Nickel Alloys for Electronics

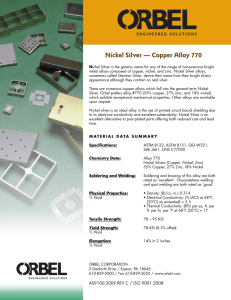

advertisement