- Wiley Online Library

advertisement

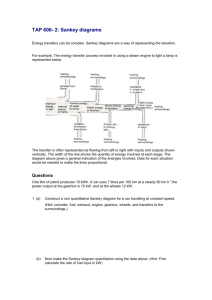

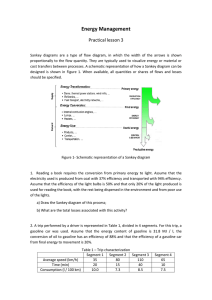

R E S E A R C H A N D A N A LY S I S The Sankey Diagram in Energy and Material Flow Management Part I: History Mario Schmidt Keywords: efficiency energy use industrial ecology industrial engineering material flow analysis (MFA) scarcity Address correspondence to: Mario Schmidt Institute of Applied Sciences IAF Pforzheim University Tiefenbronner Str. 65 D-75175 Pforzheim, Germany mario.schmidt@hs-pforzheim.de http://umwelt.hs-pforzheim.de Summary The Sankey diagram is an important aid in identifying inefficiencies and potential for savings when dealing with resources. It was developed over 100 years ago by the Irish engineer Riall Sankey to analyze the thermal efficiency of steam engines and has since been applied to depict the energy and material balances of complex systems. The Sankey diagram is the main tool for visualizing industrial metabolism and hence is widely used in industrial ecology. In the history of the early 20th century, it played a major role when raw materials were scarce and expensive and engineers were making great efforts to improve technical systems. Sankey diagrams can also be used to map value flows in systems at the operational level or along global value chains. The article charts the historical development of the diagrams. After the First World War the diagrams were used to produce thermal balances of production plants for glass and cement and to optimize the energy input. In the 1930s, steel and iron ore played a strategic role in Nazi Germany. Their efficient use was highlighted with Sankey diagrams. Since the 1990s, these diagrams have become common for displaying data in life cycle assessments (LCAs) of products. Sankey diagrams can also be used to map value flows in systems at the operational level or along global value added chains. This article, the first of a pair, charts the historical development. The companion article discusses the methodology and the implicit assumptions of such Sankey diagrams. c 2008 by Yale University DOI: 10.1111/j.1530-9290.2008.00004.x Volume 12, Number 1 82 Journal of Industrial Ecology www.blackwellpublishing.com/jie R E S E A R C H A N D A N A LY S I S Introduction The use of Sankey diagrams has long been standard practice in science and engineering. The diagrams are described as graphical heat balances (Minister of Fuel and Power 1944, 709), heat balance diagrams (Christensen 1990, 394), energy flow charts (Schnitzer 1991), or simply Sankey diagrams (Pople 2001, 138). The diagrams frequently focus on energy flow and its distribution to various sources or sinks, represented by arrows, the width of which indicates the amount of energy flow. Material flows are also frequently displayed with Sankey diagrams, and these are described, for example, as material flow charts (Koelbel and Schulze 1960). If one looks at basic articles on industrial ecology or life cycle assessment (LCA), it becomes apparent that they frequently use Sankey diagrams to show the complexity of industrial “metabolism.” For instance, Frosch and Gallopoulos (1989, 100) used a Sankey diagram showing the production, use, and subsequent whereabouts of platinum metals. Saur and colleagues (1996) produced an LCA with a Sankey diagram tracking the main material flow for the production of aluminum sheet parts in the automotive industry. Graedel (1996, 72) applied Sankey diagrams to compare material flows in biological and industrial ecology. One could almost believe that Sankey diagrams are the visual language of industrial ecology. At least since Edward Tufte, the noted scholar of visual representation, we know how important it is to visualize quantitative information in order to understand it. It is interesting to note that Tufte described Charles Joseph Minard’s map showing the losses sustained by Napoleon’s army during the Russia campaign of 1812–1813 as possibly the best statistical graphic ever drawn (Tufte, 2001, 40). It has much in common with a Sankey representation and can be found today in nearly every good book on European history. With just a few strokes, it shows the whole tragedy of the war in Russia. Industrial ecology, conversely, aims to show (and prevent) the tragedy resulting from human disregard of natural substance cycles. Graedel (1996, 73) pointed out that industrial ecology addresses the budgets and cycles of input and output streams and tries to optimize them. He went on to say that the key concepts of industrial ecology include conservation of mass and conservation of energy. This is exactly what Sankey diagrams do, as the present article shows. With their intuitive readability and transparency, they are ideal for interpreting complicated sets of resource flows. It is therefore not surprising that such diagrams were repeatedly used in the past to explain significant findings to a broad public and to launch technical or social measures. This is illustrated below with the aid of a historical incident closely connected with scarcity of resources. The article also traces the history of the Sankey diagram for the first time. It is not commonly known that the introduction of the Sankey diagram over 100 years ago, by the Irishman Riall Sankey, was initially connected with a call for efficiency, in this case for steam engines. Whether to help produce more economical cars or more productive steel plants, the Sankey diagram was subsequently used to understand and tackle consumption of scarce resources. Thermal Efficiency and Riall Sankey In the late 19th century, engineers in the upand-coming industrialized countries tried applying scientific methods to further improve steam engines and optimize them for their respective applications. The theory of thermodynamics, which was completed during these years, was a great help to the engineers. They discussed the question of what an ideal steam engine might look like with particular intensity. The best thermodynamic cycle, the Carnot process, was too abstract for practical application. Instead, William J. M. Rankine and Rudolf Clausius proposed the Rankine–Clausius process, named after them, with which real machines could be compared (Cardwell 1994, 123). In the 1870s, Willard Gibbs introduced the temperature-entropy diagram. This made it possible to show the efficiency with which a machine transfers thermal energy into work (Cardwell, 1995, 360). Sankey also examined the question of how an ideal practical steam engine could be defined and how the efficiency could be Schmidt, The Sankey Diagram in Energy and Material Flow Management, Par t I: Histor y 83 R E S E A R C H A N D A N A LY S I S measured. In this context, in a committee report of the Institution of Civil Engineers, he first used the diagram later named after him. The diagram was published in 1898 (Sankey 1898, Plate 5). Captain Matthew Henry Phineas Riall Sankey was born on 9 November 1853, the son of a general in Menagh, County Tipperary, Ireland (Anonymous 1926a, 1926b). He joined the Royal Military Academy in Woolwich, near Greenwich, at that time one of the best technical schools in the United Kingdom. Subsequently, he went on to the School of Military Engineering in Chatham, in the county of Kent. He was one of the best students, had a profound knowledge of theory, received his certificate as Royal Engineer in 1873, and then served in England, in Gibraltar, and later as an instructor at the New Royal Military College in Kingston, Canada. In 1882 he was appointed to the Ordnance Survey in Southampton. In connection with the technical printing of maps, he learned about copperplate printing. Electricity was necessary for this, which at that time was being supplied by expensive batteries. Sankey sought an alternative method using dynamos driven by constantly running steam engines. He tested several for their suitability and came across machines designed by Peter Willans, one of the leading inventors in the field of steam engines (Cardwell 1994, 122). Willans’s engines were used in the United Kingdom in most power stations. During the subsequent period, Sankey conducted various investigations, the results of which he published. Like Willans, he had an interest in the economic improvement of steam engines. At Willans’s suggestion, Sankey resigned his commission in 1889 and became a director of the firm Robinson & Willans. There he conducted various experiments, including thermodynamic tests on steam engines, and after the death of Willans in 1892 he assumed responsibility for the design of steam engines and turbines for the company. It was Sankey who, in the course of technical discussions on steam engine efficiency, declared that a standard was necessary to compare actual steam engines with a perfect steam engine and that the Rankine–Clausius engine was best suited for this purpose (Sankey 1896). The diagram used 84 Journal of Industrial Ecology for these analyses, with its important content, was not the subsequent “Sankey diagram” but instead the temperature-entropy diagram. When a commission appointed by the Institution of Civil Engineers essentially confirmed Sankey’s ideas 2 years later, he prefaced this report with an introduction that he—rather casually—supplemented with a chart in the annex (Sankey 1898). In this introduction, he compared a practicable steam engine with an idealized steam engine whose thermal flows were represented in the diagram (figure 1). He did not use this mode of representation again later. It was a by-product of the discussion of steam engine efficiency and simply served to illustrate the matter. Later, Sankey worked as a consultant and was on the boards of various firms. In his later years, from 1920 to 1921, he was president of the Institution of Mechanical Engineers. In the course of his scientific life, he published various books and technical articles, including “The Energy Chart. Practical Applications to Reciprocating SteamEngines.” Sankey died on 3 October 1925. The top chart in figure 1 shows an American steam engine (Louisville Leavitt Pumping Engine). The steam leaves the boiler with a quantity of 159,250 B.T.U./min (B.T.U. = British thermal unit, an old energy unit: 1 B.T.U. = 1.055 kiloJoules [kJ]). If the refluxes are taken into account, the net supply to the steam engine is 142,150 B.T.U. After all losses are deducted, 27,260 B.T.U. remain for the mechanical work. In the report, the thermal efficiency of the engine is given as 27,260 / 142,150 = 0.19. The bottom diagram represents an ideal steam engine with an assumed Rankine cycle. The losses cease to apply. The thermal efficiency here is quantified at 0.285. Sankey (1898) explained descriptively how the diagram was to be interpreted: No portion of a steam plant is perfect, and each is the seat of losses more or less serious. If therefore it is desired to improve the steam plant as a whole, it is first of all necessary to ascertain separately the nature of the losses due to its various portions; and in this connection the diagrams in Plate 5 have been prepared, which it is hoped may assist to a clearer understanding of the nature and extent of the various losses. R E S E A R C H A N D A N A LY S I S Figure 1 The first two energy flow diagrams of Captain Sankey (1898). They represent two steam engines—a real one (top) and an ideal one (bottom). The figures are stated in British thermal units (B.T.U.) per minute. The graphics were designed in such a way that a flow of 100,000 B.T.U./min corresponded to 1 in. in the drawing. Source: Sankey 1898, Plate 5. The boiler; the engine; the condenser and air-pump; the feedpump and the economiser, are indicated by rectangles upon the diagram. The flow of heat is shown as a stream, the width of which gives the amount of heat entering and leaving each part of the plant per unit of time; the losses are shown by the many waste branches of the stream. Special attention is called to the one (unfortunately small) branch which represents the work done upon the pistons of the engine (Sankey 1898, 279). Accordingly, the flow of heat is represented as a stream, the width of which shows the amount of heat fed into the factory and leaving it again per unit of time. The heat losses are indicated by the branches. Consequently, the useful energy, in this case the mechanically performed work, is shown very graphically in comparison with the original input. The figures are given in absolute quantities. Furthermore, the representation shows the processes involved, the boiler and the engine. Schmidt, The Sankey Diagram in Energy and Material Flow Management, Par t I: Histor y 85 R E S E A R C H A N D A N A LY S I S The diagram is immediately clear. It can be adapted flexibly to various needs and to empirical conditions. There are thus many possible ways of preparing such charts. The essential feature is the representation of flow sizes by quantified arrows— in other words, correspondingly wide arrows. The Use of Sankey Diagrams in Germany A decade later, Sankey’s diagrams were already being used internationally. In 1908, a whole series of different “heat balances” was printed in a review in the Journal of the Association of German Engineers of a blast furnace, a coke furnace, and a comparison between a steam engine and a gas engine (VDl 1908). Attention was drawn to the great superiority of the gas engine in heat utilization and to the fact that the diagram “did not need any further explanation” (VD1 1908, 2017). One of the first German-speaking engineers to use Sankey diagrams on a large scale was Alois Riedler (1850–1936), who became professor of mechanical engineering at the Technical University (TH) Berlin in 1888 and later president of the TH Berlin. Riedler traveled abroad extensively, visiting the World Expositions in Philadelphia (1876), Paris (1878), and Chicago (1893) as well as many technical teaching institutes in, for example, the United States. As a result, he was familiar with developments abroad. Riedler was very practice-driven and called for mechanical engineering laboratories to be set up at the technical universities. He also busied himself with matters such as the development of internal combustion engines, and, starting in 1903, he built up a laboratory for internal combustion engines and motor vehicles at the TH Berlin. There he developed the first roller dynamometer for motor vehicles and was the first to start scientific measurements of such vehicles. At that time, he was particularly opposed to assessing motor vehicles on the basis of the then-customary races oriented toward maximum performance parameters, such as speed. Those results were commonly used for marketing purposes in the advertisements of automobile firms. According to Riedler, however, this practice was not expedient for assessing 86 Journal of Industrial Ecology the economics of motor vehicles in practical operation. For this purpose he sought objective and plausible criteria with which he could compare vehicles, and he introduced measurements of typical driving situations on a roller dynamometer. He wanted to measure more appropriate measures of performance and loss in vehicles and engines. He can thus be considered as one of the founders of the automobile tests that are today indispensable for every car buyer. In 1911, Riedler published Wissenschaftliche Automobil-Wertung (Scientific Automobile Assessment), in which he presented his first measurements, including those of a 30 horsepower (hp) Renault, a 100 hp Benz, and a 75 hp Adler. The reasons he gave for conducting these investigations included fuel scarcity and the need to import fuel from other countries. “A vital issue for all motor vehicles: their dependence on certain fuels, especially those from foreign countries” (Riedler 1911, Report 1, 18). The results were amazing for that time. Riedler was able to show that the losses due to the driving unit were lower than generally assumed. Instead, the tires and the thermal losses of the engines had a crucial influence on the engines’ efficiency. As the rolling losses in motor vehicles consume a very large portion of the available engine output, complete clarification . . . is extremely important. . . . A slight fraction of the costs spent on the greatly flourishing advertising for pneumatics and automobiles, or a small portion of the sums that automobile clubs and even towns and cities spend on racing events would suffice for thorough investigation of this important question. (Riedler 1911, Report V, 13) The energy flow diagrams were an important medium that helped Riedler to illustrate the results clearly (see figure 2). In this concrete case, he quantified the vehicle’s effective output for overcoming air resistance, for accelerating, and for climbing gradients at ultimately only 12.5% of the fuel energy fed in. Riedler (1911) wrote, Energy diagrams graphically represent the intake, output and losses, as well as the energy amount then still available and thus provide a characteristic picture of the fuel R E S E A R C H A N D A N A LY S I S Figure 2 The energy diagram of the 20/30 hp Renault car for 60 km/h driving speed. Source: Riedler 1911, figure 12. utilization of the vehicles examined. The findings gained from the energy diagrams of energy distribution in the motor vehicle are one of the means for assessing its economic perfection. It shows the expert the points where essential improvements are possible. (Riedler 1911, Report I, 9) The systematic analyses and the representation of the results in energy flow diagrams made it possible, above all, to explain relevant characteristics. Riedler (1911, Report V, 25) scornfully remarked that among German engineers there was “no agreement of views on the meaning of the concept of efficiency” and that this led to misunderstandings and misinterpretations in the question of economic efficiency. Riedler’s work Das Maschinen-Zeichnen (Machine Drawing) in 1896 was of great significance for engine building and design. In this work he called for exact, dimensioned, black-and-white drawings adapted to the relevant purpose, and with that he became one of the founders of modern technical draftsmanship. As early as the 1913 issue, he presented an “energy diagram” alongside the entropy diagrams, showing the energy flow of a steam engine. In the textbook Das Entwer- fen und Berechnen der Verbrennungskraftmaschinen und Kraftgas-Anlagen (Designing and Calculating Internal Combustion Engines and Gas Power Plant), Gueldner (1913, 13) too presented the “special nature of a heat plan,” called the “Sankey diagram.” However, he complained that although this representation provided clarity, it was not easily and accurately drawn and was therefore more suitable for general illustration purposes than for technical use. Despite this criticism, Sankey diagrams played an important role in technical analyses of plants in Germany during the following years. As a result of the demand for reparation payments following the First World War, Germany had to handle its resources economically. The goal was to improve the yield of energy-intensive processes such as cement production, glass manufacturing, or steelmaking. Plants were measured in detail in a series of experiments, and thermal balances were drawn up to identify inefficiency and scope for improvements. This work was largely carried out by cross-company commissions serving the individual branches of industry. The importance of such savings for the national economy was often pointed out. Schmidt, The Sankey Diagram in Energy and Material Flow Management, Par t I: Histor y 87 R E S E A R C H A N D A N A LY S I S For example, in 1920 a heat-specific advisory center was set up for the German glass industry (WBG; Trier 1992). The membership dues were assessed on the basis of the fuel consumption of the firms. Thermal measurements were carried out on real plants belonging to the members in order to improve, for example, the gas generators or the smelting furnaces. Accordingly, the first known heat balance was drawn up for a whole glass smelting plant. The results were compiled in the WBG publication series and made a major contribution to the progress of thermal engineering in the glass industry. Within the cement industry, PortlandZementwerke Heidelberg-Mannheim had been conducting experiments since 1904 to utilize waste gases for steam production. In the 1920s, a furnace commission of the association of German Portland cement factories conducted comprehensive measurements and produced systematic heat balances of various cement kilns. The first Sankey diagrams for firing cement were presented in 1927 (Schott 1954) and then became an indispensable graphical instrument. The results of the analysis were used to compare various furnace types, to propose improvements in process engineering, and ultimately to compare the theoretically optimal heat balance with the real, empirical heat balance. Depending on the type of furnace, manufacturing procedure, and combustion facility, the thermal consumption of cement production in the 1920s fluctuated between twice and five times the theoret- ically necessary heat input (see figure 3, Schott 1933). Material Flow Management in the Steel Industry After the First World War, supplies of raw materials for the German steel industry were critical. There was a lack of fuels. That is why the main tasks in the 1920s and 1930s were grouped around the concepts of operating economically and improving product quality (Spingorum 1936, 1043). Today one would talk about improving efficiency and quality management. Energy expenditures accounted for about one quarter of total product production costs, which is why the Heating Center Duesseldorf of the association of German ore smelting works was set up at the beginning of the 1920s as a joint enterprise for all German smelting plants. It developed and expanded measuring systems to obtain reliable data on the production and consumption of energy resources, and its reports provided plant managers with guiding values and reference points for improvements, for more uniform use of energy, and for ongoing cost monitoring. Thanks to scheduled heat management, it became possible to lower the heat consumption needed per ton of steel by more than one quarter within the space of just 10 years. Furthermore, as of 1923, data had been collected on total “material management,” as it was called in those days—in other words, on the use Figure 3 Theoretical heat outlay (left) and practical heat consumption (right) in cement production. Source: Schott 1954, figures 3 and 4, page 154. 88 Journal of Industrial Ecology R E S E A R C H A N D A N A LY S I S Figure 4 Iron flow chart for the German iron industry. Figures related to 100% iron content in ore. Source: Reichardt 1937, figure 2. of raw and auxiliary materials and of finished and semifinished products. At the time, this was done for purposes of cost monitoring and was essentially promoted by a new species of expert—the business economist. There was also another reason for material management. Iron ore had become a scarce commodity in Germany after the country had been forced to cede the rich ore mines in Lorraine back to France after the First World War. Many iron resources in Germany were of lower quality, which made it more difficult to process them in blast furnaces. Thanks to the intelligent combination of the various processes for obtaining pig iron, it proved possible to increase the yield considerably. The use of scrap and the closing of material cycle loops (Reichardt 1937, 1104) played a key role here, as figure 4 shows with average values for the entire German economy. Whereas using Sankey diagrams became standard practice for the energy and heat industry as of 1931 (Waermestelle Duesseldorf 1931, 9), their use for quantity-related material management took off in the mid-1930s. In a lecture at an engineering conference in Breslau in 1935, Professor Paul Goerens (1935) talked about raw material management issues. In line with the times, the lecture was all about state-forced management and national autonomy. He referred to the “material flow chart” as a valuable aid that can contain quantity-based information about the origin, production, processing, and purpose of a material. He presented national balances for iron, copper, and lubricating oil. Figure 5 shows the general arrangement of a material flow chart by Goerens (H. Schmidt 1936, 14). The accompanying explanation is interesting: A raw material, R, comes from within the country, 1, or from abroad, 2, and, up to consumption, runs through a series of stages, C, D, E, F, covering selection, conversion, processing and shaping. At each stage, starting with the domestic raw material, export, 3, can take place. In addition, a part of the material is eliminated from the work flow at each stage. If it can be saved in value terms in any form and be returned to one of the preceding stages, it appears as material recirculation in various forms, 4a, 4b, 4c. If recovery does not enter into consideration either technically or economically, then the loss, sub-flow 5, appears. A loss of the material also occurs if it is used up completely during the processing stage. Also, export represents a material loss for the material economy of a country. . . . The plotting of the individual flows to scale results in a precise overview of the management of a material. Schmidt, The Sankey Diagram in Energy and Material Flow Management, Par t I: Histor y 89 R E S E A R C H A N D A N A LY S I S Figure 5 The diagram of a flow chart according to Goerens (1935). Source: Schmidt 1936, figure 1. The reflux of a part of the material to the work process resulting from circulation triggers the additional demand for new raw material. . . . Depending on the type of consumption, it is possible to make a sub-division into different material groups whereby the flow chart has a particularly descriptive form. The first group comprises all materials that are consumed completely. Examples of this are liquid fuels, solid fuels and foods. The flow pattern of such materials is characterized by the fact that it lacks the material circulation. . . . A second group consists of those materials that do not lose their material value, but of which the form of use is devalued, such as metal, rubber, lubricating oil, and paper. Apart from the case of exports, material loss only occurs as a result of wear. As wastes result from each processing stage that can be processed again, the scrap generated is not very significant for material management as long as the conversion does not cause any notable loss of material. However, the economic viability is influenced. The level of the reflux alone determines the replacement with fresh material. 90 Journal of Industrial Ecology The third group is made up of materials that serve as auxiliaries, e.g., as solvents or bonding agents in the chemical conversion of other materials. Managing these is intended to form a cycle with no loss, as far as is possible. Once the need for management has been ascertained by a material balance and material flow pattern, it will be necessary to seek ways of limiting the imports of foreign materials without harming the national economy. This includes savings measures, consulting science and research, as well as progress in technology. Furthermore, all means of reducing losses and recycling wastes are to be considered. (H. Schmidt 1936, 14) The article thus states important aspects of modern material flow management and closed cycle management—but for the purpose of a developing war economy. The special type of diagram was then taken up in many ways by the steel industry engineers to analyze the raw material situation (Bansen 1936, 1937). The seriousness with which material management was pursued in those days is really quite amazing. For instance, consider that cleaning rags were recycled in the smelting industry (Heinrich 1937). R E S E A R C H A N D A N A LY S I S It is remarkable that this “material management” in the steel industry was chiefly propagated and implemented by business economists. Altogether, these new business economists had to justify their existence in dealings with classic commercial and engineering staff. Business administration had been first introduced as an academic subject in Germany in 1898, with the first higher commercial college in Leipzig, initially under the title Private Economics or the Science of Trade (Schneider 1999, 16). Kurt Rummel, chairman of the Committee of Business Administration of the Association of German Metallurgy, pointed out the advantages and mode of operation of business administration in an article, saying that they consist in planning, planning not on the grounds of any “sensing” through fingertips, but on the basis of very carefully collected statistical and experimental findings on the passage of the material through the plants over time. All major influences are ascertained and the effects of these influences are identified with special auxiliary means and formed into a system. Thinking in terms of balances makes the sources of losses appear more clearly; calculating with carefully evaluated quantities helps to select the suitable material, the most expedient process and the correct plant. (Rummel 1936, 228) Rummel ascertained that the demand for material management personnel and a distinct material management system was very high. In the steel industry this was understandable, as that branch is based on materials (i.e., raw materials and auxiliary materials—not including fuel) that constitute 35% to 45% of costs (Rummel 1936, 222). The required investigations, therefore, track the passage of the material over time, on the basis of quantity and quality. The strict division of costs into two constituent parts, consumption in quantity units and price in money units, was said to be important: The purely quantity-based consideration is particularly important today in view of the scarcity of raw materials and the necessary careful treatment of the few raw material resources that our country is able to supply itself. (Rummel 1936, 224) In this connection, Rummel talked of a “material budget”—a concept that was taken up again in detail 60 years later in environmental science (Baccini and Bader 1996)—that explored the material balance in detail. Rummel (1936, 225) stated, Thinking in terms of balances must increasingly replace the crude term “outputs in percent.” In the heat industry the output is set against the “efficiency.” . . . However, often enough, it is not at all certain what the denominator is and what the numerator is as regards either efficiency or output. By way of example, he cited recycled scrap, which was simply left out of many net considerations, which then led to misinterpretations of the overall performance of a plant. This is, by the way, an error that is still (or once again) found in production sites that apply internal recycling today. Naturally, Rummel also continued his considerations further to obtain a value-based analysis. We must of course be clear that the quantityspecific saving that can be achieved by all these measures is only slight. In terms of value, though, as in every balance, the single percentage point saved is of key importance for the final calculation; this only becomes apparent in the profit and loss account. (Rummel 1936, 226) He then went on to consider relevant issues such as how inventories can be evaluated—for example, on the basis of purchase price, book price, or replacement price—and how capital servicing of plant installations should be taken into account. He adopted the position that existing installations, irrespective of whether they have been written off, should not be included in comparative costing. The first Sankey diagram with value flows was suggested in this connection by Warczewski (1937; figure 6). What is remarkable in this representation is that it divides input and output sides on the basis of differing criteria—according to material group and type of use—and also attempts to include the initial and final inventory. In the example, these do, after all, amount to 21% of annual turnover. This is because the question of inventory becomes relevant if the subject Schmidt, The Sankey Diagram in Energy and Material Flow Management, Par t I: Histor y 91 R E S E A R C H A N D A N A LY S I S Figure 6 Schematic annual value flow of the materials in an iron and steel works. Source: Warczewski 1937, figure 1. of the flow is no longer heat or energy but instead concrete objects that can be stored and that are subject to mass balance maintenance. These analyses were used to reduce the stock quantities as the speed of turnover increased—that is, to optimize procurement. Conclusions In the 1930s, the difficult framework conditions in the steel production sector, characterized by high prices and a scarcity of raw materials, led to what later came to be called “material management,” thus practically forcing the application of material balances or Sankey diagrams. The graphics played a major role in explaining the complicated situation to a broad public and in obtaining the necessary policy. The circumstance of this having been directly connected with Germany’s war preparations should not mask the insight that the specific concern was to achieve efficiency in raw 92 Journal of Industrial Ecology materials. One can pick up this concern again today, though for different reasons—that is, because raw materials are scarce and expensive throughout the world and their use represents a burden for the environment. Sankey diagrams might be a helpful tool to illustrate and optimize complex material flow systems again—but now with an actual view of the industrial metabolism and with the new goal of reducing the ecological impact. In this context, methodological improvements and new application areas of the Sankey diagram could be useful for practical purposes in companies. This will be the topic of part II (M. Schmidt 2008), the sequel to this article. Acknowledgements I should like to thank the three unknown reviewers for their suggestions and Linda Golding and Clayton Macdonald for their support with the language. R E S E A R C H A N D A N A LY S I S References Anonymous 1926a. Obituaries. Journal of the Institution of Electrical Engineers 64: 1210. Anonymous 1926b. Obituary. Minutes of Proceedings of the Institution of Civil Engineers 221: 271–274. Baccini, H. and H.-P. Bader. 1996. Regionaler Stoffhaushalt. Erfassung, Bewertung und Steuerung [Regional material budget. Recording, assessment and steering.] Heidelberg, Germany: Spektrum Akademischer Verlag. Bansen, H. 1936. Metallurgische Aufgaben und Moeglichkeiten zur Anpassung an die Rohstofflage. [Metallurgical tasks and possibilities of adaptation to the raw materials situation.] Stahl und Eisen [Steel and Iron] 56: 1–10. Bansen, H. 1937. Die Rohstofflage und Manganfrage in der Roheisenwirtschaft. [The raw materials situation and the manganese issue in pig iron management.] Stahl und Eisen [Steel and Iron] 57: 1109– 1114. Cardwell, D. 1994. Steam engine theory in the 19th century; from duty to thermal efficiency; from Parkes to Sankey. Transactions of the Newcomen Society 65: 117–128. Cardwell, D. 1995. Wheels, clocks, and rockets: A history of technology. New York: Norton. Christensen, S. G. 1990. Lamb’s questions and answers on the marine diesel engine. Oxford, England: Butterworth-Heinemann. Frosch, R. A. and N. E. Gallopoulos. 1989. Strategies for manufacturing. Scientific American 256(9): 94– 102. Goerens, P. 1935. Grundsaetzliche Fragen der Rohstoffbewirtschaftung. [Fundamental issues of raw materials management.] Beiheft “Technik ist Dienst am Volke” Vol. 2 [Supplement “Engineering Is Devotion for the Nation”]. Zeitschrift des Vereins Deutscher Ingenieure [Journal of the Association of the German Engineers] 79: 11–20. Graedel, T. E. 1996. On the concept of industrial ecology. Annual Review of Energy and the Environment 21: 69–98. Gueldner, H. 1913. Das Entwerfen und Berechnen der Verbrennungskraftmaschinen und Kraftgas-Anlagen. [Designing and calculating internal combustion engines and gas power plant] Third edition. Berlin: Julius Springer. Heinrich, F. 1937. Die Aufarbeitung von Putzwolle in Huettenwerken. [Processing cleaning rags in smelting works.] Stahl und Eisen [Steel and Iron] 57: 1048–1051. Koelbel, H. and J. Schulze. 1960. Projektierung und Vorkalkulation in der chemischen Industrie. [Project- ing and preliminary calculations in the chemical industry.] Berlin: Springer-Verlag. Minister of Fuel and Power. 1944. The efficient use of fuel. A text-book on fuels and their efficient utilisation for the use of students and technical men in industry. London: His Majesty‘s Stationery Office. Pople, S. 2001. AS & A Level Physics through diagrams. Oxford, England: Oxford Childrens Books. Reichardt, P. 1937. Rohstofflage, Roheisen- und StahlSortenfrage. [Raw materials situation, pig iron and steel categorising.] Stahl und Eisen [Steel and Iron] 57: 1104–1109. Riedler, A. 1911. Wissenschaftliche Automobil-Wertung. [Scientific automobile rating.] Berlin: Berichte IV des Laboratoriums fuer Kraftfahrzeuge an der Koeniglichen Technischen Hochschule zu Berlin [Reports I-V of the Laboratory for Motor Vehicles at the Royal Technical University of Berlin]. Riedler, A. 1913. Das Maschinen-Zeichnen. Begruendung und Veranschaulichung der sachlich notwendigen zeichnerischen Darstellung und ihres Zusammenhanges mit der praktischen Ausfuehrung. [Technical draftsmanship. Why technical drawings are necessary and how to produce them—their importance for practical execution.] Second edition. Berlin: Julius Springer. Rummel, K. 1936. Der Einfluss betriebswirtschaftlicher Gedankengaenge auf die Stoffwirtschaft. [The influence of business management ideas on materials management.] Stahl und Eisen [Steel and Iron] 56: 221–228. Sankey, H. R. 1896. The thermal efficiency of steamengines. Minutes of Proceedings of the Institution of Civil Engineers 125: 182–242. Sankey, H. R. 1898. Introductory note on the thermal efficiency of steam-engines. Report of the committee appointed on the 31st March, 1896, to consider and report to the council upon the subject of the definition of a standard or standards of thermal efficiency for steam-engines: With an introductory note. Minutes of Proceedings of the Institution of Civil Engineers 134: 278–283. incl. Plate 5. Also published in: The Engineer 86, Sept. 2, 1898: 236–237. Sankey, H. R. 1905. The Energy Chart. Practical Applications to Reciprocating Steam-Engines. Warwick Street: Albert Frost and Sons. Saur, K., J. Gediga, J. Hesselbach, M. Schuckert, and P. Eyrer. 1996. Life cycle assessment as an engineering tool in the automotive industry. International Journal of Life Cycle Assessment 1(1): 15– 21. Schmidt, H. 1936. Grundsaetzliche Fragen zur Rohstoffbewirtschaftung. [Fundamental issues of Schmidt, The Sankey Diagram in Energy and Material Flow Management, Par t I: Histor y 93 R E S E A R C H A N D A N A LY S I S raw materials management.] Eisen und Stahl [Steel and Iron] 56: 14–15. Schmidt, M. 2008. The Sankey diagram in energy and material flow management, Part II: Methodology and current applications. Journal of Industrial Ecology. Forthcoming. Schneider, D. 1999. Geschichte der Betriebswirtschaftslehre. [History of the theory of business administration.] In 100 Jahre Betriebswirtschaftslehre in Deutschland 1898–1998 [100 Years of Management Science in Germany 1898–1998]: 1-29, edited by M. Lingenfelder. Munich, Germany: Verlag Vahlen. Schnitzer, H. 1991. Grundlagen der Stoff- und Energiebilanzierung. [Fundamentals of material and energy balancing.] Braunschweig, Germany: Vieweg. Schott, E. 1933. Waermewirtschaft in der Zementindustrie. [Heat management in the cement industry.] Die Waerme [The Heat] 45: 736– 741. Schott, E. 1954. Arbeiten ueber Zement und Zementherstellung. [Studies on cement and cement production.] Heidelberg, Germany: PortlandZementwerke Heidelberg-Mannheim. Springorum, F. 1936. Technical developments in German iron and steel production during the last fifteen years. Stahl und Eisen [Steel and Iron] 56: 1042–1063. Trier, W. 1992. Entwicklung der Huettentechnischen Vereinigung der Deutschen Glasindustrie (HVG) und der Deutschen Glastechnischen Gesellschaft 94 Journal of Industrial Ecology (DGG). Teil 1. Von 1920/22 bis 1985. [Development of the smelting association of the German glass industry [HVG] and the German glass engineering association [DGG]. Part 1, from 1920/22 to 1985.] Glastechn. Ber. 65(4): 112–127. Tufte, E. R. 2001. The visual display of quantitative information. Cheshire, CT: Graphics Press. VDI (Verein deutscher Ingenieure [Association of the German Engineers]). 1908. Rundschau [Panorama]. Zeitschrift des Vereins deutscher Ingenieure [Journal of the Association of the German Engineers] 52(50): 2016–2019. Waermestelle Duesseldorf 1931. Anhaltszahlen fuer den Energieverbrauch in Eisenhuettenwerken. [Indicator figures for energy consumption in iron and steel plants.] Third edition. Duesseldorf, Germany: Verein Deutscher Eisenhuettenleute [Association of German Ore Smelting Works]. Warczewski, Z. 1937.: Gospodarka Materialowa I Magazynowa W Hutach Zelaznych. [Material and stock management in iron and steel plants.] Hutnik 9: 26–31. About the Author Mario Schmidt is professor of environmental management at Pforzheim University in Pforzheim, Germany, and director of the Institute of Applied Sciences IAF.