Job overview Safely installs, maintains, troubleshoots, and repairs

advertisement

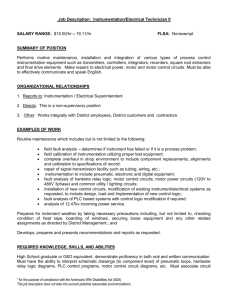

JOB POSTING INSTRUMENTATION TECHNICIAN / ELECTRICIAN / MILLWRIGHT LOCATION: Tacoma, WA SALARY: REPORTING TO: Plant Superintendent START DATE: Commensurate with experience As soon as possible COMMENTS ON IMMIGRATION: If you are applying for a position in another country, please note that the position and your application will have to be considered from an immigration perspective. Job overview Safely installs, maintains, troubleshoots, and repairs electrical and electronic instrumentation and equipment. Performs preventative maintenance and troubleshooting of all plant equipment and works with plant supervision and / or remote operations to ensure that all equipment and instrumentation is operating correctly. Job duties Adhering to all Graymont safety standards, principles, policies, and procedures. Inspect, calibrate, test and measure the functionality of instrumentation, including pressure and flow meters, electronic and pneumatic controllers, level indicators and controllers, pressure and temperature transmitters, switches and gauges, recorders, etc. Install, troubleshoot, and repair control panels and components, motor circuits, building and lighting circuits, and control circuits. Work from technical manuals, schematics, drawings, sketches, SOPs, written and verbal instructions. Working knowledge of electrical drawings, troubleshooting and repair at a level obtained through 5 years of experience as an Electrician in an industrial plant. Investigate and resolve electrical maintenance problems. Work with other functions throughout the organization. Troubleshooting and maintenance experience to include: Motor and power control circuits PLC’s and their use in diagnosing machine problems Analog and digital AC drive systems VFD drive systems Process control systems Perform preventative maintenance, troubleshooting, and maintenance tasks on mechanical, pneumatic, and hydraulic systems of the production equipment and physical plant. Rebuilding pumps, speed reducers, belt conveyors, and other types of equipment. Creating work orders, advance status, locate and issue parts and provide a detailed work order description. Cycle, count, and organize parts inventory into correct locations. Layout, fabricate and implement new equipment installations. Layout, install and troubleshoot electrical control circuits. Cut, braze, and weld steel, stainless steel, brass, and aluminum. Provide electrical and/or electronic expertise to managers, supervisors and other employees as needed. Qualifications AS degree in electricity / electronics, or a minimum of 5 years’ experience in an industrial electrician position or equivalent work experience preferred. Experience in programming and working with Programmable Logic Controllers (PLC). Journeyman Millwright certification or equivalent experience. Welding certification or equivalent experience. Operation of Forklifts, Front End Loaders and Dump Trucks Strong safety values and commitment to working safely Understanding of schematic diagrams and equipment drawings. Possess methodical approach to troubleshooting and good analytical skills. Must have strong electrical knowledge of medium voltage and below electrical systems, breakers and power distribution systems, motors, motor control equipment, instrumentation, PLC's and AC/DC drive systems. Experience with various welding techniques and fabrication Extensive experience or equivalent training in repair of all types of industrial equipment, i.e., screw and belt conveyors, bucket elevators, water and chemical pumps, gearboxes and vibrators. Contact information Please forward resumes to Steve Wennergren at swennergr@graymont.com.