Grace Materials Technologies

Technical Information

®

SYLOBEAD Molecular Sieves

for Biodiesel

Introduction

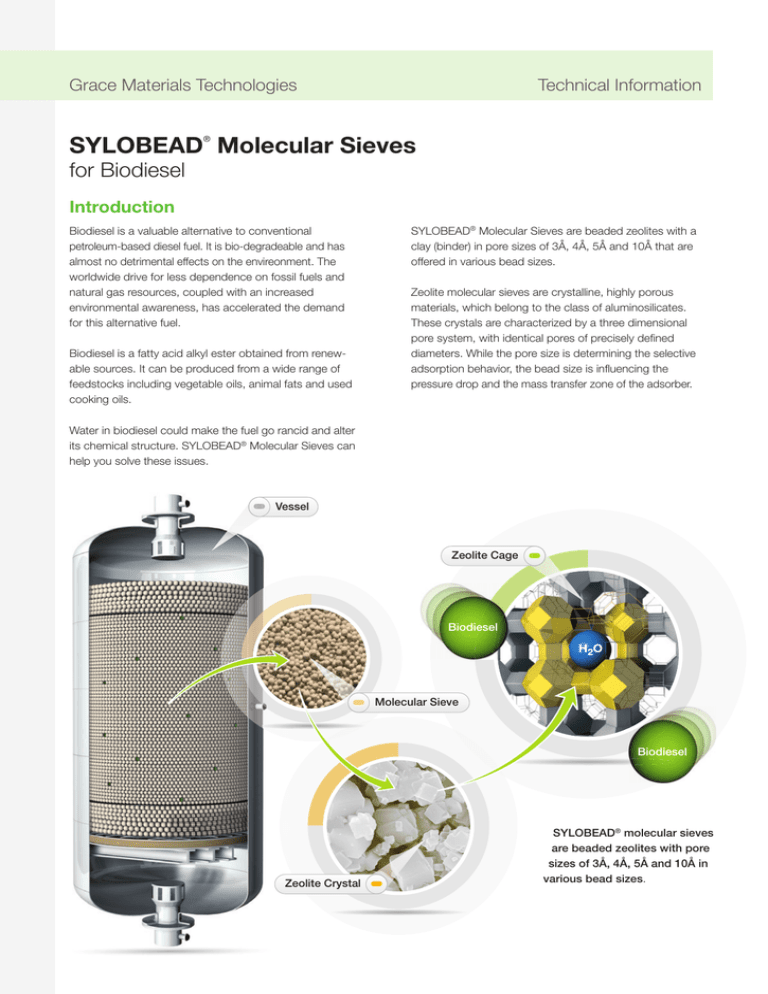

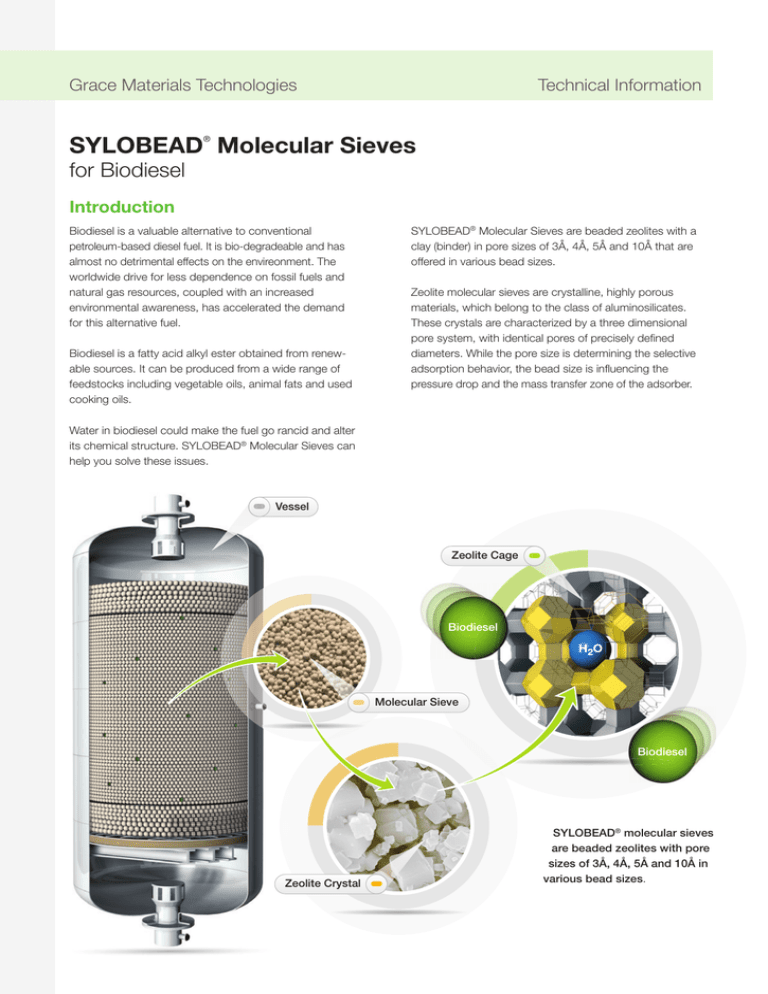

SYLOBEAD® Molecular Sieves are beaded zeolites with a

clay (binder) in pore sizes of 3Å, 4Å, 5Å and 10Å that are

offered in various bead sizes.

Biodiesel is a valuable alternative to conventional

petroleum-based diesel fuel. It is bio-degradeable and has

almost no detrimental effects on the envireonment. The

worldwide drive for less dependence on fossil fuels and

natural gas resources, coupled with an increased

environmental awareness, has accelerated the demand

for this alternative fuel.

Zeolite molecular sieves are crystalline, highly porous

materials, which belong to the class of aluminosilicates.

These crystals are characterized by a three dimensional

pore system, with identical pores of precisely defined

diameters. While the pore size is determining the selective

adsorption behavior, the bead size is influencing the

pressure drop and the mass transfer zone of the adsorber.

Biodiesel is a fatty acid alkyl ester obtained from renewable sources. It can be produced from a wide range of

feedstocks including vegetable oils, animal fats and used

cooking oils.

Water in biodiesel could make the fuel go rancid and alter

its chemical structure. SYLOBEAD® Molecular Sieves can

help you solve these issues.

Vessel

Zeolite Cage

Biodiesel

H2O

Molecular Sieve

Biodiesel

Zeolite Crystal

SYLOBEAD® molecular sieves

are beaded zeolites with pore

sizes of 3Å, 4Å, 5Å and 10Å in

various bead sizes.

The Biodiesel Process

Process Flow Scheme

Biodiesel will typically be produced according to the

process scheme shown to the right.

The biodiesel must meet certain standards, such as

ASTM D6751 or EN14214. The current standards have

set the water specification at 500 ppm maximum; however, it is expected that in the future this specification

might be reduced even further. Although not miscible

with water, biodiesel is a very hygroscopic fluid. When

biodiesel is stored in tanks for a longer period of time

(>24 h), water absorption is reported to take place.

Water in biodiesel can alter its chemical structure and

increase the free fatty acids levels.

Purified Feedstock for

Biodiesel Production (Oils, Fats)

Solvent

(e.g., Methanol)

Catalyst

Transesterification

Glycerol

Biodiesel Impurities

In some cases, microbial growth has been observed in

biodiesel, potentially causing fuel filter plugging. In order to

overcome this issue and deliver to the end user biodiesel

that safely meets the above mentioned standards, longer

term stored biodiesel must be additionally dried. Biodiesel

drying with molecular sieves is a well established process

that can be applied to storage tanks in remote areas, far

away from the biodiesel manufacturing plants.

Crude Biodiesel

(Mixture of FAAE*)

Purification / Drying

Biodiesel, pure or mixed with fossil based diesel, that

contains water above this 500 ppm level, might cause

severe damage to the engine. The water might result in

the formation of acids and, consequently, corrosion

problems in the engine and peripheral devices.

Grace is one of the first companies offering

molecular sieves for this application.

Storage

Biodiesel

Drying

Biodiesel to Application

(Fuel Blending)

*FAAE = Fatty Acid Alkyl Ester

What We Offer

In addition to our SYLOBEAD® molecular sieve and silica

gel product range, Grace also offers a range of specialty

products and technologies that have been developed

specifically for edible oil and fat refining and associated

industries. Grace TRISYL® silica is engineered to

significantly reduce polar contaminants from biodiesel

feedstock oils and fats. For more details, please refer to

our TRISYL® silica literature, available at

www.grace.com/Products/TriSyl.

2

The SYLOBEAD® Advantages

SYLOBEAD® MS518 Molecular Sieve is a 4Å product

that has been specifically sized to improve mass transfer

in order to cope with the viscous biodiesel.

Grace brings a team of experts working together to assist

you in setting up and designing your biodiesel drying unit.

We continously seek to improve our products, adapt them

for new applications and add new products to our portfolio.

SYLOBEAD® MS518 Molecular Sieve shows the

following product characteristics:

The Biodiesel Drying Process

< Good selectivity for water

< Excellent adsorption capacity

< Sound kinetics, even with

high-viscous fluids (2 – 5 cP)

< Suitable mechanical strength

For more details, please refer to our SYLOBEAD® portfolio

leaflet. There you can also find information on other 4Å

SYLOBEAD® products, in case other bead sizes are required.

Biodiesel drying takes place in a circuit consisting of the

storage tank, a heat exchanger and an adsorber unit.

A pump is circulating the biodiesel until the desired

moisture content (typically 200 ppm) has been reached.

Depending on the technical environment at the final user,

the unit can be operated with a regeneration system or

to the exhaustion of the adsorbent. The way to set up

such a SYLOBEAD® MS518 Molecular Sieve based

drying unit with a regeneration system is shown below.

Our Technical Support is available to discuss with you a

solution tailored for your needs. Please contact us.

Purge off Gas (N2)

From X

Solvent

From Y

Compressor

(Optional if closed

loop regeneration)

Steam

CW

Biofuel

Solvent

+ H2O

Steam

Inert Gas

or Optional

Silica Gel

Steam

Molecular Sieve

Silica Gel

Solvent

Dry Biofuel

CW

SYLOBEAD® MS518 Molecular Sieve based drying unit

Off Spec

Solvent

+ Biofuel

To X

Distillation

Biofuel

To Y

3

Grace is a leading global supplier of catalysts; engineered and packaging materials; and,

specialty construction chemicals and building materials. The company's three industry-leading

business segments – Grace Catalysts Technologies, Grace Materials Technologies and Grace

Construction Products – provide innovative products, technologies and services that enhance

the quality of life. Grace employs approximately 6,000 people in over 40 countries.

Grace has met all REACH requirements for the given deadline for Tier 1, December 1, 2010,

and can hereby assure today’s and future customers full REACH compliance of its products.

This assurance also includes the very diverse use of a spectrum of our products.

World Headquarters

Latin America

Europe

Asia/Pacific

W. R. Grace & Co.-Conn.

7500 Grace Drive

Columbia, Maryland 21044/USA

Tel.: +1 410 531 4000

NA Toll Free: +1 800 638 6014

Fax: +1 410 531 4273

Grace Brasil Ltda

Rua Albion, 229 - 10o andar, cj 104

Lapa, São Paulo - SP/Brasil

Cep 05077-130

Tel.: +55 11 3133 2704

Fax: +55 11 3133 2706

Grace GmbH & Co. KG

In der Hollerhecke 1

67545 Worms/Germany

Tel.: +49 6241 403 00

Fax: +49 6241 403 1211

Grace China Ltd.

19th Floor, K Wah Centre

1010 Huai Hai Zhong Road

Shanghai, 200031/ China

Tel.: +86 21 5467 4678

Fax: +86 21 5405 1500

The information contained herein is based on our testing and experience and is offered for the user’s consideration, investigation and verification.

WARRANTIES EXPRESSED OR IMPLIED, regarding results obtained from the use of our products, MUST BE DISCLAIMED since customer

operating and use conditions vary and are beyond our control. Test methods are available on request.

GRACE®, SYLOBEAD®, TRISYL® and ENRICHING LIVES, EVERYWHERE.® are trademarks, registered in the United States and/or other countries,

Enriching Lives, Everywhere.®

of W. R. Grace & Co.-Conn. This trademark list has been compiled using available published information as of the publication date of this brochure

and may not accurately reflect current trademark ownership or status.

© 2012 W. R. Grace & Co.-Conn. All rights reserved. Printed in Germany / September 2012 / Ref: sylobead_biodiesel_TI_E / studiohauck

www.grace.com