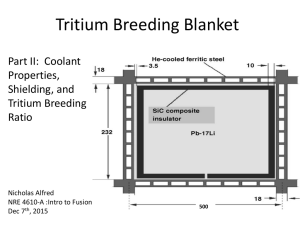

Tritium transport analysis in HCPB DEMO blanket with the FUS

advertisement