 10-feet above grade (Figure 7). From there, two heavy-gage copper down-conductors lead to a ring ground buried around the tower’s base. The ring is bonded to driven, 10-feet x ¾-inch copper-clad electrodes. Also connected to the ring is a third copper cable. That cable grounds the tower’s steel structure and is exothermically welded to the tower’s base to ensure durability and lasting reliability (Figure 8). The coax braid is further grounded at the exterior and interior firewalls (Figure 5). FIGURE 8. The photo on the right shows the reliable, exothermically welded grounding connection to the center cable, which connects the tower’s steel structure to a buried bare-copper ring ground surrounding the tower and to the interior grounding bar shown in Figure 9. COPPER ELECTRICAL APPLICATION - POWER QUALITY • The ring-round and its driven electrodes, plus down-conductors from the tower and grounding conductors from elsewhere in the facility are collected at an interior copper grounding bar located on the inside of an exterior wall just below the space for cable penetrations (Figure 9). • Finally, all sensitive electronic equipment is properly bonded in its racks, with cables firmly attached to individual pieces of equipment at locations that can easily be inspected (Figure 10). The racks themselves are also grounded. It should be pointed out that neither the COMTEC facility nor any of the county’s properly grounded auxiliary transmission stations have ever experienced a lightning-induced service disruption. For that, Macomb County residents can thank smart decisions by COMTEC management, proper design and installation, regular maintenance, and of course, robust, all-copper grounding and lightning protection systems. The Principals FIGURE 9. The facility’s interior grounding bar is located on the inside of an exterior wall, immediately below penetrations for cables from the tower. Various green wires connect to those cables and to other grounding bars at the facility. Victoria Wolber is Director of Emergency Management and Communications for Macomb County, Michigan. Wolber is a firm advocate of 100 percent uptime for the safety center and insisted that the work of re-structuring the center’s electrical grounding and lightning protection systems be undertaken by professionals knowledgeable in the technology. She can be reached at vicki.wolber@macombgov.org. Greg Fair is a 20-year veteran project manager and field superintendent with Guardian Equipment, a Michigan firm that specializes in lightning protection. Guardian designed and installed the COMTEC center’s grounding and lightning protection systems working to the three major lightning protection codes. Fair can be reached at greg.fair@guardianequipment.com, 248-449-5200. FIGURE 10. Properly bonded communications equipment features individual ground leads to each cabinet. The rack itself is also bonded (not shown). Grounding, bonding and power feeds for sensitive equipment should be isolated from standard equipment or lightning circuits. COPPER ELECTRICAL APPLICATION - POWER QUALITY copper.org A6173 XX/16