Characterization of Friction Loss in Pelton Turbine - Purdue e-Pubs

advertisement

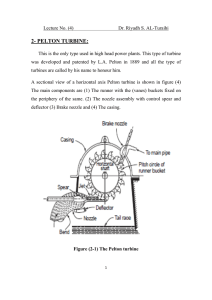

Purdue University Purdue e-Pubs International Refrigeration and Air Conditioning Conference School of Mechanical Engineering 2010 Characterization of Friction Loss in Pelton Turbine Yannick Beucher ARMINES / Ecole des Mines de Paris Elias Voulawz Ksayer ARMINES / Ecole des Mines de Paris Denis Clodic ARMINES / Ecole des Mines de Paris Follow this and additional works at: http://docs.lib.purdue.edu/iracc Beucher, Yannick; Ksayer, Elias Voulawz; and Clodic, Denis, "Characterization of Friction Loss in Pelton Turbine" (2010). International Refrigeration and Air Conditioning Conference. Paper 1077. http://docs.lib.purdue.edu/iracc/1077 This document has been made available through Purdue e-Pubs, a service of the Purdue University Libraries. Please contact epubs@purdue.edu for additional information. Complete proceedings may be acquired in print and on CD-ROM directly from the Ray W. Herrick Laboratories at https://engineering.purdue.edu/ Herrick/Events/orderlit.html 2274, Page 1 CHARACTERIZATION OF FRICTION LOSS IN PELTON TURBINE Y. BEUCHER1, E. BOULAWZ KSAYER1, D. CLODIC1 1 Center of Energy and Processes, Ecole des Mines de Paris, Paris, FRANCE E-mail : yannick.beucher@mines-paristech.fr, elias.boulawz_ksayer@mines-paristech.fr ABSTRACT The Pelton turbine can be used as a two-phase expander. The characterization of the Pelton turbine as two-phase expander consists in analyzing the power loss sources to evaluate the machine performance. In this study, the friction loss of a Pelton wheel is presented. A Pelton wheel has been realized with aluminum buckets and has been mounted on a test bench. The examination of experiments dealing with drag force in the Pelton turbine shows that the wheel friction losses are an important part of turbine losses when it is shrouded and operate in high density atmosphere. Experimental results show that losses by drag friction of a turbine enclosed in 0.5 MPa of R-134a atmosphere and rotating at 3000 rpm, can reach 3000 W, which is equal to the available power in the fluid jet. A CFD model of Pelton wheel has been done to analyze and reduce the friction losses in order to develop an efficient turbine. Modeling shows that with lowering the number and the size of the buckets, friction loss can be decreased by 30%. 1. INTRODUCTION In conventional vapor compression cycle, energy available in the high-pressure refrigerant is not recovered. During the isenthalpic expansion, the kinetic energy in liquid flow is dissipated to the refrigerant as friction heat. Due to the separation between refrigerant expansion step and kinetic energy recovery step, kinetic turbines are an attractive process for refrigerant expansion energy recovery. Many studies have been performed on turbine as two-phase expansion device but essentially for geothermic applications (Elliott, 1982, Comfort and Beadle, 1978, Austin et al., 1973). Some researches have been performed more specifically on two-phase mixture flow (air and water) on the Pelton turbine, or with kinetic turbine for refrigerant expansion (with CO2 and R-22) (Elliott, 1982, Akagawa and Asano, 1986, Tondell, 2006). The Pelton turbine, which is an impulse turbine, composed of a wheel with buckets and a nozzle (Figure 1) can be used as expansion device for refrigerant as R-134a. The nozzle converts the potential pressure energy of refrigerant into kinetic energy. The jet hits buckets and forces the wheel to rotate, which generates mechanical energy on the shaft. The Pelton wheel is enclosed and undergoes mainly vapor refrigerant density (which corresponds to evaporator pressure). This atmosphere increases friction losses that are generally neglected when the Pelton turbine is used in hydroelectric dam surrounded by air at atmospheric pressure. Figure 1: Schematic view of a Pelton Turbine. A Pelton wheel will be analyzed to evaluate and characterize drag loss due to the fluid friction on the Pelton buckets during wheel rotation. International Refrigeration and Air Conditioning Conference at Purdue, July 12-15, 2010 2274, Page 2 2. DRAG THEORY A solid body moving in a fluid is subjected to a force, called drag, which is opposed to body motion. The drag force depends on the fluid (or body) velocity, the contact surface area, the fluid density and an empiric factor called drag coefficient. The power loss by drag friction is estimated by Eq. 1: ܲௗ ൌ ܥ ߩܸ ଷ ܣ ʹ (1) The Pelton wheel is composed of three elements: the disk or runner, the buckets, and the shaft. All components generate some losses by friction with the fluid. Tondell (2006) uses a general formula with an empiric coefficient to evaluate the overall loss: ܲ௧ ̱߱ଷ ܴସ ሺܴ ݇Ǥ ݄ሻ (2) With h the bucket height and k an empiric coefficient taking into account the influence of the three elements. To evaluate disk friction (in the Pelton wheel, the disk is the runner on which buckets are attached) several studies have been done. Gülich (2003) presents many correlations for different flow regimes and geometric parameters. Some studies on computer hard disk have been done and can be useful for high rotating speed. To evaluate the influence of buckets on friction, theory about gear friction loss is used. Actually geometries of Pelton wheels are similar to gear where buckets should be substituted by teeth. Diab et al (2004) evaluate the power loss due to friction on gear teeth by: ݔ ܲ ൌ ܼߩܾ߱ݔଷ ሺܴ െ ሻଷ ʹ (3) Diab et al. add a variable, x, which represents the teeth active length. The active length is the teeth length that enters in contact with the fluid. In fact, when the gear is rotating, each tooth is hidden by the following tooth in the runner and so a certain part of each tooth is not in contact with the fluid (Figure :2). The active length depends on the size and number of buckets. The higher the number of buckets, the more the buckets hide themselves, but in the same time, the whole active length increases. Considering the angle between buckets, the active surface could be estimated for the tested Pelton wheel (Figure 3). 100000 90000 80000 Surface(mm²) 70000 Activesurface 60000 Totalsurface (without protection) 50000 40000 30000 Figure 2: Schematic view of the gear active length. 10 12 14 16 18 20 22 24 26 Bucketnumber Figure 3: Comparison between the active surface and the total surface of the Pelton wheel tested as a function of the bucket number. 3. EXPERIMENTATIONS AND PELTON LOSSES EVALUATION A test bench is mounted to evaluate the turbine losses. The Pelton wheel has 24 aluminum buckets (Figure 4). The wheel axis is connected to a motor via a torque meter and the enclosure tightness is ensured by lip seal (Figure 5). Characteristics of Pelton wheel are given in Table 1. International Refrigeration and Air Conditioning Conference at Purdue, July 12-15, 2010 2274, Page 3 Table 1 Pelton wheel characteristics. Wheel radius (without bucket) (mm) 130 Wheel thickness (mm) 14 Axis radius (mm) 10 Bucket height (mm) 60 Bucket width (mm) 60 Bucket depth (mm) 17 Bucket thickness (mm) 3 To evaluate the friction losses, the Pelton wheel is driven by the motor from 0 to 3000 RPM. The enclosure is filled with air or R-134a gas from 0.05 MPa to 0.5 MPa. The resistive torque is measured by a torque meter during the wheel rotation. A test is done with a vacuum enclosure in order to measure mechanical losses only (seal and bearing frictions) and to substract it from others results. Besides, the Pelton wheel will be modeled on the commercial CFD software Fluent. First, simulations are made with the experimental conditions. Then, several simulations are performed to know the impact of material roughness, of the number of buckets and of the shape of buckets on the friction losses. Figure 5: Schematic view of the test bench. Figure 4: Picture of Pelton wheel tested. 4. EXPERIMENTALS RESULTS Summary of some experimentation results of the test bench is shown in Figure 6. The experimentation made in vacuum shows linear losses. The resistive torque applied by seal and bearing is constant and the power loss is proportional to the rotating speed. The power loss increases with the gas density and the rotating speed. Loss paths are coherent with the drag theory: they rise linearly with density and proportionally to the power three of the rotating speed. For high density, mechanicals friction losses are negligible compared to drag friction losses. 4000 4000 r134a5bar 3500 3000 r134a4bar 3000 2500 r134a2bar 2000 r134a1bar 1500 air5bar 1000 500 Powerloss(W) Powerloss(W) 3500 2500 r134a5bar experimental 2000 r134a1bar gearformula 1500 air2bar 1000 vacuum 500 0 R134a5bar gearformula r134a1bar experimental air2bargear formula 0 0 1000 2000 3000 Rotatingspeed(RPM) Figure 6: Experimental results of the Pelton friction losses 0 1000 2000 3000 air2bar experimental Rotatingspeed(RPM) Figure 7: Comparison between experimental results of the Pelton friction power losses and calculated results with gear formula. With experimental results, it is possible to extract a coefficient (corresponding on CD*A in the drag equation (1)) specific to the tested Pelton turbine. Nevertheless, this coefficient is not constant if the Pelton wheel is used with air or R-134a. It means that the drag coefficient takes into account a large number of phenomena that are International Refrigeration and Air Conditioning Conference at Purdue, July 12-15, 2010 2274, Page 4 difficult to evaluate theoretically. However, Equation (3) for the gear friction loss can be used to estimate the power loss by friction (Figure 7). This formula gives good results compared to experimental data and can be used in first approximation to evaluate the Pelton turbine losses (calculated losses are majored by 20% in Figure 7). With these turbine loss results, it is possible to evaluate the energy potential of the Pelton wheel in a refrigeration system. Assuming that the expansion in the nozzle is isentropic, the maximum power of the jet and its speed can be calculated. So, for a given refrigerant flow, the turbine maximum recoverable power can be estimated. ܸ ൌ ඥʹɄ୬ ሺ݄௦ െ ݄ ሻ ܲ ൌ ݉ᇱ כ ܸଶ ʹ (4) (5) ܲ ൌ ʹ כɄ୵ ݉ כᇱ ܷ כ൫ܸ െ ܷሻ൯ (6) The evaluation is done for a 100 kW cooling capacity chiller (Table 2). The maximum available jet power is 3000 W, and the Pelton wheel must rotate to 3000 RPM to recover all the jet power. At this evaporating pressure, and rotating speed, the friction losses (Figure 6) are almost equal to the available maximum jet power (Figure 8). Maximumpoweravailable 3500 3000 2500 Table 2: Characteristics points of a 100-kW chiller. 2000 1500 1000 500 0 0 500 1000 1500 2000 2500 3000 3500 RotatingSpeed(RPM) 100 kW chiller T condenser (°C) 45 P condenser (bar) 11.6 Subcooling (°C) 3 T evaporator (°C) 2 P evaporator (bar) 3.14 R134a flow (kg/s) 0.677 Vj isentropic (m/s) 95 Figure 8: Theoretical maximum power recoverable by the Pelton wheel used in 100-kW chiller The energy available during the fluid expansion is compared to the energy lost by friction. In considering a chiller (7-12 °C) having an evaporation temperature of 2°C, a condensing temperature of 45°C, a sub-cooling of 3 K and a superheat of 5 K, the available power from the Pelton turbine has been calculated (with an expansion efficiency of 80% and a recovery yield of the wheel of 60%). For the evaporation temperature of 2°C, the isentropic speed of exit from the nozzle is 95 m/s, so the optimal radial velocity of the Pelton wheel is 47.5 m/s, which corresponds to 2800 RPM for the tested whee. Friction losses are estimated with the gear formula majored by 20%. Several fluids are evaluated and calculations show that the Pelton turbine becomes interesting for a chiller capacity of 100-kW (Figure 9). The turbine efficiency can reach 40% for a chiller of 200 kW operating with R-152a (Figure 10). International Refrigeration and Air Conditioning Conference at Purdue, July 12-15, 2010 5 45% 4,5 40% 4 35% Turbineefficiency RecoverablePower(kW) 2274, Page 5 3,5 3 r134a 2,5 propane 2 1,5 r152a 1 30% 25% r134a 20% propane 15% r152a 10% 1234yf 1234yf 5% 0,5 0 0% 0 50 100 150 200 250 0 50 ChillerCapacity (kW) 100 150 200 250 ChillerCapacity (kW) Figure 9: Recoverable power by the Pelton turbine tested for several fluids. Figure 10: Turbine efficiency depending on the chiller capacity. 5. SIMULATIONS RESULTS For friction power losses, one of the most influencing parameters is the surface area in contact with the fluid. To characterize this influence, simulations using a commercial CFD software Fluent® are done. Several simulations are made by varying the density inside the turbine enclosure. The frictional losses are evaluated for densities of 1.225 kg/m3 (representing an air pressure of 100 kPa), and 2.5 kg/m3 (air at 200 kPa), 3.6 kg/m3 (air 300 lPa) and 21.4 kg/m3 (R-134a at 500 kPa) (R-134a has been overheated by friction losses during testing on the bench, which has reduced the density from 25 to 21.4 kg/m3). Experimental results obtained in the same initial conditions are compared with simulation results. 3000 Density (kg/m3) Powerloss(W) 2500 21.4mod 2000 21.4exp 3.6mod 1500 3.6exp 1000 2.5mod 2.5exp 500 1.2mod 1.2exp 0 0 500 1000 1500 2000 2500 Rotatingspeed(RPM) Figure 11: Comparison between experimentations and simulations of friction losses. The first finding is that the model overestimates losses. The average value of the error reaches 25%. This error increases with speed but not with density. The model is also more stable to high pressures (gap constant for all speeds unlike the lower pressures where the gap fluctuates). However, the shape of the curve is identical for the model as well as for the experiments. The model is valid to assess the relative influence of different parameters of the wheel on friction losses due to the drag force. Parameters that will be analyzed are the number of buckets and then shape. 5.1 Number of buckets The bucket number of the Pelton wheel used for experimentation could be oversized. The optimal theoretical number of buckets is easily quantifiable. Buckets should be in a sufficient number for all of the jets to come in contact with the wheel. When the wheel is rotating, buckets intercept the jet one after another. If the wheel turns too fast compared to the jet speed, the bucket may leave the jet path before it strikes the bucket and the energy of the jet is lost. On the other hand, the maximum force applied by the jet on the wheel is achieved when the trajectory of the jet is perpendicular to the height of the bucket. So a good wheel has enough buckets to recover all the jet energy, but a number adequate to recover the full jet force. International Refrigeration and Air Conditioning Conference at Purdue, July 12-15, 2010 2274, Page 6 ߙ ൌ ିଵ ൬ ܴ ݁ ൰ ܴ (7) With : e : distance between the base of the bucket and the jet (mm) Ri : disk (without buckets) radius (mm) R0 : wheel radius (mm) Figure 12: Schematic view of the angle between buckets necessary to recover full force of the jet. Using equation (7) and Figure 12, the number of buckets necessary to recover the maximum force is calculated. The manufacturer data of the Pelton wheel tested (originally designed to recover the potential energy of a small water stream with a jet diameter of 20 mm) allow calculating that to benefit of the maximum jet force, the wheel must have 12 buckets. So the design of the wheel tested, with 24 buckets, is done to guarantee full recovery of the jet energy. The size of the buckets also changes the drag formation because the surface in contact with the flow is changed. According to Hutchinson (1923), to achieve the best performance, the area occupied by the jet into the Pelton bucket should not exceed 10% of the projected area of the bucket and the jet diameter should not exceed 30% the bucket height. The jet size of the R-134a flow is not known. Nevertheless, assuming isentropic expansion of R134a, in a 100 kW chiller cycle, the jet diameter should be half as large as the water jet (designed for the Pelton wheel tested). However, the bucket surface is four times more important than necessary for this jet diameter. Several simulations are done to characterize impact of the surface on power loss. Normal buckets are buckets of the tested Pelton wheel. Smalls ones have a surface four times as less as normal buckets (Figure 13). Power loss by drag is 20% lower when the number of buckets is divided by two (Figure 14). This result is not coherent with the drag equation; the total surface of the 12 buckets is half of what it is with 24, so friction loss should be divided by two. Nevertheless, this result seems in agreement with the active surface theory because divide by two the number of buckets does decrease the active area of 15% only (Figure 3). Again, difference between power loss with 24 small and 24 normal buckets cannot be explained by normal drag equation (Figure 14). The surface is divided by 4 but not the loss. Contrariwise active surface is just divided by two while losses decrease by 50% (Figure 3). 3000 Powerloss(W) 2500 2000 24normal buckets 1500 12normal buckets 1000 24small buckets 500 0 0 1000 2000 3000 4000 Rotatingspeed(RPM) Figure 13 Pelton wheel modeled. One with 24 normal buckets, one with 12 normal buckets and one with 24 smalls buckets Figure 14 Comparison between simulation of power lost by Pelton wheel of 24/12 and normal/small buckets 5.2 Shape of buckets In general, the friction losses depend on the contact surface between the object and the flow (equation 1). The losses generated by a single bucket are analyzed to know the influence of shape of the bucket surface on friction. Only the back of the bucket is changed because it is this side which is taken into account in the calculation of International Refrigeration and Air Conditioning Conference at Purdue, July 12-15, 2010 2274, Page 7 drag. The back of the first bucket has a slightly convex shape (as the bucket of the Pelton wheel tested), the second has a flat surface because this form is the most generator of drag in the aerodynamic theory (Figure 15). Figure 15 One bucket Pelton wheel modeled. One with convex shape, the other with flat surface 600 7000 500 6000 400 300 Flat 200 Convex Powerloss(W) Powerloss(W) According to the literature, the drag coefficient of a convex body in a high speed flow (Re> 104) is between 2 and 3 times smaller than a flat body of the same size. The wheels were modeled with air at a pressure of 100 kPa (or a density of 1,225 kg/m3) (Figure 16) and 1 MPa (or a density from 12.25 kg/m3) (Figure 17). The shape of plate bucket generates 2 times more loss at 3000 RPM than the normal convex bucket. 100 5000 4000 3000 Flat 2000 Convex 1000 0 0 0 500 1000 1500 2000 2500 3000 0 500 Rotatingspeed(RPM) 1000 1500 2000 2500 3000 rotatingspeed(RPM) Figure 16 Comparison between power lost by wheel with one flat/convex bucket at 100 kPa Figure 17 Comparison between power lost by wheel with one flat/convex bucket at 1 MPa 300 3000 250 2500 200 150 Flat 100 Convex 50 Powerloss(W) Powerloss(W) The common form of buckets, with a slightly convex surface on the back, seems to be most relevant to limit the formation of drag. This result is consistent with the theory of aerodynamics. However, this result is valid when the flow does not encounter a single bucket and therefore the entire surface of the trough is a barrier to fluid. In the case of the superposition of the buckets, the screening effect canceled common bucket advantage (Figure 18 and Figure 19). 2000 1500 Flat 1000 Convex 500 0 0 0 500 1000 1500 2000 2500 3000 0 Rotatingspeed(RPM) 500 1000 1500 2000 2500 3000 Rotatingspeed(RPM) Figure 18 Comparison between power lost by wheel with 24 flat/convex buckets at 100 kPa Figure 19 Comparison between power lost by wheel with 24 flat/convex buckets at 1 MPa 6. CONCLUSION According to the simulation results, friction loss on Pelton wheel can be reduced by at least 30% if the turbine is sized with jet specification and well designed. With this improvement, using Pelton wheel on refrigeration system is competitive for chiller with a minimal cooling capacity of 100 kW. The power lost by fluid friction can be estimated with gear formula. Pelton buckets protect each others from the flow and the active surface theory is coherent with results. To improve turbine efficiency research should be done on mechanicals losses (mainly in seals frictions). Nevertheless, Pelton turbine is not really appropriate to recover energy from a two-phase fluid. International Refrigeration and Air Conditioning Conference at Purdue, July 12-15, 2010 2274, Page 8 NOMENCLATURE R V U h m’ P CD A Z b wheel radius speed rotating speed enthalpy mass flow power drag coefficient surface number of teeth tooth width Greeks ȡ density Ȧ rotating speed Ș efficiency m m/s m/s kJ/kg kg/s W adim m² adim. m Subscripts and superscripts e s j rec n w inlet outlet jet recovery nozzle wheel kg/m3 rad/s % REFERENCES Akagawa, K., Asano, Y., 1986, Performance of Pelton-type Turbine driven by gas-liquid two phase flow, Bulletin of JSME, vol. 29, No. 247, p. 106-112. Austin, A. L., Higgins, G. H., Howard, J. H., 1973, The total flow concept for recovery of energy from geothermal hot brine deposits, Lawrence Livermore Laboratory, 45 p. Comfort, W. J., Beadle, C. W., 1978, Design considerations for a two phase turbine, Polyphase Flow in Turbomachinery, Lawrence Livermore Laboratory, 18 p. Diab,Y., Ville, F., Velex,P., 2004, Windage loss in High speed gears – preliminary experimental and theorical results, Journal of mechanical design, vol. 126, no 5, p. 903-908. Elliott, D.G., 1982, Theory and Tests of Two-Phase Turbines, Jet Propulsion Laboratory, JPL Pub B1-105, 150 p. Gülich, J. F.,2003, Disk friction losses of closed turbomachine impellers, Forschung im Ingenieurwesen, vol. 68, p.87-95. Hutchinson, E., 1923, The tangential impulse water wheel, Chapter 1, Impulse turbines, The electric journal, p. 1-12 Tondell, E., 2006, CO2-expansion work recovery by impulse turbine, PhD at NTNU (norway) , 136p. International Refrigeration and Air Conditioning Conference at Purdue, July 12-15, 2010