Reinforcing Bar Supports

Use the right supports to prevent problems, enhance durability, and maintain

structural integrity

M

ost design specifications call for reinforcing bars to be precisely and accurately

spaced. The most common way of

spacing reinforcing bars is through

the use of reinforcing bar supports.

These supports come in a va ri e t y

of configurations for various applications and can be made of metal,

concrete, fiber-reinforced cement,

plastic, or other material. The ma-

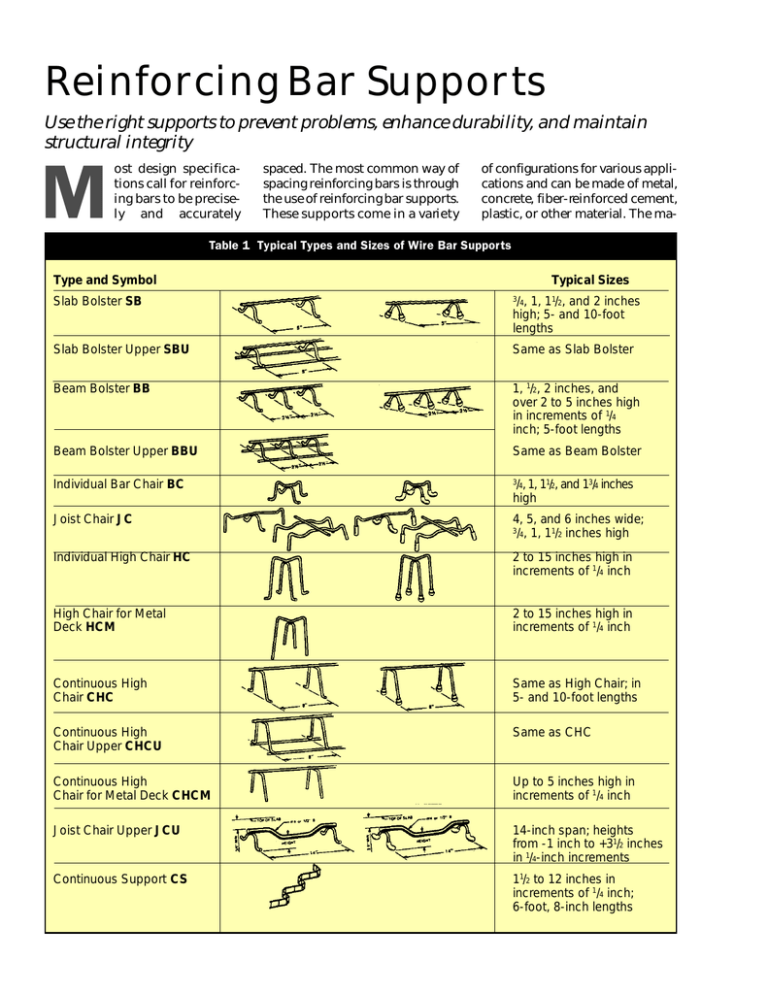

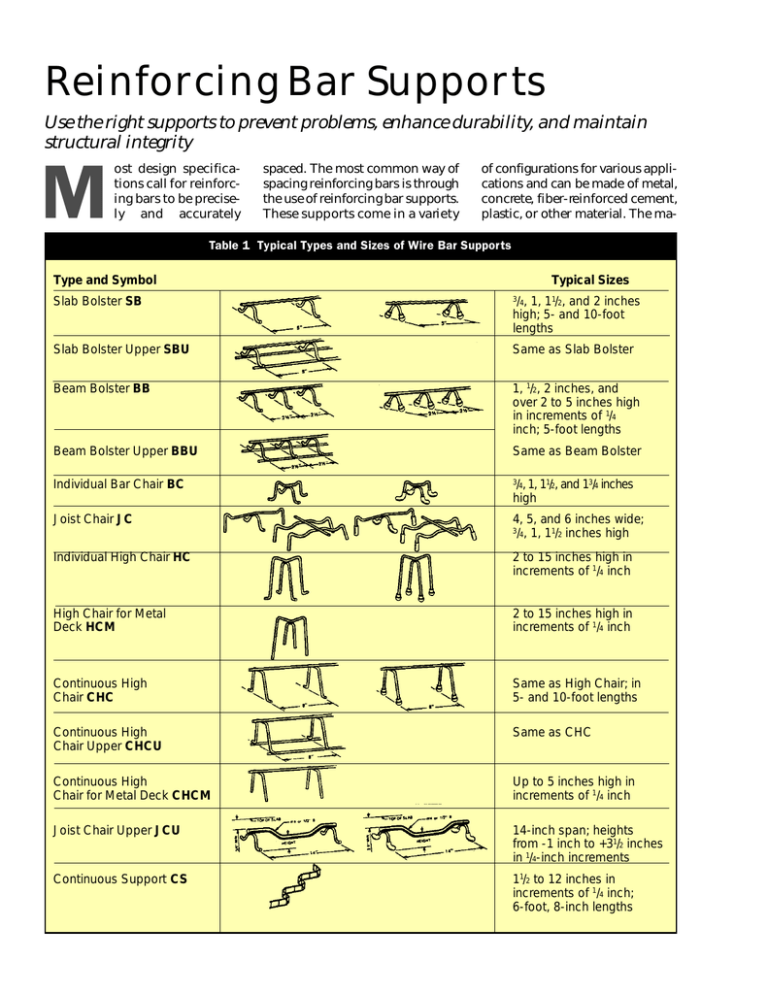

Table 1 Typical Types and Sizes of Wire Bar Supports

Type and Symbol

Typical Sizes

Slab Bolster SB

3/4, 1, 11/2, and 2 inches

high; 5- and 10-foot

lengths

Slab Bolster Upper SBU

Same as Slab Bolster

Beam Bolster BB

1, 1/2, 2 inches, and

over 2 to 5 inches high

in increments of 1/4

inch; 5-foot lengths

Beam Bolster Upper BBU

Same as Beam Bolster

Individual Bar Chair BC

34

Joist Chair JC

/ , 1, 11/2, and 13/4 inches

high

4, 5, and 6 inches wide;

/ , 1, 11/2 inches high

34

Individual High Chair HC

2 to 15 inches high in

increments of 1/4 inch

High Chair for Metal

Deck HCM

2 to 15 inches high in

increments of 1/4 inch

Continuous High

Chair CHC

Same as High Chair; in

5- and 10-foot lengths

Continuous High

Chair Upper CHCU

Same as CHC

Continuous High

Chair for Metal Deck CHCM

Up to 5 inches high in

increments of 1/4 inch

Joist Chair Upper JCU

14-inch span; heights

from -1 inch to +31/2 inches

in 1/4-inch increments

Continuous Support CS

11/2 to 12 inches in

increments of 1/4 inch;

6-foot, 8-inch lengths

jority of the information in this article is derived from Reference 1.

Wire Bar Supports

Metal bar supports usually are

made of plain or stainless steel wire

and are one of the most common

types used (Table 1). Lower portions of wire supports may have a

plastic coating to prevent rusting,

or are manufactured in whole or

part of stainless steel. Both types

can be used where light grinding

(1/16 inch or less) or sandblasting of

the concrete will be done.

Plastic-coated wire bar supports

(Class 1—maximum protection) are

intended for use in situations of

moderate to severe exposure. The

plastic coating usually is applied by

the manufacturer by dipping or by

using premolded slip-on plastic tips.

No matter which method is used, inspect the coating or tip before use

to ensure that it will not chip, crack,

deform, peel, or come loose under

ordinary job conditions.

Stainless steel protected bar

supports (Class 2—moderate protection) are for use in moderate-exposure applications. One type of

stainless steel support is fabricated

from steel wire and has a stainless

steel tip or leg extension attached

to each leg. Tipped bar supports

generally provide a minimum of 1/4

inch of stainless steel protection

from the form surface, while supports with leg extensions generally

provide a minimum of 3/4 inch of

protection. Legs on other types of

wire bar supports are fabricated

THE

MOST COMMON WAY OF

SPACING REINFORCING BARS

IS THROUGH THE USE OF

REINFORCING BAR SUPPORTS.

entirely from stainless steel.

Bright basic wire bar supports

(Class 3—no protection) have no

p rotection against rusting and

a re intended for use where surface blemishes can be tolera t e d

or where the supports do not

come in contact with exposed

concrete surfaces.

Concrete Bar Supports

Precast concrete bar supports

(Table 2) are normally available in

three styles: plain, with wires, and

doweled. Plain concrete bar supports are used to support bars off

the ground. Concrete bar supports

usually come with two wires cast

into the support’s center. The wires

are used to hold the support

against vertical forms or to hold the

concrete bar support in place by tying it to reinforcing bars.

Doweled concrete bar supports

are cast with a 21/4-inch-deep hole

in the center. The hole usually is

large enough so that a #4 reinforcing bar can be inserted into it. The

reinforcing bar thus inserted usually has a 90-degree bend at its top.

This allows reinforcing steel to be

placed across the horizontal portion of the bent bar. At the same

time, the concrete bar support can

be used to support bottom bars off

the ground by placing them on the

shoulders of the bar support.

Fiber-reinforced Supports

Cementitious fiber- re i n f o rc e d

bar supports (Table 3) are available

in two types: plain and with wire.

Most are chemically inert and bond

naturally to the concrete. Both

types can be used for both hori zo ntal and vertical reinforcing steel

Table 2 Typical Types and Sizes of Precast Concrete Bar Supports

Type and Symbol

Typical sizes (inches)

Plain Block

PB

A—3/4 to 6

B—2 to 6

C—2 to 48

Wired Block

WB

A—3/4 to 4

B—2 to 3

C—2 to 3

Tapered Wired Block

TWB

A—3/4 to 3

B—3/4 to 21/2

C—11/4 to 3

Combination Block

CB

A—2 to 4

B—2 to 4

C—2 to 4

D—fits #3 to #5 bar

Dowel Block

DB

A—3

B—3 to 5

C—3 to 5

D—hole to accommodate a #4 bar

Table 3 Typical Types and Sizes of Cementitious Fiber-reinforced Bar Supports

Type and Symbol

Typical Sizes

(inches)

Description

Slab Bolster

SB

3/4 to 3 high;

2, 3, 12, 36 long

Supports lower slab

reinforcing steel; also

comes in circular shape

for architectural work

and square shape for

heavy reinforcement

Beam Bolster

BB

same as above

Supports lower beam

bars and heavy slab bars

Bar Chair

BC

34

Supports bars in slab

and deck construction;

comes with or without

tie wire in three types:

single, double, and triple cover

/ to 2 high

Single Cover

High Chair

HC

Double Cover

34

/ to 3 high

Supports upper slab

bars directly or supports

lower slab bars; comes

with or without tie wires

Triple Cover

34

Clip-on Spacers

CS

/ to 2 concrete

cover

Vertical Spacers

VS

34

Double Clips

Available with double or

single clips; provides

necessary cover between

vertical bars and formwork

Single Clip

/ to 3 concrete

cover

support. Many supports of this type

are available in configurations that

offer multiple support heights from

the same support.

All-plastic Bar Supports

Many all-plastic bar supports

(Table 4) can be used for both horizontal and vertical re i n f o rc i n g

steel due to their snap-on action or

other method of attachment. Allplastic supports offer the advantages of being lightweight, nonp o ro u s, and chemically inert to

c o n c re t e. Properly designed allplastic supports should have

rounded seating areas to pre ve n t

their punching holes in formwork.

They also should not deform under

load when subjected to normal

temperatures encountered during

use, nor should they shatter or severely crack under impact loading

when used in cold weather.

According to one report (Ref. 2),

because all-plastic bar supports

and spacers are subject to temperature effects, they should have at

least 25% percent of their gross

plane area perforated to compensate for the difference in the coefficient of thermal expansion between the plastic and concrete. The

same report also notes that allplastic supports should be placed

no closer than 12 inches apart

along a bar.

All-plastic supports do not rust,

therefore eliminating blemishes on

concrete surfaces. These supports

Available with hooks for

attaching to bars;

provides cover between

vertical bars and

formwork; triangular in

shape and 12 inches long

are said to be especially suitable

where moderate to severe exposure

will be encountered or when grinding of the concrete is necessary. In

addition, all-plastic supports may

be used to support epox y- c o a t e d

reinforcing bars.

Supports for Epoxy-coated Bars

Ep ox y-coated re i n f o rcing bars

have become a widely used corros i o n - p rotection system for re i nf o rced concrete stru c t u re s. Sp ecial types of bar supports should

be used with epox y-coated bars.

This is done to prevent damaging

the coating on the bars duri n g

field placement and to pre vent a

potential source of corro s i o n

w h e re the bar supports contact

Table 4 Typical Types and Sizes of All-plastic Bar Supports

Type and Symbol

Bottom Spacer BS

Typical Sizes

(inches)

3/4 to 6 high

Description

Generally for horizontal work;

not recommended for ground

or exposed-aggregate finish

Bottom Spacer,

Clamp-on BS-CL

34

Generally for horizontal work;

provides bar clamping action;

not recommended for ground

or exposed-aggregate finish

High Chair HC

34

For use on slabs or panels

High Chair,

Variable HC-V

21/2 to 61/4

For horizontal and vertical

work; provides for different heights

Wheel Spacer

3/8 to 3 concrete

cover

Generally for vertical work;

bar clamping action and minimum

contact with forms; applicable for

column reinforcing steel

/ to 2 high

/ to 5 high

the coated bars.

To prevent problems when using

epoxy-coated reinforcing bars, the

Concrete Reinforcing Steel Institute

recommends the following:

1. Wire bar supports should be

coated with dielectric (nonconducting) material, such as epoxy or

plastic, compatible with concrete,

for a distance of at least 2 inches

from the point of contact with the

epoxy-coated reinforcing bars, or

2. Bar supports should be made

of dielectric material. In addition,

if precast concrete blocks with em-

bedded wire ties or precast concrete doweled blocks are used, the

wires or dowels should be epoxycoated or plastic-coated, or

3. Reinforcing bars that are used as

support bars should be epoxy-coated. In walls reinforced with epoxycoated bars, spreader bars (where

specified) also should be epoxy-coated. Proprietary combination bar

clips and spreaders used in walls with

epoxy-coated bars should be made

of corrosion-resistant material or

coated with dielectric material.

References

1. Manual of Standard Practice, Chapter 3—Bar Supports, Concrete Reinforcing Steel Institute, 933 N. Plum

Grove Rd., Schaumburg, Ill. 60173.

2. “Selection of Bar Spacers for Reinforced Concrete,” Concrete, November 1968, Cement and Concrete Association, London, England.

PUBLICATION #C940569

Copyright © 1994, The Aberdeen Group

All rights reserved