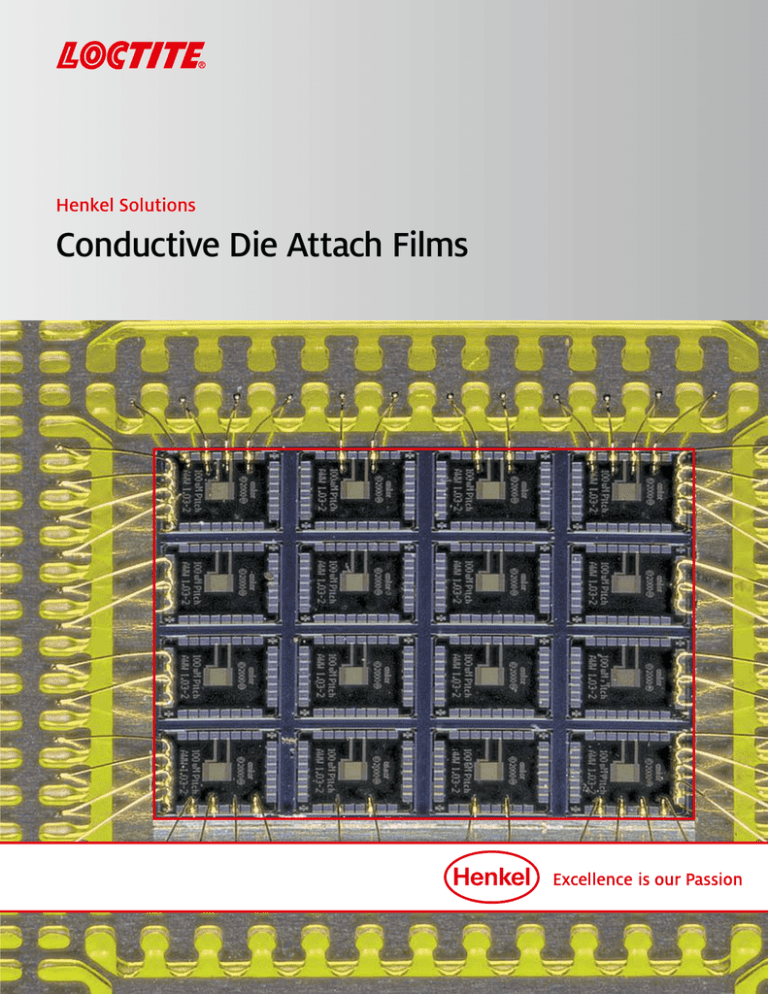

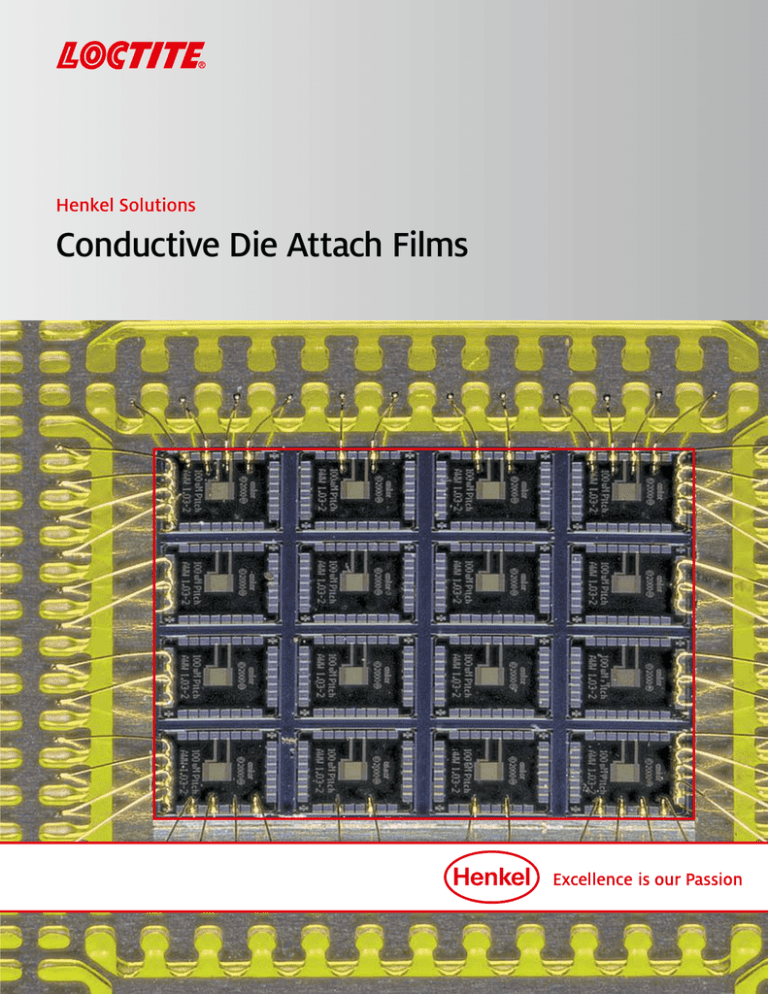

Henkel Solutions

Conductive Die Attach Films

Conductive Die Attach Film

Henkel was the first to develop and introduce conductive die attach film (CDAF) to the

semiconductor market. A groundbreaking market development, this innovation was

viewed by the semiconductor industry as a significant breakthrough that would enable

more capable and cost-effective lead frame package designs. Indeed, this has been the

result, as numerous semiconductor packaging specialists have leveraged Henkel’s CDAF

advantages for new and better package designs.

LOCTITE® ABLESTIK C100 was the premier material in Henkel’s CDAF line, and, since

then, the company has expanded the suite of conductive films to address various lead

frame and laminate package requirements. Each material offers different properties

and characteristics – from dicing die attach capability to varying thermal and electrical

performance to cost competitiveness – but all of them deliver the undeniable

advantages of film-based materials over that of conventional die attach paste.

Some of the most notable comparable benefits of film vs. paste are:

• Design flexibility and ability to integrate more die per package due to tight clearance

between the die and die pad

• Allows for thinner packages with higher densities

• Facilitates thin-wafer handling

• Provides for a clean process with no bleed, uniform bondlines and no kerf creep

Consumers continue to demand ever smaller and more capable devices, and Henkel’s

CDAF materials are making this ongoing product dynamic possible.

Paste with Fillet

Film with Controlled Fillet

Conductive film technology enables

tighter die-to-pad ratio

Package Trends – Wire Bonded

Higher functionality and efficiency

Miniaturized Packages (QFN, DFN, SOs)

Higher Density Packages

•Increased die-to-pad ratio

• Multi-die packages

•In some cases, D/P ratio close to 1.0

• SiP – LGA/PBGA

Thinner Packages (QFN, SO, QFP)

•Packages < 0.3mm

•Thinner die < 75µm

•Thinner DA bondline thickness < 20µm

Current Material Challenges on Lead Frames

Conducting die attach paste

•Dispensing: Optimize dispense patterns for various die sizes – 0.2mm x 0.2mm to > 10mm x 10mm

•Fillet & Bleed: Forces engineers to have a minimum keep out zone around die

•Bondline Control: Especially for smaller die, BLT control is challenging and leads to die tilt

•Kerf Creep: For thinner wafers, uneven fillet height can lead to kerf creep

Control Flow Solutions

Enables miniaturization

Reduces Footprint

• Shorter interconnection

• Faster signal speed

•Less Au wire, lead frame and EMC used

• Lower TCoO

Henkel’s Solution to Control Flow

Product space

Higher electrical (RDSon) and

thermal (Rth) performance

A4: Low warpage, ultra-high thermal, MSL1, < 15µm thick

CDF 800P

MSL2 on all LF finish

CDF 200P

CDF 500P

CDF 500P

MSL1 on all LF finish

MSL2 on Laminates

L: QFN

2mm x 2mm

CDF 600P

4mm x 4mm

6mm x 6mm

Die Size

8mm x 8mm

Thermal and Electrical for CDAF

Stable in-package performance

•Thermal Conductivity (W/mK) is an intrinsic material property

•Thermal Resistance, Rth (K/W), is a geometry-dependent value that allows us to better compare materials in a

functional package

•70% - 90% of the Rth is due to the interfaces and is not captured in thermal conductivity values

Thermal Resistance (Rth)

Comparison of paste and film materials

3.0

2.5

2.5 x 2.5 x 0.36mm2 Si-back die

QFN 7 x 7mm, PPF (pad 5.8 x 5.8mm)

30 min ramp to 200˚C + 1 hr cure

Rth(K/W)

2.0

1.5

1.0

CDF 500P

11

3.5

6.5

1-27.8 1

2100A

QMI529HT

CDF 600P

CDF 800P

1.6

FS 849-TI

8008HT

2.5

8290

84-1LMISR4

3.8

QMI519

2

0

CDF 200P

.5

1

Thermal Conductivity (W/mK)

Electrical Resistance RDSon

In-package performance

0.08

2.0 x 2.9 x 0.18mm; TiNiAg-back die

TO-220, Cu pad

0.07

RDSon (ohm)

0.06

0.05

0.04

0.03

0.02

CDF

QMI519

84-1LMISR4

8008HT

CDF

QMI529HT

200P 800P

CDF

FS 500P849-TI

Portfolio of CDAF Products

Film and paste performance comparison

UNIT

CDF

200P

QMI519

84-1LMISR4

8290

8008HT

CDF

800P

QMI529HT

CDF

500P

FS

849-TI

CDF

600P

2100A

ohm-cm

0.0014

0.0001

0.0002

0.008

0.00006

0.0003

0.00004

0.0002

0.00002

0.0008

0.05

Thermal Conductivity

W/mK

2

3.8

2.5

1.6

11

3.5

6.5

1-2

7.8

1

1.35

CTE Alpha1

ppm/C

48

40

40

81

37

40

53

60

44

75

65

CTE Alpha2

ppm/C

120

140

150

181

62

118

156

245

155

320

200

Glass Transition

Temperature

˚C

15

75

120

38

264

11

3

10

211

-5

60

Modulus @ 25˚C

MPa

5,400

5,300

3,930

3,034

6,659

7,100

3,300

6,300

7,800

3,000

3,200

Modulus @ 250˚C

MPa

1,000

284

303

117

2,450

900

-

130

1,070

40

230

HDSS (260˚C) on Ag

kg/mm2

1.3

0.8

0.2

0.6

0.7

1.0

0.5

0.7

0.5

0.7

0.4

Room Temp DSS on PPF

kg/mm2

2.14

4.9

3.0

5.0

-

> 2.0

-

-

-

-

-

Room Temp DSS on Ag

kg/mm2

3.02

4.8

2.3

5.1

1.5

> 2.0

2.2

-

-

-

-

Room Temp DSS on Cu

kg/mm2

3.17

1.8

1.2

2.5

1.5

> 2.0

-

-

-

-

-

Cohesive

Cohesive

-

Cohesive

Cohesive

Cohesive

-

Cohesive

Cohesive

MATERIAL PROPERTY

Volume Resistivity

PERFORMANCE

Failure Mode

Thermal Resistance, Rth

Cohesive Cohesive

K/W

1.5

1.3

0.83

1.8

1.5

0.81

0.77

1.5

0.72

2.1

2.3

ohm-cm

0.075

0.044

0.033

n/a

0.067

0.032

0.042

0.055

0.038

n/a

n/a

RDSon Shift (500 TC)

%

2.2

n/a

10.0

n/a

n/a

5.7

42.0

n/a

28.0

n/a

n/a

RDSon Shift (1,000 TC)

%

6.6

n/a

15.6

n/a

n/a

6.4

42.0

n/a

28.8

n/a

n/a

3

MSL1

capable

for

small

die

3

1

MSL1

capable

for

small

die

1

MSL1

capable

for

small

die

2

(PBGA)

2

(PBGA)

-

-

-

2

-

1

3

2

(PBGA)

2

(PBGA)

30 min

ramp to

175˚C +

30 min

soak @

175˚C

30 min

ramp to

100˚C +

30 min

soak @

100˚C +

30 min

ramp to

200˚C +

60 min

soak @

200˚C

30 min

ramp to

175˚C +

15 min

soak @

175˚C

RDSon

JEDEC MSL 260˚C

(on 7 x 7mm PPF QFN with

2.5 x 2.5 x 0.33mm die)

MSL

level

1

MSL1

capable

for

small

die

JEDEC MSL 260˚C

(on 7 x 7mm PPF QFN

with 5 x 5 x 0.36mm die)

MSL

level

2

-

30 min

ramp to

200˚C

+ 60

min

soak @

200˚C

30 min

ramp +

hold 60

min @

100˚C +

15 min

ramp +

hold 60

min @

200˚C

PROCESSING

Cure

profile

30 min ramp

to 175˚C +

60 min soak

@ 175˚C

30 min

ramp to

175˚C +

15 min

soak @

175˚C

20 sec @

280˚C

30 min

ramp to

200˚C

+

60 min

soak @

200˚C

30 min ramp

to 185˚C +

30 min soak

@ 185˚C

30 min

ramp to

200˚C

+

60 min

soak @

200˚C

AMERICAS

ASIA-PACIFIC

HEADQUARTERS:

CHINA

No. 332 Meigui South Road

WaiGaoQiao Free Trade Zone

Shanghai 200131, P.R. China

Tel: +86.21.3898.4800

Fax: +86.21.5048.4169

UNITED STATES

Henkel Electronic Materials LLC

14000 Jamboree Road

Irvine, CA 92606

USA

Tel: +1.714.368.8000

Tel: +1.800.562.8483

Customer Support: +1.888.943.6535

Fax: +1.714.368.2265

Henkel Electronic Materials LLC

20021 Susana Road

Rancho Dominguez, CA 90221

USA

Tel: +1.310.764.4600

Fax: +1.310.605.2274

BRAZIL

Henkel Brazil

Av. Prof. Vernon Krieble, 91

06690-250 Itapevi,

Sao Paulo, Brazil

Tel: +55.11.3205.7000

EUROPE

BELGIUM

Henkel Electronic Materials (Belgium)

Nijverheidsstraat 7

B-2260 Westerlo

Belgium

Tel: +32.1457.5611

Fax: +32.1458.5530

Henkel Huawei Electronics CO. LTD

Songtiao Industrial Park Lianyungang

Jiangsu Province 222006 China

Tel: +86.518.8515.5336

Fax: +86.518.8515.3801

JAPAN

Henkel Japan Ltd.

27-7, Shin Isogo-cho

Isogo-ku Yokohama, 235-0017

Japan

Tel: +81.45.758.1900

KOREA

Henkel Technologies (Korea) Ltd.

6th Floor

Dae Ryung Techno Town II

569-21 Gasan-dong,

Geumcheon-gu, Seoul 153-771

Korea

Tel: +82.2.6675.8000

MALAYSIA

Henkel (Malaysia) Sdn. Bhd

Lot 62049, Jalan Portland,

Tasek Industrial Estate,

31400 Ipoh, Perak, Malaysia

Tel : +605-5476811

Fax: +605-5471868

TAIWAN

Henkel Taiwan Ltd

Room A4, 19F-1, No.6, Sihwei 3rd Rd,

Lingya Dist., Kaohsiung, Taiwan

Tel: 886-7-335-7970

Fax: 886-7-335-1057

Across the Board,

Around the Globe.

www.henkel.com/electronics

All marks used above are trademarks and/or registered trademarks of Henkel and its affiliates in the U.S., Germany and elsewhere.

© 2014 Henkel Corporation. All rights reserved. 12016/LT-6901 (3/14)