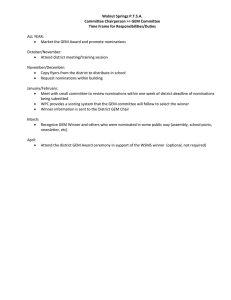

GEM LITHO USA

advertisement

Market SPOTLIGHT GEM LITHO USA “By being able to profitably serve our smallest clients, we’ve made GEM better able to serve all our clients. In this, ECRM’s WorkMates NEWS software is our indispensable partner. It’s a technology whose time has definitely come.” -- Artie Marin, GEM Design Department GEM Litho-Print (GEM) is a 50-year-old, cold-web general commercial printer in Houston, Texas, specializing in printing tabloid and broadsheet newspapers flyers, shoppers and other colorful newsprint products. The firm services clients of all sizes, from small, one-person community newspapers, to giant food store chains. With print runs ranging from a few thousand, to a million-plus, GEM uses Harris eight-unit and four-unit web presses operating 24/7. GEM’s present owners, Steven Gregory and Artie Marin, were formerly the press and prepress supervisors of the firm. They bought GEM in 2001 and have made technology choices that have maximized its efficiency, productivity and profitability. The partners’ objective was to be able to service all clients and never turn away business because a run might be thought “too small.” Never Say Never “Today, when others say ‘no,’ we say ‘yes,’ says Artie Marin. “We can, because we’ve re-designed and re-engineered our process to make it fit short, as well as long runs. In fact, we have recently been able to eliminate the concept of ‘prepress’ from our process, by redesigning our workflow around ECRM’s WorkMates NEWS software application.” Marin continues, “WorkMates NEWS is a smart software solution that does everything and more a skilled operator can do to ready a file for printing. The differences are, it’s automatic, it’s fast, it doesn’t make mistakes, never tires, and runs 24 hours a day.” Eliminating Prepress He explains, “Today, ‘digital desktop publishing’ is the workflow just about everyone uses. The old idea of ‘prepress’ has gone the way of film and celluloid collars. Job creation is now typically done by designers working at Macs. Once we decided that ‘prepress’ wasn’t a true function any more, we simply eliminated it as a department. Instead, we increased our design group, and widened its franchise to include supervising automatic page-makeup and preflighting by our ECRM WorkMates NEWS workflow software, as well as CTP plate production by our ECRM NEWSmatic platesetter.” Mike Marin, Artie’s son, works in the design department at GEM and echoes his father’s enthusiasm for WorkMates NEWS, saying, “WorkMates NEWS actually assembles, preflights and pagepairs a job automatically. It even fixes mistakes, proofs it as required, and sends it on to the platesetter. No ‘operator’ needs to get involved. Instead, a designer simply checks the progress and can do other creative tasks while WorkMates NEWS does the actual work. This saves lots of time and cost.” Creative Destruction is Good Business Artie Marin provides this comparison, “In the old days, 2-3 days of costly labor might have been needed to assemble and plate a color grocery ad. Now, we can do it all in just 4 hours!” Economists call it “creative destruction” when you replace old, inefficient ways by more-productive methods. Artie Marin calls it good business. “By being able to profitably serve our smallest clients, we’ve made GEM better able to serve all our clients. In this, ECRM’s WorkMates NEWS software is our indispensable partner. It’s a technology whose time has definitely come.” ECRM Headquarters: 554 Clark Road Tewksbury, MA 01876 USA Tel: (+1) 978.851.0207 Fax: (+1) 978.851.7016 sales@ecrm.com