Top 10 Pro Stock Innovations

advertisement

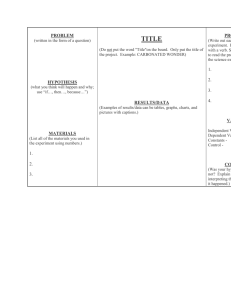

Top 10 Pro Stock Innovations A list of the major developments that transformed Detroit’s factory hot rods from nine-second near-stock vehicles to today’s 6.5-second, 211-mph entries T he original Pro Stockers that debuted at the 1970 Winternationals would compare closest with today’s Stock entries. Built entirely from production bodies with only three-point roll bars, 1 stock front and rear suspensions, and nine-inch tires, these vehicles bore little resemblance to today’s highly sophisticated tube-chassis counterparts, which are powered by 500-cid engines Clutchless four-speed Lenco transmission During the first three Pro Stock seasons, the transmission of choice was the manual four-speed, a carryover from the handicap Super Stockers and the match race A/FX cars of the mid-1960s, but the breakage-prone manual transmissions required a high degree of maintenance at a tremendous cost. As elapsed times approached the low-nine-second range, only a handful of drivers could drive a four-speed with any degree of consistency. When the Lenco transmission, which allowed gear changes without the use of the clutch, was introduced at the 1973 Winternationals, most teams had switched to the new design by the conclusion of the rainpostponed event. Gifted four-speed drivers such as Ronnie Sox and Don Nicholson, whose times actually slowed with the Lenco, objected to the new transmission, but with so many more drivers benefiting from the clutchless design, the Lenco was used for many years before it was replaced by the even more efficient models produced by G-Force and Liberty. 4 In a revival of the popular A/FX match races of the mid-1960s, racers such as Bill Jenkins, Don Nicholson (pictured), and Dick Landy and the Sox & Martin team began converting their handicap-start Super Stockers and A/MP entries into heads-up match race machines with 427-cid engines. Their spectacular nine-second runs with a full-bodied production car caught the imagination of fans and inspired the creation of Pro Stock in 1970. Car Craft magazine Bill Jenkins’ ’72 Vega Jenkins won the first two national events of the 1970 season with his ’68 Camaro, but Dodge and Plymouth entries triumphed at the remaining five events that year and won seven of eight in 1971. Concerned that domination of Pro Stock by one brand might cause fans to lose interest in the category, NHRA introduced weight breaks for the 1972 season that allowed small-block wedge engines to run at 6.75 pounds per cubic inch, canted-valve wedge engines at 7.00 pounds per cubic inch, and big-block Hemis at 7.25 pounds per cubic inch. Jenkins showed up at the 1972 Winternationals with a ’72 Vega that featured a tube-chassis frame with a roll cage, though the stock A-arm front suspension was still retained. The combination proved to be nearly unbeatable. Jenkins defeated five Hemi-powered entries in the Winternationals’ 32-car field and won five of the remaining seven events that year in the most successful season of his career. 3 that produce approximately 1,400 horsepower. The following are the 10 more significant developments in the evolution of Pro Stock. 1969 “heads-up” Super Stockers When Super Stock was introduced in 1967, the category featured a variety of classes and cars competing with handicap starts that were based on national records. But fans of the popular match race circuit back then preferred heads-up action, so the top Super Stockers, such as the SS/B Hemi Darts and Barracudas, raced against 427-cid big-block A/MP Camaros and 427-cid SOHC A/MP Mustangs. Racing at a weight break of seven pounds per cubic inch, these cars put on dazzling displays of rosin burnouts and nine-second runs despite weighing nearly 3,000 pounds. NHRA quickly reacted to this exciting concept and announced at the 1969 World Finals in Dallas that a new heads-up category, Super Stock (eventually renamed Pro Stock), would debut at the 1970 Winternationals. The rules were nearly identical to those employed by their 1969 predecessors; the use of fiberglass hoods, fenders, and a hood scoop were the only modifications allowed to the otherwise stock bodies. 2 by John Jodauga Though it still used a stock front end with factory A-arm front suspension, Jenkins’ ’72 Camaro is largely credited as being the first tube-chassis Pro Stock car. It also featured a full roll cage, a significant advancement over the threepiece roll bars that were initially used in 1970. The Lenco transmission, which used a separate lever for every gear, was a planetary-type design that did not require the clutch pedal to be depressed for shifting. First introduced at the 1973 Winternationals, it not only reduced breakage and maintenance costs but also allowed many more drivers to run as quick as the most skilled four-speed campaigners. Bill Jenkins’ ’74 Vega Jenkins may have won more races with his ’72 Vega, but his ’74 model was his most innovative entry. Among the car’s more prominent features was the use of a dry-sump oil system, a first for drag racing applications, and the introduction of the McPherson strut front suspension; both features are standard in today’s Pro Stockers. The dry-sump design was instrumental in producing major horsepower gains. The lowered front ends of the Pro Stock cars left little room for a deep sump pan, which subjected the crankshaft to the powerrobbing process of sloshing through the engine oil, but with the dry-sump system, most of the oil is stored in a remote oil tank, allowing the crankshaft to rotate freely without any contact with excess oil. The McPherson struts, developed by Jenkins and Roger Lamb, not only provided a lighter and more stable front suspension than the stock A-arm designs but also created more room that allowed more leeway in exhaust-header design to provide even more horsepower gains. Few cars featured more lasting innovations than Jenkins’ ’74 Vega. With it he introduced the dry-sump oil system to drag racing and the McPherson strut front suspension, which was vastly superior to factory A-arms and torsion-bar designs. 62 ✦ National DRAGSTER 5 Gapp & Roush four-door Maverick NHRA continued to refine its weight-break format to include wheelbase factors, which allowed cars that had wheelbase dimensions longer than 105 inches to run with less weight. The Gapp & Roush Ford team noted that the new rules allowed it to run at 6.45 pounds per cubic inch with a car that had a long wheelbase, as opposed to the 6.80 factor for shorter cars, such as the conventional Pinto. The team commissioned Don Hardy to quickly build a 108-inch-wheelbase four-door Maverick, which made its debut at the 1974 Summernationals. Running with 125 to 130 pounds less weight than the Pintos, the team had the quickest car in eliminations and easily reached the final. Only a huge holeshot by final-round opponent Larry Lombardo kept the team from the winner’s circle; Lombardo drove Bill Jenkins’ Vega to a 9.11 to 9.02 win. Weight breaks continued to be a major element in Pro Stock competition for many years until they were replaced by the 500-cid heads-up format that was established for all brands in 1982. 6 When NHRA allowed lighter weight breaks for cars that had a wheelbase of 105 inches or longer, the Ford team of Wayne Gapp and Jack Roush wasted no time in taking advantage of the rules by quickly building a four-door Maverick, which became known as “the taxi.” Bob Glidden and Nicholson also took the same path with the longer-wheelbase ’70 Mustangs. Kick-out oil pans S-A Design The advantages of a dry-sump oil system were known long before they were introduced to drag racing applications in 1974, but the benefits of the kick-out oil pan were accidentally discovered. David Reher and Buddy Morrison were attempting to film the pattern of oil flow within the crankcase using special pans that had Plexiglas windows. After the window repeatedly fogged up, they removed the pan from the engine and placed it on the floor and used an extended oil pickup. During the filming process, someone happened to look at the dynamometer instruments and noticed a tremendous gain in power. This told them that even with the use of a drysump system, oil bouncing off the sides of the pan and back onto the crankshaft was still reducing power, so they designed an oil pan that was as wide as possible to fit within the chassis framerails. Significant power gains were soon realized. 7 500-cid rule By 1981, the weight-break formula had been expanded from engine types (wedge, canted-valve, and Hemi designs) to each factory brand and size. Because 11 different engines received their own specific weight breaks, there were 22 weight-break designations at the beginning of the 1981 season. These factors were subject to change throughout the season, and it seemed that any time a team gained in performance, it was penalized with a heavier weight break. Drivers complained that those who worked the hardest were being penalized the most. NHRA officials and factory representatives from Detroit agreed that the system had become too cumbersome for racing teams and fans, so the 1982 rules were changed to dictate that all cars run engines at a maximum cubic-inch displacement of 500 and that car weight be a minimum of 2,350 pounds including the driver. The complaints and protests ended immediately, and Pro Stock was propelled into the seven-second zone overnight; the national record was lowered from 8.23 to 7.82 at the season-opening Winternationals. 8 The kick-out oil pan, which provided more room on the side of the pan that received the oil tossed from the crankshaft, cut down on the power normally lost by the oil droplets bouncing back onto the crankshaft. The last major change to the Pro Stock rules took place in 1982, when NHRA replaced the increasingly cumbersome weight-break formula with the introduction of the 500-cid mountain motors. All cars were required to run at a minimum weight of 2,350 pounds including the driver. Frank Iaconio won the first race under the new format, at the 1982 Winternationals. DRCE engine series Though sophisticated tube-chassis designs had been on the Pro Stock scene for many years, until the early 1980s racers still relied on radically modified versions of production blocks and cylinder heads, a very costly process, especially in the case of the small-block Chevys and Fords, which used cast-iron heads. But this changed in the mid-1980s with the introduction of the Oldsmobile Drag Racing Competition Engine (DRCE), which was developed under the leadership of Dave Jarrard, who worked with a number of leading engine builders and cylinder-head experts to develop the first factory-produced 500-cid drag racing engine. The first DRCE engine was debuted at the 1983 Gatornationals and featured siamesed cylinders with thick walls and a priority oil system. The heads had symmetrical ports, as opposed to the production big-block Chevy heads that used a combination of short and long intake runners. The heads were also produced with small combustion chambers and intake and exhaust ports to give engine builders more leeway in creating their modifications. Greg Anderson and Jason Line used the latest version of this engine design, the GM DRCE-3, to produce record-breaking 211-mph runs at this year’s ACDelco NHRA Gatornationals. to page 64 Detroit’s increased interest in quarter-mile competition resulted in the production of the first factory-developed 500-cid engine for drag racing, the Oldsmobile DRCE. Pictured is the engine campaigned by Warren Johnson in 1984. Johnson helped provide input for the engine’s design. Note that this was before W.J. began covering up his intake-manifold runners. April 6, 2007 ✦ 63 from page 63 9 Aero hood scoop Hood scoops, an iconic symbol in Pro Stock, have been on the scene ever since the class’ creation. The first designs were the rear-inlet “mailbox” scoops used by Chevrolet racers and the boxy “snorkel” scoops used by Dodge and Plymouth teams. The tall dimensions of the tunnel-ram intake manifold required large scoops, and though the scoops provided adequate air to the engine, they created a significant amount of aerodynamic drag. In the mid-1980s, GM officials conducted wind-tunnel tests to create a hood scoop that would be integrally engineered with the airflow characteristics of the car’s body to minimize aerodynamic deficiencies. Hood scoops became standard equipment on Pro Stockers by 1986, and various refinements of their design are still used. The aero scoop, first used extensively in 1986, was an attempt to cut down on the aerodynamic drag created by the previous models, which had a more boxy design. The shape was developed in wind-tunnel tests and was integrated with the car’s basic airflow characteristics to increase top-end speeds. 10 Raised power bands A main reason for Greg Anderson and teammate Jason Line combining to win 19 of 23 events in 2004 was their use of engines with a power band that was raised within the rpm range. This concept had been around for years and is based on the basic principle that the higher an engine is revved, the more combustion strokes are produced, resulting in more power to the rear wheels. And though this theory has not been a secret, successfully implementing its principles requires extensive work in camshaft and valvetrain design and integrally engineered changes in the induction system and cylinder heads. Running a 500-cid engine at more than 10,000 rpm also takes its toll on the longevity of parts. Anderson and Line’s success in employing this concept has resulted in new speed records, from 205.57 to 207.18 mph in 2004 and from 209.75 to 211.69 this season, and four consecutive NHRA Pro Stock world championships. Greg Anderson and Jason Line raised the bar for Pro Stock engine builders when they increased the engine power band to a higher rpm level in 2004. It was a difficult assignment that required a massive engine redesign, but the effort resulted in 19 victories in 23 events for the team that year. 64 ✦ National DRAGSTER